Accurate joint cutting device for bridge road

A road and precise technology, applied in the field of precise seam cutting devices for bridges and roads, can solve the problems such as the lack of precise socket structure, inconvenient moving operations, and inconvenient transportation of the seam cutting devices, so as to improve construction quality, facilitate movement and construction, and cut The effect of precise control of seam depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

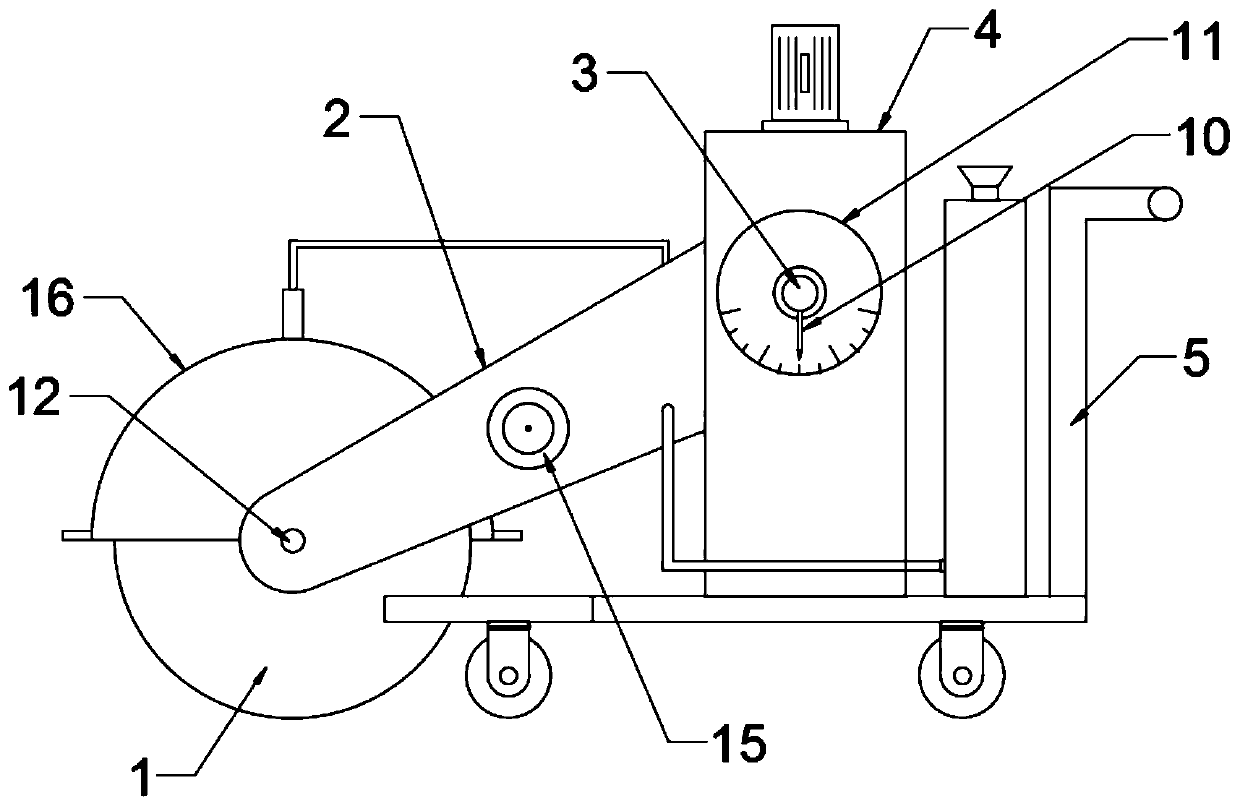

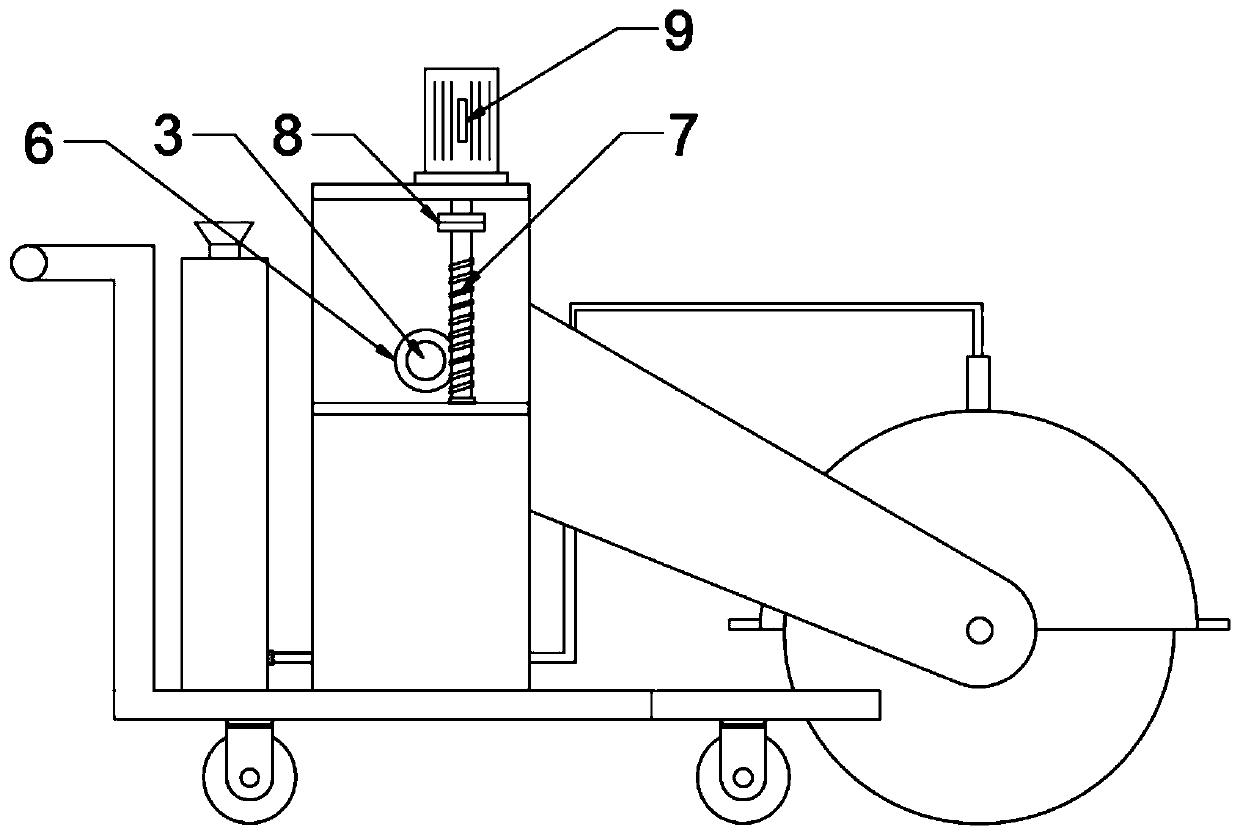

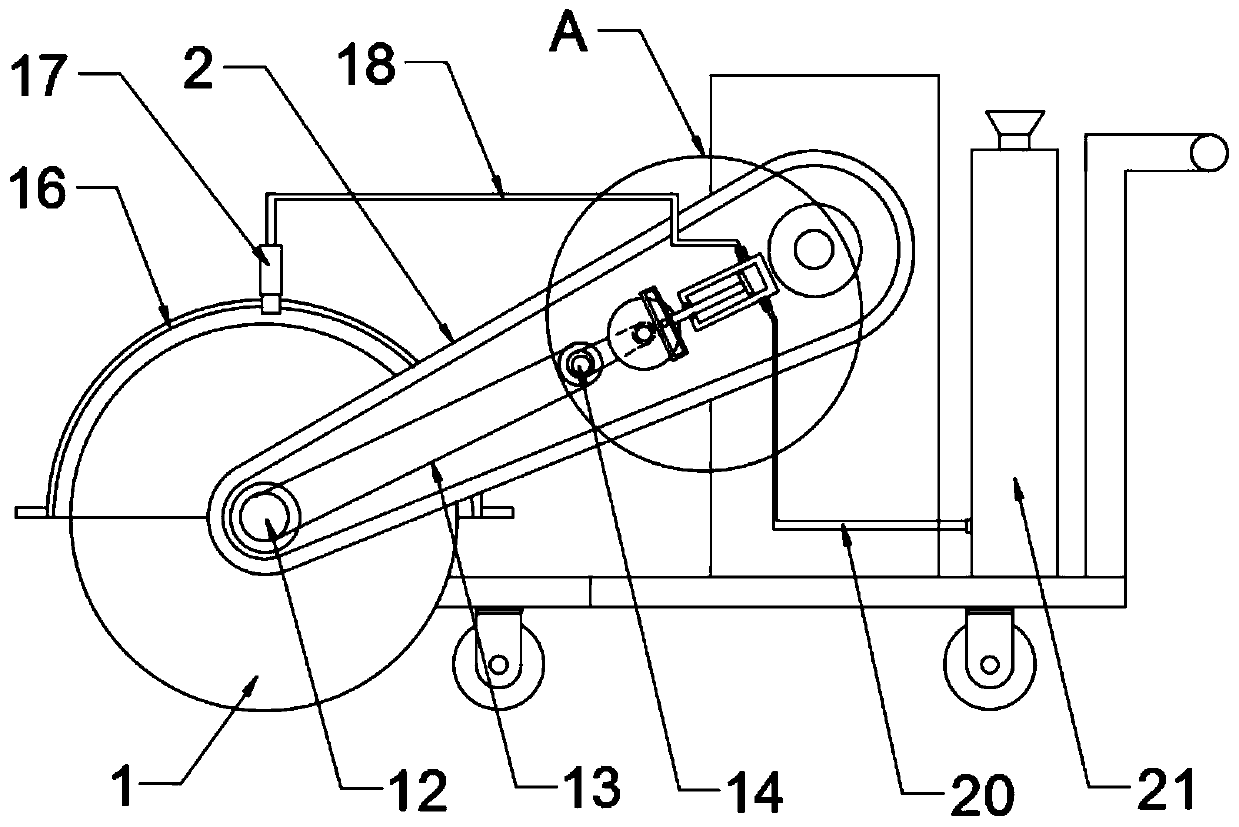

[0022] see Figure 1-5 , in an embodiment of the present invention, a bridge road precision slitting device includes a cutting wheel 1 and a cart 5; the cutting wheel 1 is rotatably connected to a swing arm 2 through a wheel shaft 12, and the swing arm 2 is rotatably