Apparatus and method for forming unidirectional or bidirectional barbs on suture

A suture, one-way technology, used in surgical instruments, trocars, etc., can solve the problems of low cutting efficiency, inability to guarantee product quality, and difficulty in ensuring stability and diversity, and achieve the effect of convenient and precise control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

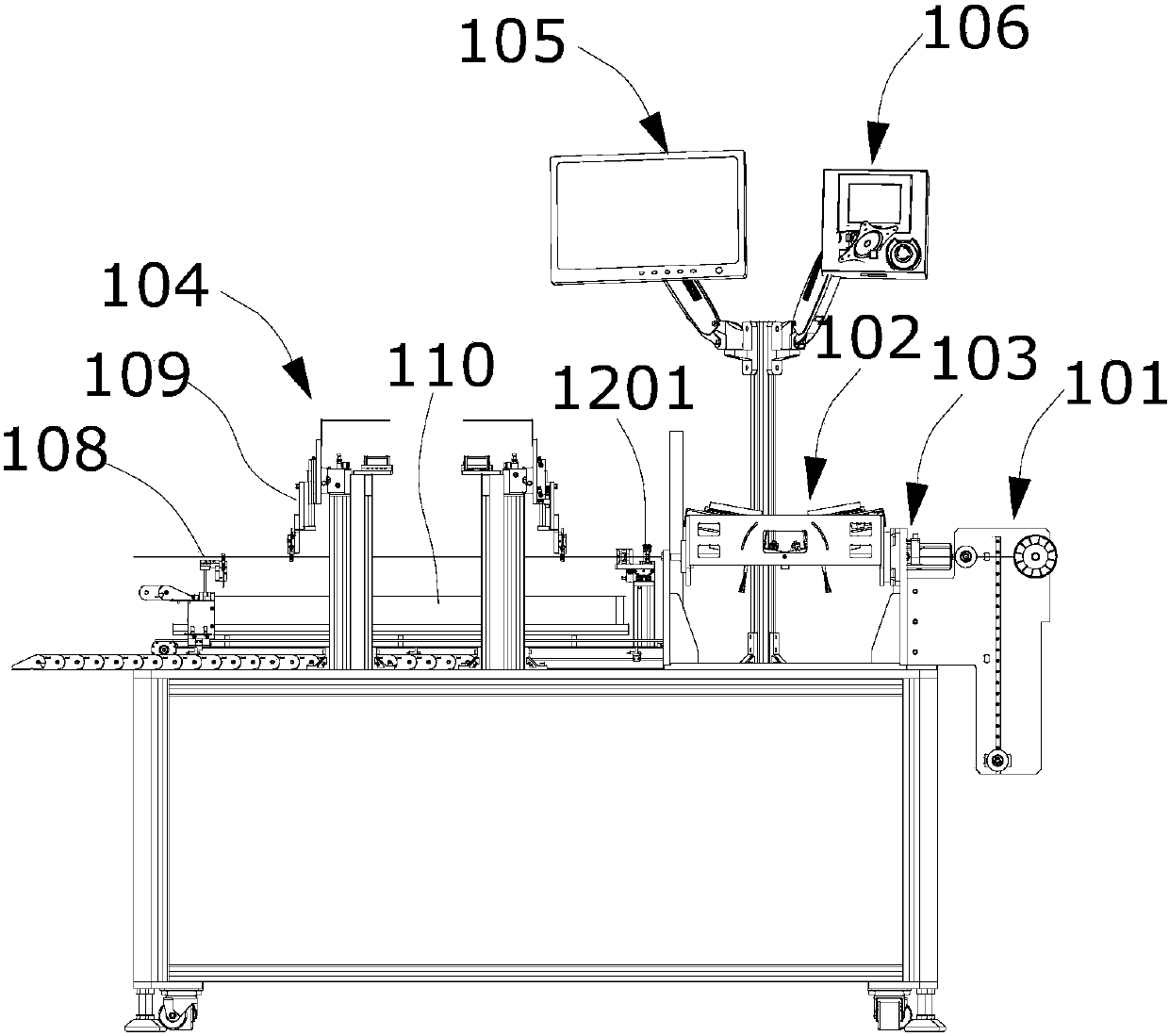

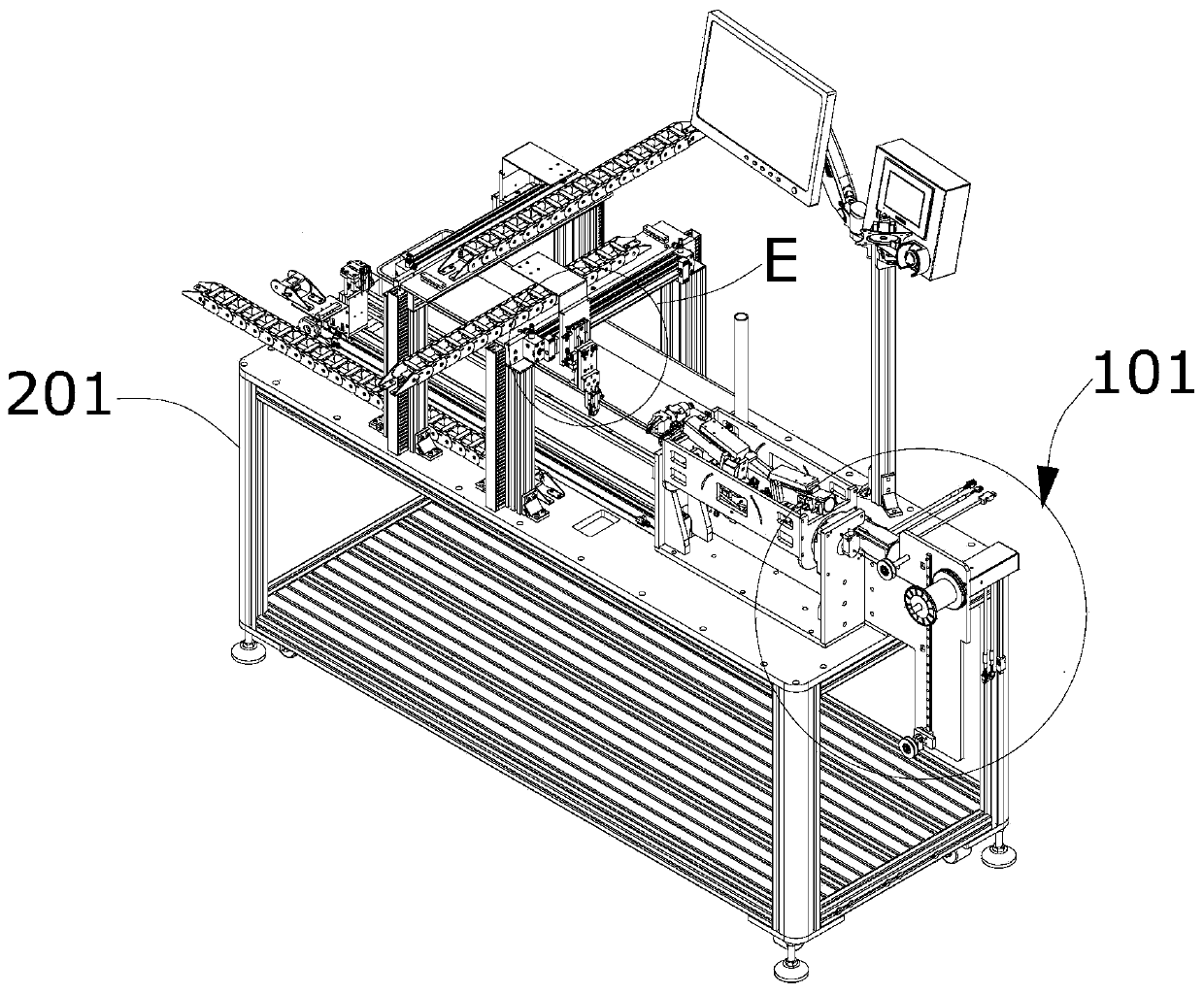

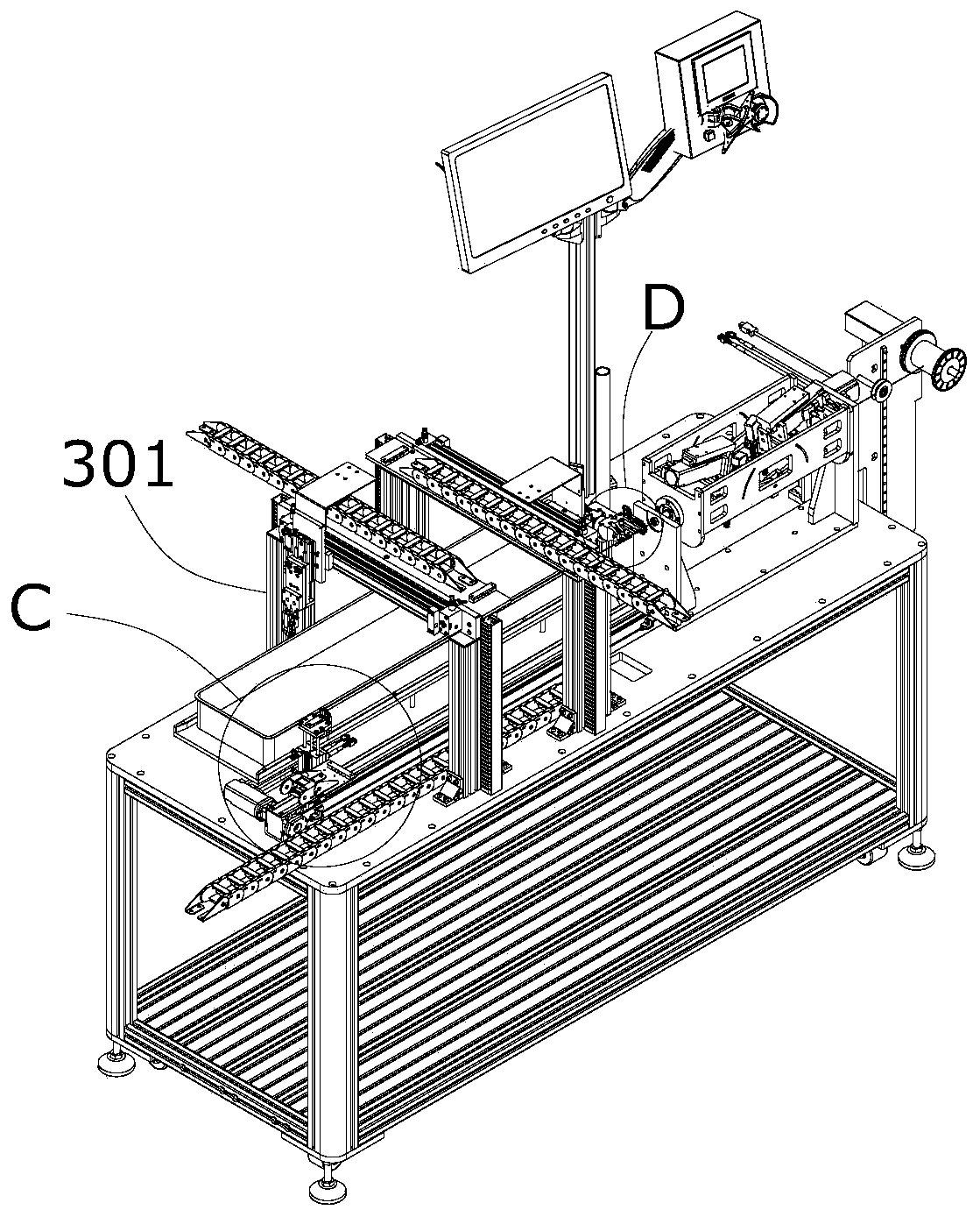

[0108] The following structural drawings further illustrate the present invention:

[0109] Such as figure 1 , figure 2 with image 3 , Figure 4 As shown, a device for forming one-way or two-way barbs on sutures includes: a thread supply assembly 101 that provides suture raw materials and positions the sutures; forms one-way or two-way barbs on the suture raw materials; A bidirectional barb cutting mechanism 102; before forming the barb or in the process of forming the barb, a turning mechanism 103 that adjusts the circumferential angle of the cutting mechanism; and a finished wire removal mechanism that removes the processed wire 104; at the same time, the present invention is also provided with a display 105 for displaying processing parameters and processing results and a touch screen 106 for inputting equipment parameters.

[0110] The whole device of the present invention can be automatically controlled by the control element, and the control element (or controller)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com