Hot-line work wire stripper capable of preventing conductor from being damaged

A technology of live work and wire stripper, which is applied in the direction of line/collector parts, circuits, electrical components, etc., and can solve the problems of too deep cutting, wire core damage, and easily damaged wire core, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The embodiments of the present invention will be further described below in conjunction with the present invention:

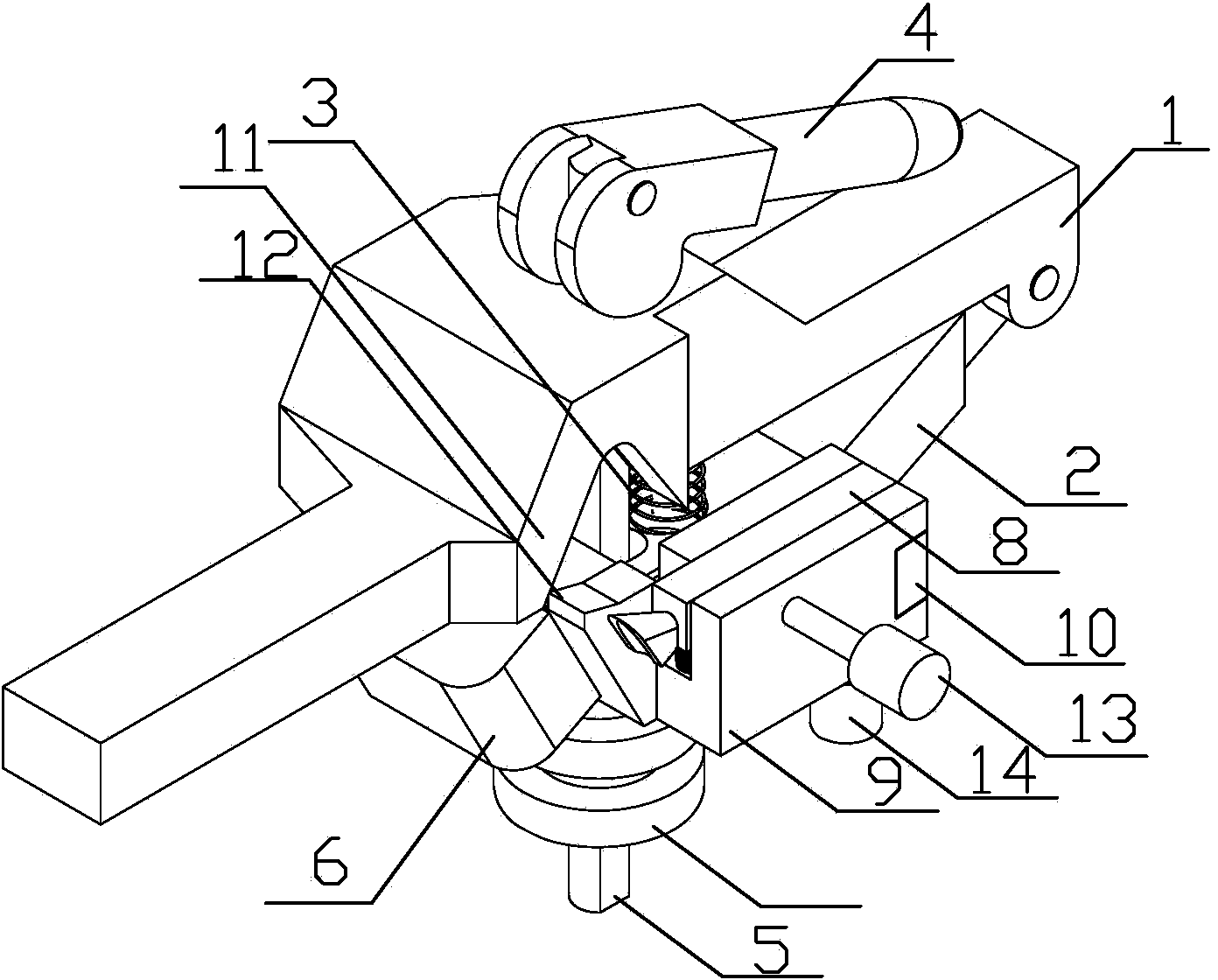

[0014] Wire core damage wire stripper for live working, including upper pliers body 1, lower pliers body 2, return spring 3, handle 4, connecting rod 5, alarm 6, adjusting nut 7, cutting knife 8, upper pliers body 1 and lower The head of the pliers body 2 is hinged, the return spring 3 is located between the upper pliers body 1 and the lower pliers body 2, the connecting rod 5 penetrates the upper pliers body 1 and the lower pliers body 2, the connecting rod 5 has a thread at one end, and the handle is "9 ”Type handle, the unthreaded end of the connecting rod 5 is hinged with the thicker end of the handle 4. Two adjusting nuts 7 move up and down through the thread at one end of the connecting rod 5 to adjust and fix the distance between the upper clamp body 1 and the lower clamp body 2. The tail of the lower pliers body 2 is provided with an alarm 6, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com