Patents

Literature

48results about How to "Precise control of cutting depth" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

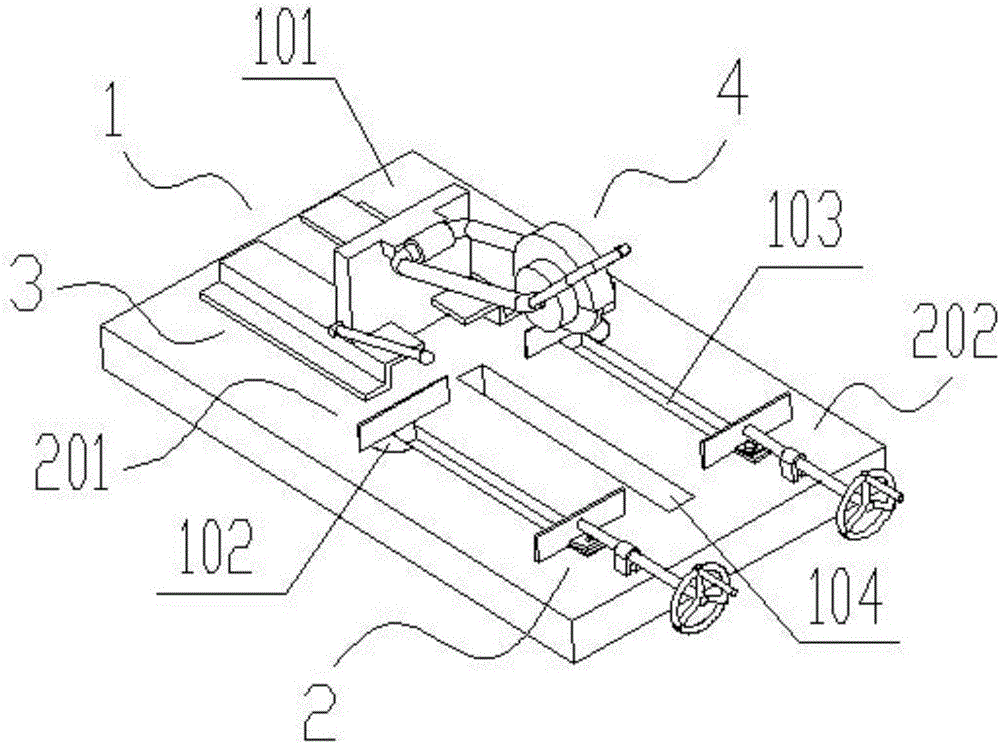

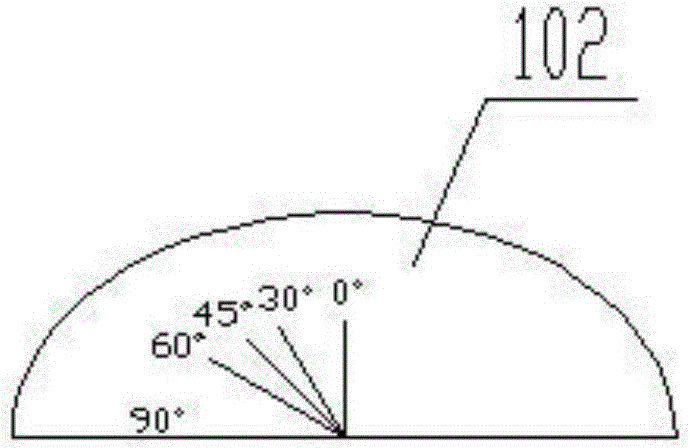

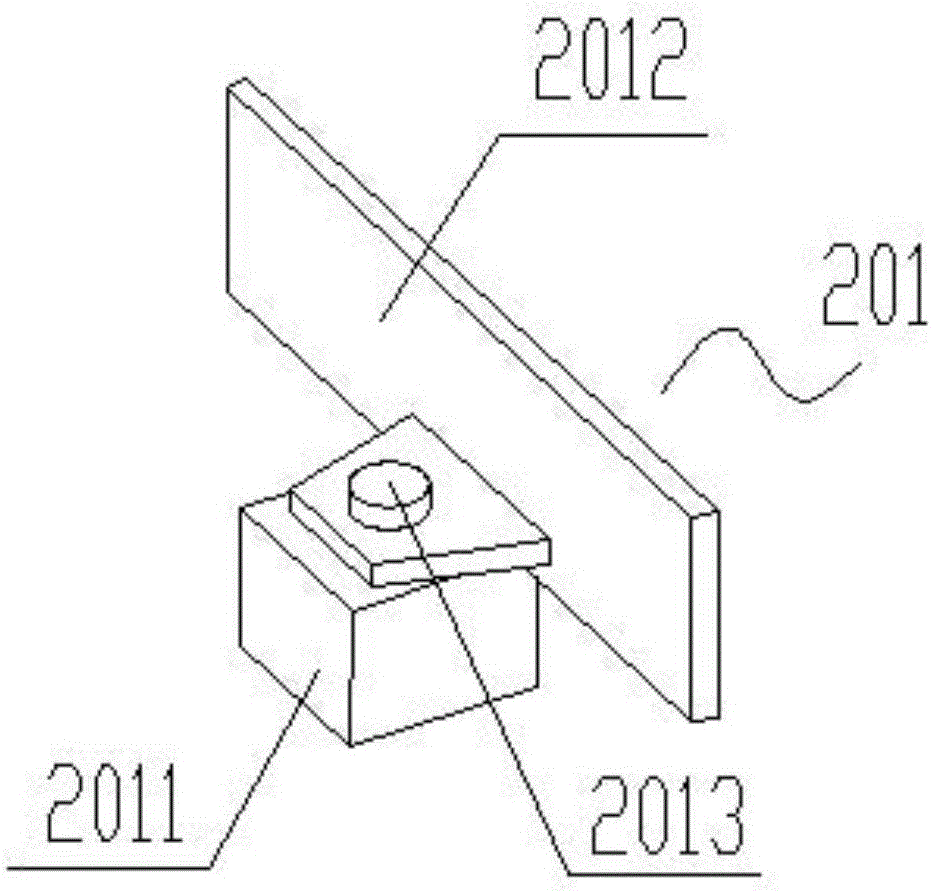

Cutting device for preparing rock samples containing different dip angle structural surfaces and operation method

ActiveCN105773850AAvoid offsetAvoid damagePreparing sample for investigationWorking accessoriesEngineeringRock sample

The invention discloses a cutting device for preparing rock samples containing different dip angle structural surfaces and an operation method, relates to the technical field of rock mechanics tests, and comprises a base device, a sample fixing device, a combined bracket and the cutting device. A sample fixing mode is perfect, can realize fixation of the rock samples by various dip angles, guarantees symmetric stress of the samples in the cutting process, and prevents deviation and fracture of the cutting samples and unevenness of cut surfaces; rubber layers cover the surfaces of a fixed baffle plate and an auxiliary baffle plate, so that the rock samples are guaranteed to be not damaged in the clamping and fastening process; length marks, depth marks and angle marks are arranged for precisely controlling fixing angles, fixing positions and cutting depths of the samples; the cutting device uses a diamond saw blade with excellent rigidity and small thickness, so that the damage of the rock samples can be reduced in the cutting process, the integrity of the rock samples is guaranteed, and the service life is longer; and the cutting device is simple in structure, safe and convenient for operation, low in cutting cost and maintenance cost, small in size, light in weight and convenient for carrying.

Owner:ANHUI UNIV OF SCI & TECH

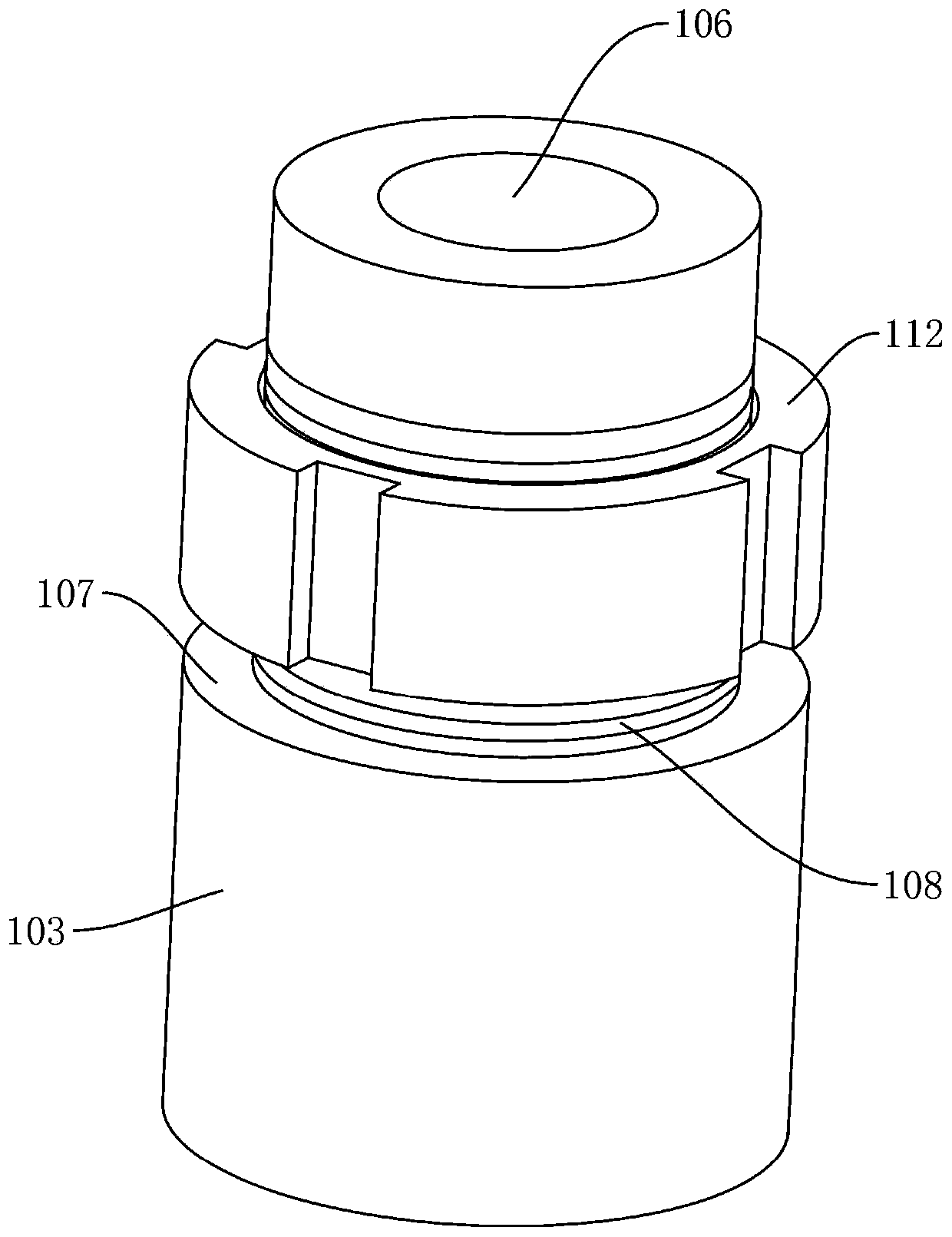

Wallpaper cutter

ActiveCN105108800ARegular shapePrecise control of cutting depthMetal working apparatusEngineeringMechanical engineering

The invention discloses a wallpaper cutter, comprising an adjusting driving mechanism, a positioner, and a cutting tool. The adjusting driving mechanism comprises an adjusting handle and an adjusting main body. The internal of the adjusting main body is hollow. The adjusting handle comprises a holding head and a central spindle. The upper end of the central spindle is connected with the holding head, and the lower end extends into the hollow inner cavity of the adjusting main body. The central spindle is rotatably installed in the hollow inner cavity. The cutting tool is installed on the lower end of the central spindle and rotates synchronously with the central spindle. When the cutting tool rotates, the blade of the cutting tool forms a round motion trail. The positioner is a set of sleeve installed on the adjusting main body. The cutting tool is on the inner side of the positioned. The positioned and the adjusting main body are connected by threads, so that cutting depth of the blade of the cutting tool is adjusted through rotating the positioned. When the wallpaper cutter repairs part irregular damaged positions of a wallpaper, the whole wallpaper does not need to be dismounted, and the wallpaper can be repaired. The wallpaper cutter is beneficial for improving efficiency for repairing part irregular damages of wallpaper in a passenger cabin.

Owner:GUANGZHOU AIRCRAFT MAINTENANCE ENG

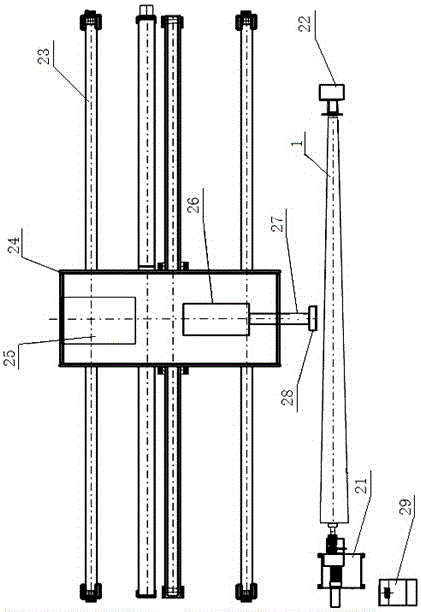

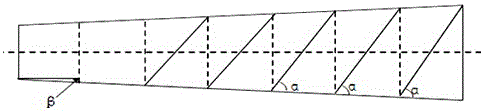

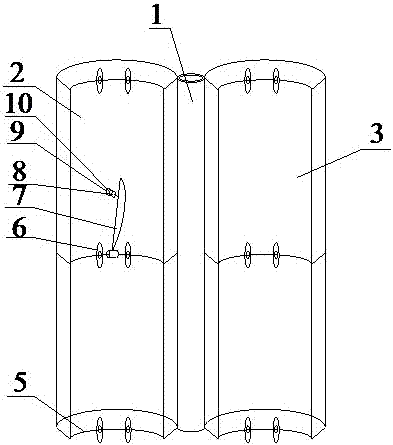

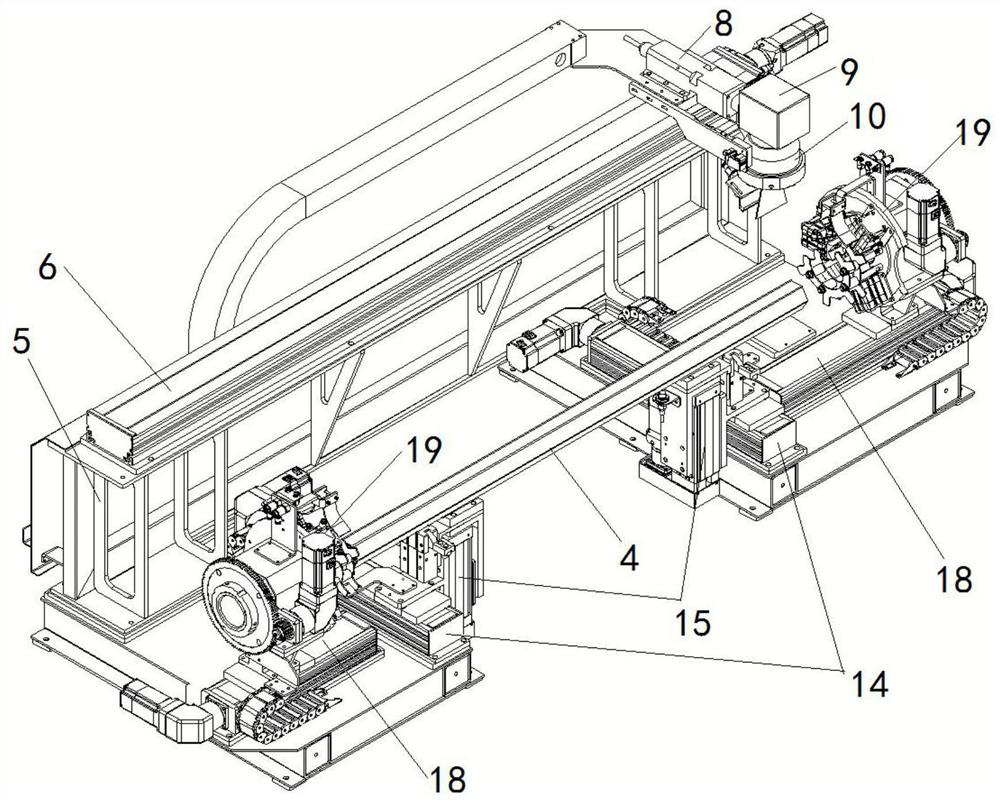

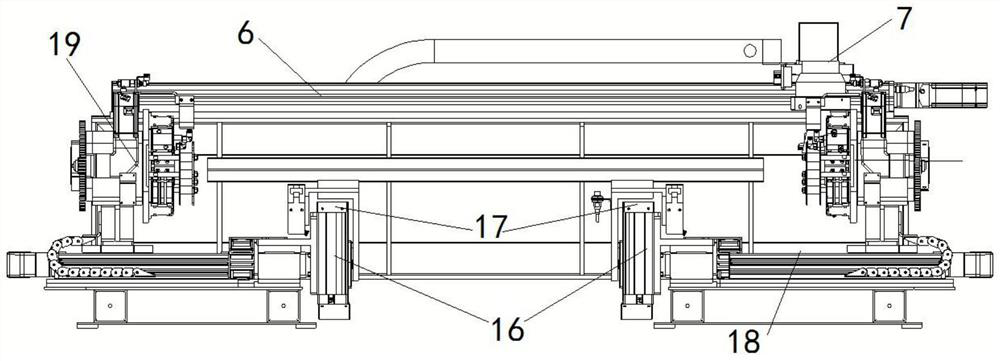

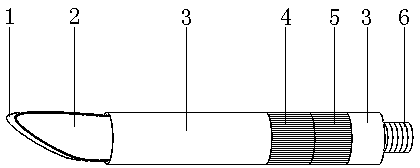

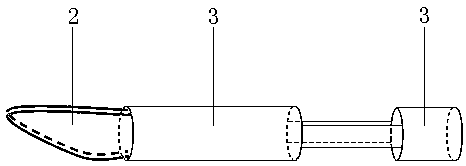

Machining method and system for novel conical composite material electric pole

The invention discloses a machining method and system for a novel conical composite material electric pole. The method includes the steps that first, an electric pole mold core and necessary tool components are erected in a four-axis winding system, and glass fibers with an inner layer of adhesive and an outer layer of adhesive which are prepared according to a certain proportion and formulas are wound around the surface of the electric pole mold core; after being wound, the glass fibers are moved into an electric heating curing furnace together with the electric pole mold core to be cured and shaped; and after being shaped, the cured conical composite material electric pole product is moved into a cutting mold release machine together with the electric pole mold core, and with the ends cut off, the composite material electric pole is released from the electric pole mold core. The conical composite material electric pole manufactured through the method has the beneficial effects of being capable of achieving low-carbon environment protection, easy to transport and install due to the light weight, high in strength, long in service life, good in weather resistance, corrosion resistance and insulating performance, high in natural hazard resisting capacity and the like and can well replace traditional reinforced concrete electric poles and steel tube towers in the projects of power transmission and distribution lines, communication lines communication towers and the like.

