Lifting platform used for tile cutting machine and tile cutting machine

A lifting platform and cutting machine technology, applied in the direction of working accessories, manufacturing tools, stone processing equipment, etc., can solve the problems of cutting blade breakage, troublesome operation, limited use occasions, etc., to improve processing accuracy and efficiency, and improve the lifting/lowering process Smooth, wide-ranging effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

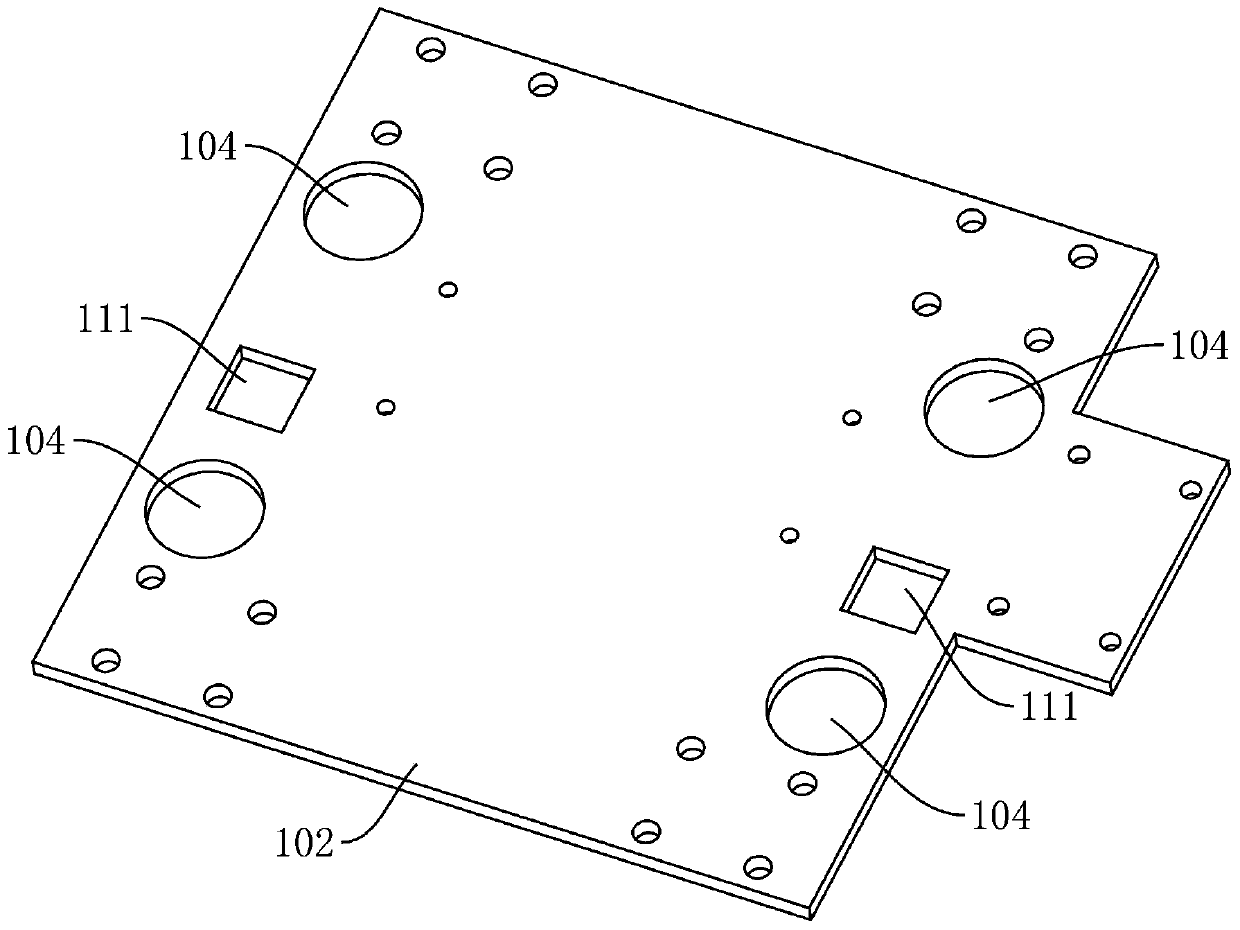

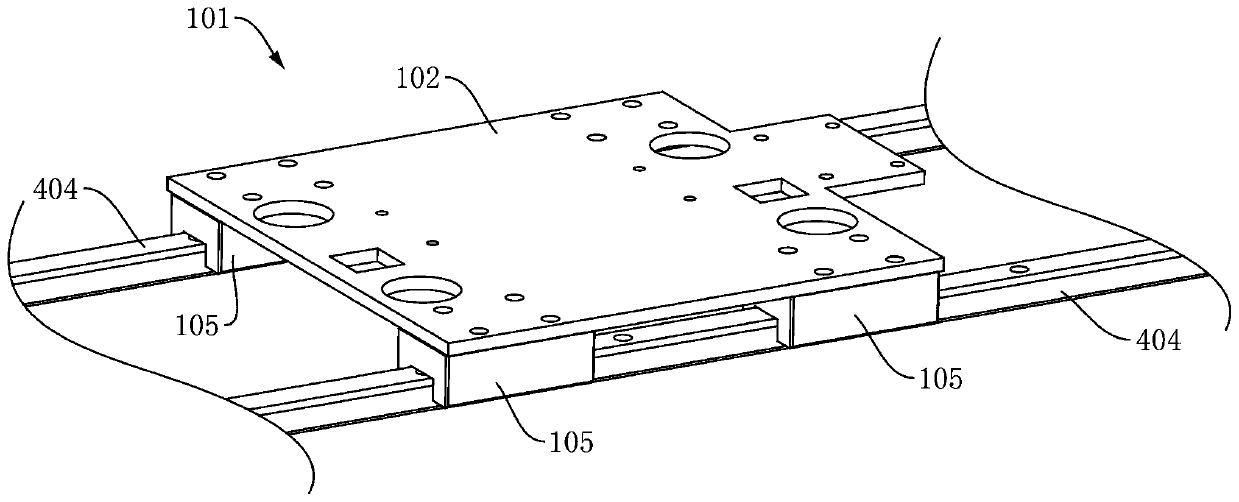

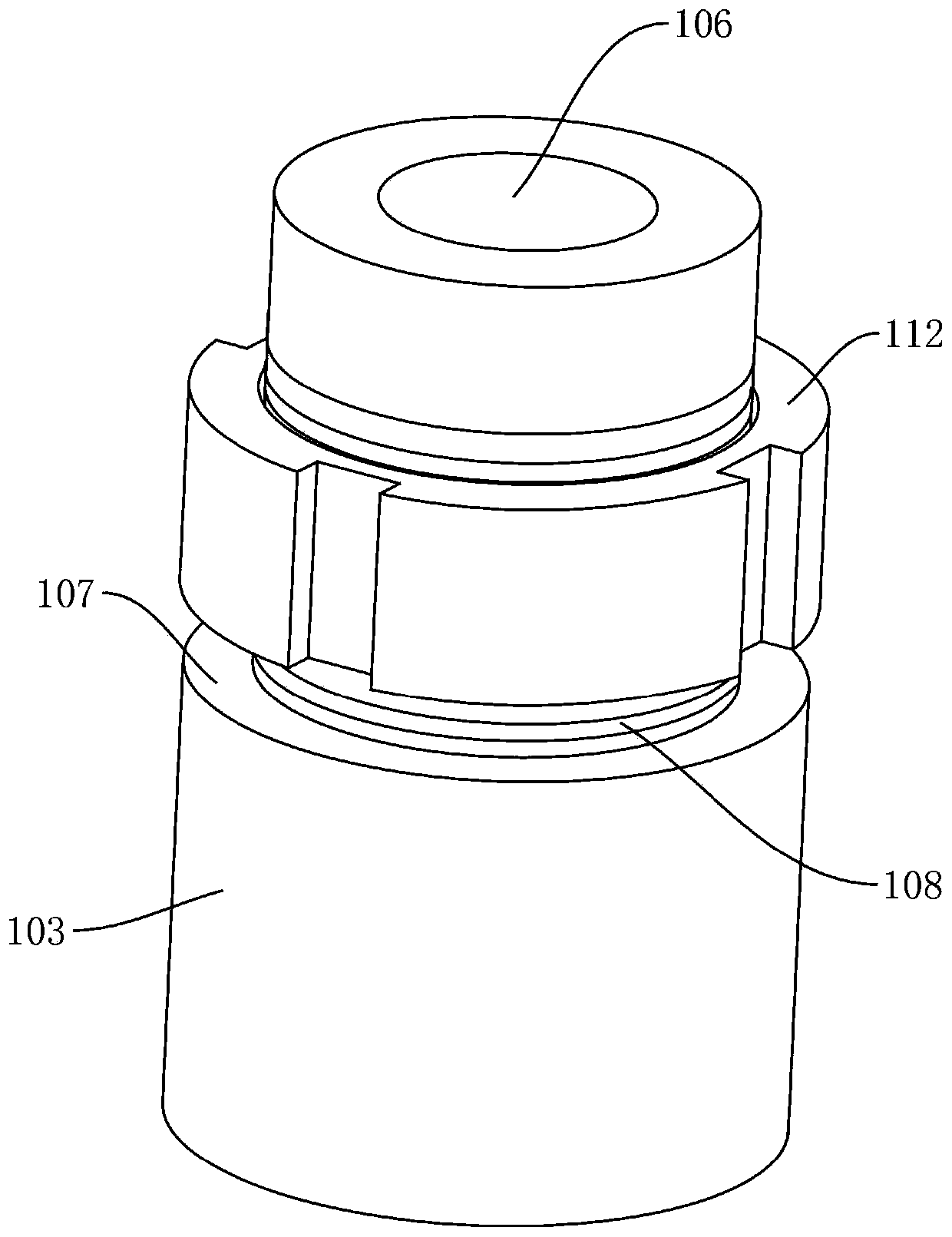

[0045] see figure 2 , Figure 5 , Figure 6 , Figure 7 and Figure 8In this embodiment, a lifting platform for a tile cutter is provided, including a movable part 201 and a fixed part 101, wherein the movable part 201 is used for installing a motor 401 and a cutting piece 