Manufacturing method for anti-falling light TPU protective sleeve

A production method and a technology of a protective case, which are applied to household components, applications, household appliances, etc., can solve the problems of soft TPU with poor hand feeling, poor weight anti-collision effect, single structure, etc., and achieve enhanced anti-drop performance and good anti-drop Effect, weight reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

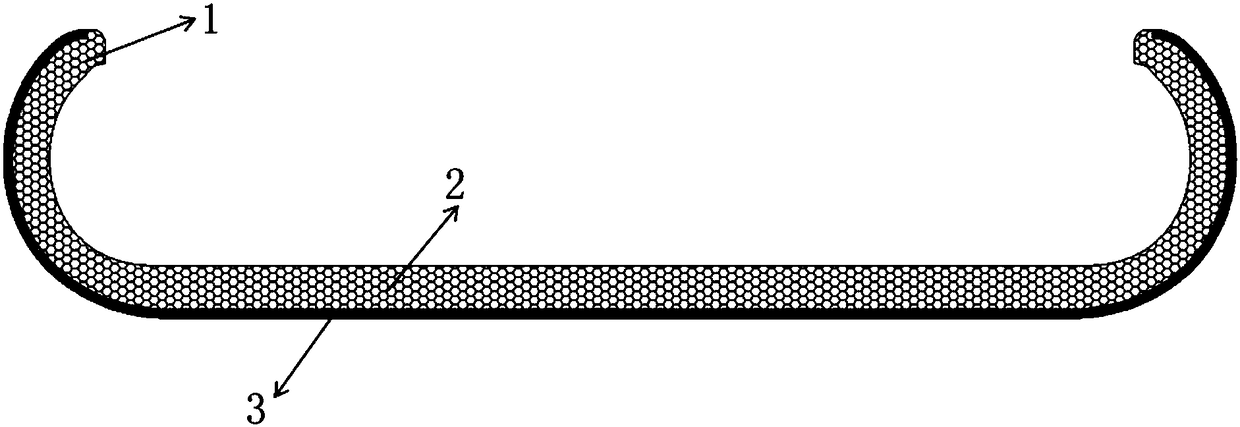

[0026] As shown in the figure, it shows a specific embodiment of the present invention. As shown in the figure, a method for making a drop-resistant lightweight TPU protective cover disclosed by the present invention includes the following steps:

[0027] (1) Die-cut PU leather according to the shape of the protective case;

[0028] (2) Put the PU leather after punching into the injection mold;

[0029] (3) Clamp the mold for injection molding; after the TPU material is pressurized at high temperature in the barrel of the injection molding machine by the injection molding machine, bubbles are generated inside the TPU material, and then the TPU material that generates bubbles is injected into the injection mold by the screw rod and then cooled and formed;

[0030] (4) After the mold is opened, the finished product is obtained.

[0031] In some preferred embodiments, it also includes a step of baking the TPU material, the step of said baking is to heat and bake the TPU material...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com