Owner:ANHUI HUIKE HENGYUAN COMPOSITE MATERIAL CO LTD

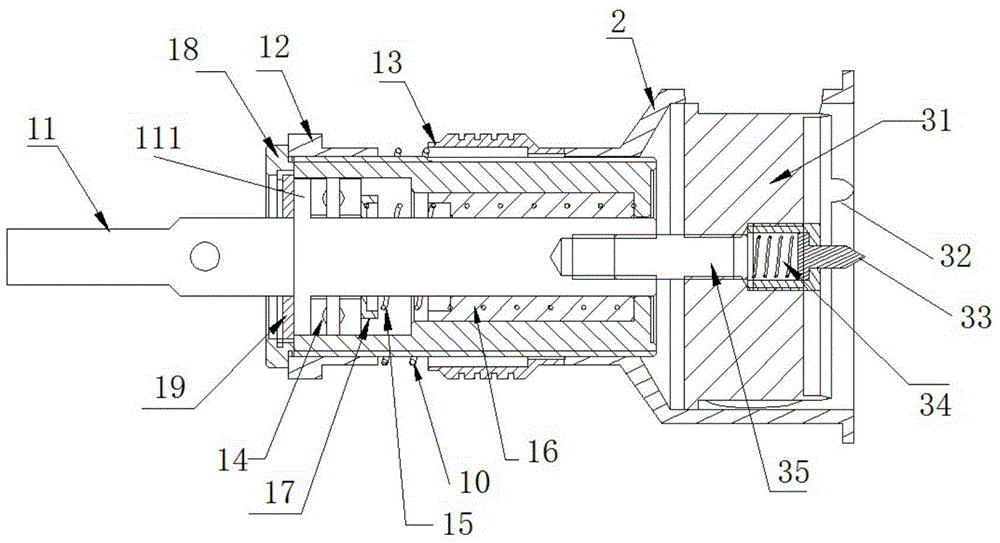

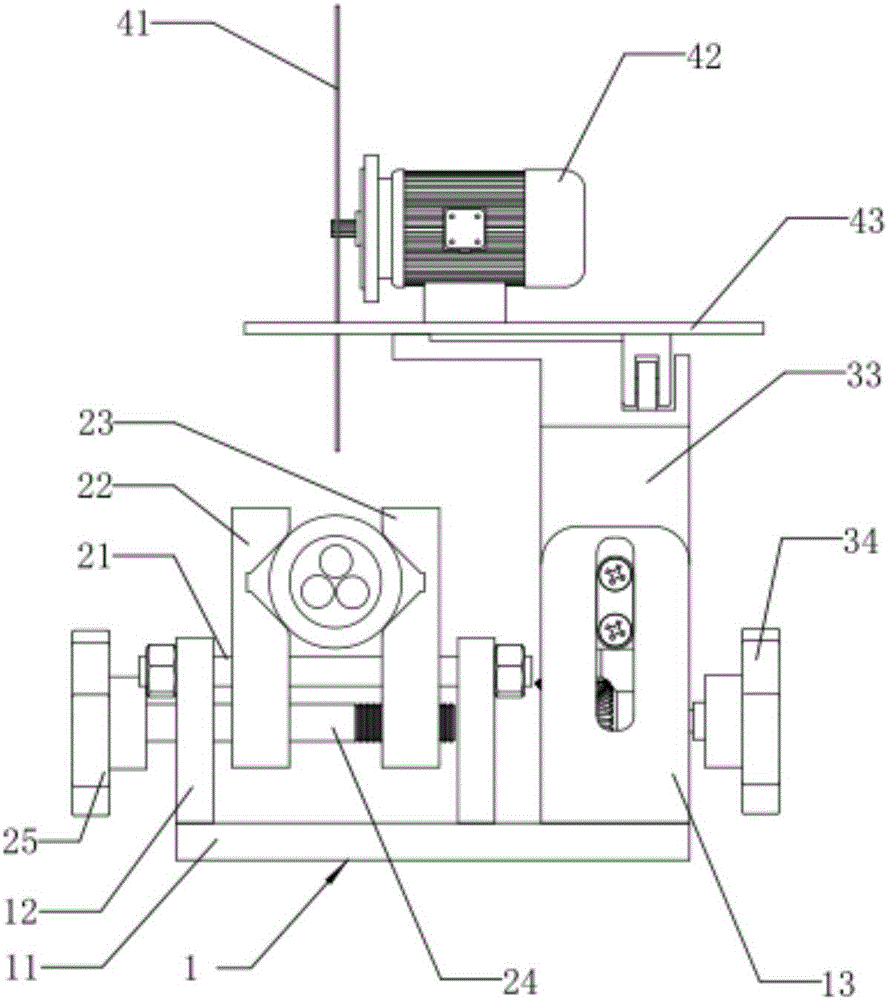

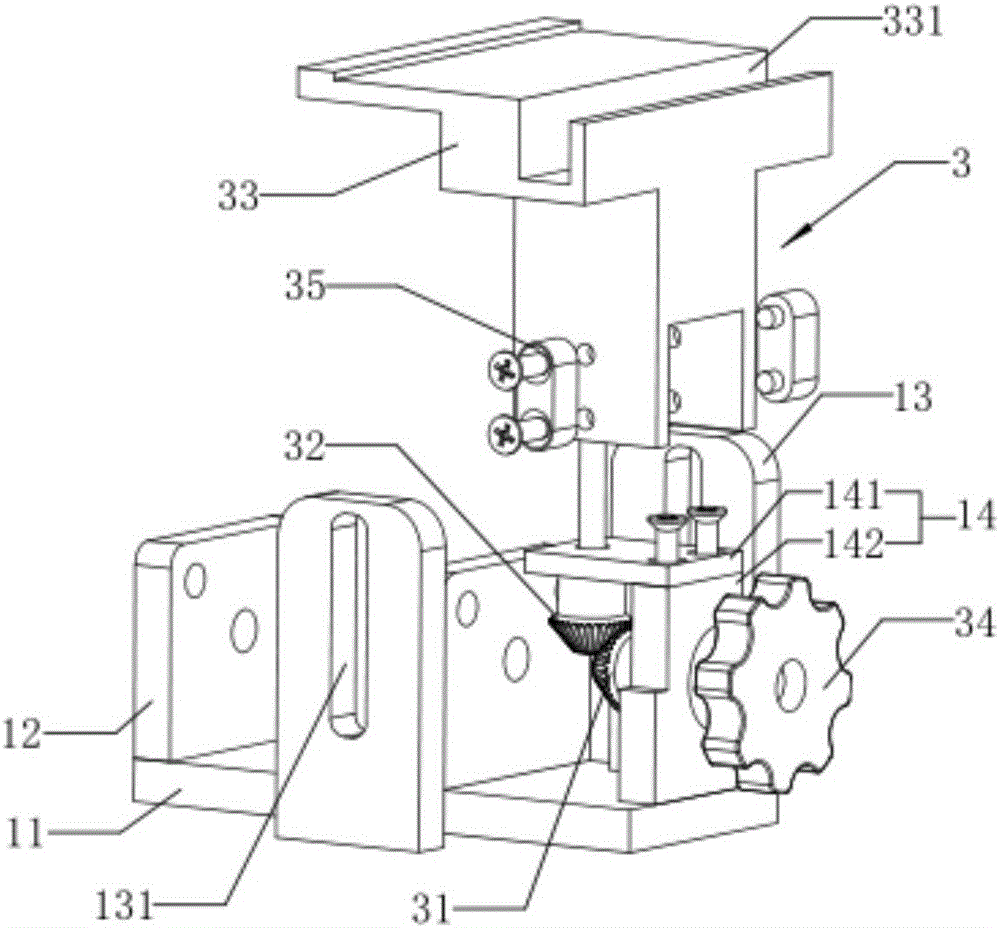

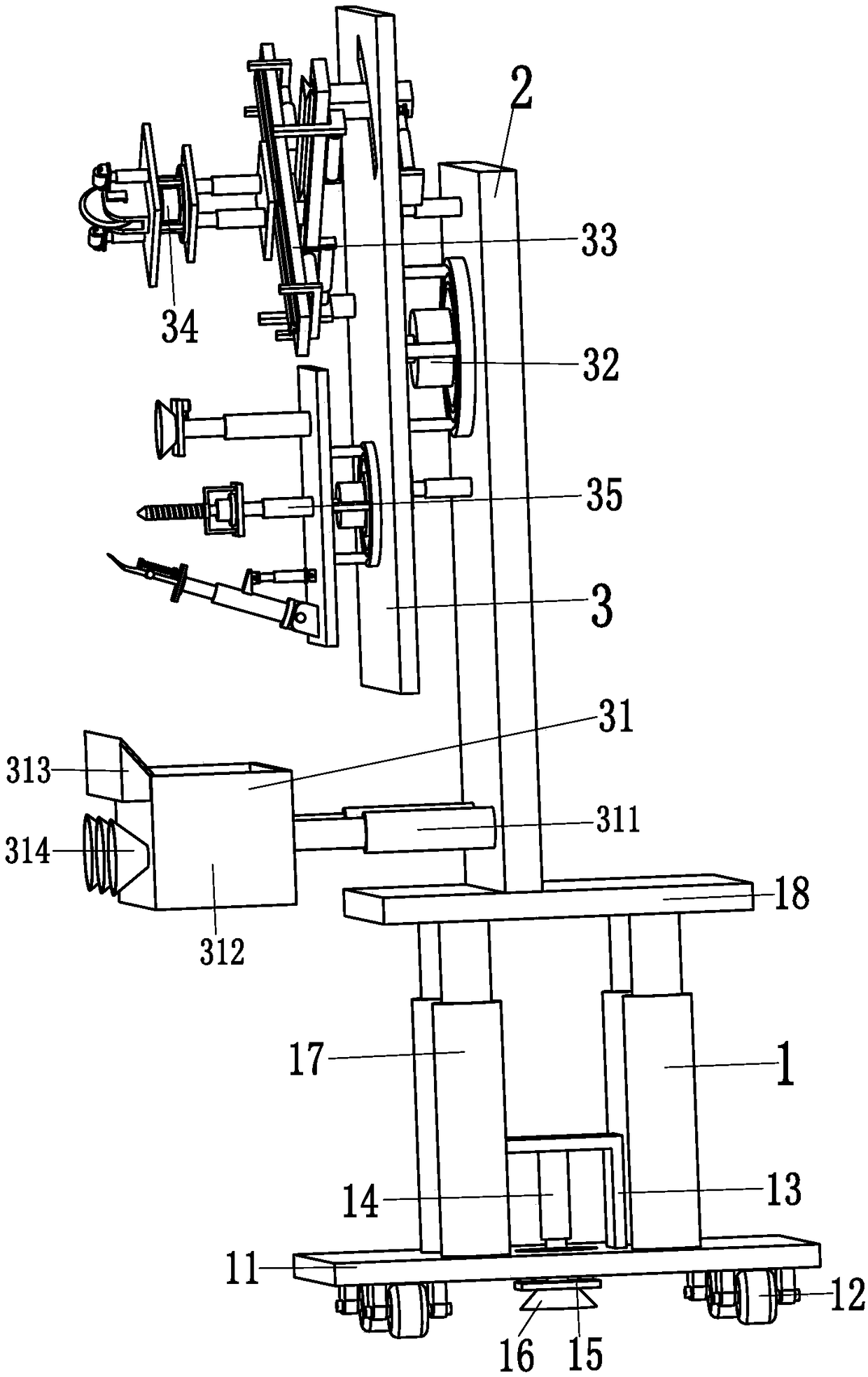

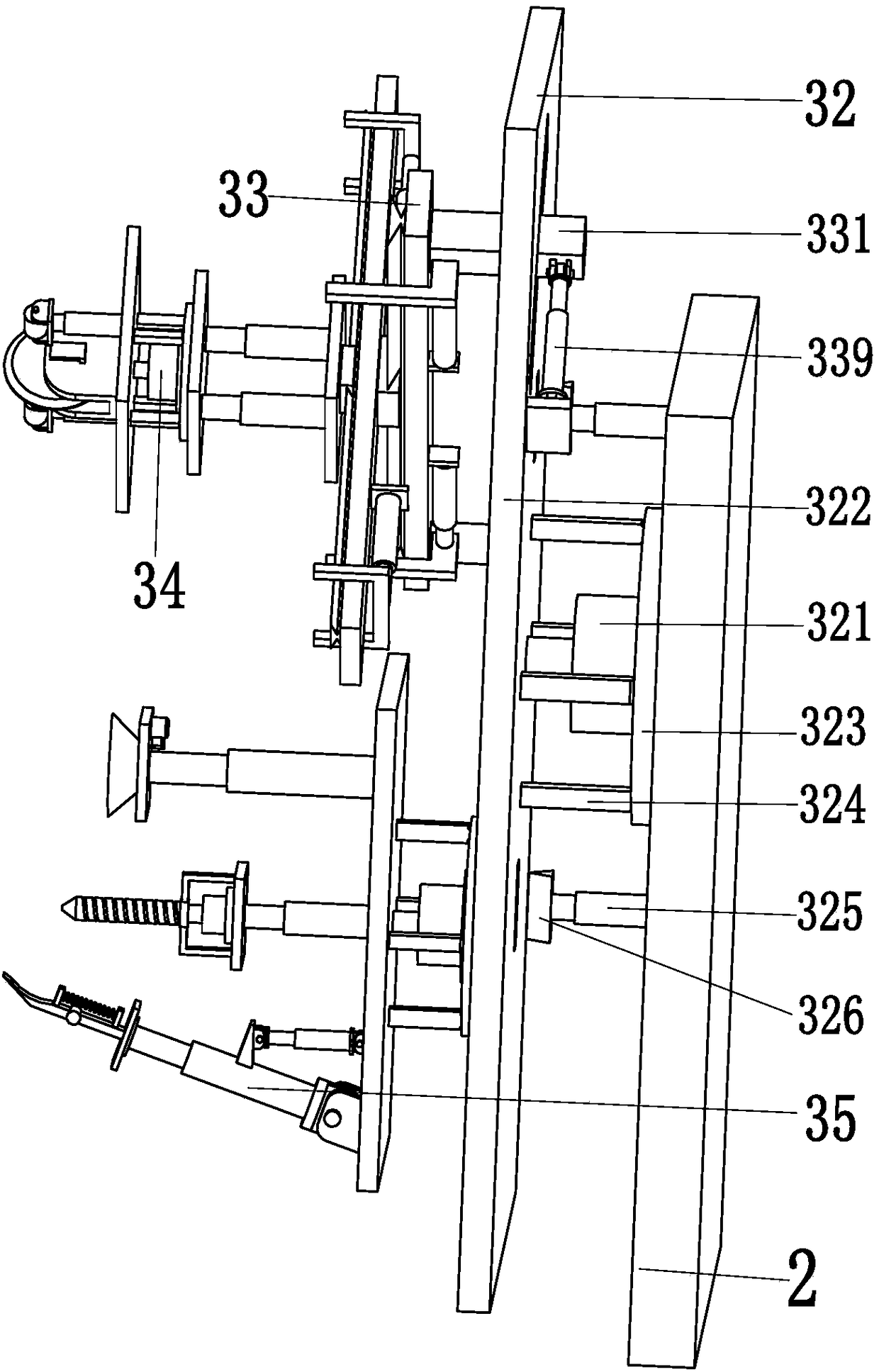

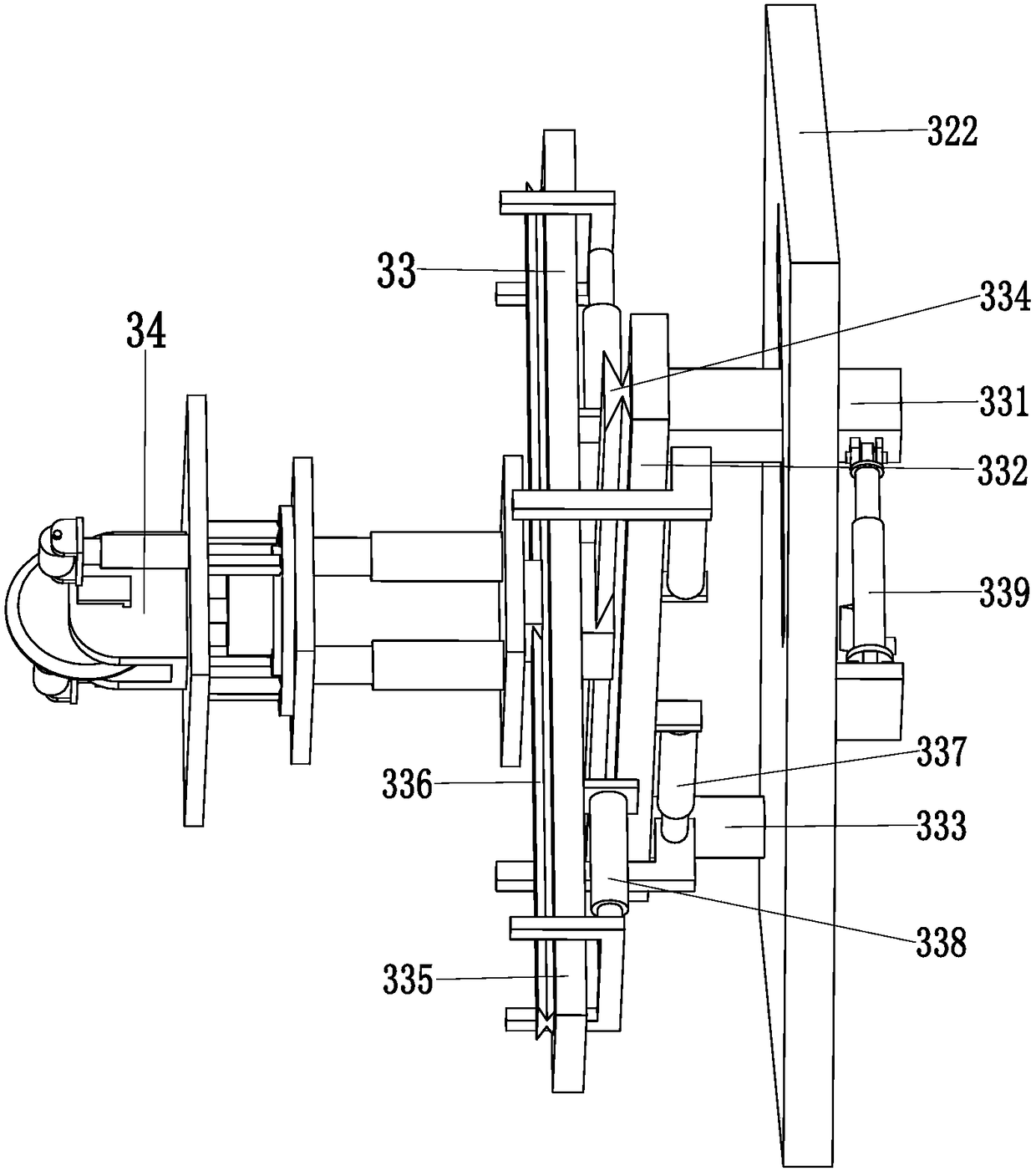

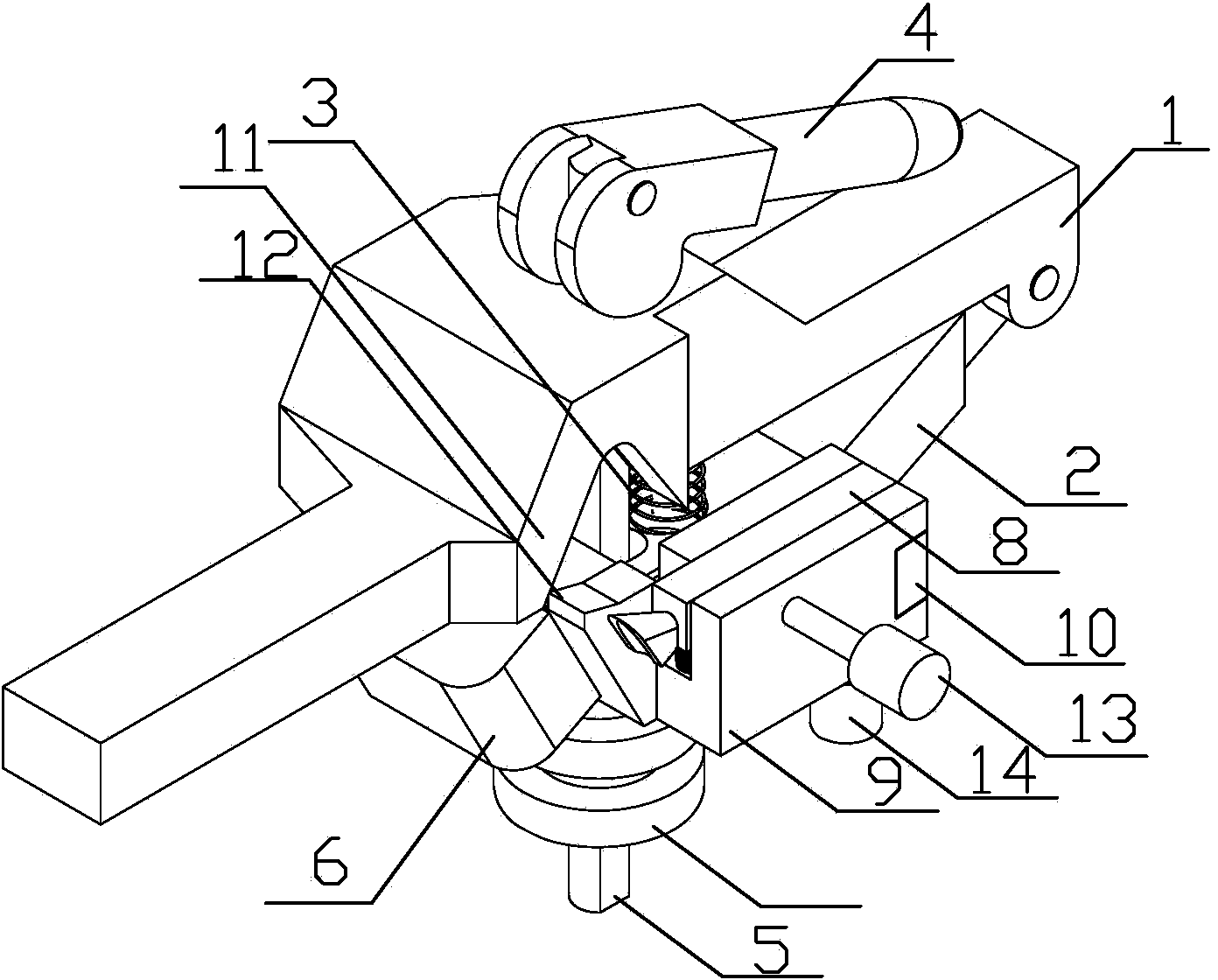

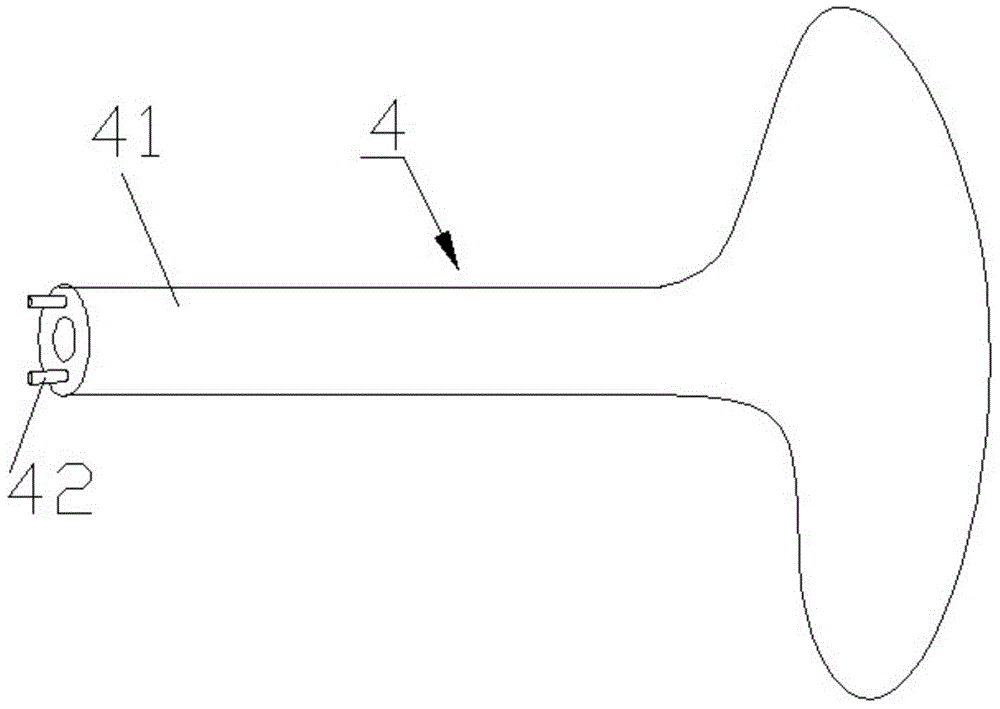

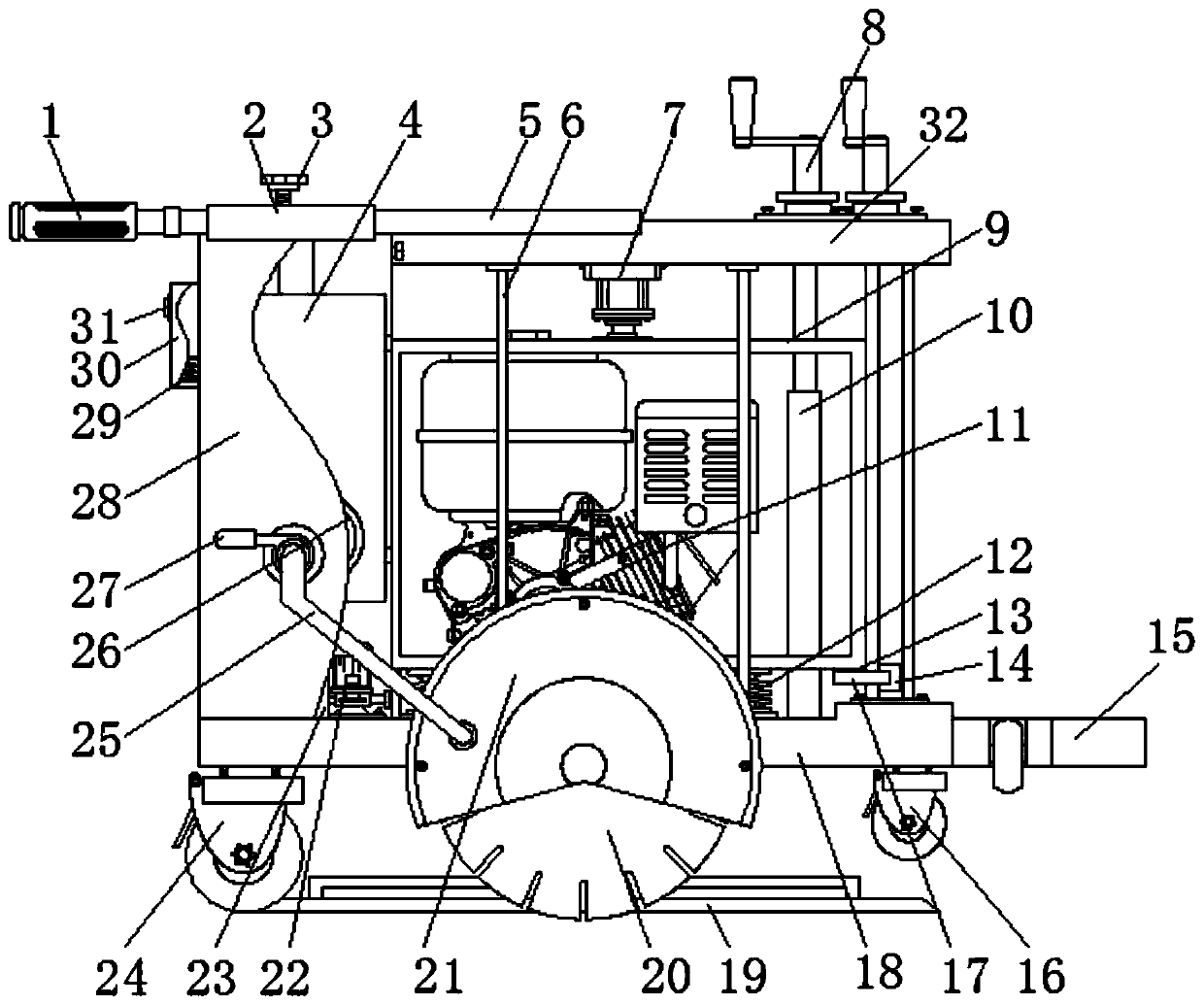

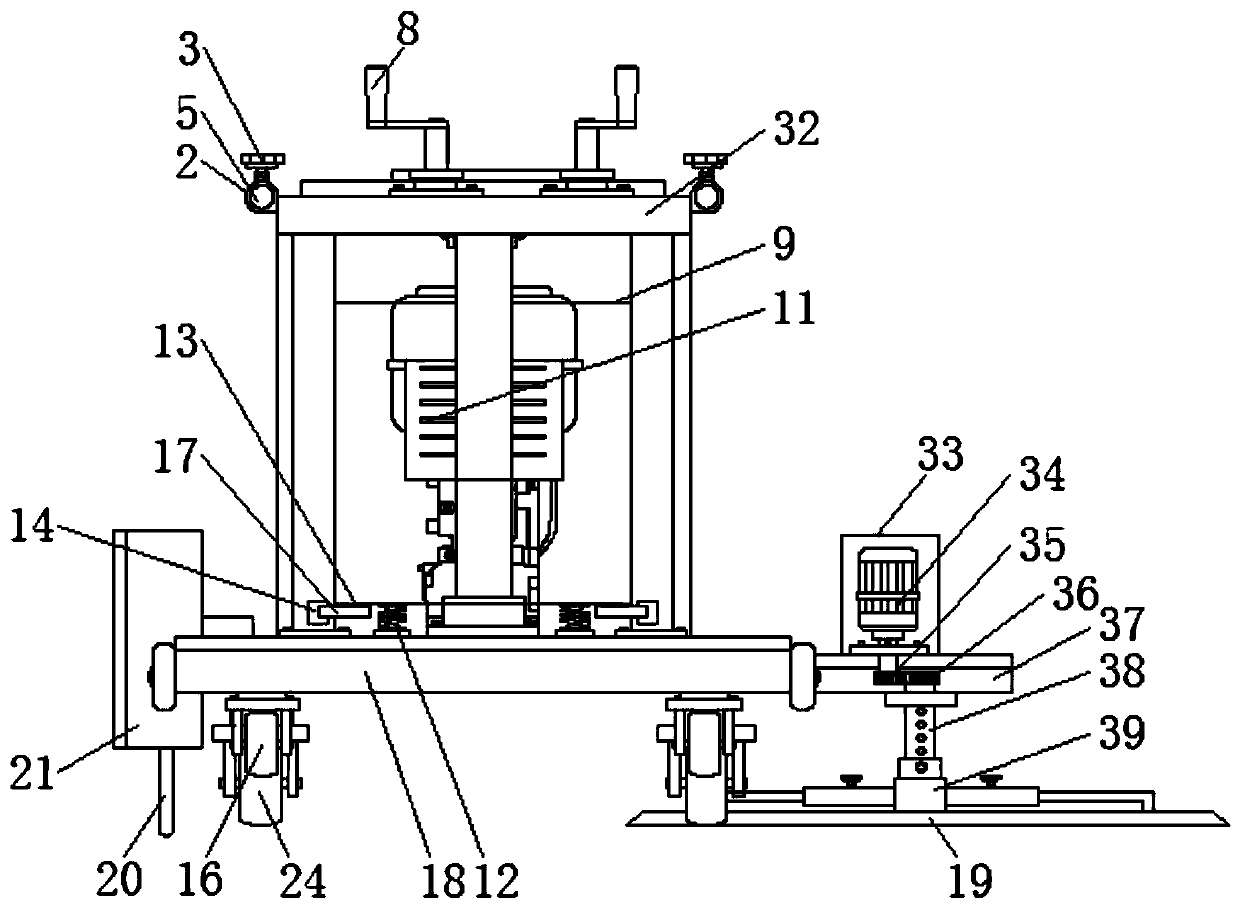

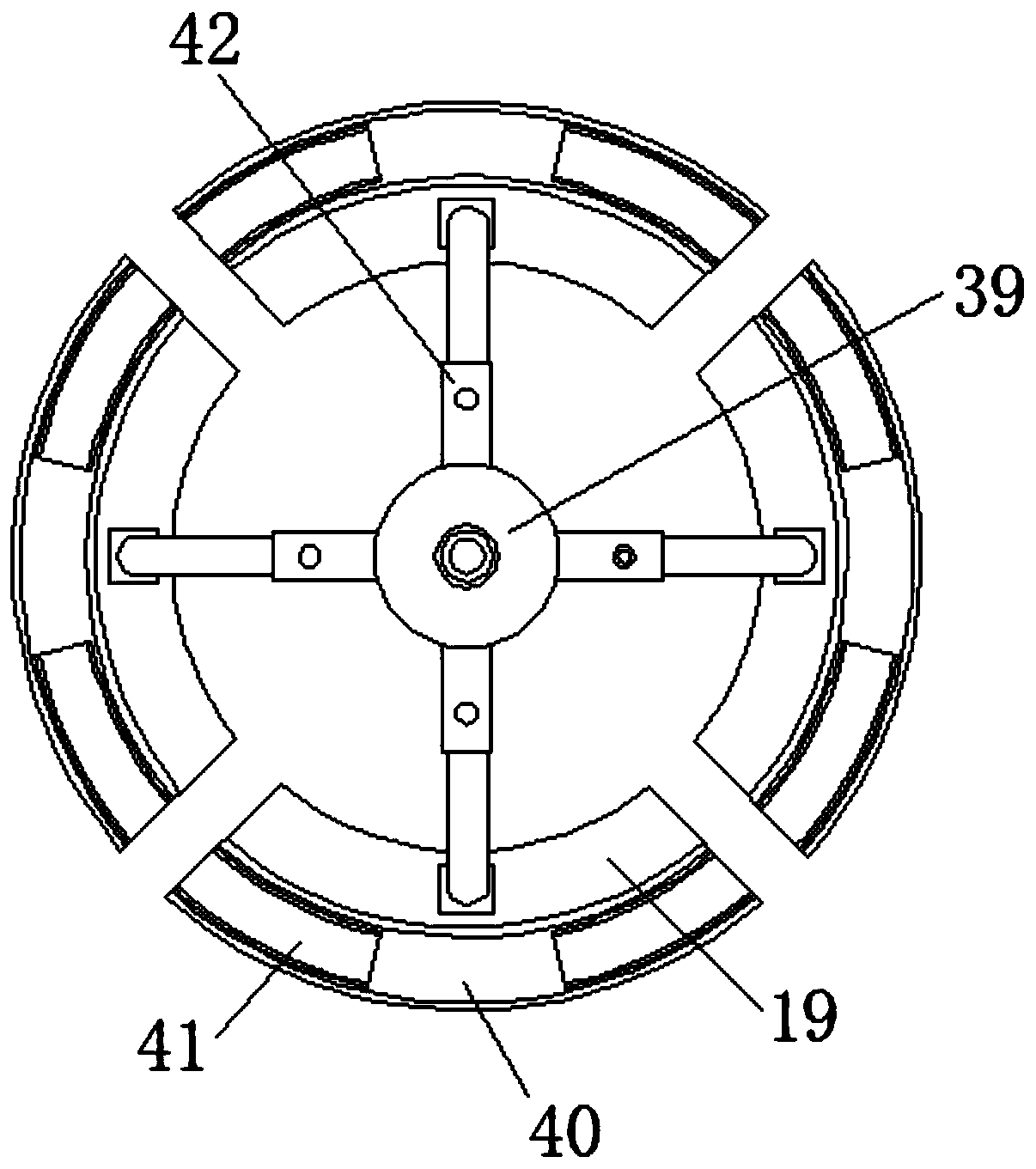

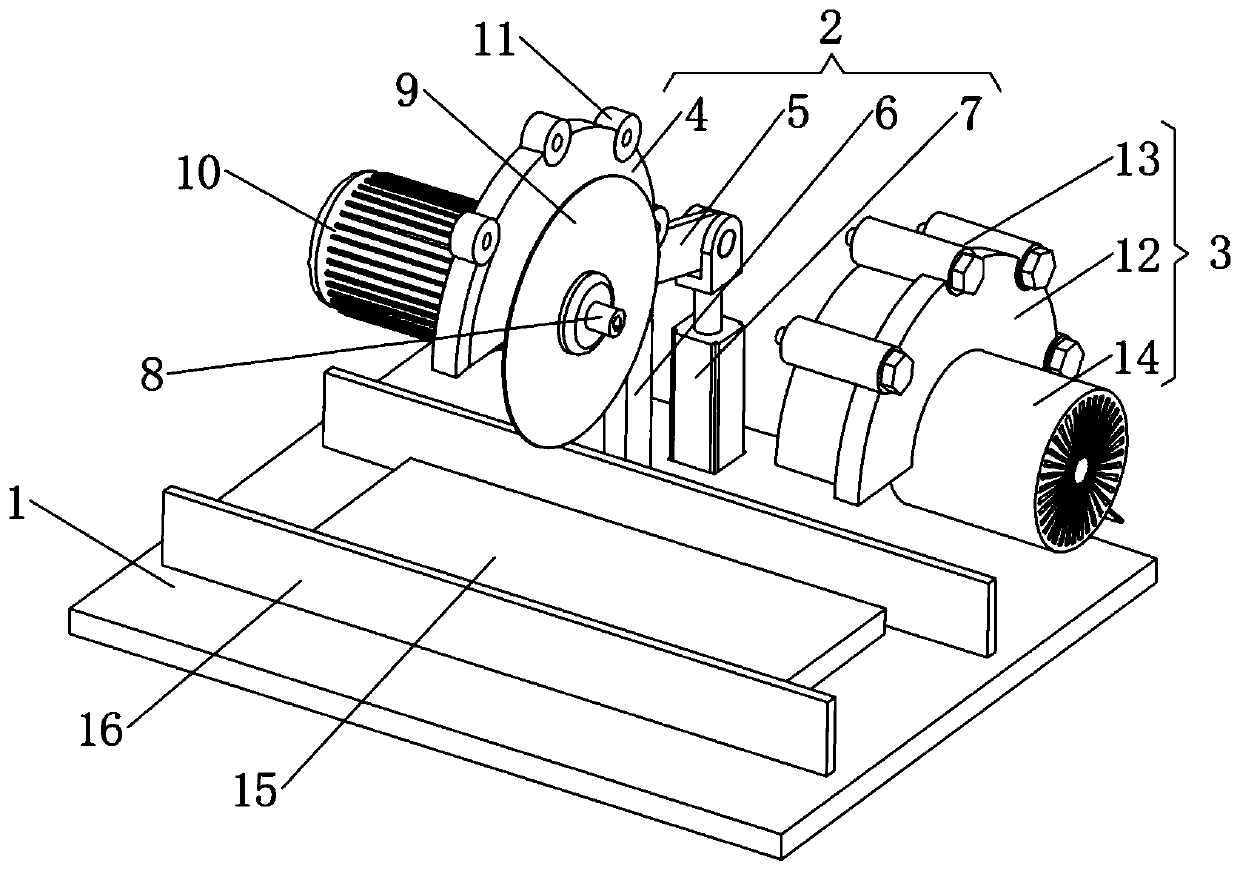

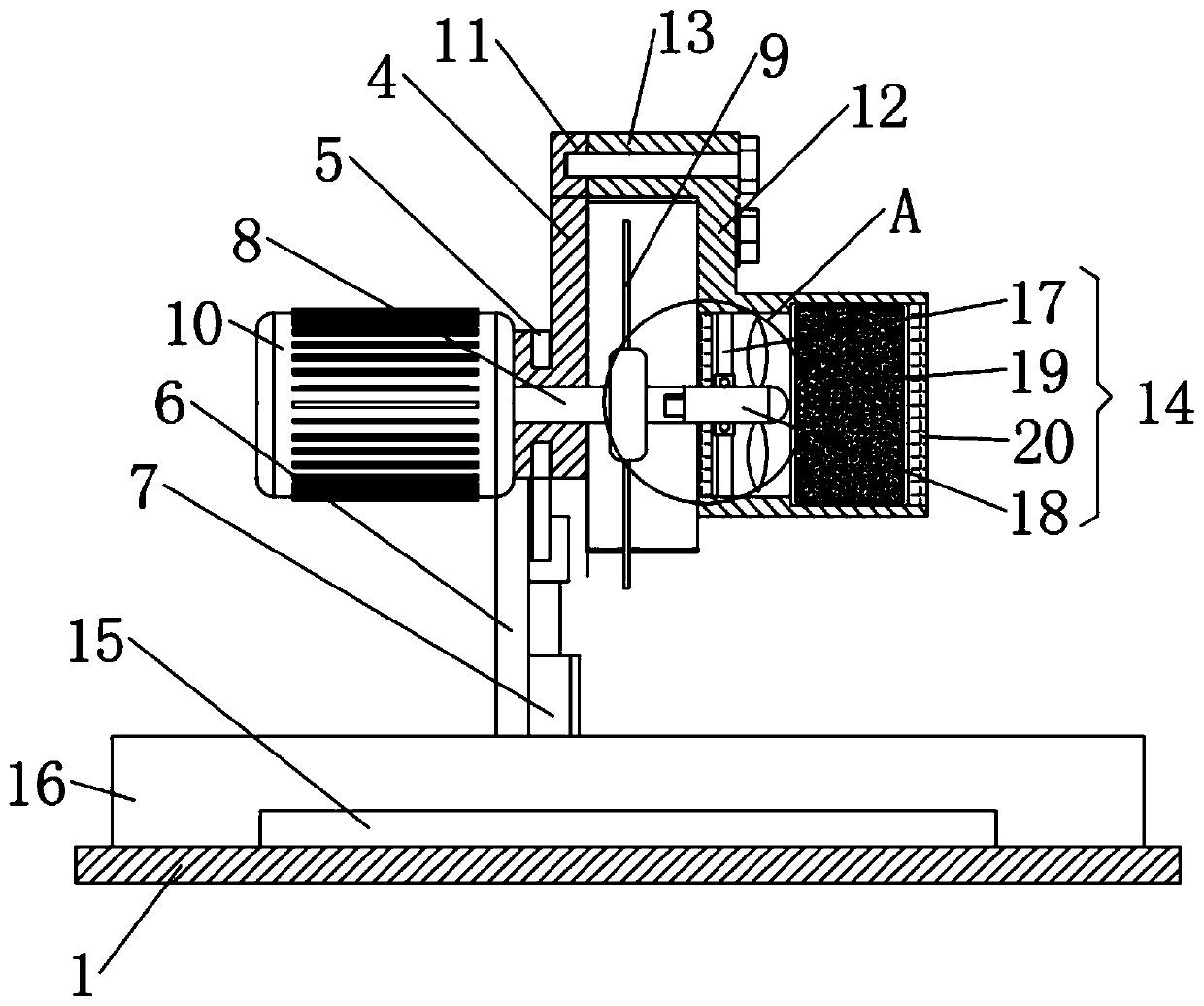

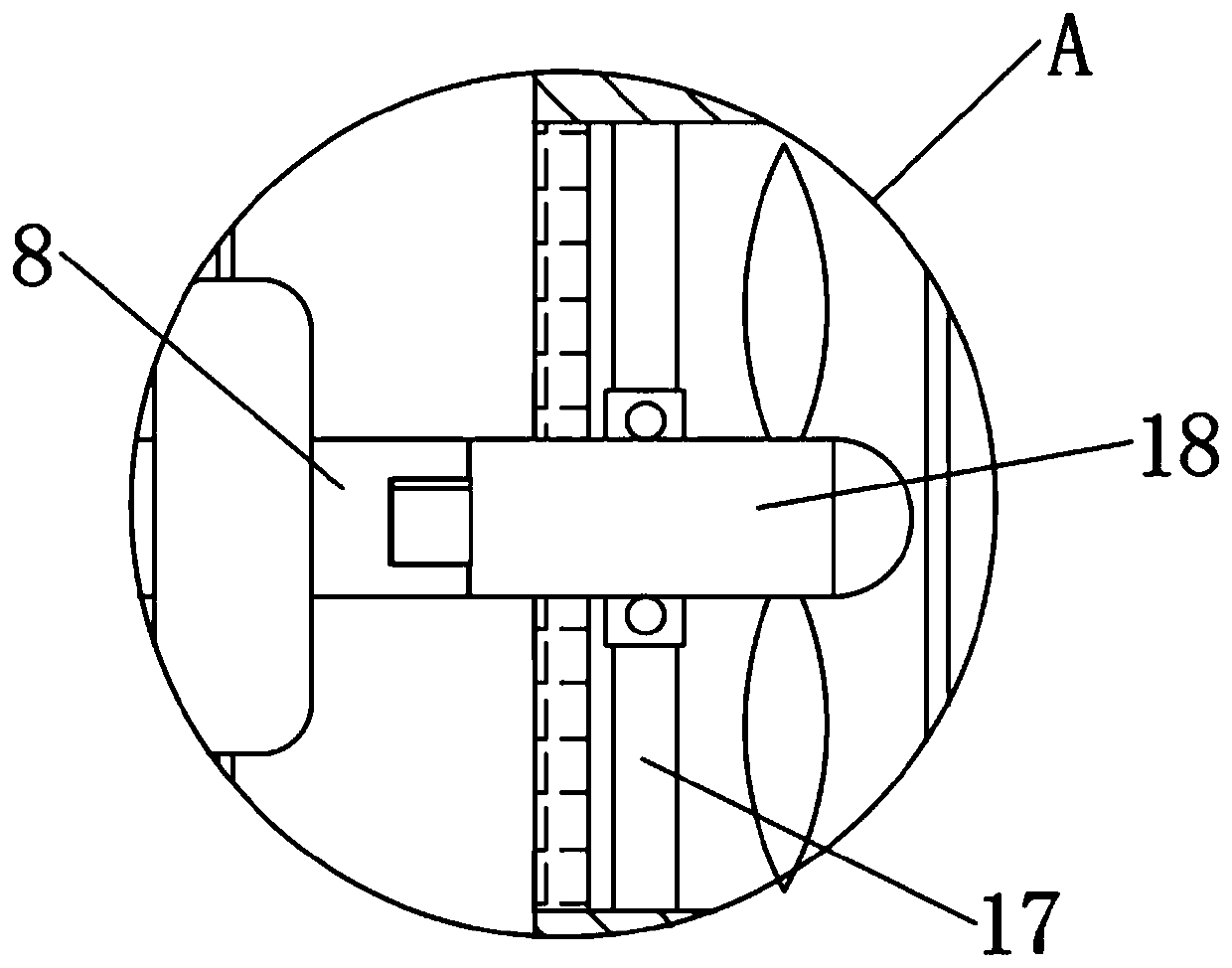

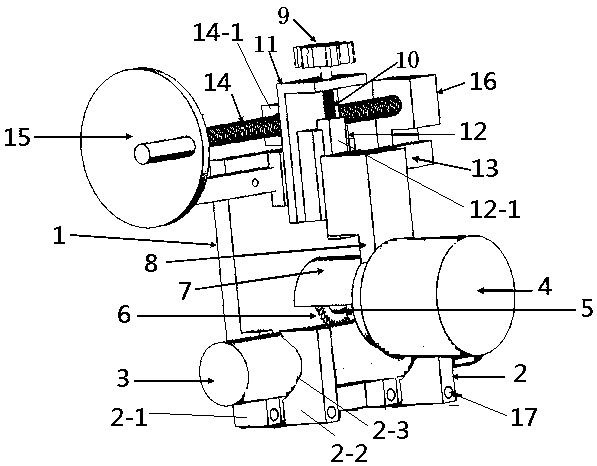

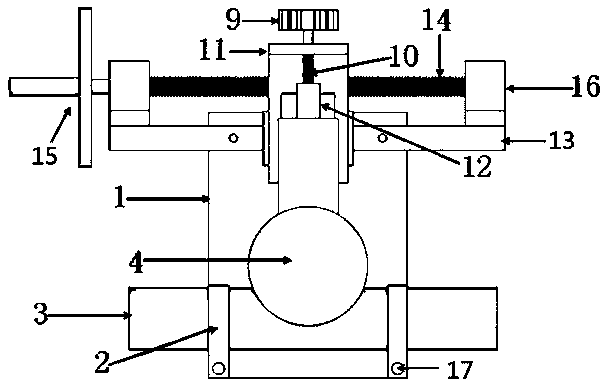

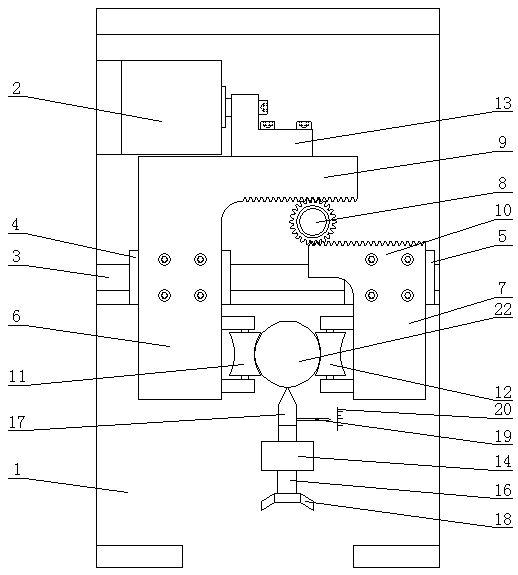

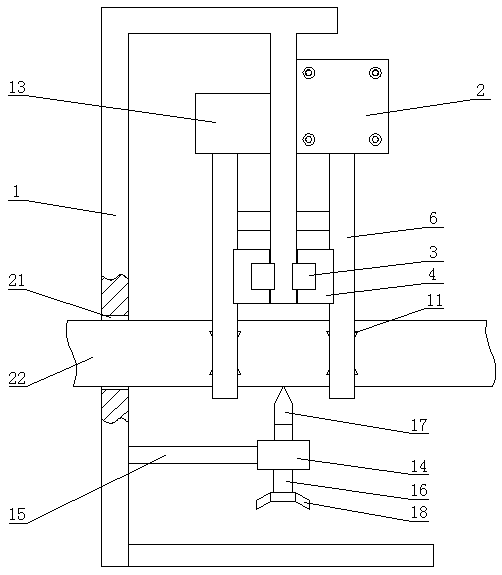

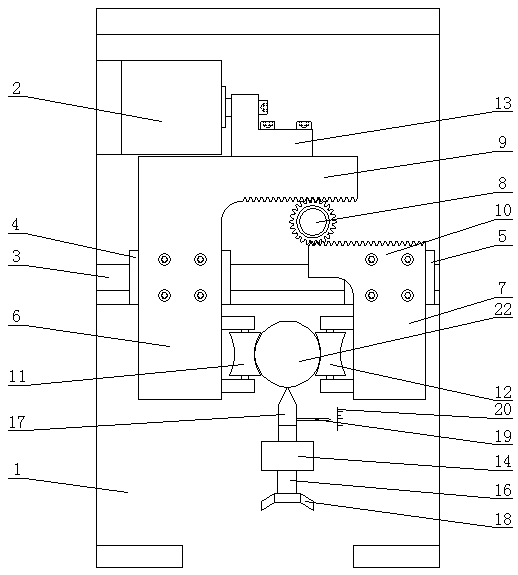

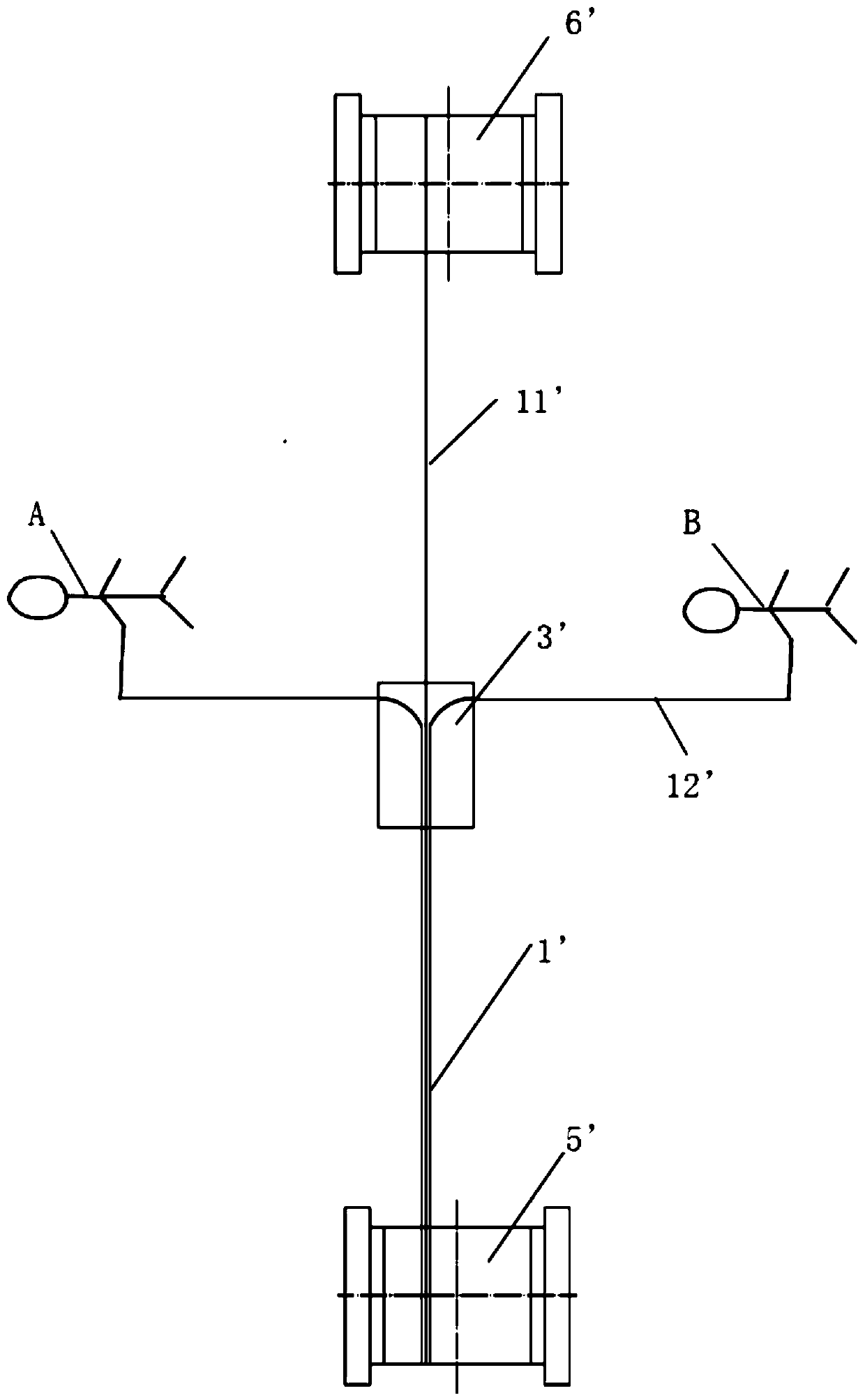

Electric breaking-in tool for crimping wire clamp and operation method

ActiveCN105958379AGood demolition effectPrecise control of cutting depthApparatus for overhead lines/cablesEngineeringMobile station

The invention discloses an electric breaking-in tool for a crimping wire clamp. The electric breaking-in tool for the crimping wire clamp comprises a base, a clamping mechanism, a lifting mechanism and a cutting mechanism, wherein the clamping mechanism is arranged at one side of the base; the lifting mechanism is arranged at the other side of the base; the cutting mechanism is connected to the upper part of the lifting mechanism; the base comprises a bottom plate, clamping mounting plates, lifting mounting plates and a bevel gear mounting plate; the clamping mechanism comprises a slide bar, a fixed clamping block, a sliding clamping block, a screw rod and a clamping handwheel; the lifting mechanism comprises a driving bevel gear, a driven bevel gear, a lifting platform and a lifting handwheel; and the cutting mechanism comprises a cutting disk, a motor and a forward-backward mobile station. The invention further provides