wallpaper cutter

A wallpaper cutting and locator technology, applied in metal processing and other directions, can solve problems such as time-consuming and labor-intensive, and achieve the effects of convenient operation, improved repairing efficiency, and regular shape.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

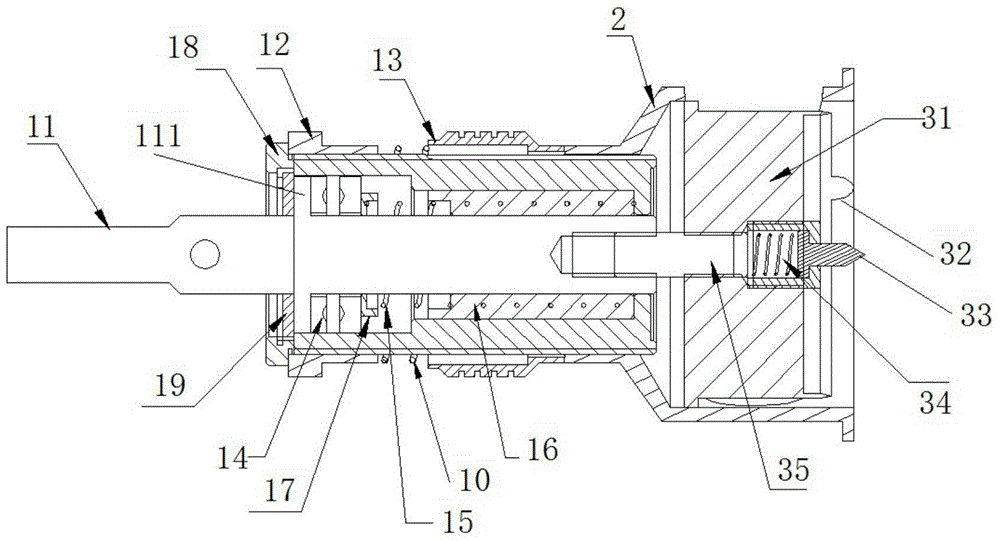

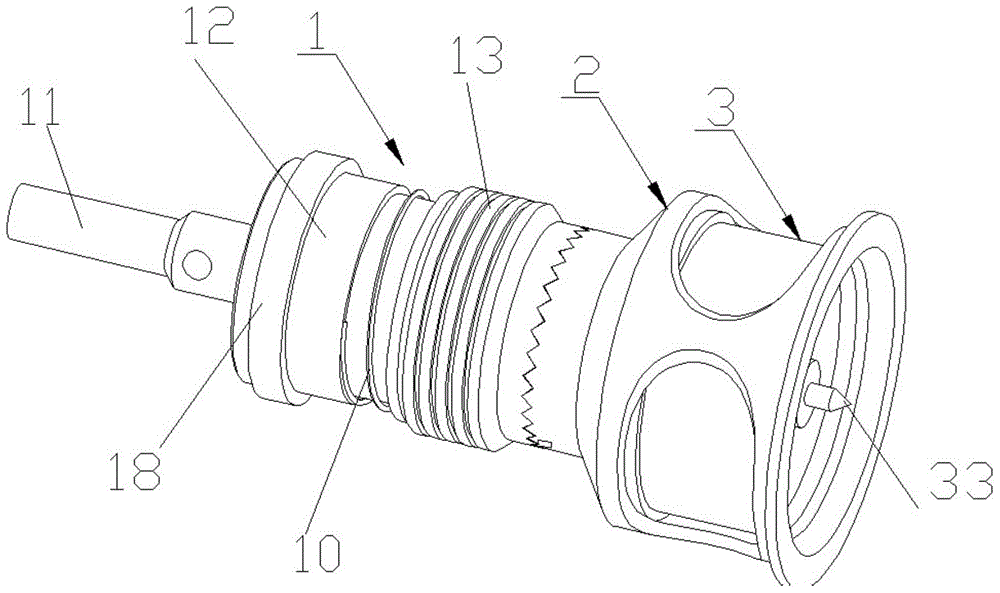

[0022] Such as figure 1 , 2 As shown, the wallpaper cutter of the present invention includes an adjustment driving mechanism 1 , a positioner 2 and a cutter 3 .

[0023] In this embodiment, the cutter 3 is composed of a circular base 31 , four blades 32 , a centering pin 33 and a stud 34 .

[0024] The blades 3 are evenly distributed on the circumference of the bottom surface of the circular base 31, and the blades are along the circumferential direction, so that when driven to rotate, the motion track of the blades is running, thereby cutting out regular circular wallpapers. The blade thickness of the knife of the present invention is 0.3 mm, and the effective blade height is 2 mm ± 0.5 mm, which can ensure the cutting quality and prevent the electric wires and other parts behind the wallpaper from being cut by the blade being too long.

[0025] The central positioning pin 33 is located at the center of the bottom surface of the circular base 31 and is used to rotate the ci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com