Novel road cutter

A cutting machine and road technology, applied in the field of new road cutting machines, can solve the problems of consuming manpower and failing to meet cutting requirements, and achieve the effects of saving manpower, shortening the driving distance, and reducing dust.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

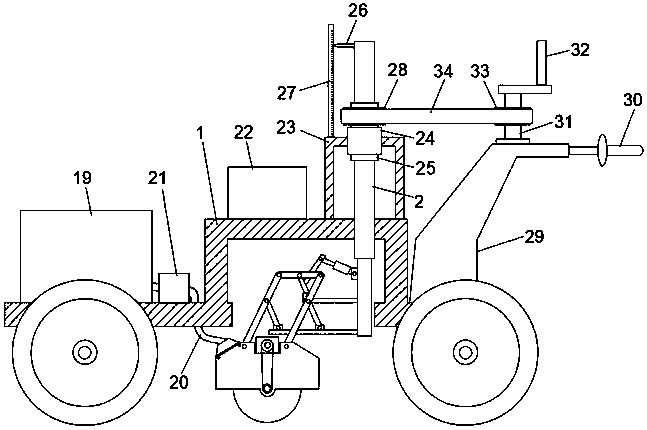

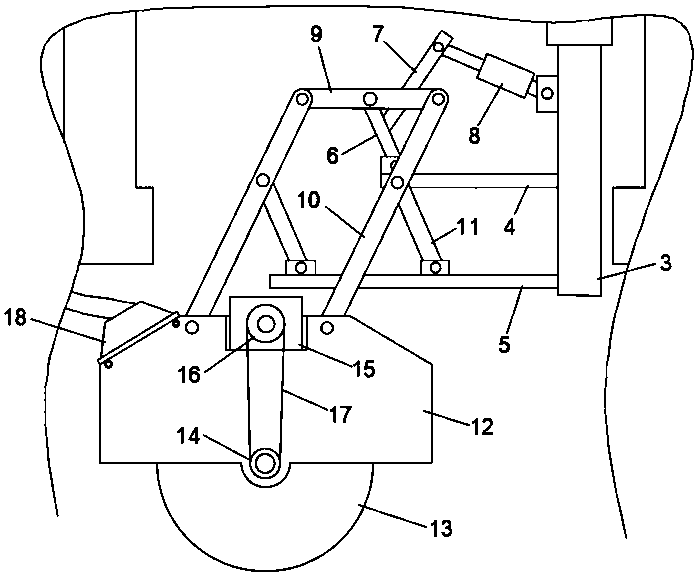

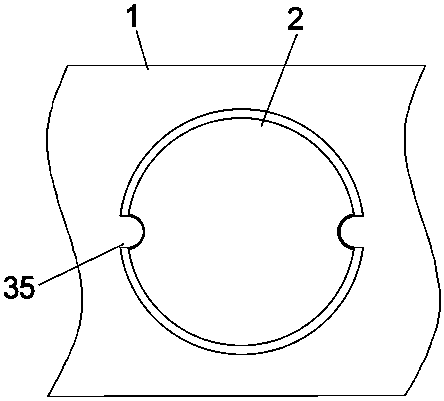

[0023] refer to Figure 1-3 , a new type of road cutting machine, comprising a frame 1, the bottom of the frame 1 is equipped with traveling wheels, the middle of the frame 1 adopts an arched structure, the upper end of the arched structure slides through and is connected with a movable column 2, and the bottom of the movable column 2 is welded There is a mounting plate 3, a first bracket 4 and a second bracket 5 are welded on the side wall of the mounting plate 3, the upper surface of the first bracket 4 is rotatably connected with a first strut 6, and the middle part of the first strut 6 is fixedly connected with an inclined setting The transmission rod 7 of the transmission rod 7 is also welded with a mounting seat on the side wall of the mounting plate 3, and a cylinder 8 is movably installed on the mounting seat. The output end of the cylinder 8 is movably connected with the end of the transmission rod 7 away from the first pole 6. One end of the rod 6 away from the first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com