an operation method of the tool. By the electric breaking-in tool for the crimping wire clamp, the cutting depth and position can be accurately controlled; the breaking-in effect is good; the common problems that the wire clamp is not cut off due to deviating cutting and over-shallow cutting, a guide wire is cut due to over-deep cutting and the like in the prior art are solved; and meanwhile, the operation is simple, convenient and labor-saving, use is safe and the operation efficiency is high.

Owner:国网安徽省电力有限公司亳州供电公司 +1

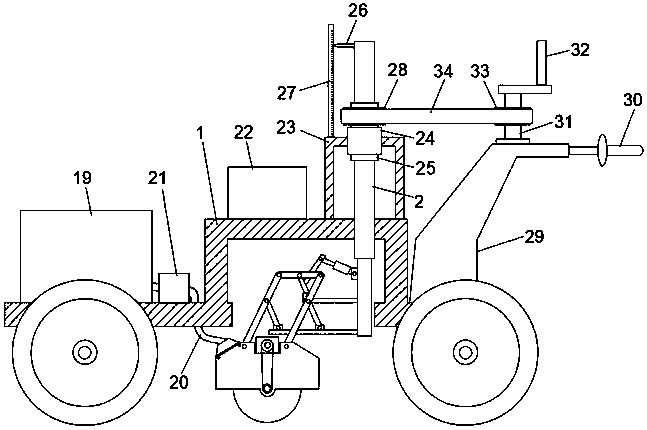

Non-damage automatic treatment device for building wall surface

ActiveCN108612332AStable supportPrecise control of cutting depthBuilding repairsHydraulic cylinderMarking out

The invention relates to a non-damage automatic treatment device for a building wall surface. The non-damage automatic treatment device comprises a supporting device, a cleaning side plate and a cleaning device, wherein the cleaning side plate is installed at the top of the supporting device, and the cleaning device is installed on the left side surface of the cleaning side plate; the supporting device comprises a supporting bottom plate, walking wheels, a supporting bracket, a pressing push rod, a pressing plate, a pressing suction cup, a supporting hydraulic cylinder and a supporting top plate. The non-damage automatic treatment device can solve the existing problems that when broken tiles on a wall are removed, dangers exists when the tiles are cut manually, the tiles after being cut are difficult to recycle, the tiles need to be marked out first, the cutting depth of the tiles is difficult to be accurately controlled, the cut tiles after being cut need to be manually hooked up, andmanually picking of the cut tiles after being cut is prone to scratching hands. The non-damage automatic treatment device can realize the functions of stably supporting the broken tiles on the wall surface, cutting, drilling and sucking the broken tiles, and recycling the sucked tiles.

