Electric breaking-in tool for crimping wire clamp and operation method

A crimping and wire clip technology, applied in the direction of overhead lines/cable equipment, etc., can solve the problems of damage to conductors, hidden dangers to operator safety, time-consuming and labor-intensive, etc., to achieve precise control of cutting depth and position, easy operation good effect of dismantling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with accompanying drawing:

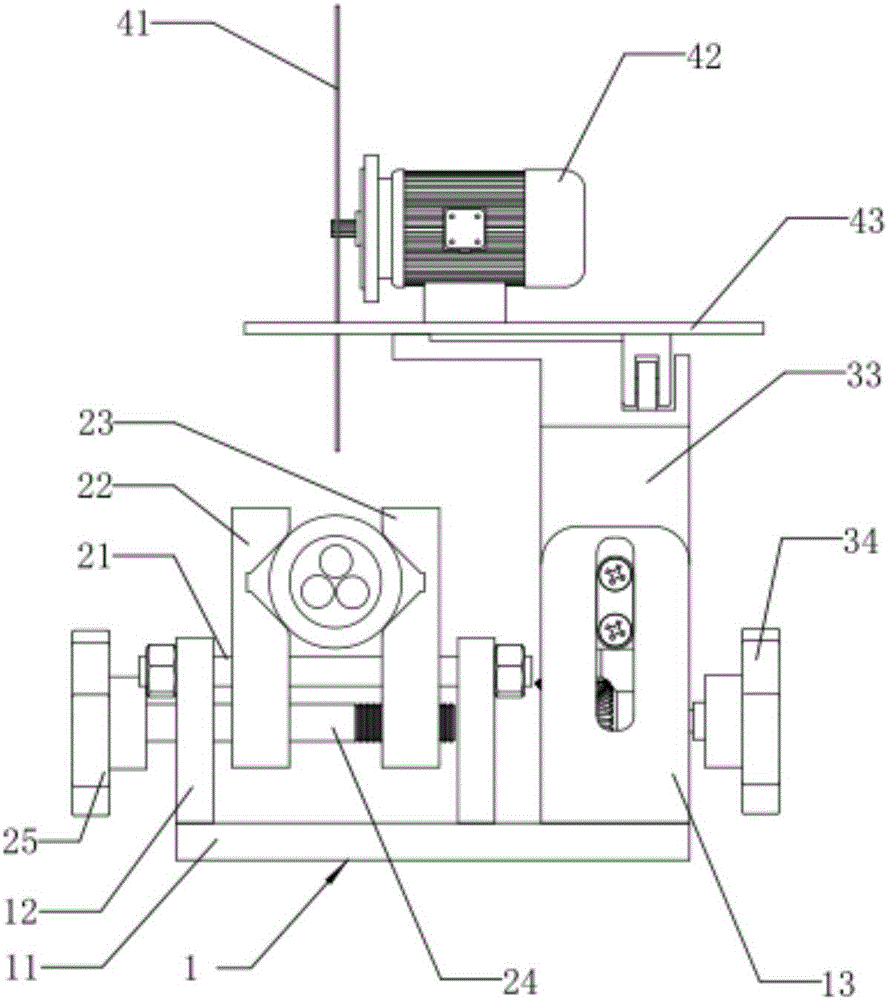

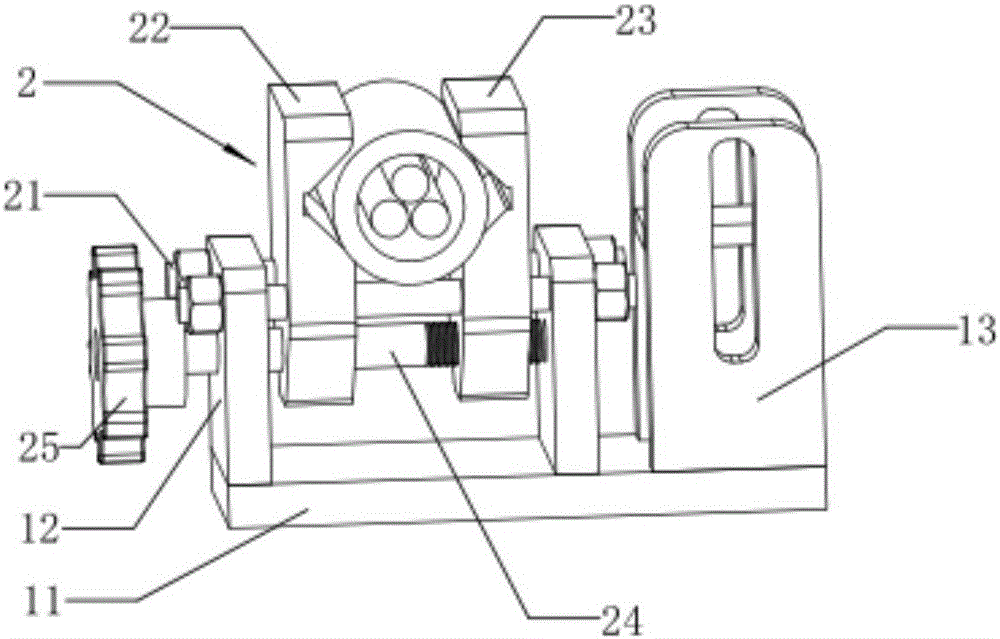

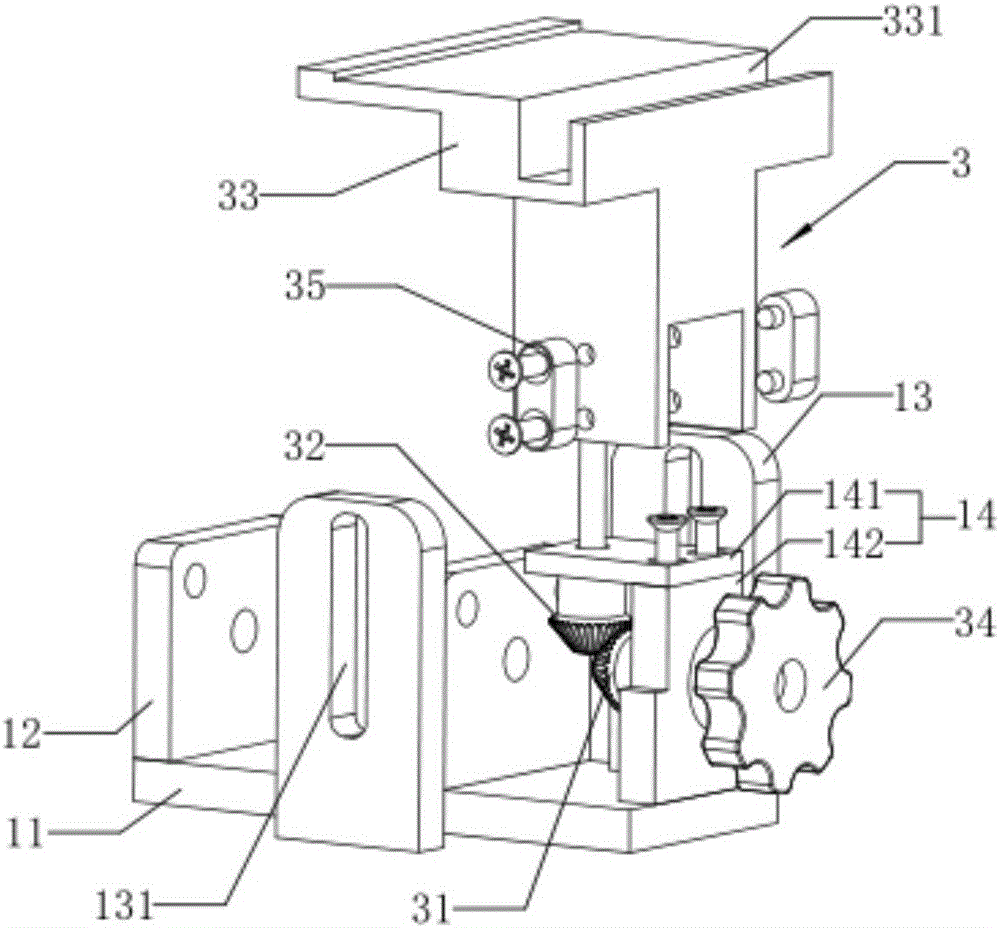

[0032] Such as Figure 1-4 As shown, the crimping type wire clamp electric rescue tool includes a base 1, a clamping mechanism 2 installed on one side of the base 1, a lifting mechanism 3 installed on the other side of the base 1, and a cutting mechanism connected above the lifting mechanism 3 4;

[0033] The base 1 includes a bottom plate 11, on which two parallel-opposed clamping mounting plates 12 are welded, and two parallel-opposed lifting mounting plates 13 are welded, and a bevel gear mounting plate 14 is arranged between the lifting mounting plates 13 , the bevel gear mounting plate 14 is connected by a horizontal plate 141 and a vertical plate 142 to form a "7" shape;

[0034] The clamping mechanism 2 includes a slide bar 21, a fixed clamp block 22, a slide clamp block 23, a screw rod 24 and a clamping hand wheel 25, the slide bar 21 is installed on the clamping ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com