Device for peeling off sheath of optical cable and application method of device

An optical cable and sheath technology, which is applied in the field of precise exploitation devices for optical cable sheaths, can solve the problems of laborious hand cranking, complicated assembly, and large friction between the optical cable and the outer peripheral surface of a rolling wheel, etc., and achieves the effect of reducing pulling resistance and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

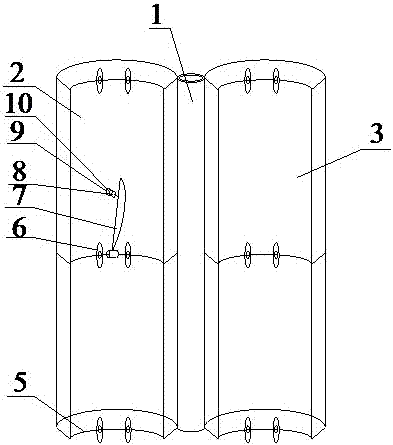

[0057] refer to image 3 and Figure 6 , the precise stripping device for the optical cable sheath described in this embodiment is different from Embodiment 1 in that:

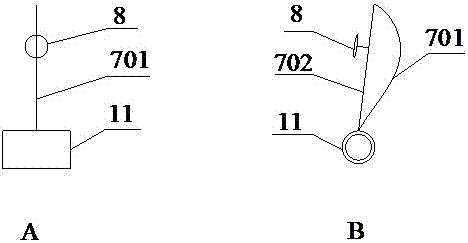

[0058] A skinning knife 7 is respectively arranged on the wheel shaft in the middle of the first arc-shaped cylinder 2 and the second arc-shaped cylinder 3, the bottom end of the skinning knife is rotatably connected with the wheel shaft, and the blade 701 of the skinning knife is vertically facing For the optical cable to be stripped, the blade back 702 of the stripping knife is provided with a back iron 8 .

[0059] In this embodiment, the number of stripping knives is 2, and they are respectively located on the axles in the middle of the first arc-shaped tube 2 and the second arc-shaped tube 3. At this time, one stripping operation can form two strips on the same optical cable sheath. Cutting the line, the outer skin is divided into two pieces, and the manual peeling is easier and labor-saving.

[0060] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com