Owner:中铁十七局集团城市建设有限公司

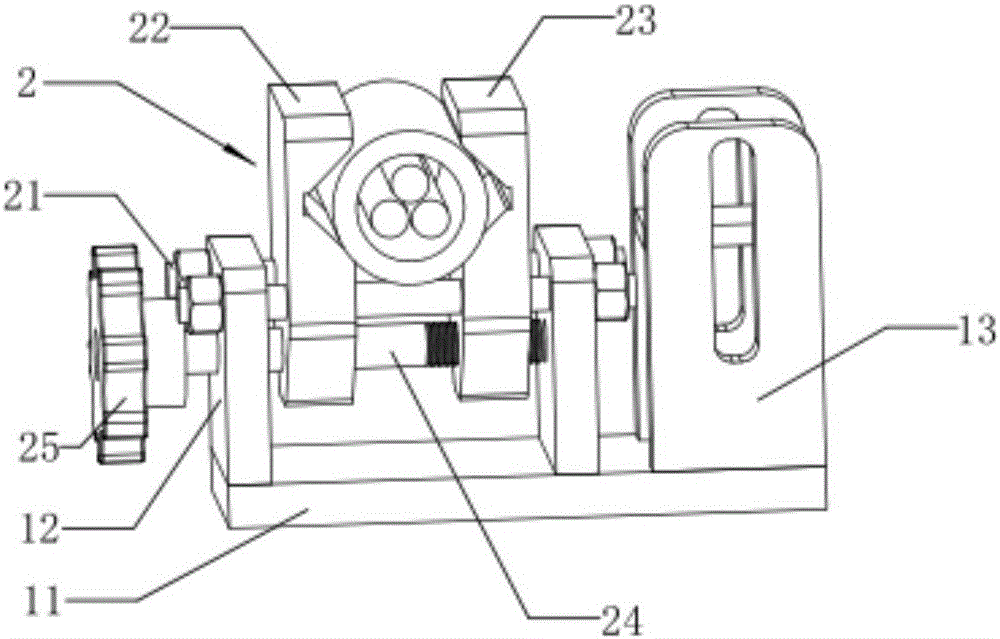

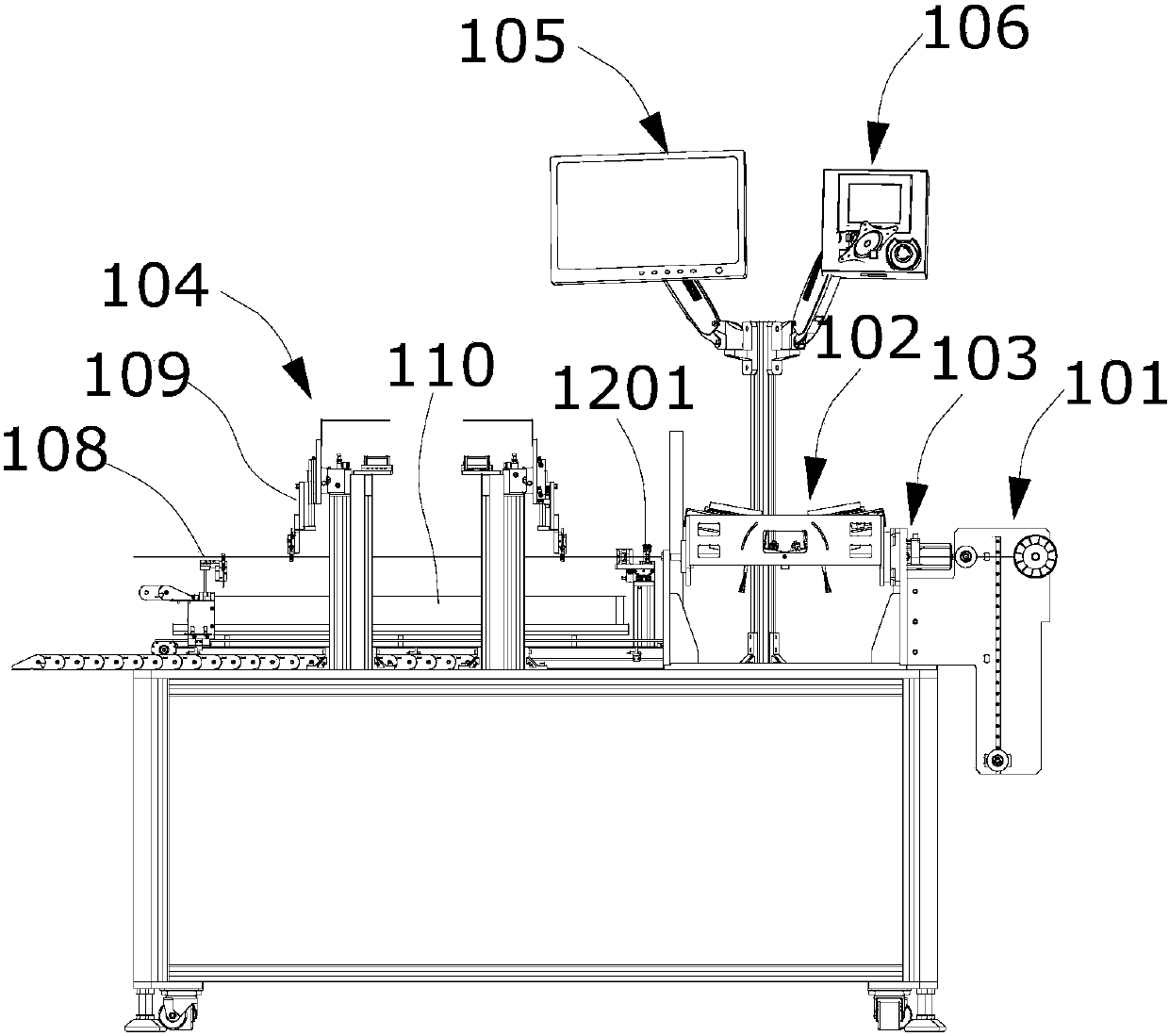

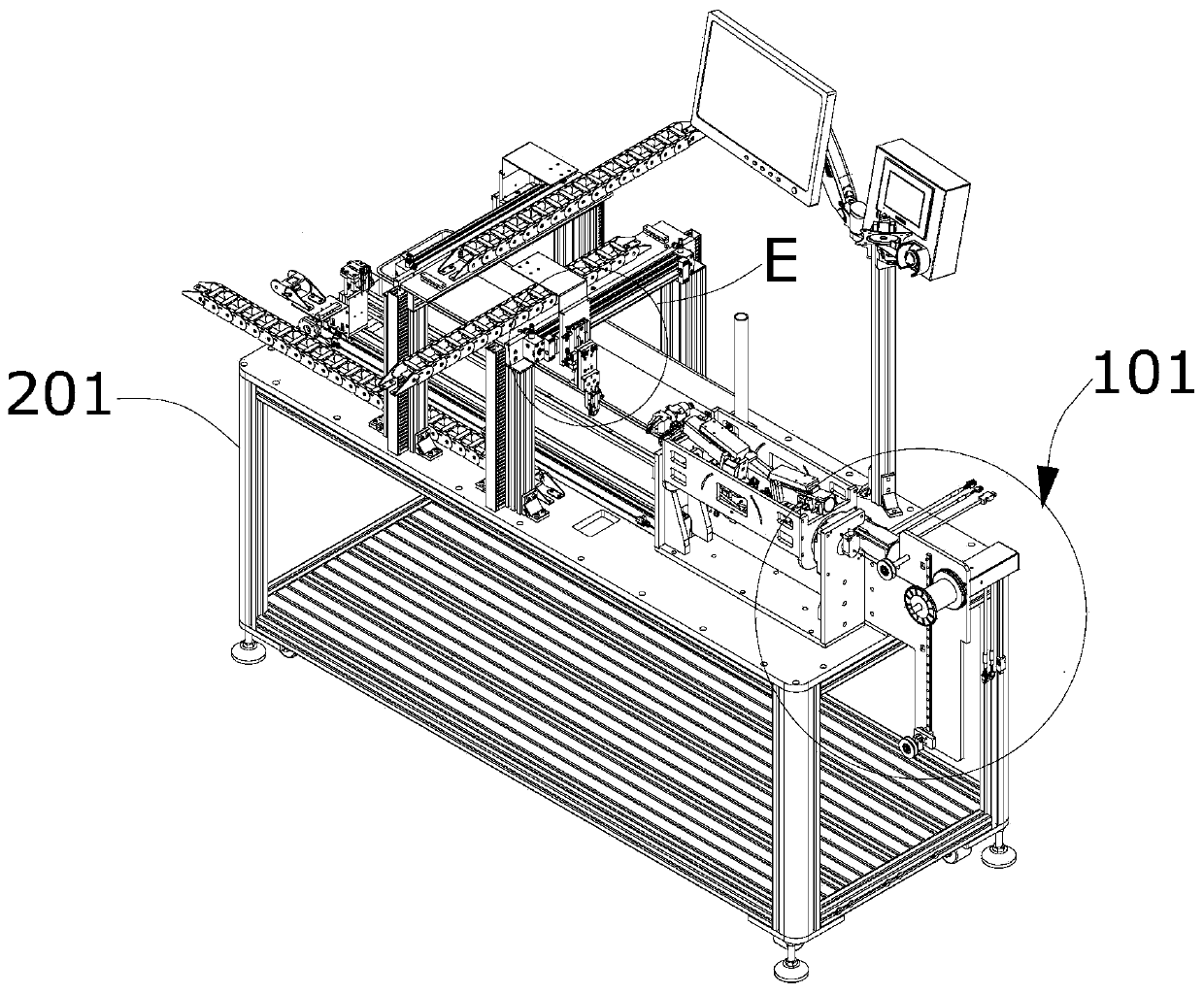

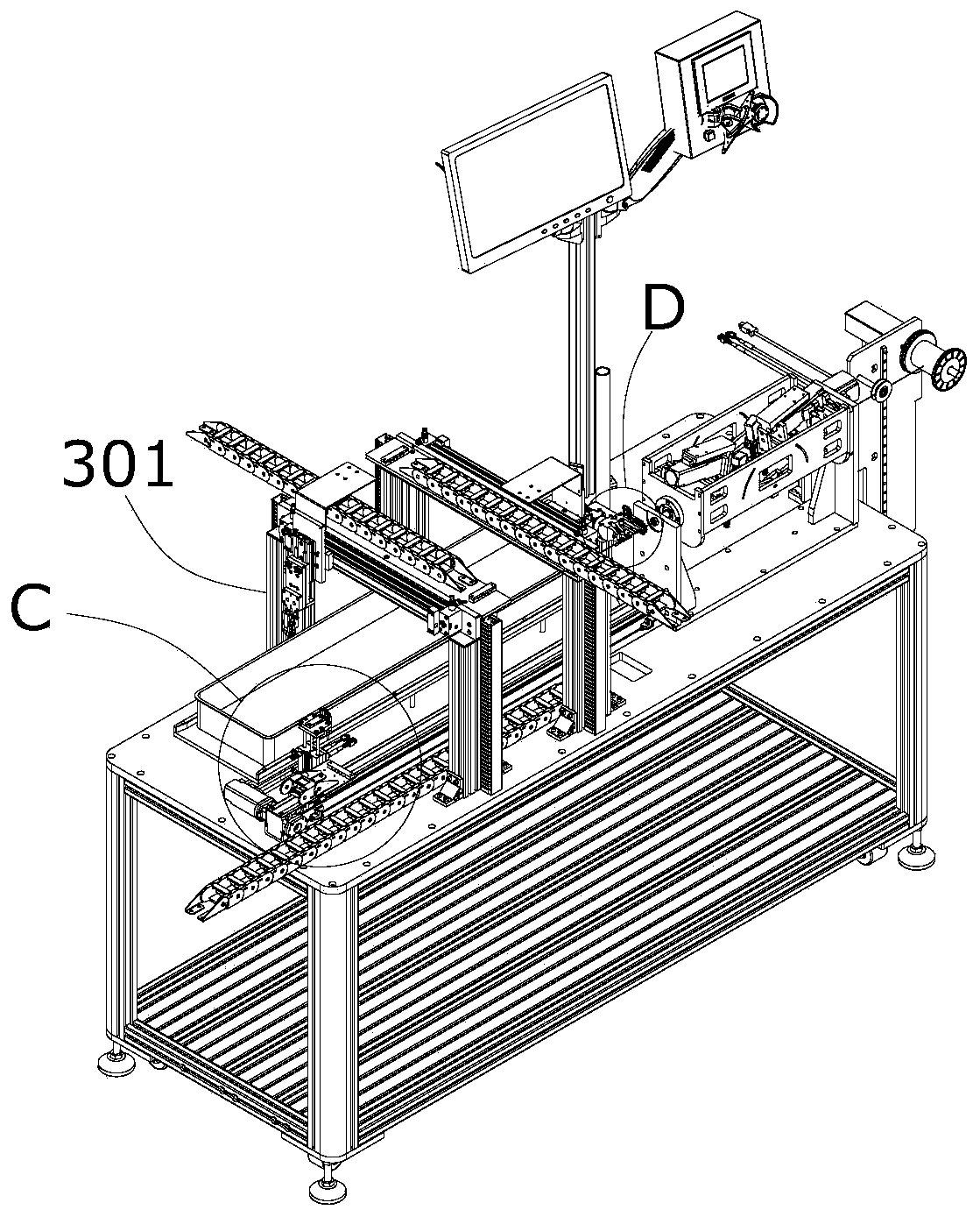

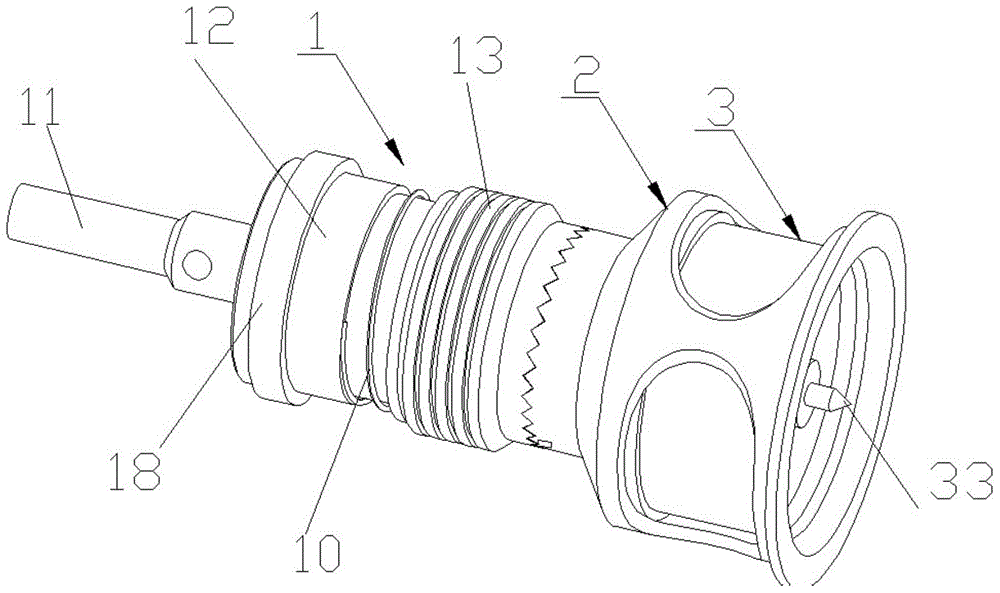

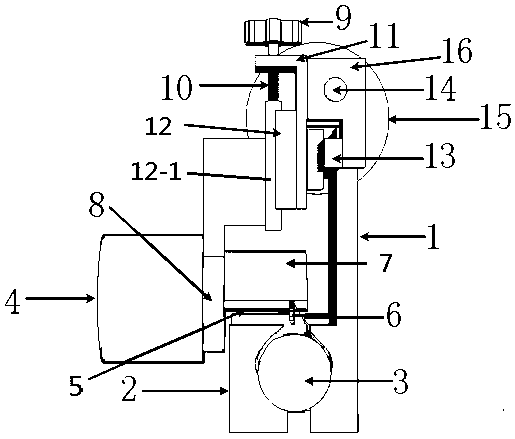

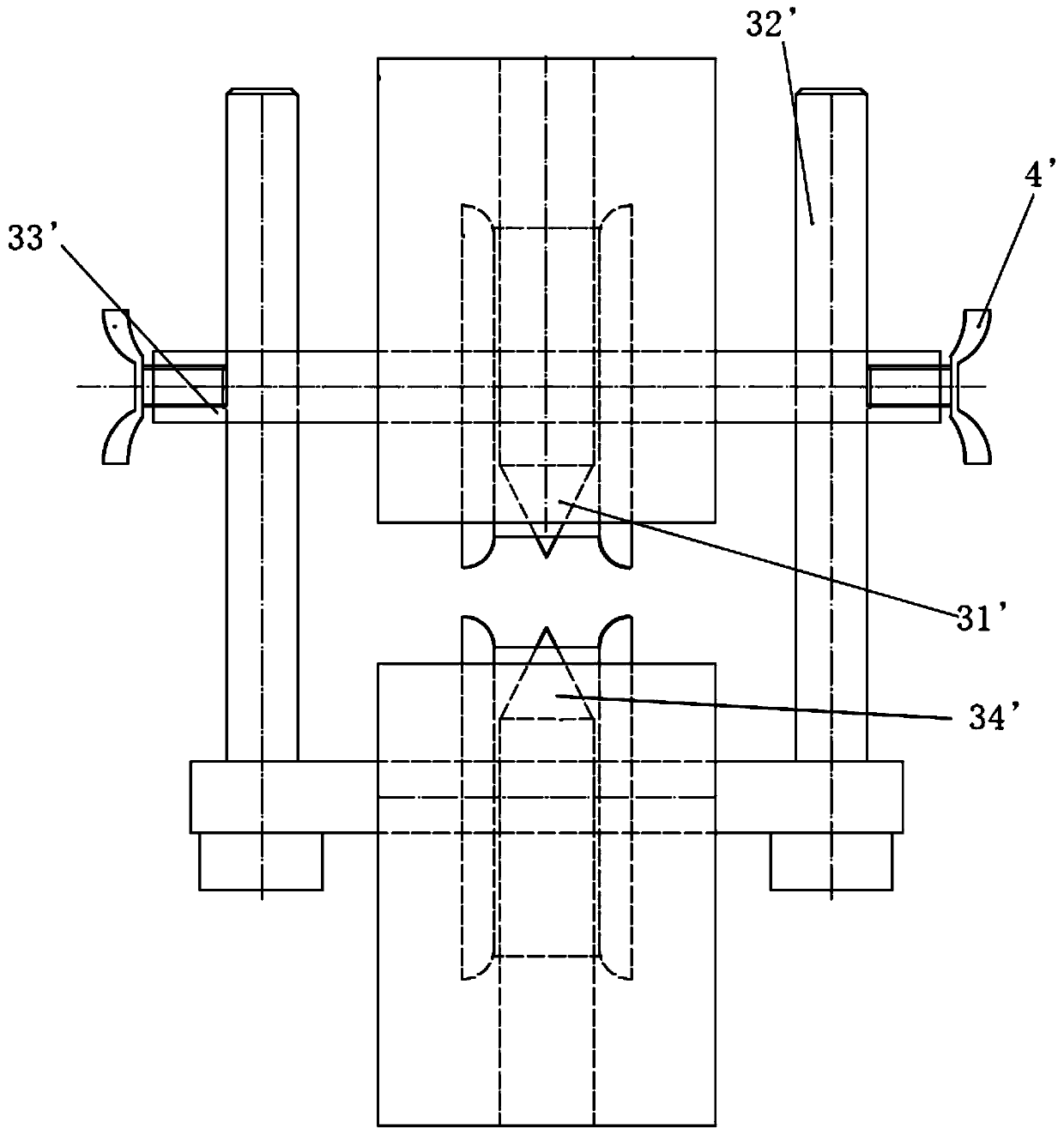

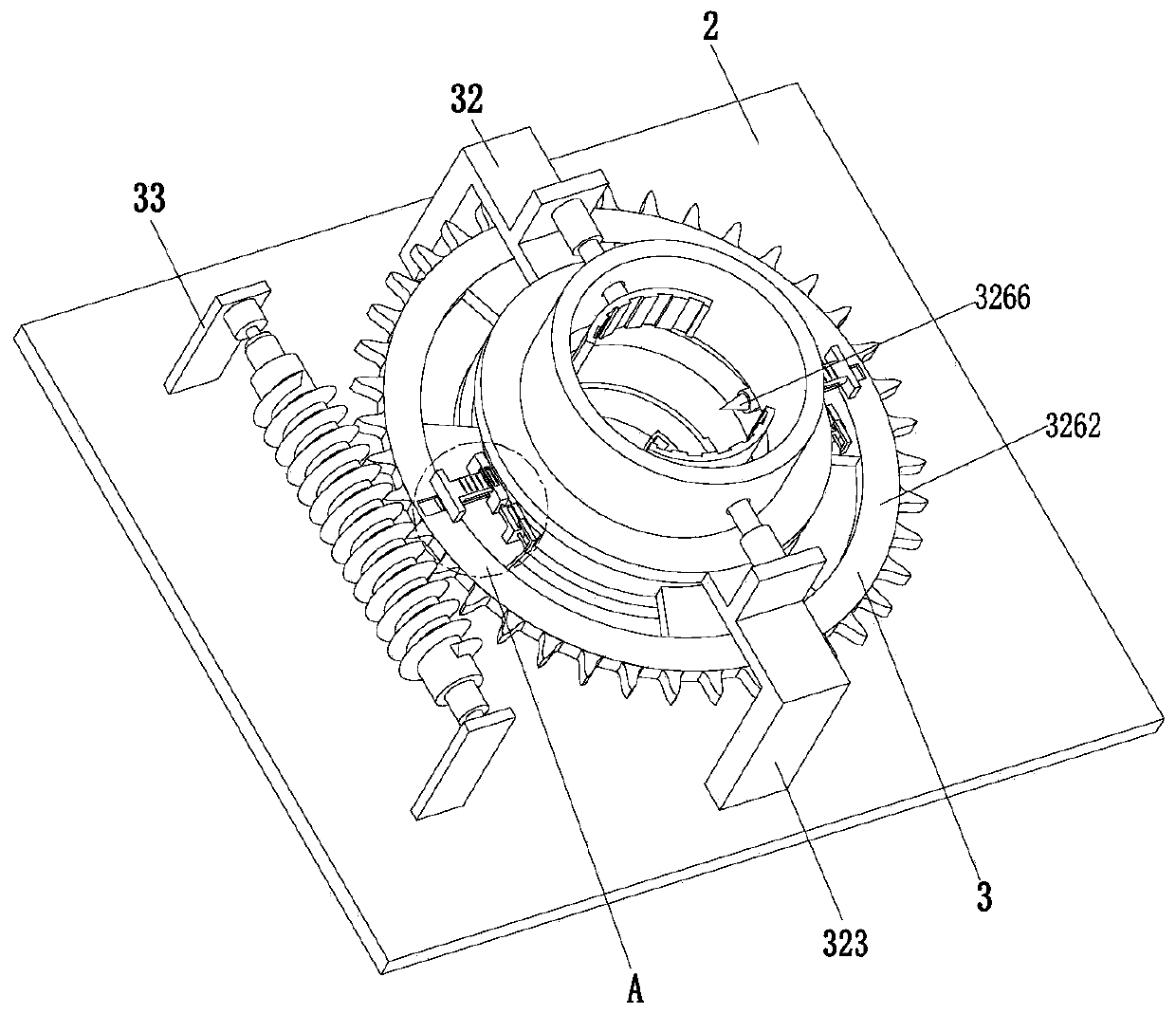

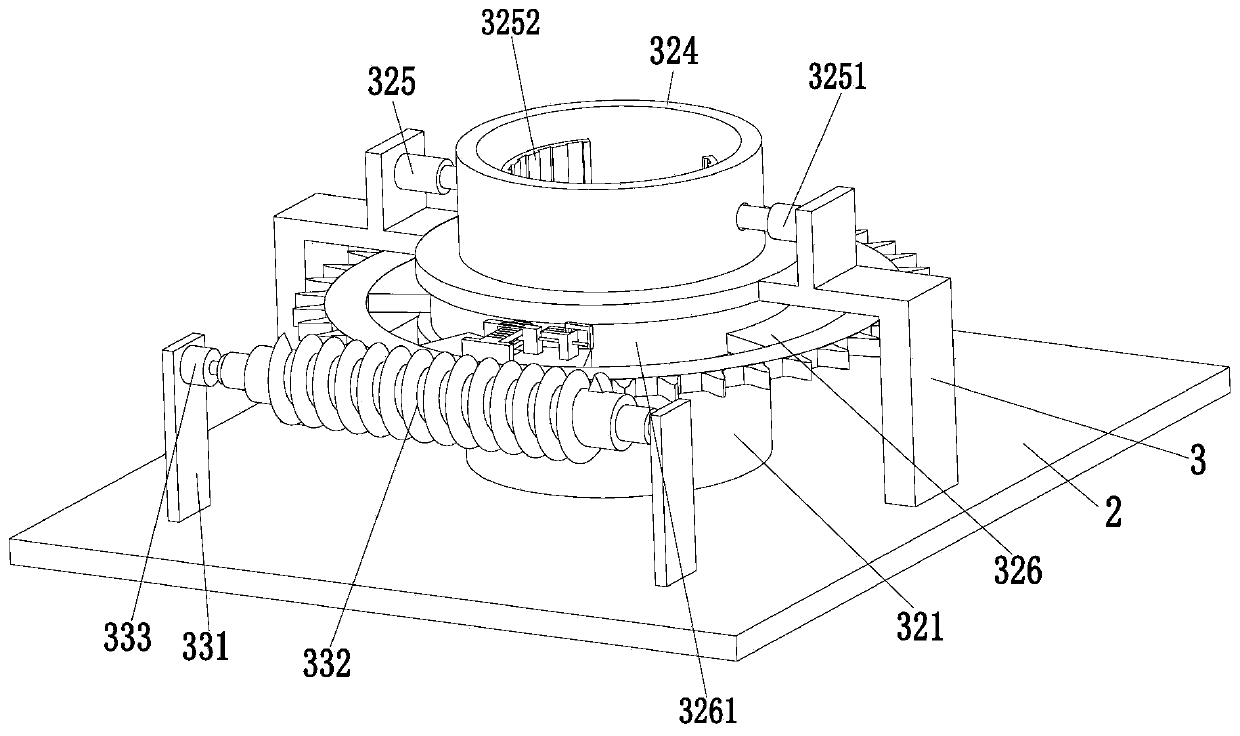

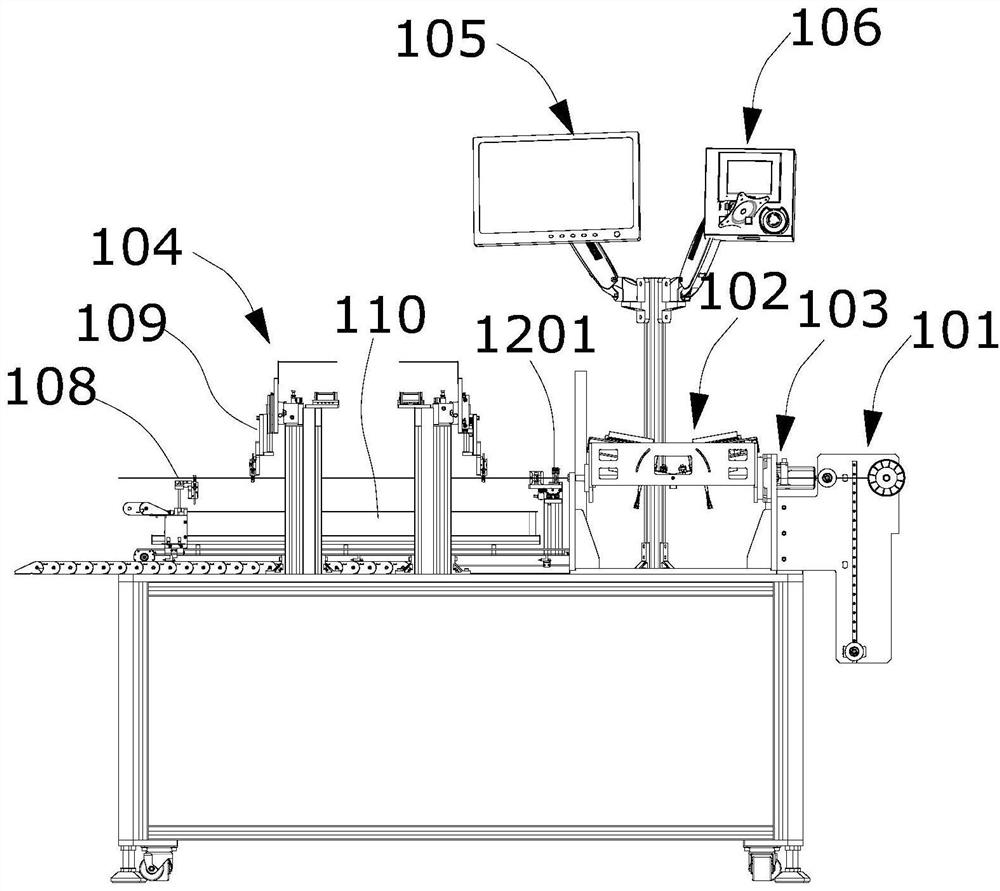

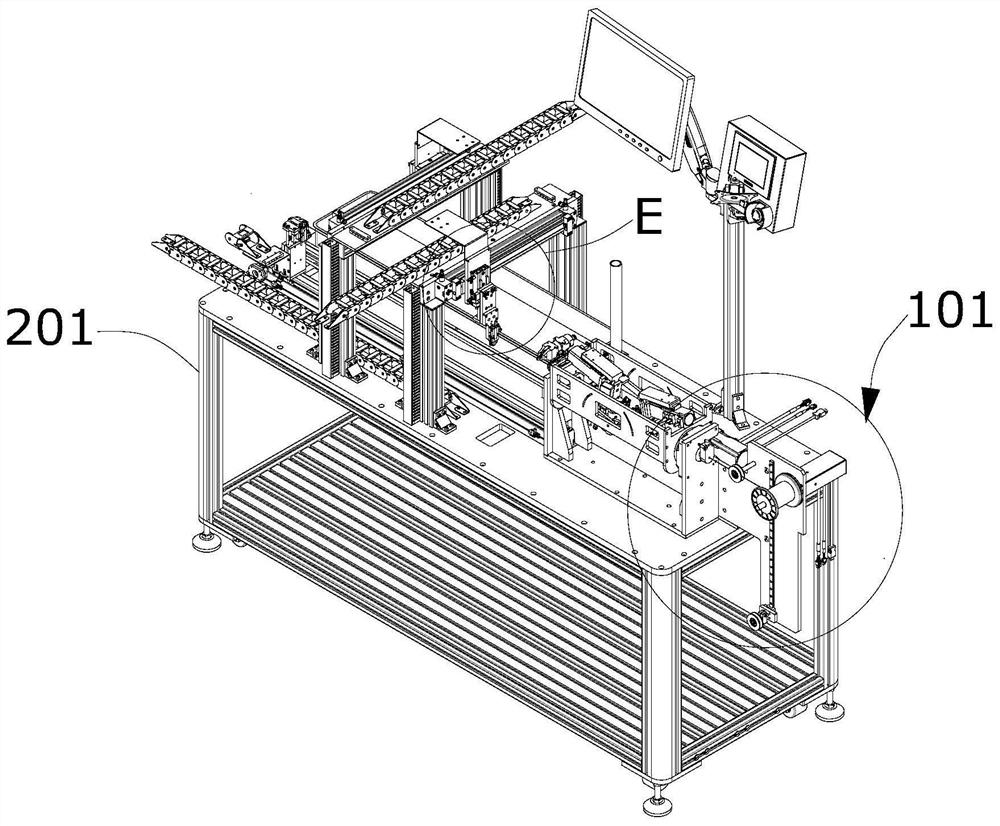

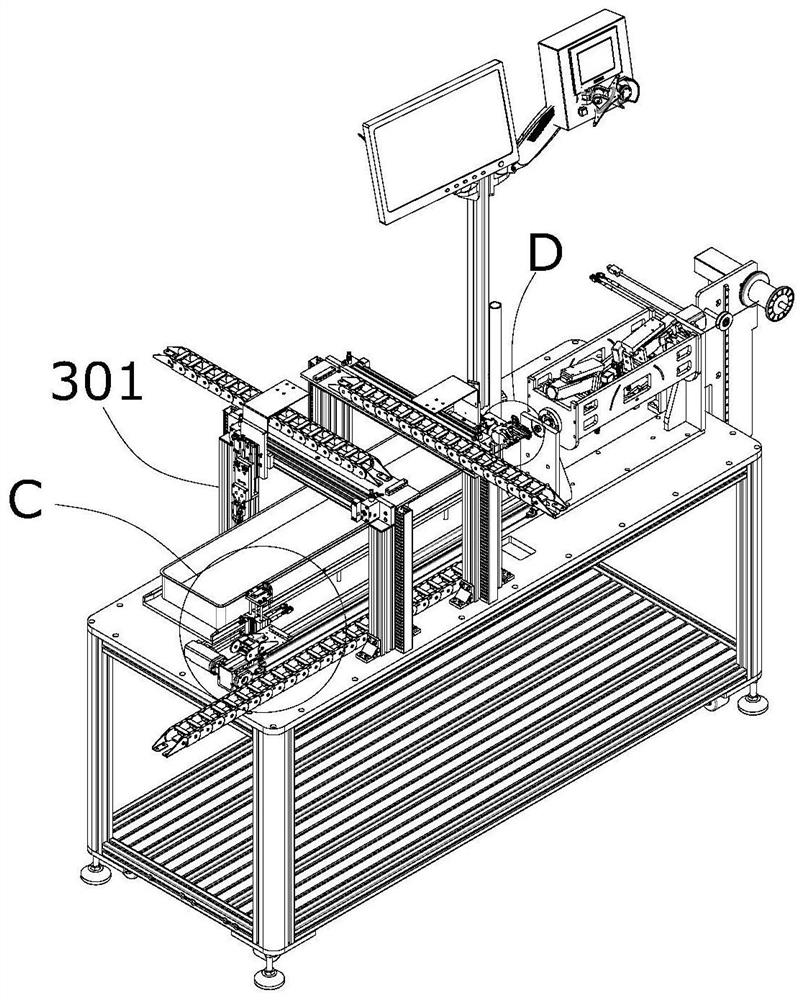

Apparatus and method for forming unidirectional or bidirectional barbs on suture

ActiveCN111134748AAchieve clampingAccurately getSuture equipmentsSurgical needlesWire rodEngineering

The invention discloses an apparatus for forming unidirectional or bidirectional barbs on a suture. The apparatus comprises a thread supply assembly which is used for providing a suture raw material thread and positioning the suture; a cutting mechanism which is used for forming unidirectional or bidirectional barbs on the suture raw material thread; a turning-over mechanism which is used for adjusting a circumferential angle of the cutting mechanism; and a finished wire removal mechanism which is used for removing the processed wire. By adopting the apparatus, a suture product with unidirectional