An anti-falling device for a construction site elevator

A construction site and elevator technology, which is applied in transportation, packaging, elevators, etc., can solve the problems of poor anti-fall performance and achieve the effect of avoiding losses and good anti-fall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

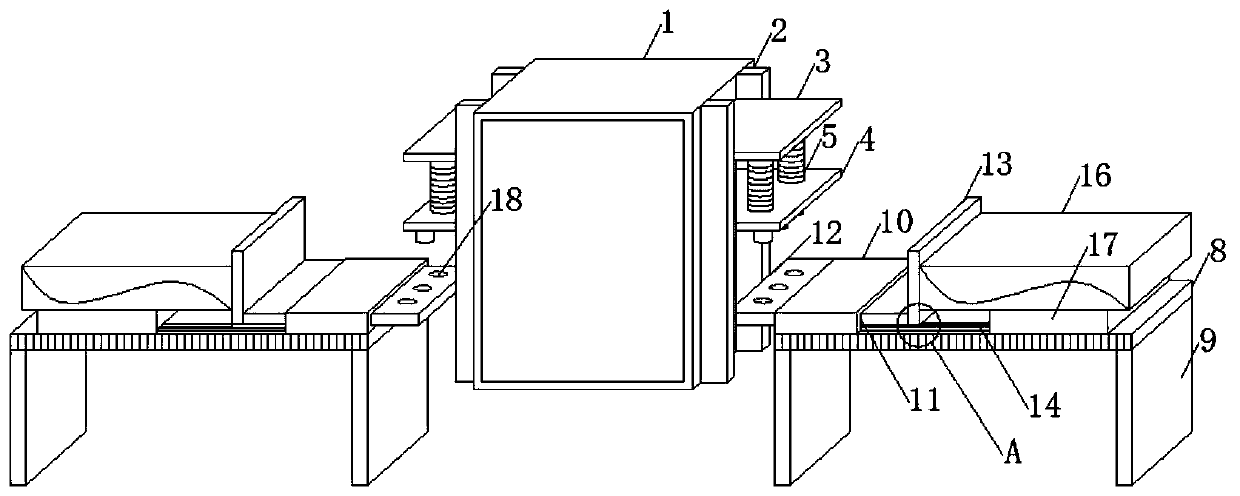

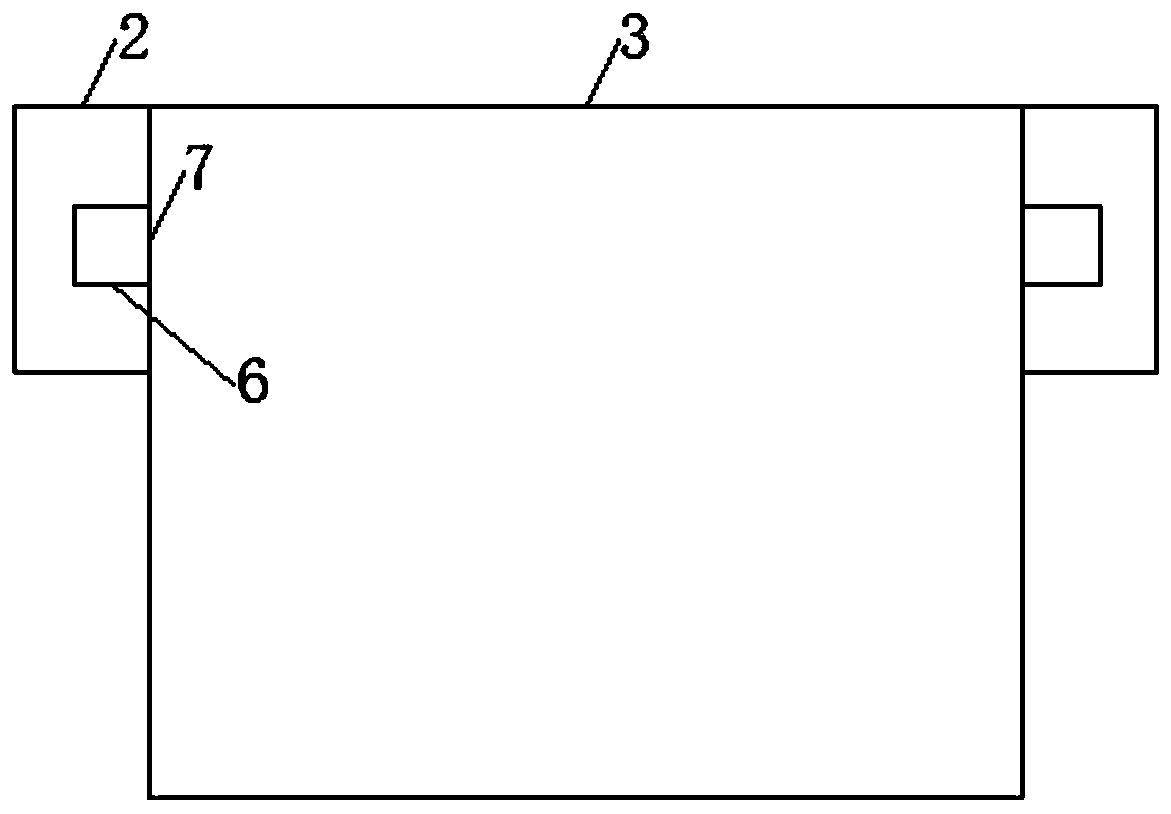

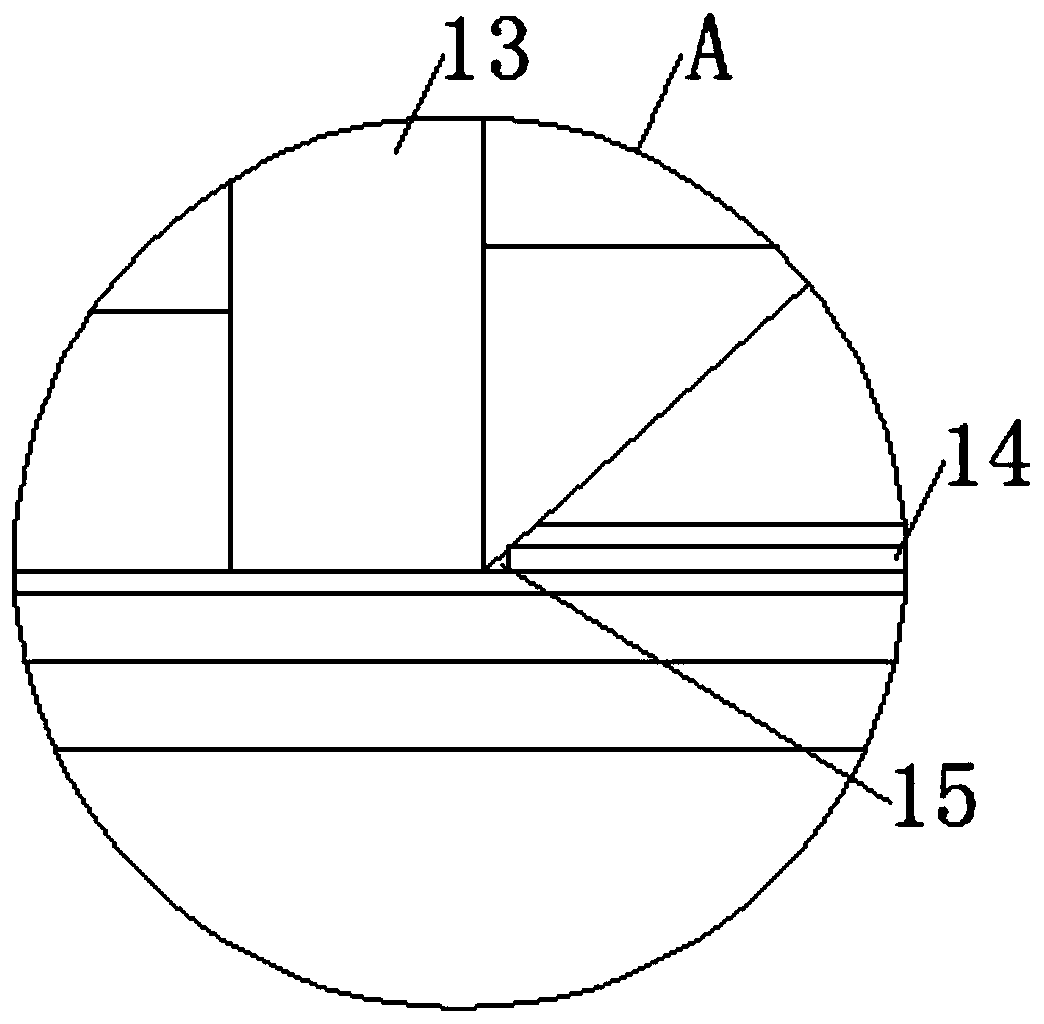

[0023] like Figure 1-8 As shown, this specific embodiment adopts the following technical solutions: a construction site elevator anti-falling device, including a base plate 8, two base plates 8 are arranged in total, two base plates 8 are arranged side by side, and two base plates 8 There is an elevator 1 between them, and two limit rails 2 are fixedly installed on both sides of the elevator 1, and the two limit rails 2 on the same side of the elevator 1 have a longitudinal The center line is symmetrically distributed. A fixed plate 3 and a movable plate 4 are arranged before the two limiting rails 2. The movable plate 4 is located below the fixed plate 3. The upper end of the movable plate 4 and the lower end of the fixed plate 3 pass through The spring bar 5 is fixedly connected, and the middle part of the opposite side of the two limit rails 2 is provided with a chute 6, and both sides of the moving plate 4 are fixedly connected with a slider 7, and the thickness of the sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com