connected to a rotating shaft 3 The support plate 4 is fixedly connected to the bottom plate of the cart 5; the axle 12 is connected to the output shaft 14 of the drive motor 15 through the first transmission belt 13, and the drive motor 15 is fixedly connected to the outer wall of the swing arm 2 by means of bolts , the output shaft 14 extends into the swing arm 2, and the first transmission belt 13 is nested in the swing arm 2 to prevent dust from polluting the transmission parts; the drive motor 15 is connected in series with the vehicle power supply and the motor switch through wires, and the vehicle power supply Fixedly connected with the bottom plate of the cart 5, the motor switch is fixedly connected with ...

Embodiment 2

[0025] The difference between this embodiment and Embodiment 1 is that in order to reduce the volume of the device, the front end of the bottom plate of the trolley 5 is provided with a through groove, which facilitates the nesting of the swing arm 2 in the through groove and reduces the lateral length of the device; at the same time, A synchronous water spray mechanism is nested in the swing arm 2; the synchronous water spray mechanism includes a water pump 19, and the water pump 19 is nested in the swing arm 2 and is fixedly connected with the inner wall of the swing arm 2; The shell 16 and the top of the protective shell 16 are pierced with a nozzle 17, the nozzle 17 is connected to the water pump 19 through the water inlet pipe 18, and a first one-way valve is provided at the connection between the water inlet pipe 18 and the water pump 19, and the first one-way valve prevents water backflow Water cylinder 19; said water pump 19 communicates with a water tank 21 through a w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com