or bidirectional barbs can be quickly and accurately obtained through the cutting mechanism; and the processing of barbs at different circumferential positions can be realized through the turning-over mechanism, and thereby a suture product with various barb layouts can be quickly and efficiently obtained. When the apparatus performs barb processing on the suture, the cutting mechanism is mainly moved, and the suture is only used for axial micro-movement, so that the processing accuracy is easier to control. A cutting depth of a blade can be accurately controlled by a linear drive assembly, and at the same time the processing of barbs with different depths can be realized.

Owner:ZHEJIANG APELOA JIAYUAN BIOMEDICAL MATERIAL

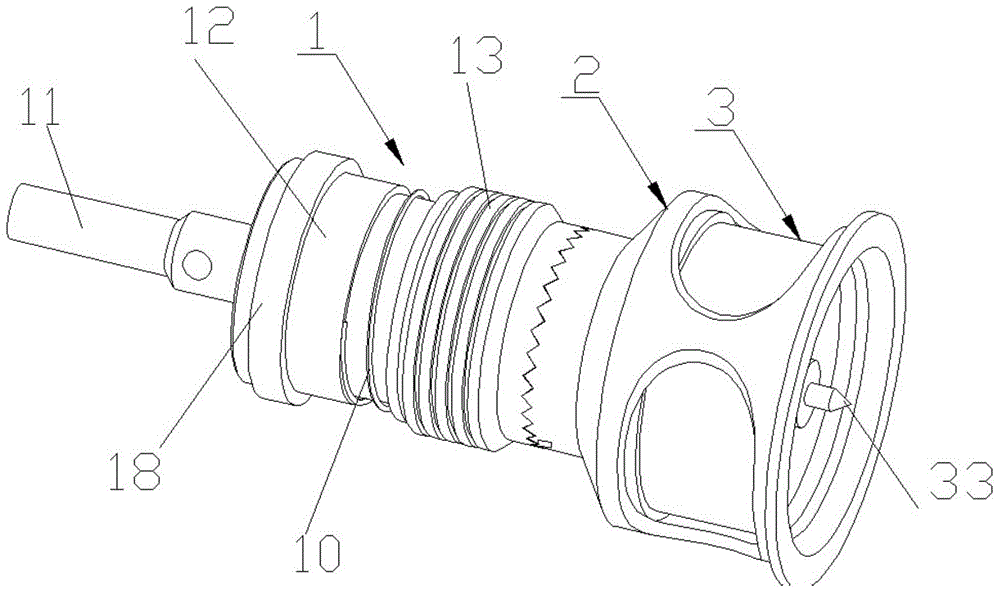

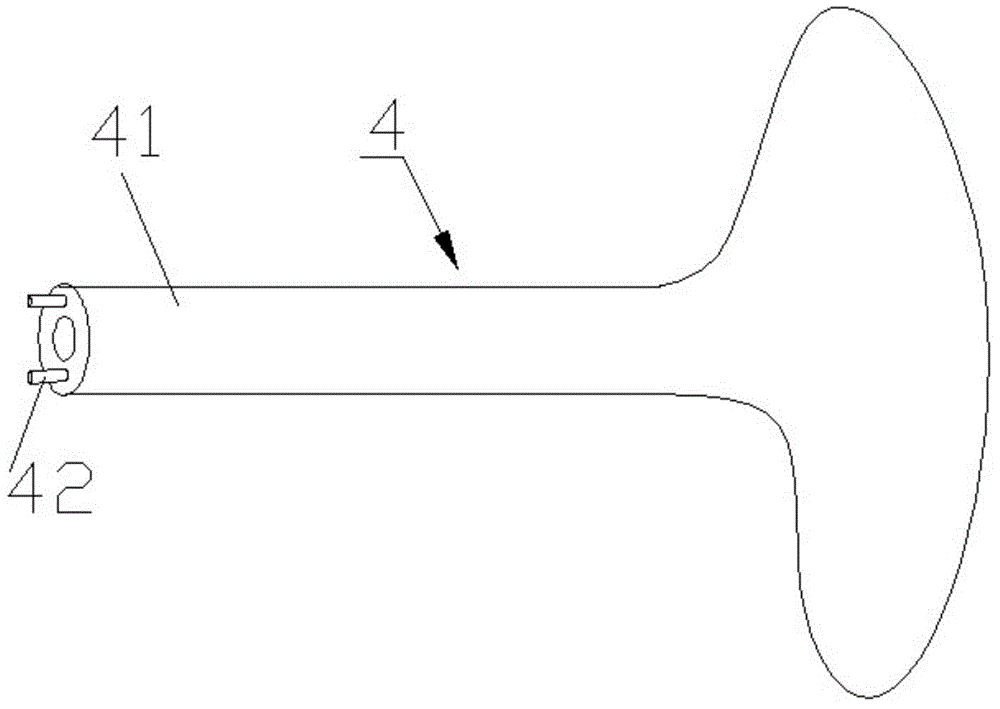

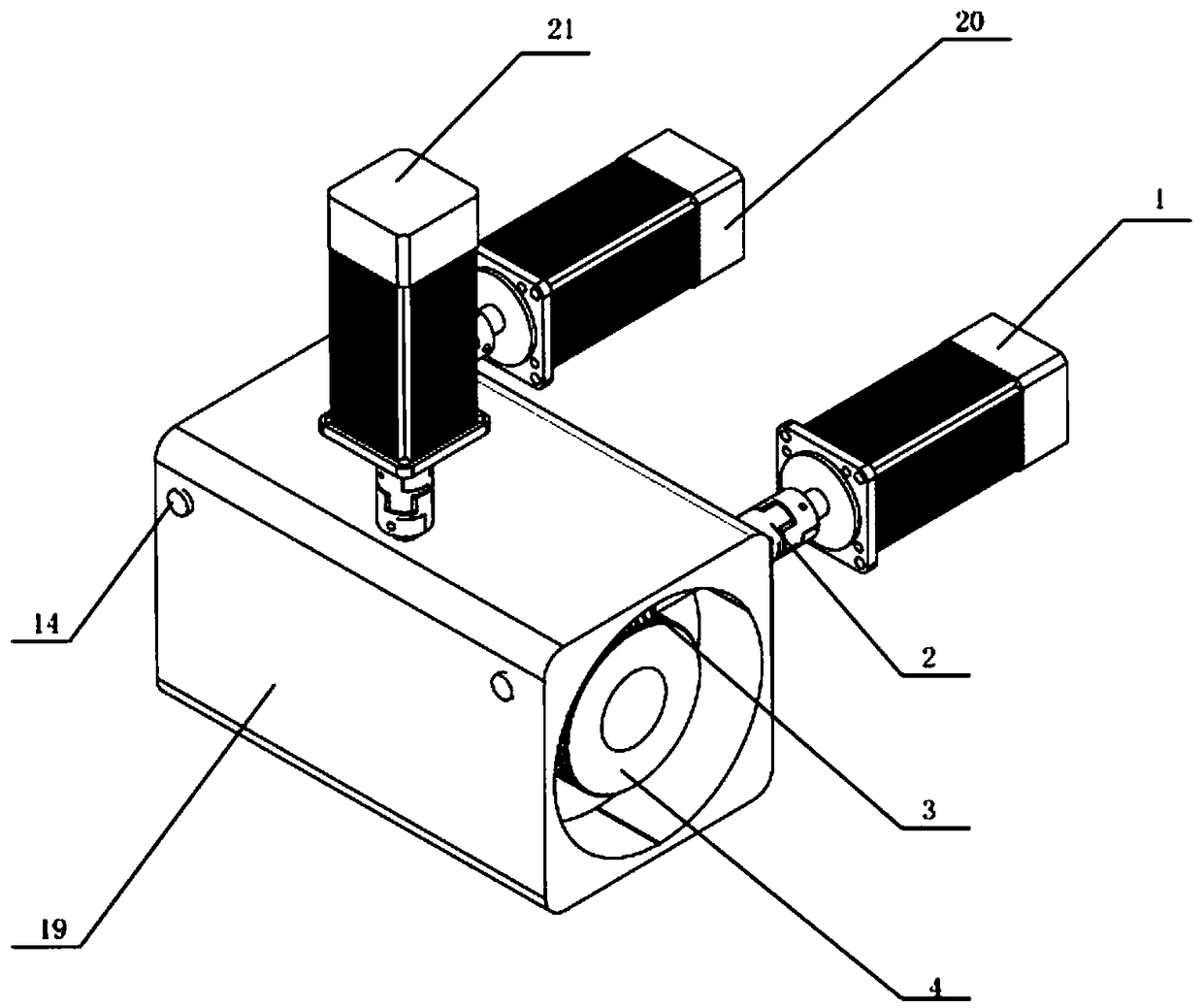

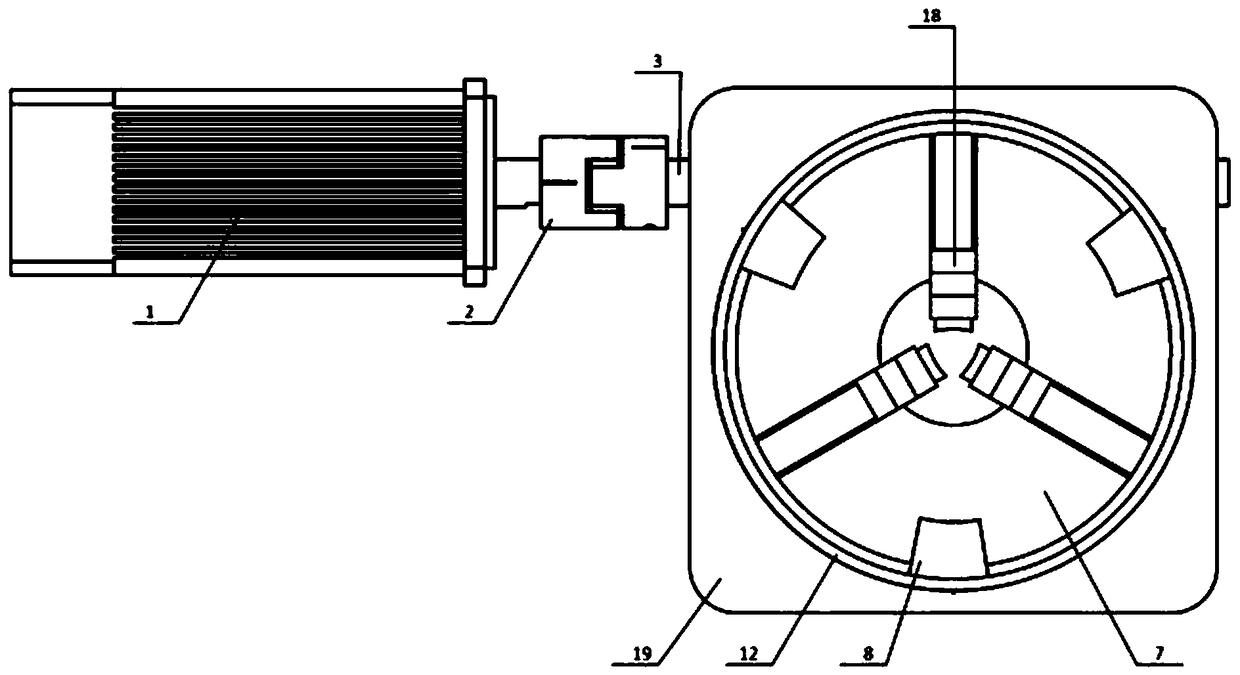

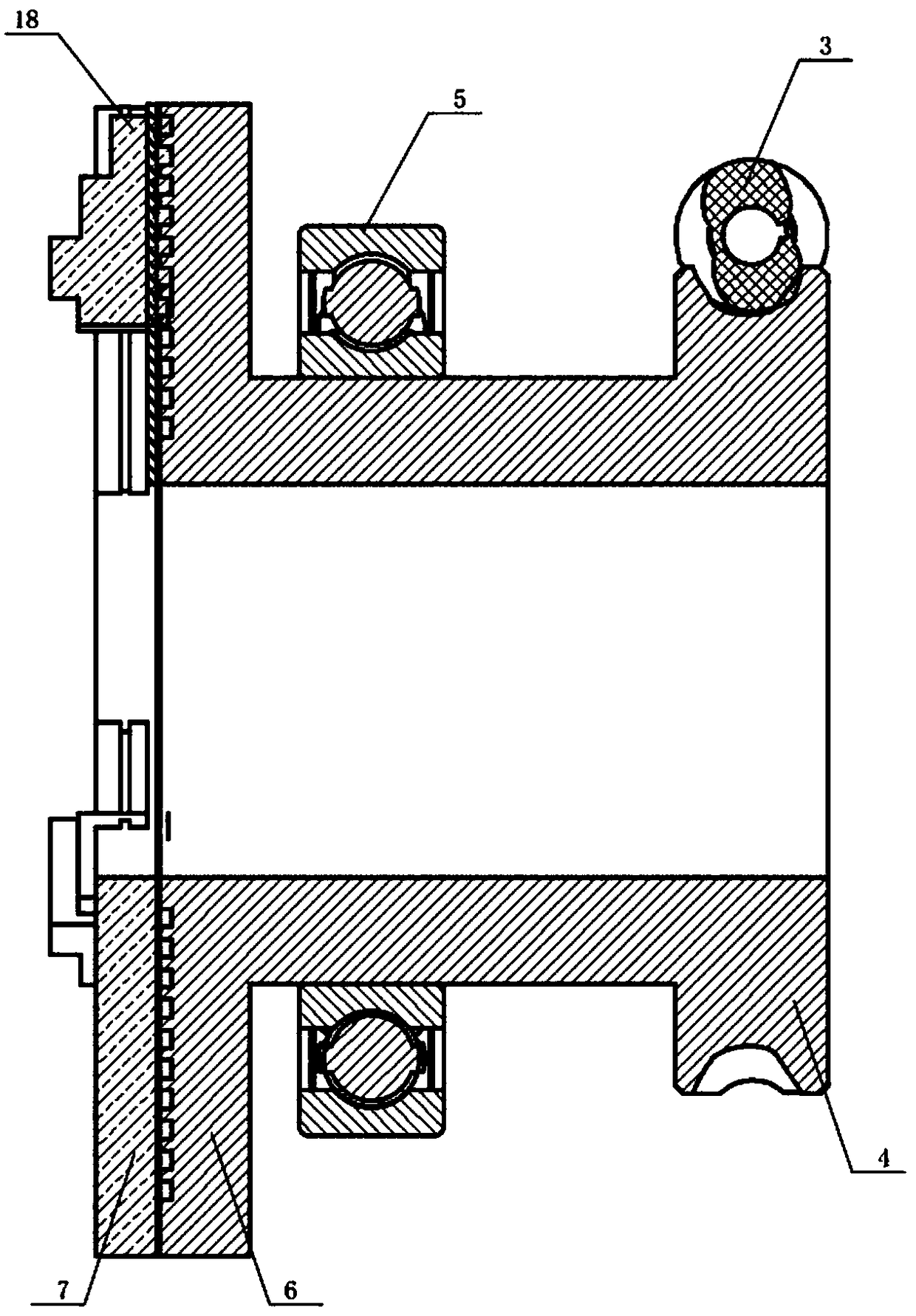

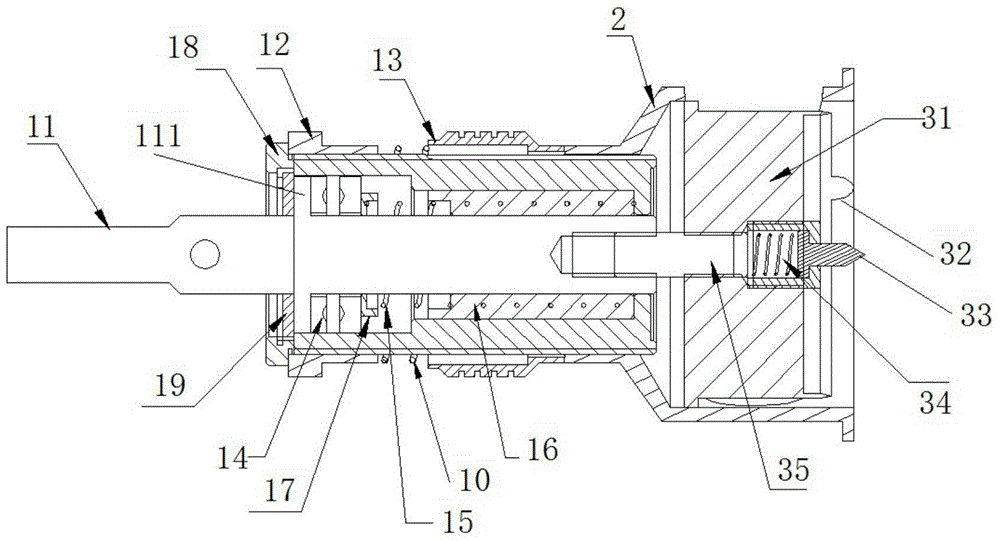

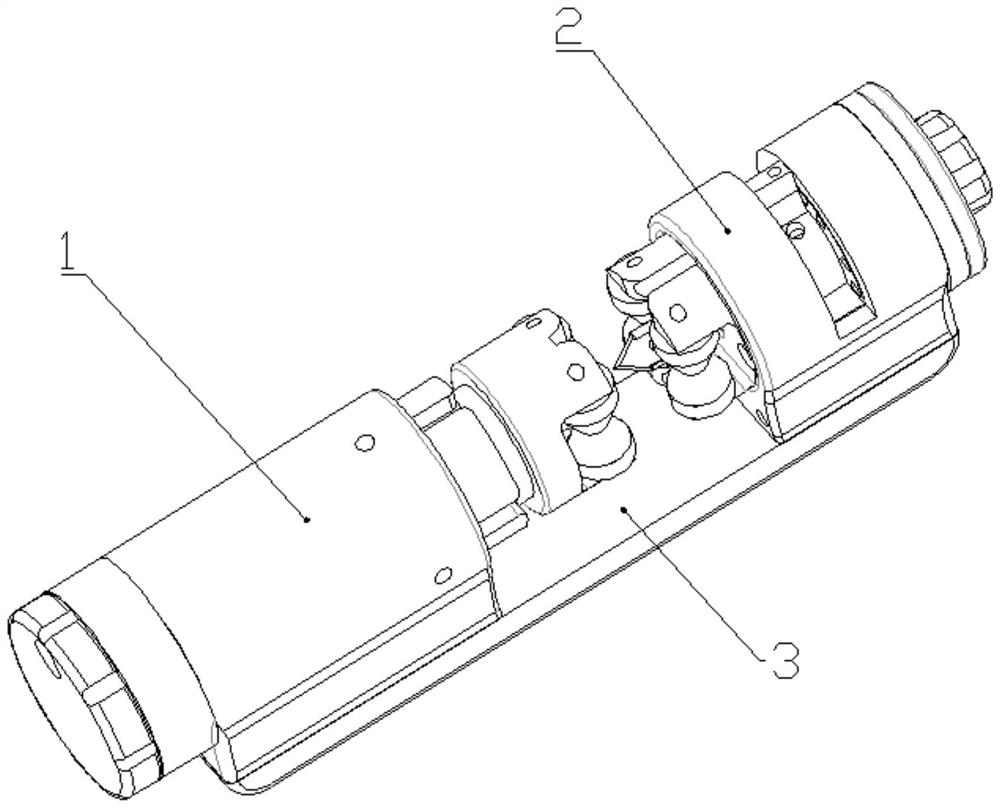

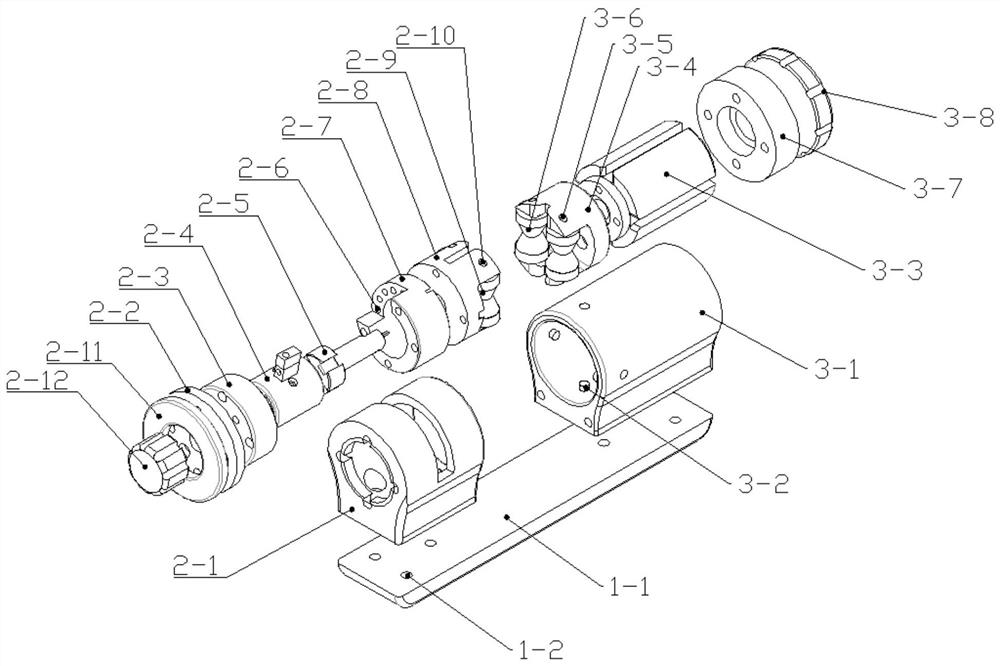

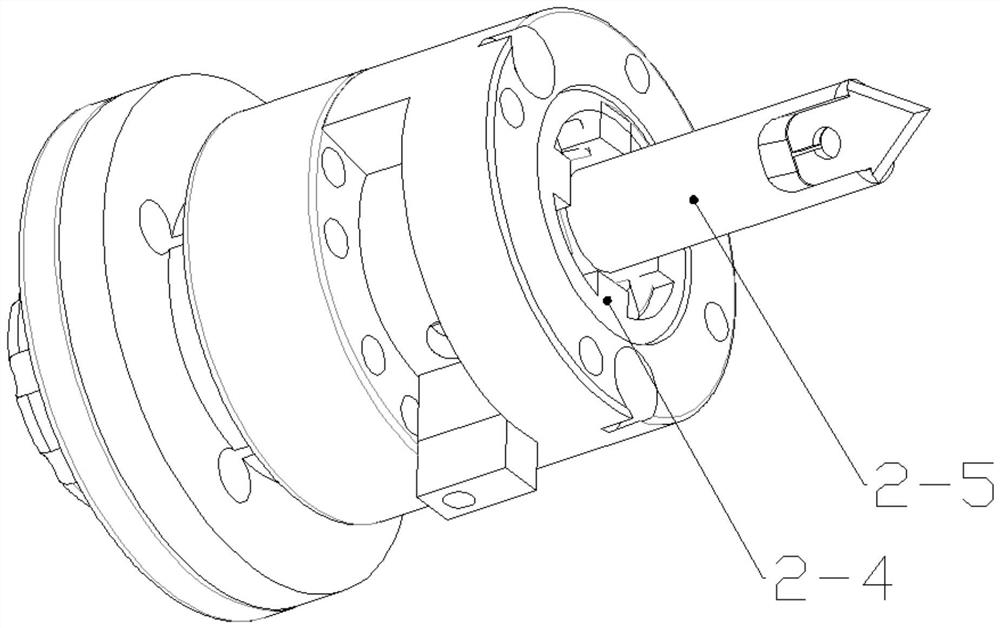

Pressure maintaining cutting device for natural gas hydrate sampling pipe

ActiveCN109262698ASolve installation difficultiesSimple structureMetal working apparatusTemperature controlEngineering

