Water conservancy and hydropower engineering gate slot second-stage concrete dismantling method

A second-phase concrete, water conservancy and hydropower technology, applied in water conservancy projects, water conservancy engineering equipment, marine engineering and other directions, can solve problems such as high noise and poor danger, and achieve the effect of solving high noise, low input cost, and easy popularization and use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

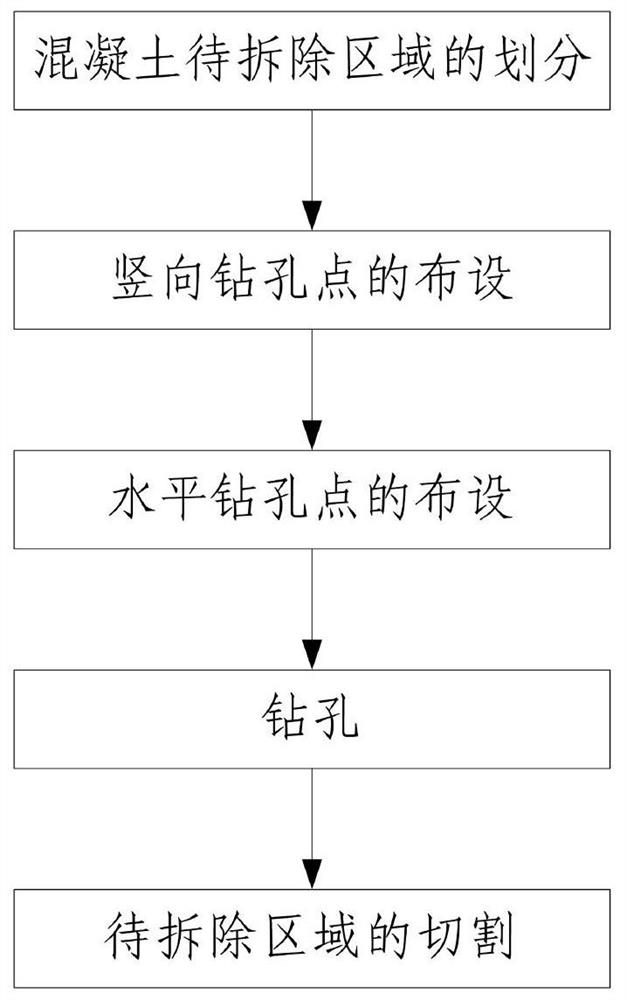

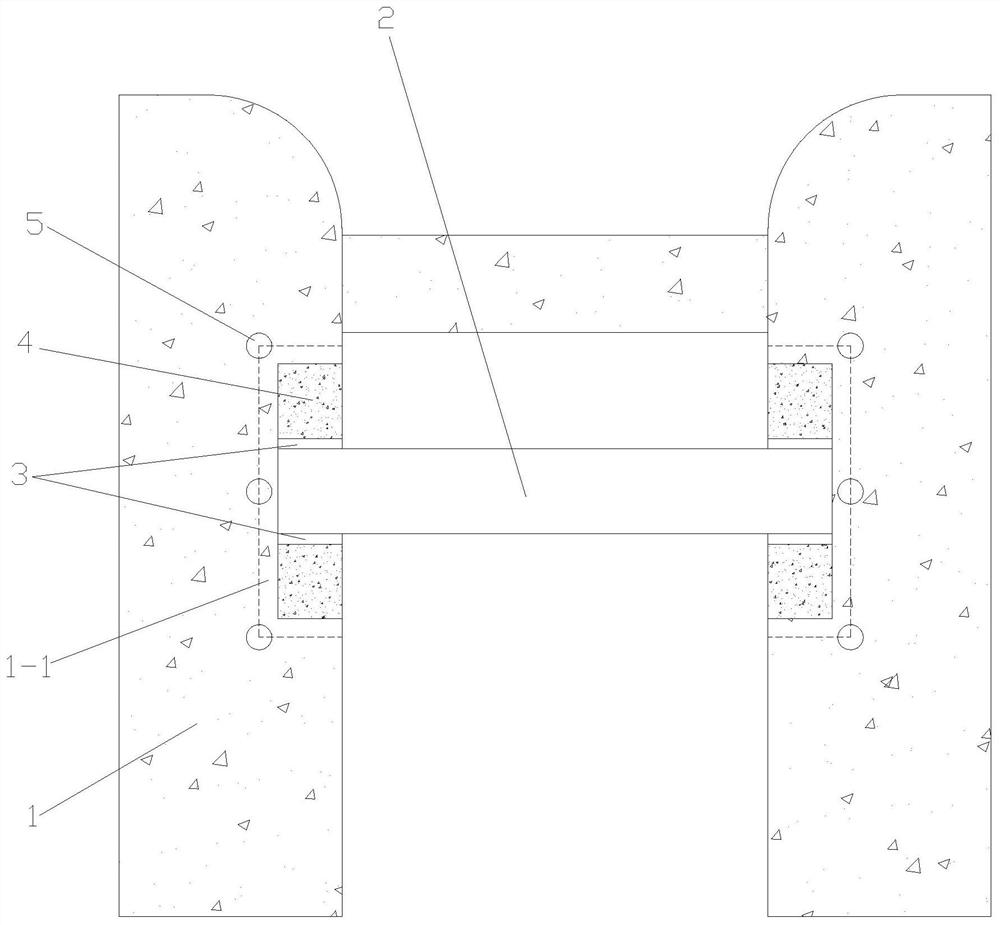

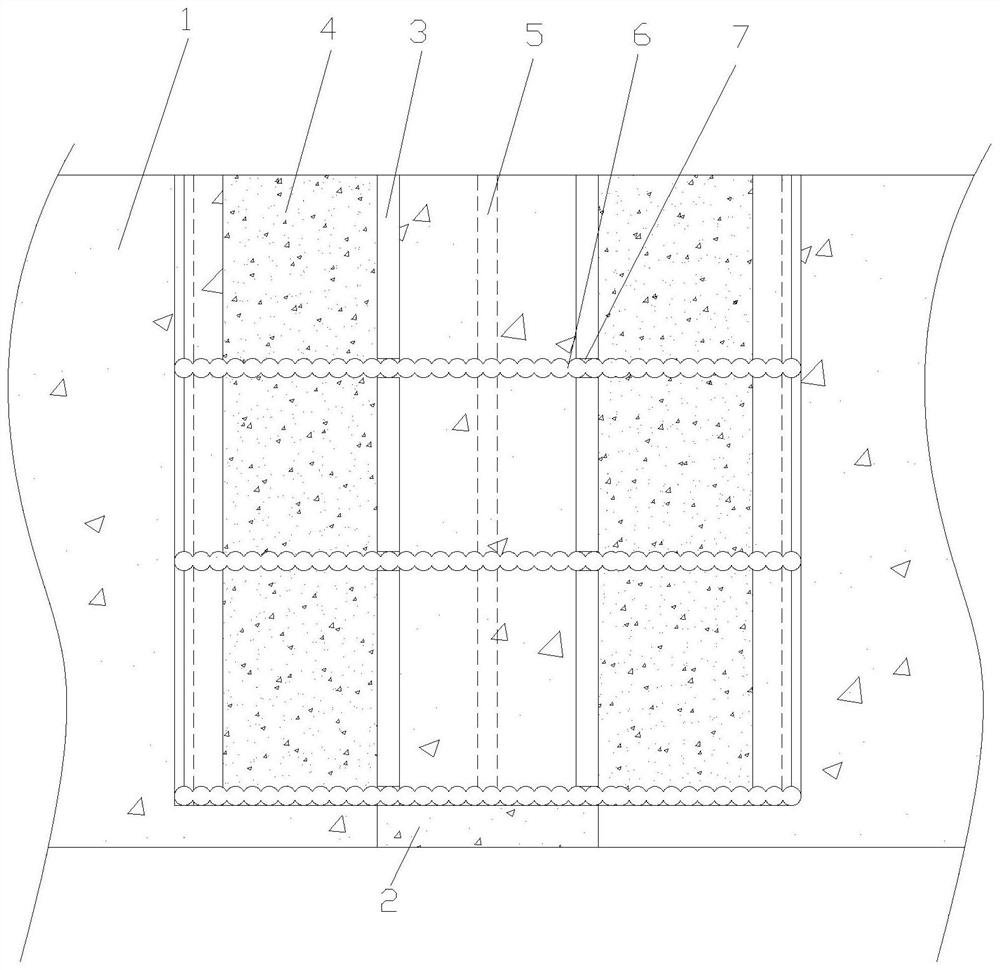

[0051] like Figure 1 to Figure 3 Shown, a kind of water conservancy and hydropower project door slot second-stage concrete demolition method described in the present invention, the second-stage concrete 4 that is removed is used for pouring the outer sidewall of door slot track 3 and first-stage concrete pier 1 into one, and the removed The second-stage concrete 4 and the door slot track 3 are all located in the U-shaped installation groove of the first-stage concrete pier 1, and the method includes the following steps:

[0052] Step 1. Division of concrete areas to be demolished:

[0053] The area to be removed is planned at the U-shaped installation groove of the first-stage concrete gate pier 1. The outer contour of the area to be removed is consistent with the outer contour of the U-shaped installation groove, and the outer contour of the area to be removed is consistent with the shape of the U-shaped installation groove. The distance between the outer contour lines of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com