403, and the fixed part 101 is used for installing on a guide rail 404, and can move along the length direction of the guide rail 404, the movable part 201 is connected with the fixed part 101, and forms a mobile pair with the fixed part 101 that can move up / down in the vertical direction, that is, the movable part 201 can be relatively fixed The part 101 moves up / down, and synchronously drives the motor 401 and the cutting piece 403 on it to move up / down, so as to effectively adjust the distance between the cutting piece 403 and the ceramic tile or stone below, so that the ceramic tile and stone can be easily cut. Various shapes of the surface, especially grooves with different processing depths, compa...

Embodiment 2

[0060] This embodiment provides a tile cutting machine, including a guide rail 404, a motor 401, a transmission shaft 402, a second transmission mechanism 405 and the aforementioned lifting platform, such as Figure 10 As shown, the fixed part 101 is fixed on the guide rail 404 and can slide along the length direction of the guide rail 404, the motor 401 is fixed on the movable part 201, and the output shaft of the motor 401 communicates with the second transmission mechanism 405 through the second transmission mechanism 405. The transmission shaft 402 is connected, the transmission shaft 402 is fixed on the movable part 201, the transmission shaft 402 is used to install the cutting piece 403, the second transmission mechanism 405 can be a belt transmission mechanism or a gear 304 transmission mechanism or a chain transmission mechanism, etc. The motor 401 drives the cutting piece 403 to rotate through the second transmission mechanism 405, thereby realizing the cutting functio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com