The invention relates to a high pressure maintaining cutting technology, and aims at providing a pressure maintaining cutting device for a natural gas hydrate sampling pipe. The pressure maintaining cutting device for the natural gas hydrate sampling pipe comprises a hollow tubular outer cylinder used for pressure maintaining, a tool feeding and retracting mechanism, a circumferential rotation mechanism and a clamping mechanism; a tool feeding and retracting internal component, a circumferential rotation internal component and a clamping internal component are arranged in the outer cylinder insequence through a bearing and a matched bearing base; and the circumferential rotation speed and radial feeding speed of a tool bit and the clamping speed of a clamping jaw are determined by controlling the rotation speed of a motor. The pressure maintaining cutting device for the natural gas hydrate sampling pipe has the advantages that pressure is balanced, the structure is simple and basically symmetric, and the installation is convenient and simple; cutting is uniform, the disturbance of a sample is reduced during cutting, a sample cutting device does not generate secondary pollution tothe sample, and cutting is carried under pressure maintaining and temperature control conditions; and the cutting depth, the tool feeding and retracting speed of cutting and cutting speed can be controlled accurately.

Owner:GUANGZHOU MARINE GEOLOGICAL SURVEY +1

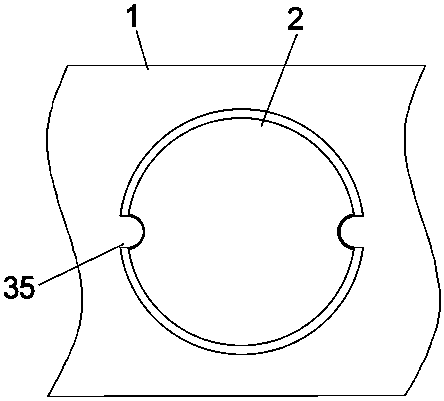

Device for peeling off sheath of optical cable and application method of device

ActiveCN106950647AEasy to pullRealize free separation and combinationOptical light guidesElectronic waste recyclingPower cableEngineering

The invention discloses a device for peeling off the sheath of an optical cable and an application method of the device, and belongs to the technical field of power cable peeling tools. The device comprises a rotating shaft, a first arc-shaped barrel, and a second arc-shaped barrel, wherein the first and second arc-shaped barrels are connected with the rotating shaft. The inner sides of the first and second arc-shaped barrels are respectively provided with three or more wheel axles in the length direction, wherein each wheel axle is provided with two rolling wheels. The wheel axle(s) located at the central part of the first arc-shaped barrel and / or the second arc-shaped barrel are / is provided with a plurality of peeling cutters. The bottoms of the peeling cutters are rotatingly connected with the wheel axles, and the edges of the peeling cutters are perpendicular to a to-be-peeled optical cable. The backs of the peeling cutters are provided with back irons. The first arc-shaped barrel and / or the second arc-shaped barrel are / is provided with through holes which are in threaded connection with magnetic fine tuning parts, wherein the magnetic fine tuning parts attract the back irons. The device is novel in structure, is reasonable in design, is small in size, is light in weight, is portable, is flexible for use, is small in peeling resistance, and facilitates the precise control of the cutting depth of the peeling cutters.

Owner:PINGDINGSHAN POWER SUPPLY ELECTRIC POWER OF HENAN +1

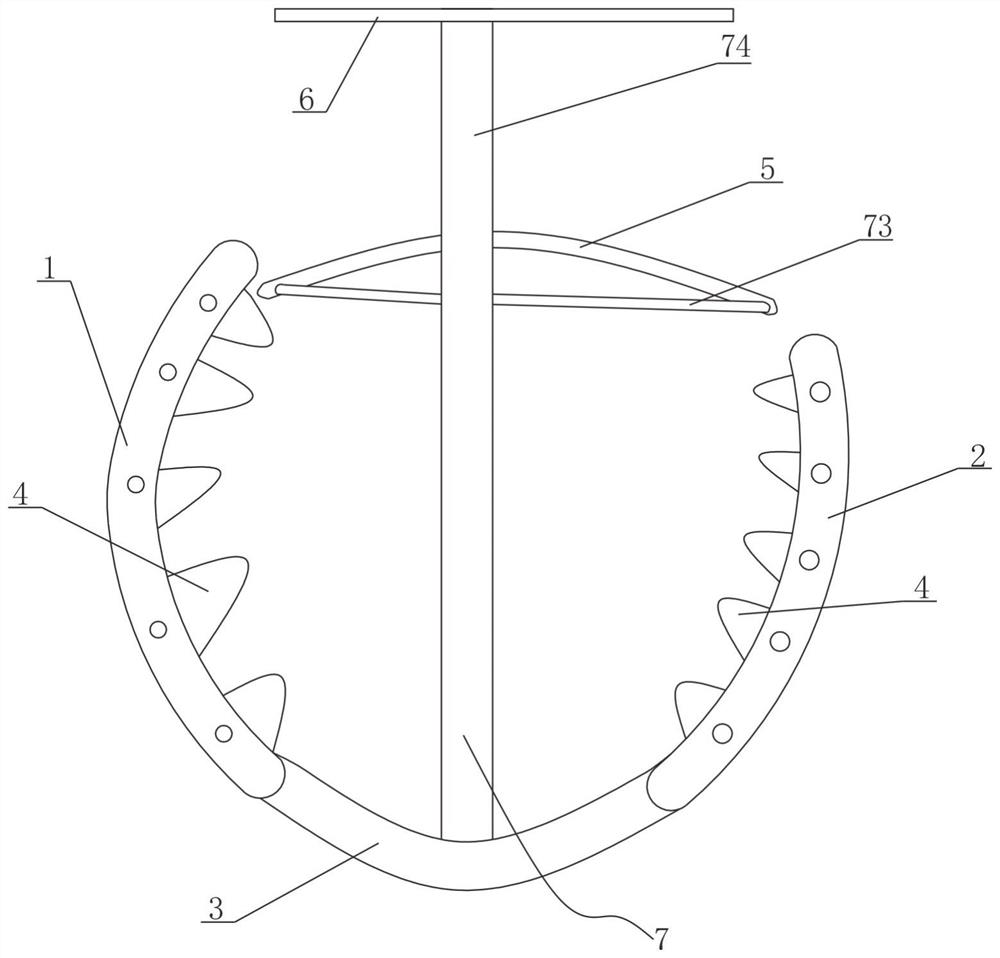

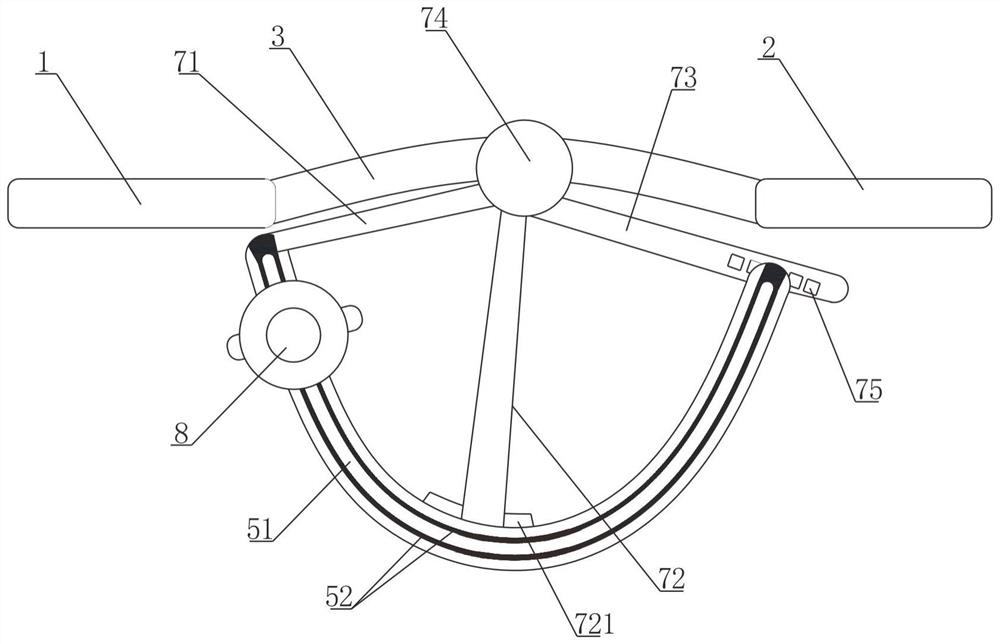

Thyroid separator

The invention provides a thyroid separator and relates to the technical field of surgical assistant instruments. The thyroid separator comprises a left arc-shaped plate and a right arc-shaped plate which are arranged oppositely, wherein the left arc-shaped plate and the right arc-shaped plate are integrated through a base, and a plurality of edge pliers which are distributed along arc line directions are arranged at inner sides of the left and right arc-shaped plates separately and are connected to the left arc-shaped plate or right arc-shaped plate through pivoting. A radian-adjustable separation guiding rack is arranged at the rear side above the left and right arc-shaped plates and is supported on the base through a supporting frame, a main body of the separation guiding rack is transparent, a guiding groove is formed in the separation guiding rack, light-proof locating strips are arranged at the two side edges of the guiding groove, and a direct illuminating lamp is arranged abovethe separation guiding rack. A surgical knife device is arranged in the guiding groove in a sliding manner and comprises a knife head, wherein the knife head is connected to a telescoping mechanism, and the telescoping mechanism is connected with a telescopic meter. The problem of wedgelike thyroid excision in the prior art that accurate excision cannot be achieved is solved.

Owner:WEST CHINA HOSPITAL SICHUAN UNIV

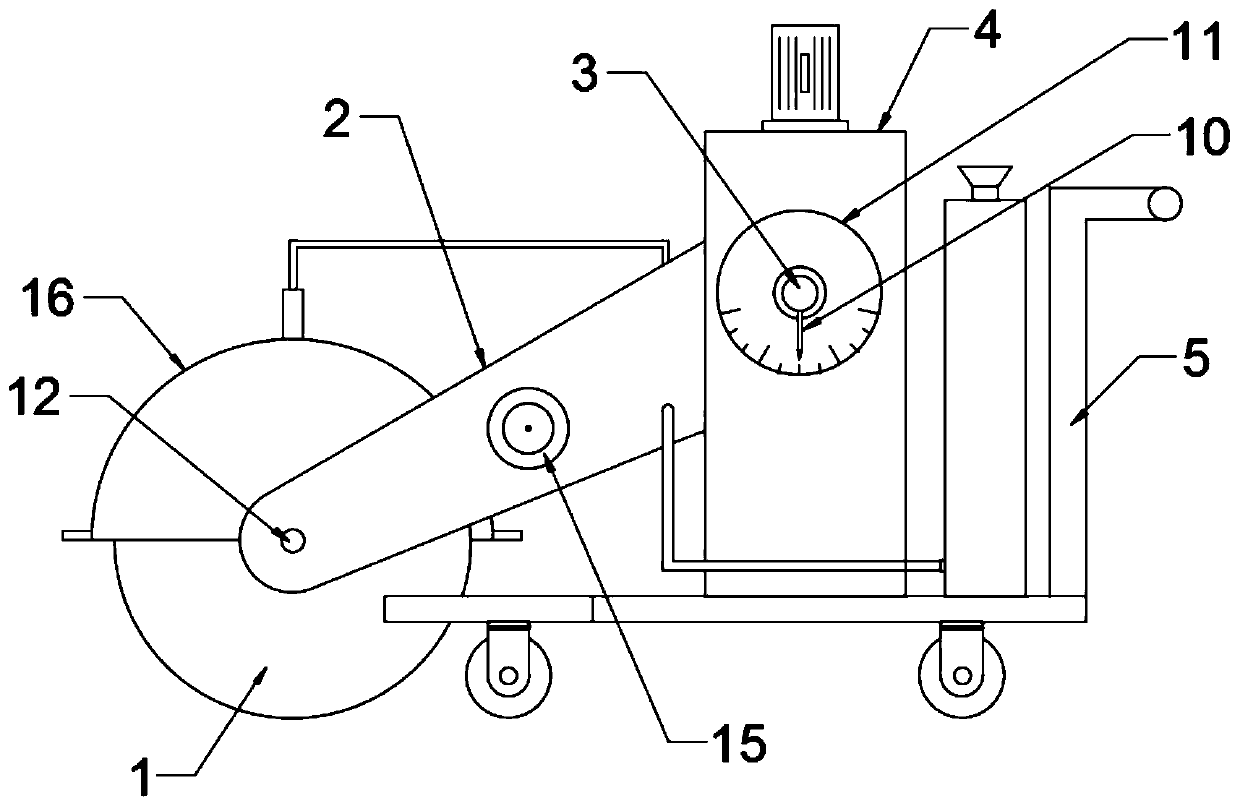

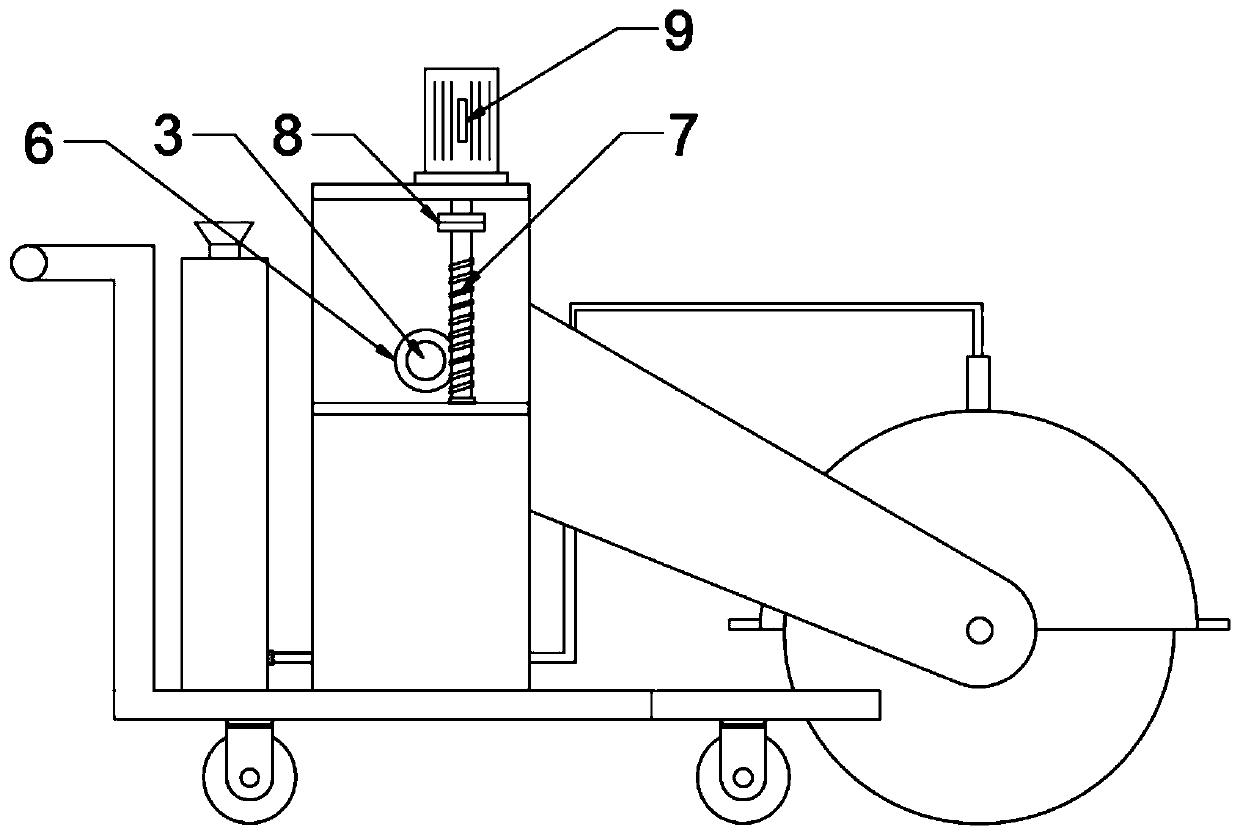

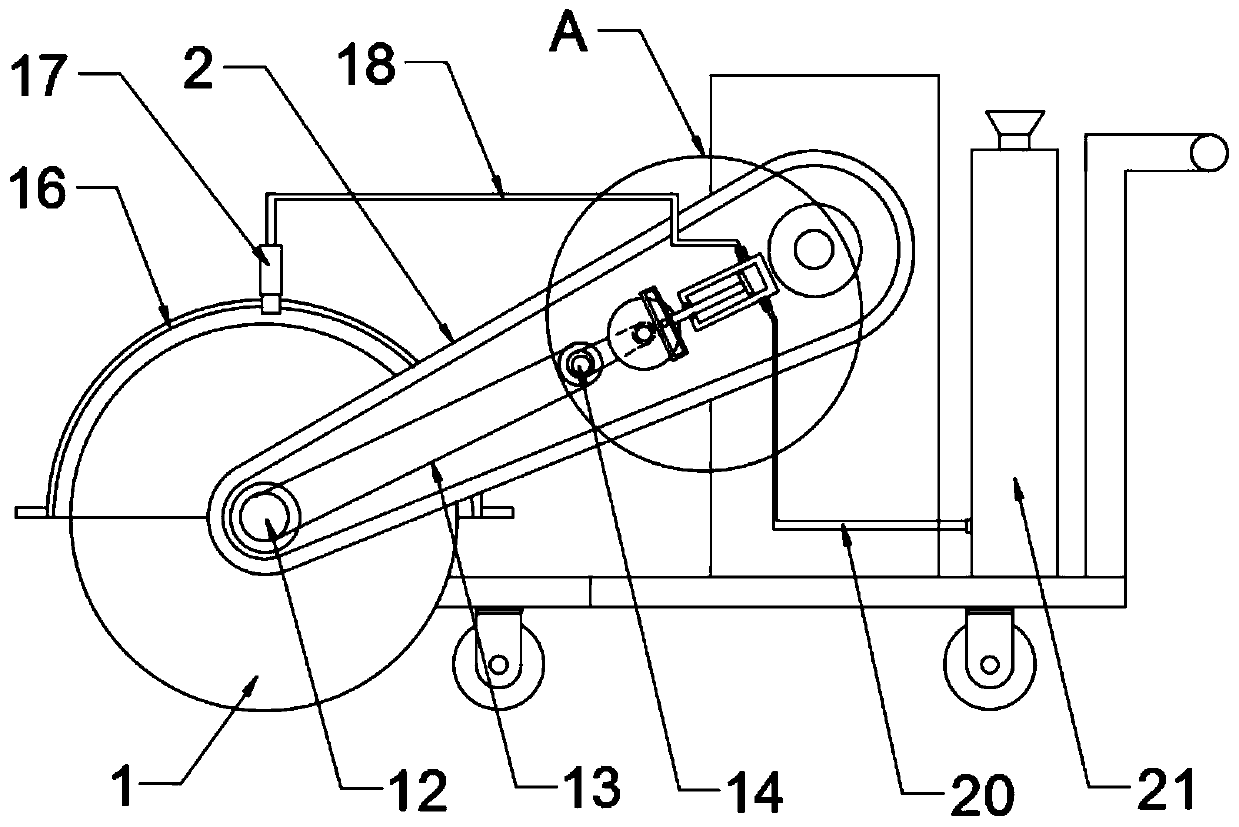

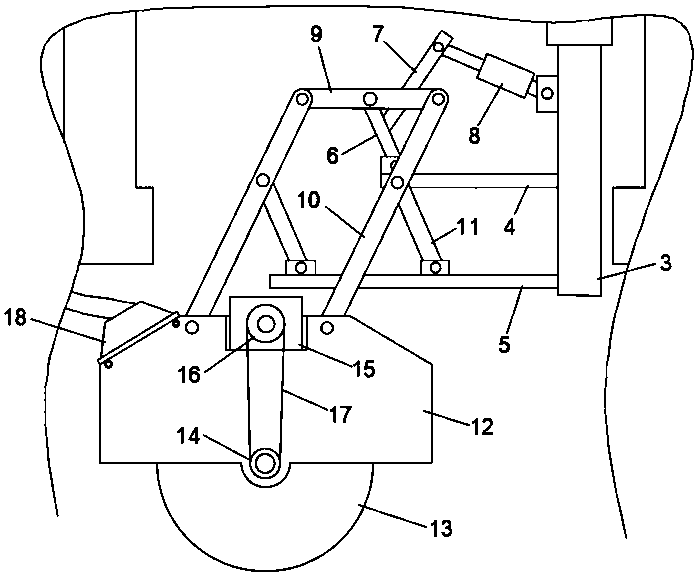

Accurate joint cutting device for bridge road

InactiveCN110952429AAvoid pollutionPrecise control of cutting depthRoads maintainenceCouplingElectric machinery

The invention discloses an accurate joint cutting device for a bridge road. The accurate joint cutting device comprises a cutting wheel and a cart. The cutting wheel is rotationally connected with a swing arm through a wheel shaft, the swing arm is rotationally connected with a supporting plate through a rotating shaft, and the supporting plate is fixedly connected with a bottom plate of the cart.The rear end of the rotating shaft extends to the rear side of the supporting plate, the rear end of the rotating shaft is fixedly connected with a worm gear, the worm gear is meshed with a worm, theworm is connected with a stepping motor through a coupler, the front end of the rotating shaft is fixedly connected with a pointer, and a dial is arranged on the inner side of the pointer. By arranging the swing arm, the rotating shaft, the worm wheel, the worm, the pointer and the dial, the height of the cutting wheel is accurately and visually adjusted, so that the joint cutting depth is accurately controlled, and the construction quality is improved; through the synchronous water spraying mechanism integrated in the swing arm and the cart bottom plate with the through groove in the front end, the overall size of the device is reduced, the driving structure of the device is simplified, movement and construction of the device are facilitated, and dust pollution is avoided.

Owner:王敏帆

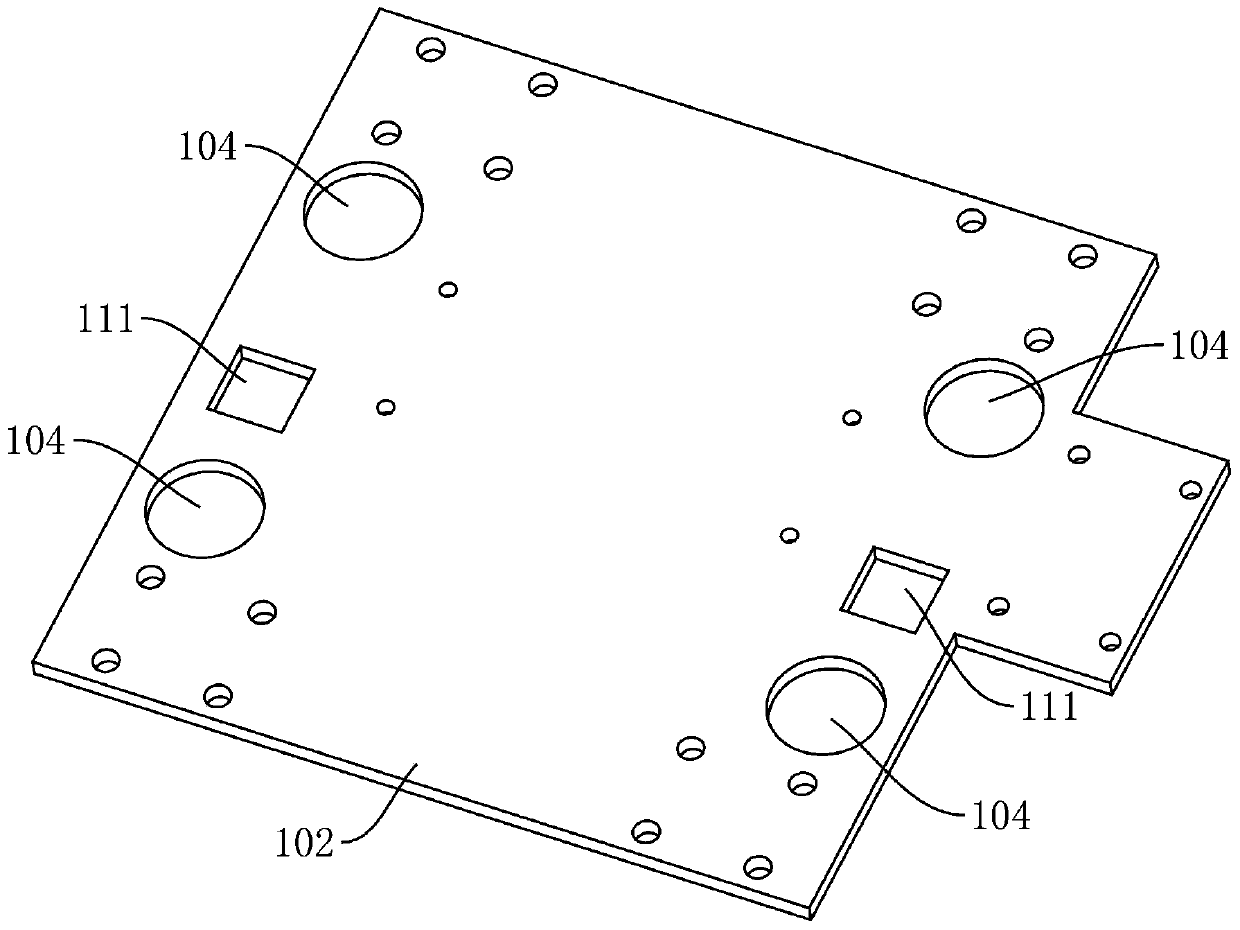

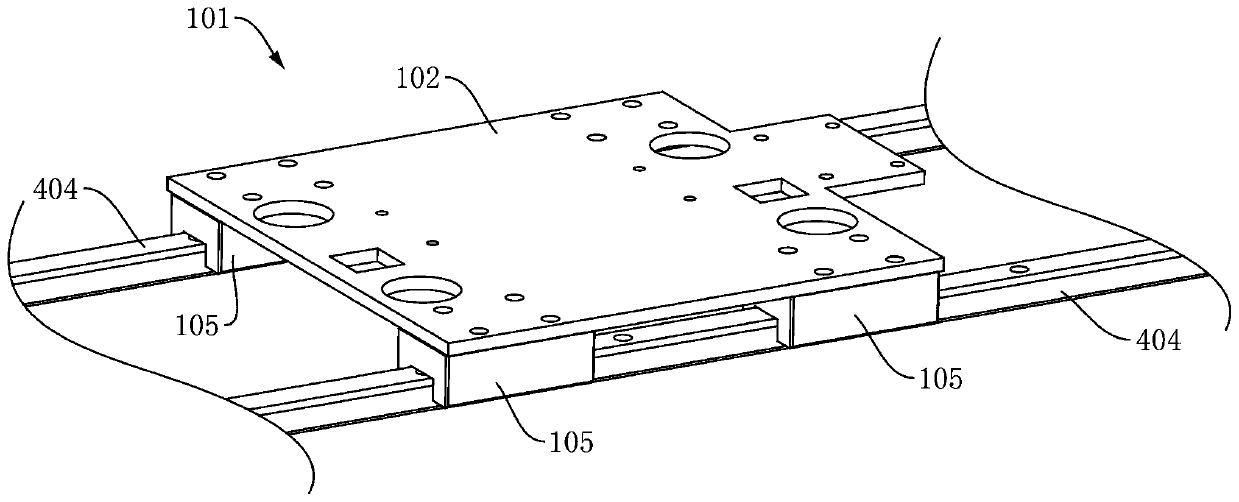

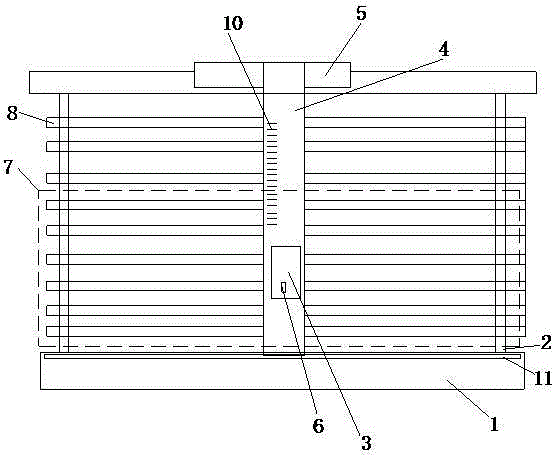

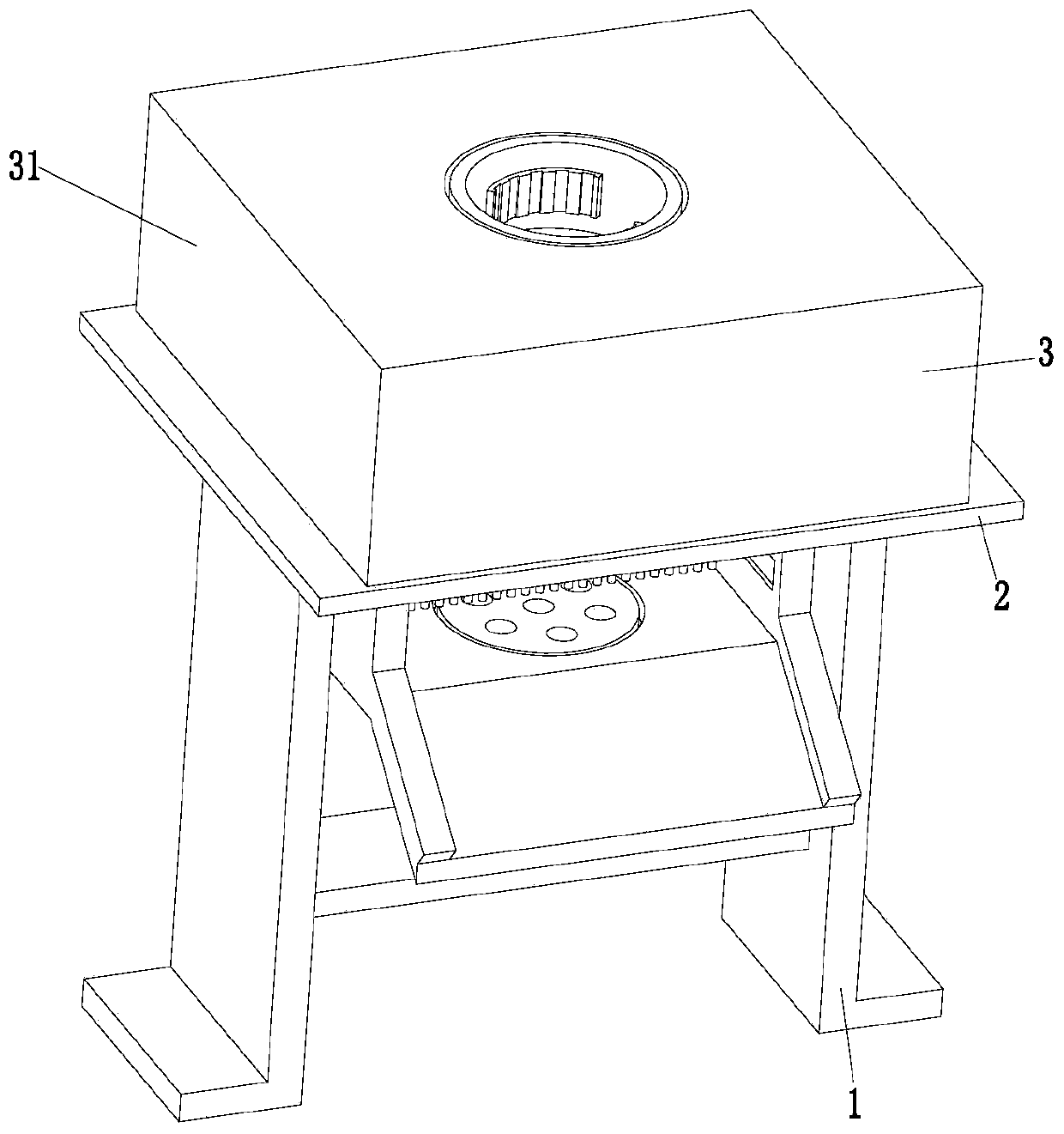

Lifting platform used for tile cutting machine and tile cutting machine

PendingCN109877983ACompact structureEasy to adjustWorking accessoriesStone-like material working toolsEngineeringMachining process

The invention relates to a lifting platform used for a tile cutting machine and the the tile cutting machine. The lifting platform comprises a movable part and a fixed part. The movable part is used for installing a motor and a cutting blade. The fixed part is used for being installed on a guide rail. The movable part is connected with the fixed part and forms a movable pair with the fixed part, wherein the movable pair can move upwards or downwards in the vertically direction. The lifting platform is compact in structure, the height of the cutting blade can be adjusted conveniently, rapidly and efficiently in the tile machining process, the grooving and cutting depth can be accurately controlled, fine adjustment is conducted after cutting blade abrasion, in addition, operation in the adjusting process can be better simplified, and the machining precision and efficiency are improved.

Owner:四川省万光机械设备有限公司

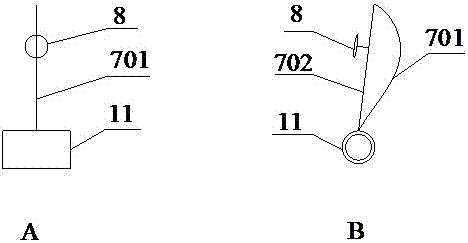

Hot-line work wire stripper capable of preventing conductor from being damaged

ActiveCN103531990AAvoid damageNo offsetLine/current collector detailsApparatus for removing/armouring cablesEngineeringMechanical engineering

The invention provides a hot-line work wire stripper capable of preventing a conductor from being damaged, which comprises an upper pliers body, a lower pliers body, a return spring, a handle, a connecting rod, an alarm, adjusting nuts and cutting knife. When the cutting knife is fed and the tip of the cutting knife just touches the conductor, the alarm gives out an alarm sound to prevent the conductor from being cut and damaged; when a position adjusting bolt is clockwise adjusted, the cutting knife is driven by the spring to cut into the insulating rubber of a cable, the tail part of the cutting knife accurately points out cutting knife feeding depth on a ruler to enable an operator to accurately control the cutting knife feeding depth; the cable is fixedly arranged in a cable trough through a cable bracket and the cutting knife is guaranteed to realize equal-depth uniform cutting; and the return spring is prevented from being deviated or distorted during working.

Owner:STATE GRID CORP OF CHINA +2

wallpaper cutter

ActiveCN105108800BPrecise control of cutting depthImprove repair efficiencyMetal working apparatusScrew threadCentral spindle

The invention discloses a wallpaper cutter, comprising an adjusting driving mechanism, a positioner, and a cutting tool. The adjusting driving mechanism comprises an adjusting handle and an adjusting main body. The internal of the adjusting main body is hollow. The adjusting handle comprises a holding head and a central spindle. The upper end of the central spindle is connected with the holding head, and the lower end extends into the hollow inner cavity of the adjusting main body. The central spindle is rotatably installed in the hollow inner cavity. The cutting tool is installed on the lower end of the central spindle and rotates synchronously with the central spindle. When the cutting tool rotates, the blade of the cutting tool forms a round motion trail. The positioner is a set of sleeve installed on the adjusting main body. The cutting tool is on the inner side of the positioned. The positioned and the adjusting main body are connected by threads, so that cutting depth of the blade of the cutting tool is adjusted through rotating the positioned. When the wallpaper cutter repairs part irregular damaged positions of a wallpaper, the whole wallpaper does not need to be dismounted, and the wallpaper can be repaired. The wallpaper cutter is beneficial for improving efficiency for repairing part irregular damages of wallpaper in a passenger cabin.

Owner:GUANGZHOU AIRCRAFT MAINTENANCE ENG

A road circumference manhole cover cutting machine

The invention discloses a road circumference well lid cutting machine which comprises a base, wherein a rotating rack is fixedly connected onto an outer wall on one side of the base by virtue of bolts; a driven gear is arranged inside the rotating rack; a rotating rod is welded to a central position at the bottom of the driven gear; a rotating rod seat is arranged at one end, which is far away from the driven gear, of the rotating rod; a telescopic rod is welded on the outer wall on one side of the rotating rod seat; a disc is welded at one end, which is far away from the rotating rod seat, ofthe telescopic rod. According to the cutting machine disclosed by the invention, the distance between the disc and the rotating rod seat can be adjusted according to requirements by virtue of the telescopic rod, so that the cutting radius is adjusted. A channel is erected between two adjacent discs and is withdrawn from the groove, and the cutting machine conveniently moves in the channel. On onehand, requirements of different cutting radiuses are met, the applicability is improved, and the construction cost is reduced; on the other hand, the cutting stability is ensured, deviation of the cutting position is avoided, the destruction range is narrowed, and the working efficiency is improved.

Owner:武晓丹

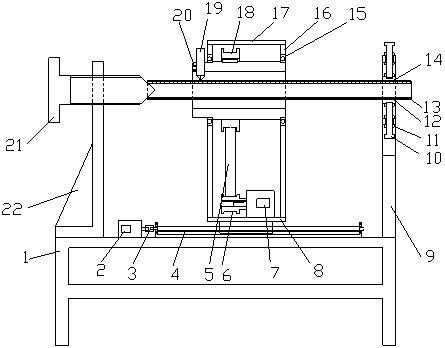

Cutting machine with smoke removing device

InactiveCN109702271AReasonable structureFunctionalMetal sawing devicesMaintainance and safety accessoriesActivated carbonDrive shaft

The invention discloses a cutting machine with a smoke removing device. The cutting machine comprises a base, a cutting frame and the smoke removing device; the cutting frame comprises a support protecting plate, a driving connecting rod, a fixed hinge column and a hydraulic device; the fixed hinge column and the hydraulic device are vertically arranged on the upper surface of the base; and the smoke removing device comprises a smoke removing protecting plate, a connecting sleeve and a smoke removing machine body. The cutting machine is provided with the smoke removing device; an electric fanshaft is linked with a driving shaft of a motor through a spline connecting mode; when the motor is started to work, fan blades on the right side of the driving shaft can be driven to rotate without adding a power device, so that the energy consumption is saved; smoke is removed through activated carbons under driving by the fan blades; and through the activated carbons, fine particles and some poisonous gas in the smoke can be absorbed, so that the excellent working environment is guaranteed.

Owner:盐城唯宏特通用机械有限公司

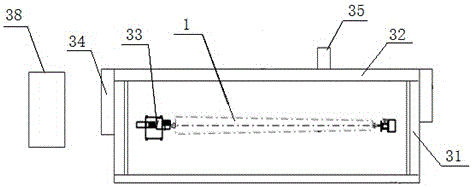

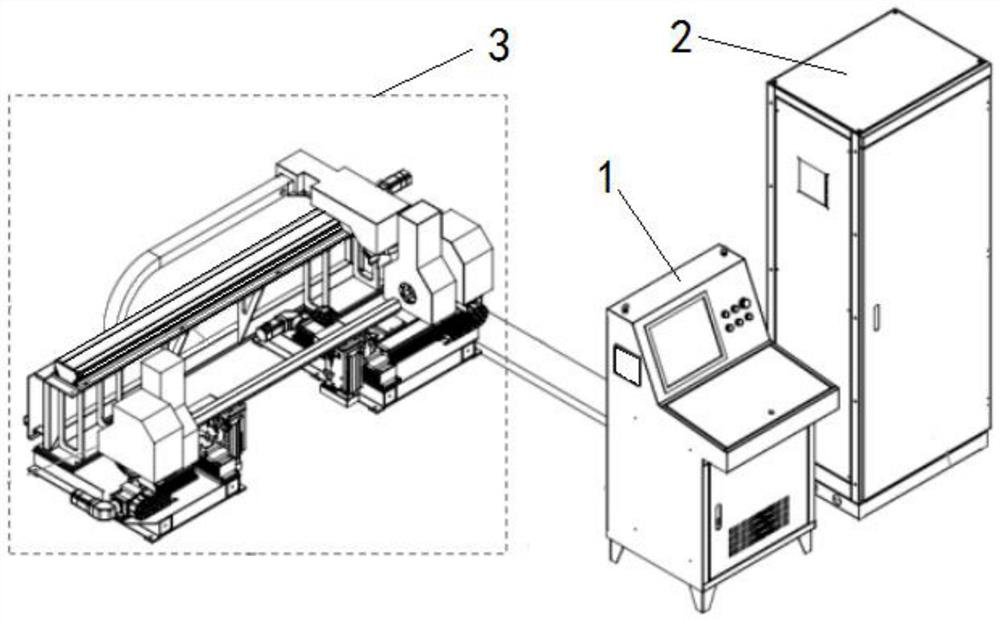

Outer cladding workpiece metal outer sleeve laser non-penetration cutting device and method

InactiveCN111774736APrecise control of cutting depthHigh degree of automationWelding/cutting auxillary devicesAuxillary welding devicesStructural engineeringLaser cutting

The invention discloses an outer cladding workpiece metal outer sleeve laser non-penetration cutting device and method. The outer cladding workpiece metal outer sleeve laser non-penetration cutting device comprises a laser cutting device, a computer cabinet and an electric control cabinet; the laser cutting device comprises a rack, a cutting unit, a moving unit and a clamping unit, and the cuttingunit, the moving unit and the clamping unit are arranged on the rack; the cutting unit is arranged on the rack in a sliding mode in the X axial direction; a metal sleeve assembly is arranged on the moving unit and can drive the metal sleeve assembly to move in the Y axial direction and the Z axial direction; the clamping unit is used for clamping the metal sleeve assembly and can drive the metalsleeve assembly to rotate in the X axial direction; the metal sleeve assembly is arranged in parallel with the rack; and the electric control cabinet and the laser cutting device are respectively electrically connected with the computer cabinet. According to the outer cladding workpiece metal outer sleeve laser non-penetration cutting device and method, laser automatic cutting can be remotely controlled outside a hot chamber, the fixed focal length cutting of the uneven surface of the metal outer sleeve is allowed, the metal outer sleeve is cut layer by layer, the cutting depth of the laser can be accurately controlled, the surface of the outer cladding workpiece is avoided from being cut and damaged, the cutting efficiency is high, and the environmental pollution is low.

Owner:武汉翔明激光科技有限公司

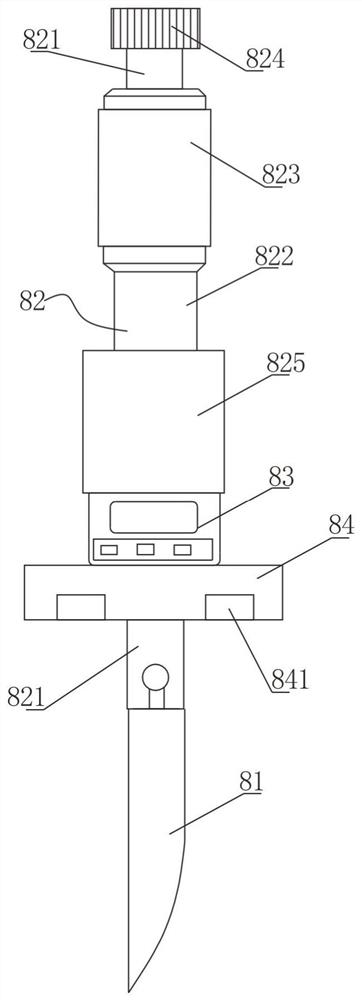

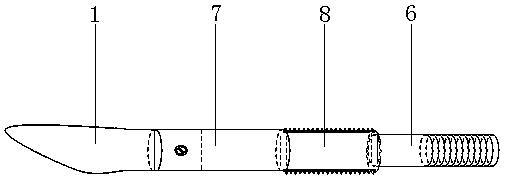

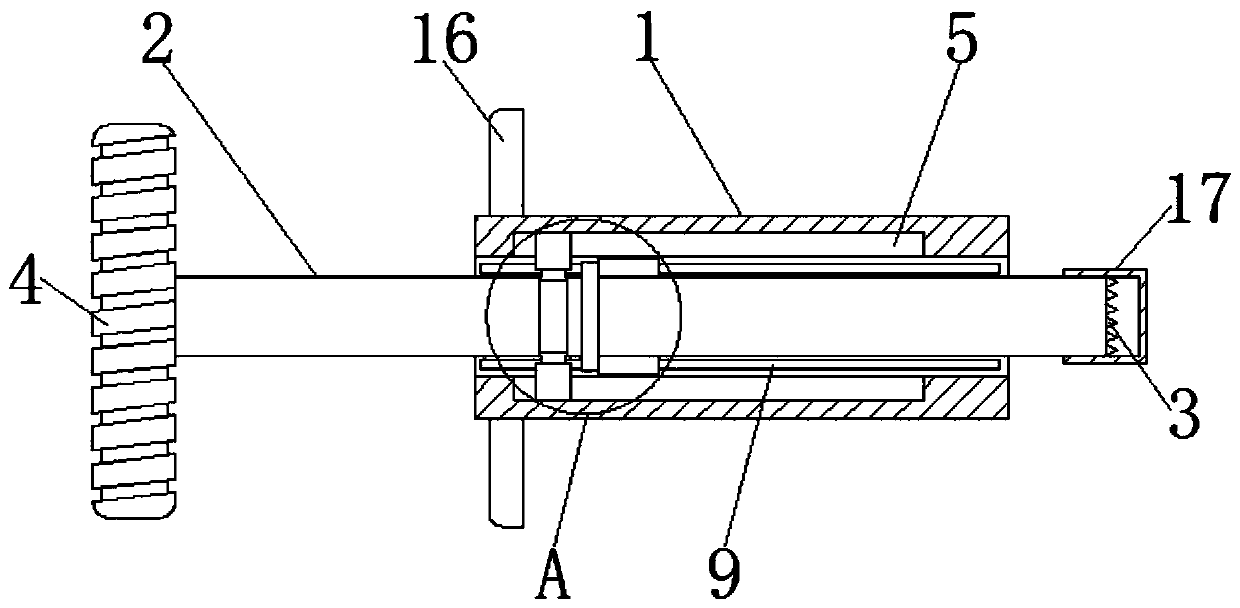

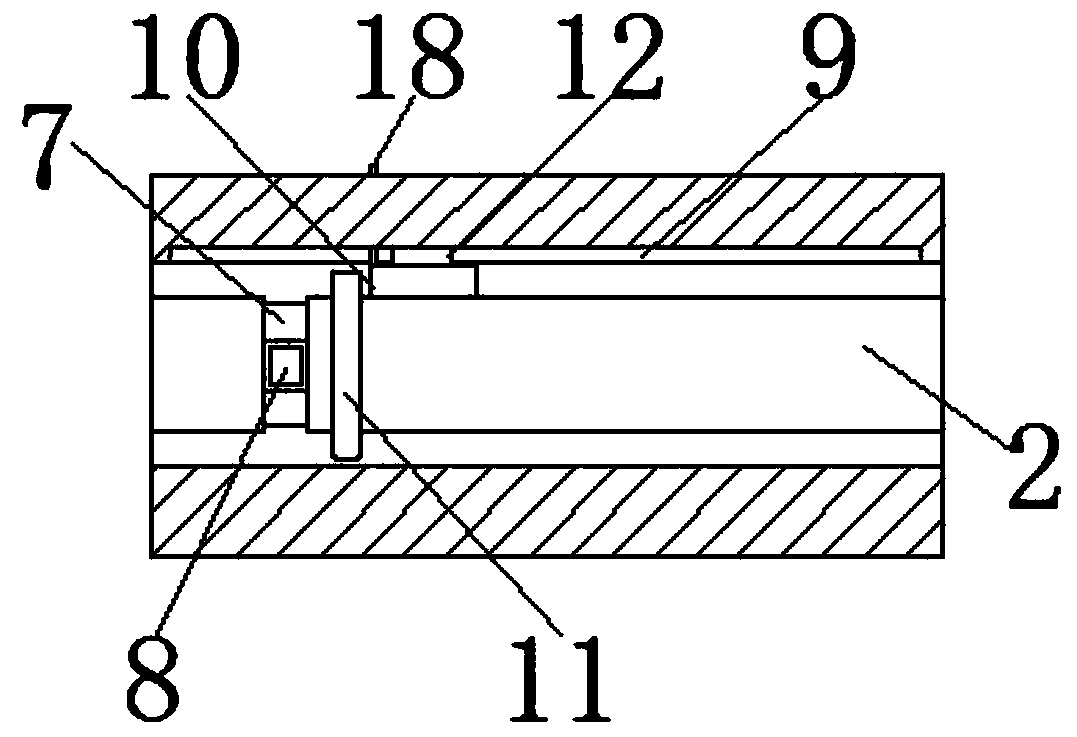

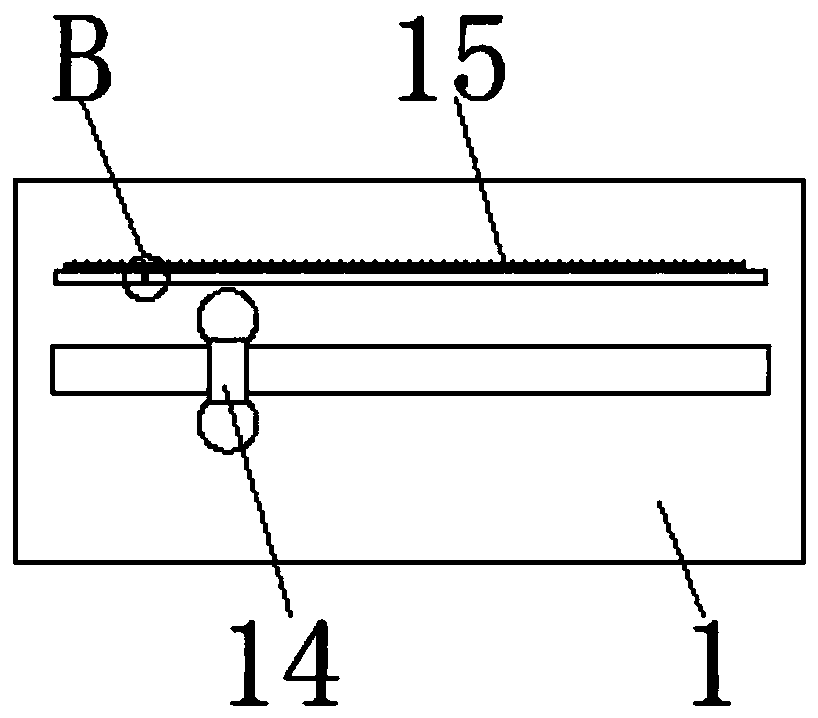

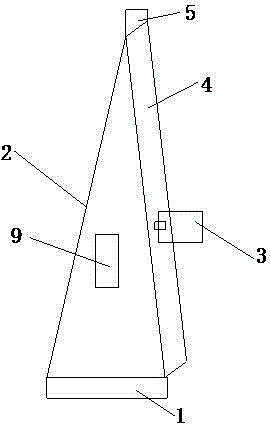

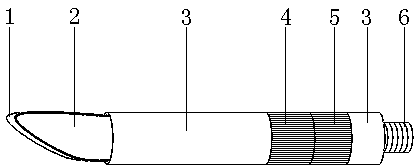

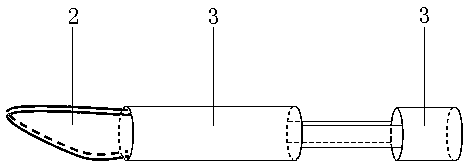

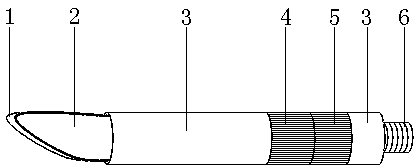

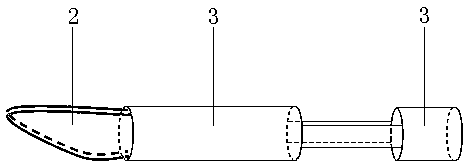

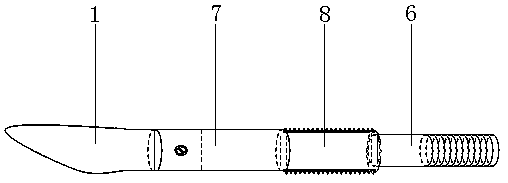

Surgical scalpel with cutting depth being precisely adjustable

InactiveCN107773290AControl the depth of cutPrecise control of cutting depthIncision instrumentsPulp and paper industrySurgical department

The invention relates to a surgical scalpel with precise and adjustable cutting depth, which belongs to the field of medical devices. The ordinary surgical scalpel is improved, and a bracket is installed on the back of the cutting blade. There is a scale on both sides of the cutting blade, and a piece of the same limit piece is installed on both sides of the cutting blade to connect with the knife body. The inside of the knife body is equipped with a bracket, and the rear half of the knife body is installed with an adjusting nut and a lock nut that are engaged with the strip bolt. Therefore, the structure can accurately control the cutting depth of the surgical blade. A surgical scalpel with precise and adjustable cutting depth: comprising a cutting blade, a limit plate, a knife body, an adjusting nut, a locking nut, a scale, a bracket, and a strip bolt.

Owner:SHIYAN TAIHE HOSPITAL

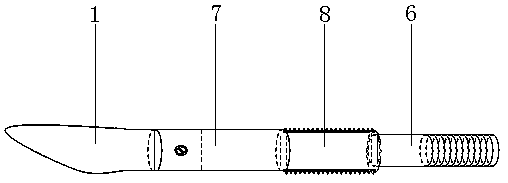

Minimally invasive tool for shaping foramen intervertebrale

PendingCN110464415APrecise control of cutting depthSolve problems that cannot be precisely controlledSurgical sawsForamen intervertebraleEngineering

The invention discloses a minimally invasive tool for shaping foramen intervertebrale. The minimally invasive tool comprises a sleeve, wherein a trepan pipe is arranged on the left side of the sleeve;the right end of the trepan pipe penetrates through the right side of the sleeve; annular teeth are punched to the right end of the trepan pipe; a handle is welded to the left end of the trepan pipe;first sliding grooves are formed in the top and the bottom of the inner surface of the sleeve; and a first sliding block is in sliding connection to the inner wall of each first sliding groove. According to the minimally invasive tool disclosed by the invention, through mutual cooperation of the sleeve, the trepan pipe, the annular teeth, the handle, the first sliding grooves, the first sliding blocks, an annular sliding groove, second sliding blocks, second sliding grooves, a limiting block, a limiting ring, a third sliding block, a threaded groove, an adjusting bolt, a graduation line and ameasuring rod, the problem that the cutting depth of an existing trepan cannot be accurately mastered is solved; and when the trepan is used, the cutting depth can be accurately controlled through fixing the limiting block, so that the controllability of the trepan is improved, and the safety when the trepan is used is also guaranteed.

Owner:SUN YAT SEN MEMORIAL HOSPITAL SUN YAT SEN UNIV

High-precision cable peeler

PendingCN112838527AImprove cutting efficiencyReduce use costApparatus for removing/armouring cablesStructural engineeringKnife blades

The invention provides a high-precision cable peeler, and relates to the technical field of cable peeling, the high-precision cable peeler comprises a connecting mechanism, a cutting mechanism and a telescoping mechanism, wherein the connecting mechanism comprises a connecting plate and connecting screws, and the two ends of the connecting plate are connected with the cutting mechanism and the telescoping mechanism through the connecting screws respectively; the cutting mechanism comprises a cutting column frame, a horizontal rotary positioning piece, a direction positioning piece top cover, a direction positioning piece and a first roller frame, and is used for controlling rotation of parts in the cutting column frame and telescopic adjustment of a blade; the telescopic mechanism comprises a telescopic column frame, a second positioning pin, a positioning telescopic column and a second roller carrier and is used for controlling axial stretching and horizontal rotation of parts in the telescopic column frame. According to the cable peeler, cable cutting with any switching of two modes and three mmanners can be achieved, the problem that the cable is prone to horizontal and vertical displacement in the cutting process is effectively solved, meanwhile, the cutting depth can be accurately controlled, and therefore high-precision cutting of the blade to the cable is achieved.

Owner:董建雄

Power cable accessory removal tool

InactiveCN110690668AThere is no need to worry about scratching the staffTo prevent the phenomenon of scratching the staffLine/current collector detailsApparatus for removing/armouring cablesTool bitPower cable

The invention relates to a power cable accessory removal tool for removing the copper connection pipe of an intermediate joint of a power cable, and belongs to the technical field of power cable maintenance tools. The power cable accessory removal tool includes a support base mechanism, wherein a cutter head cutting mechanism for cutting the copper connection pipe is installed on the support basemechanism; a cutting depth control mechanism for adjusting the cutting depth is installed above the cutter head cutting mechanism; the cutter head cutting mechanism and the cutting depth control mechanism are connected through a cutter head fixer; and a cutting trajectory control mechanism for driving the cutting depth control mechanism to horizontally move left and right is installed on the top of the support base mechanism. The power cable accessory removal tool can safely, conveniently, and quickly cut the copper connection pipe of the intermediate joint of the cable.

Owner:YANTAI POWER SUPPLY COMPANY OF STATE GRID SHANDONG ELECTRIC POWER +1

Composite aluminum plate grooving and cutting-off machine

InactiveCN105171789ASimple structureAccurate control of cutting depthMetal working apparatusVertical motionElectric machinery

The invention discloses a composite aluminum plate grooving and cutting-off machine. A V-shaped support is arranged on a base. A plurality of transverse supporting strips are fixedly arranged on the front side of the support. Auxiliary cutting plates are arranged on the supporting strips. A limiting groove for limiting composite aluminum plates is formed in the front sides of the auxiliary cutting plates. A vertical-motion guide rail is arranged between the base and the top of the support. The top of the vertical-motion guide rail is matched with a left-right movable guide rail. A grooving tool is arranged on the vertical-motion guide rail. A blade adjustor is arranged on the grooving tool. A control switch is connected with the vertical-motion guide rail, a motor of the left-right movable guide rail and a grooving motor of the grooving tool. The vertical-motion movable guide rail and the base are provided with scale marks facilitating adjustment of the cutting length. The composite aluminum plate grooving and cutting-off machine is simple in structure, can accurately control the cutting depth, is convenient and reliable to operate and high in practicability, and greatly improves the production efficiency.

Owner:浙江德清森朗装饰材料有限公司

An optical fiber longitudinal stripping device

The invention relates to an optical fiber longitudinal stripping device. The device comprises a frame. An upper portion of the frame is provided with an air cylinder. The frame below the air cylinder is provided with two sets of clamping devices. The two sets of clamping devices are arranged symmetrically. A piston rod of the air cylinder is connected to a first movable plate of two sets of clamping devices through a first connection board. A lower portion of the frame is connected to a knife holder through a second connection board. The knife holder is located at a position which is between a first pulley and a second pulley and is below the first pulley and the second pulley. A screw passes through the knife holder and is connected with a screw thread. An upper end of the screw is provided with a stripping knife. A lower end of the screw is provided with a nut. The screw is provided with a pointer used for displaying a stripping knife moving distance. The pointer corresponds to a graduation line on the frame. A position on the frame, which corresponds to the position between the first pulley and the second pulley, is provided with a through hole. The structure is designed reasonably and usage is convenient. An optical fiber is fixed firmly. A phenomenon that an optical cable slides leftwards and rightwards because of uneven stress during a stripping process is avoided and a cutting depth of the stripping knife can be accurately controlled.

Owner:STATE GRID SHANDONG ELECTRIC POWER +1

Cable stripping unit and cable stripping device with scale labels

InactiveCN109799584APrecise control of cutting depthFibre mechanical structuresMechanical engineeringEngineering

The invention relates to the technical field of optical cables, and discloses a cable stripping unit and a cable stripping device with scale labels. The cable stripping unit comprises a lower cutter assembly, supporting rods, an adjusting piece and an upper cutter assembly, wherein the supporting rods are arranged in the vertical direction and are separately arranged on the two sides of the lowercutter assembly; scales are arranged on the supporting rods on the two sides; the adjusting piece is arranged horizontally, is connected with the two supporting rods, and can slide vertically along the supporting rods; the upper cutter assembly is connected with the adjusting piece; the adjusting piece can drive the upper cutter assembly to lift; the upper cutter assembly and the lower cutter assembly are opposite to each other; and an optical cable is arranged between the upper cutter assembly and the lower cutter assembly. The distance between an upper cutter and a lower cutter can be adjusted accurately so as to control the cutting depth of a cable.

Owner:GUANGDONG HENGTONG PHOTOELECTRIC SCI & TECH +1

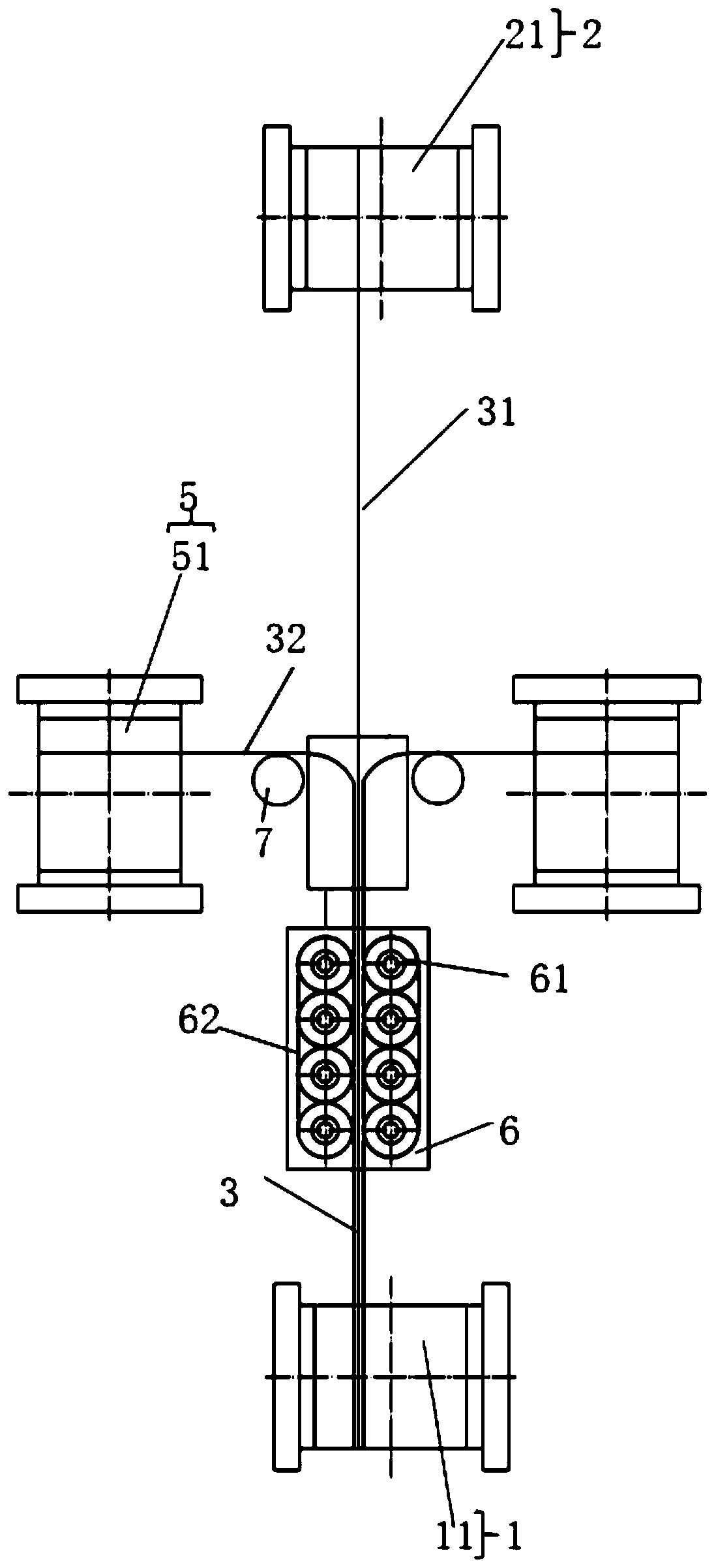

A kind of tubular bus stripping device and process

InactiveCN106953273BPrecise control of cutting depthPrecise control of cutting lengthApparatus for removing/armouring cablesMotor driveBall screw

The present invention provides a tube-type bus peeling device and technology, and belongs to the peeling technology field. The device comprises a tube-type bus location clamping device and a tube-type bus cutting device, and the tube-type bus cutting device comprises a cutter mobile device and a cutter driving device which are mutually connected; the cutter mobile device drives the cutter driving device to move along the tube-type bus axial direction; the cutter driving device drives a cutter to rotate around the periphery of a tube-type bus; the cutter mobile device comprises a leading screw motor and a ball screw connected with the leading screw motor; the cutter driving device comprises a cutter, a cutter support, a cutter motor and a synchronous belt, and the cutter is fixed at one end of a cutter support; and the cutter support is installed at one end of the cutter and is movable connected with the bottom of the cutter support, the bottom of the cutter support is provided with a cutter motor, the cutter motor drives the synchronous belt, and the synchronous belt drives one end, equipped with the cutter, of the cutter support to rotate along the periphery of the tube-type bus. The tube-type bus peeling device is accurate to peel, simple in structure and high in production efficiency.

Owner:深圳市智豪特材科技有限公司

Rapid stripping and connecting device for electric power

InactiveCN109842060ASuitable for strippingAdapt to connectivityLine/current collector detailsCoupling device detailsElectric power systemEngineering

The invention provides a rapid stripping and connecting device for electric power. The rapid stripping and connecting device comprises a connecting mechanism, a supporting plate and a stripping mechanism, wherein the upper end of the connecting mechanism is provided with a supporting plate, and the stripping mechanism is arranged on the upper end of the supporting plate. The rapid stripping and connecting device can solve the problems that: wire strippers on the market are prone to damage inner cores of electric wires in stripping and affect the load carried by the electric wires when in use;the wire strippers on the market can only strip electric wires for household use, and are not easy to strip thick wires such as high-voltage wires quickly; the wire strippers and connectors on the market have relatively single function, a stripping and connecting integrated device is rare, the usage is not convenient and the like. The rapid stripping and connecting device can realize the functionof rapidly stripping and connecting electric wires of various diameters, and has the advantages of being simple in operation, stripping rapidly, adapting to electric wires of various specifications, not damaging the inner cores of electric wires and the like.

Owner:陈军旗

A device and method for forming one-way or two-way barbs on sutures

The invention discloses a device for forming one-way or two-way barbs on a suture thread, comprising: a thread supply assembly, which provides a suture thread raw material thread and positions the suture thread; a cutting mechanism, which forms a barb on the suture thread raw material thread One-way or two-way barbs; turning mechanism to adjust the circumferential angle of the cutting mechanism; finished wire removal mechanism to remove the processed wire. With the device of the present invention, the cutting mechanism can be used to quickly and accurately obtain suture products with one-way or two-way barbs; the turning mechanism can be used to process barbs at different circumferential positions, and various types of sutures can be obtained quickly and efficiently. Suture product in barb layout. When the present invention performs barb processing on the suture thread, the cutting mechanism mainly moves, and the suture thread only moves slightly in the axial direction, and the machining accuracy is easier to control. The cutting depth of the blade can be precisely controlled through the linear drive assembly, and at the same time, the Processing of barbs of different depths.

Owner:ZHEJIANG APELOA JIAYUAN BIOMEDICAL MATERIAL

High-precision scalpel

InactiveCN107811682AControl the depth of cutPrecise control of cutting depthIncision instrumentsSurgical bladePulp and paper industry

A high-precision scalpel of the present invention belongs to the field of medical equipment. The ordinary surgical scalpel is improved. A bracket is installed behind the cutting blade. The second half of the bracket is set as a strip bolt, and a scale is set behind the bolt. The two sides of the cutting blade are respectively provided with a piece of the same limit piece to connect with the knife body, the inside of the knife body is equipped with a bracket, and the second half of the knife body is installed with an adjusting nut and a lock nut that are intermeshed with the strip bolt, so that the structure can be Precisely control the cutting depth of the surgical blade. A high-precision scalpel: including a cutting blade, a limit plate, a knife body, an adjusting nut, a locking nut, a scale, a bracket, and a strip bolt.

Owner:FANGXIAN COUNTY ZHONGYI EQUIP

High-precision surgical knife using method

InactiveCN107811677AControl the depth of cutPrecise control of cutting depthIncision instrumentsSurgical bladePulp and paper industry

A method for using a high-precision scalpel according to the present invention belongs to the field of medical equipment. The ordinary surgical scalpel is improved, and a bracket is installed behind the cutting blade. Scale, the two sides of the cutting blade are respectively provided with a piece of the same limit piece to connect with the knife body, the inside of the knife body is equipped with a bracket, and the second half of the knife body is installed with an adjusting nut and a lock nut that are intermeshed with the strip bolts. This structure can precisely control the cutting depth of the surgical blade.

Owner:FANGXIAN COUNTY ZHONGYI EQUIP

Novel road cutter

InactiveCN108842582AStable speedPrecise control of cutting depthRoads maintainenceRoad surfacePulp and paper industry

The invention discloses a novel road cutter which comprises a rack. A walking wheel is mounted at the bottom of the rack, an arch-shaped structure is arranged in the middle of the rack, a movable column is slidably connected to the upper end of the arch-shaped structure in a penetrating manner, the part, on the upper side of the arch-shaped structure, of the movable column, is connected to a driving mechanism, a mounting plate is welded to the bottom of the moving column, a first bracket and a second bracket are welded to the side wall of the mounting plate, a first supporting rod is rotatablyconnected to the upper surface of the first bracket, an obliquely arranged transmission bar is fixedly connected to the middle of the first supporting rod, a mounting seat is also welded to the sidewall of the mounting plate, and an air cylinder is movably mounted on the mounting seat. The novel road cutter provided by the invention can control the cutting depth of a cutting blade precisely, sothat the maintenance and repair effect of a road can be ensured. The cutting blade can move along the horizontal direction to cut the pavement, so that staffs need not to push the device to move integrally to cut the pavement, therefore, the pushing distance is shortened, the manpower is saved and the novel road cutter is used more conveniently.

Owner:李亚丽

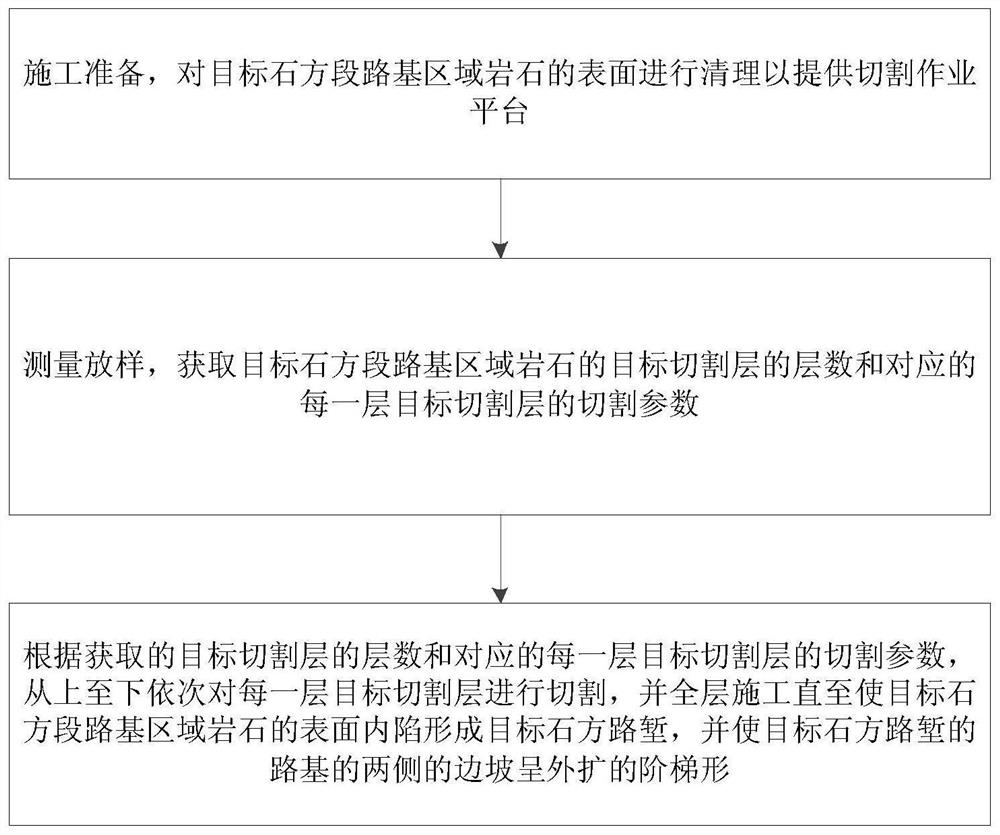

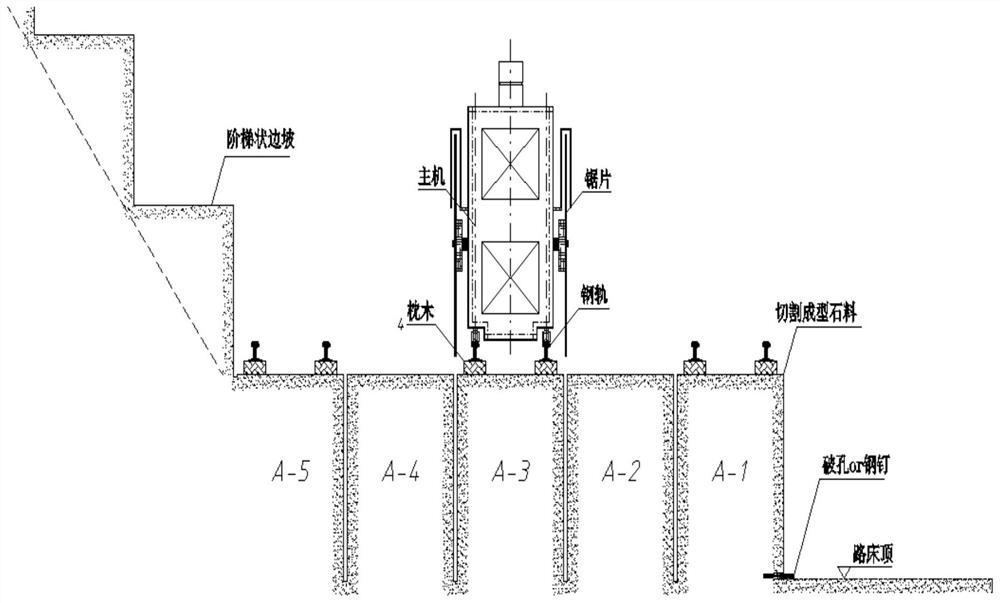

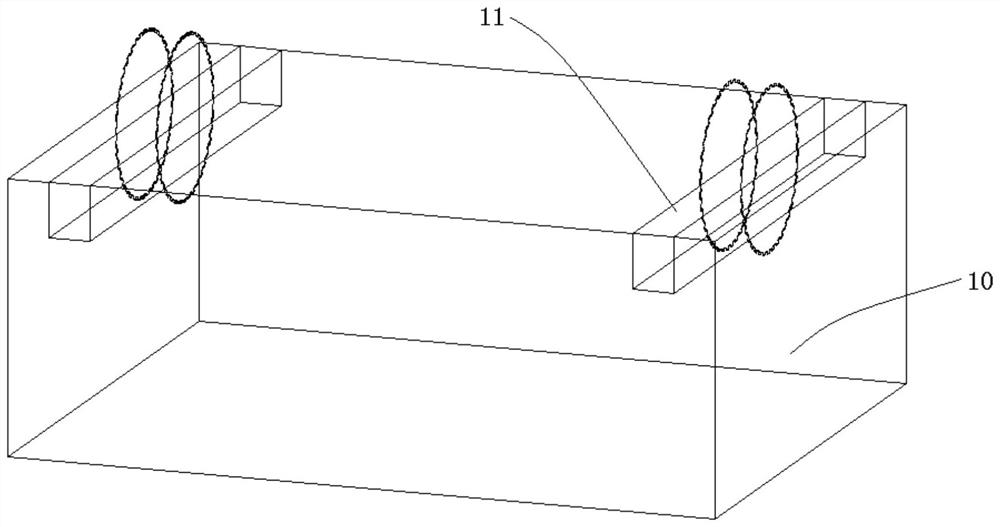

Construction method for excavating stone cutting in cutting mode and stone cutting

ActiveCN112265154AExcavation construction with little vibrationConstruction vibration is smallWorking accessoriesExcavationsArchitectural engineeringStructural engineering

The invention discloses a construction method for excavating of a stone cutting in a cutting mode and the stone cutting. The method comprises the following steps that S101, measuring and setting out are conducted, specifically, the number of target cutting layers of rock in a roadbed region of a target stone section and the cutting parameters of each corresponding target cutting layer are obtained; and S102, according to the obtained number of the target cutting layers and the corresponding cutting parameters of each target cutting layer, the target cutting layers are cut in sequence from topto bottom, and full-layer construction is conducted till the surface of the rock in the roadbed region of the target stone section sinks inwards to form a target stone cutting, and the slopes on the two sides of the roadbed of the target stone cutting are in an outwards-expanded step shape. According to the construction method for excavating of the stone cutting in a cutting mode, the technical problems that in the blasting excavation process of an existing stone cutting and side slopes, due to vibration damage, the stability of the side slopes is poor, and potential safety hazards of blastingexcavation construction are large are solved.

Owner:CCFEB CIVIL ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com