Pressure maintaining cutting device for natural gas hydrate sampling pipe

A cutting device and hydrate technology, applied in metal processing and other directions, can solve the problems of slow cutting speed, inconvenient operation, and difficult operation of parts, and achieve the effect of convenient and simple installation, avoiding difficult installation, and controllable cutting process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The following examples can make those skilled in the technical field understand the present invention more comprehensively, but do not limit the present invention in any way.

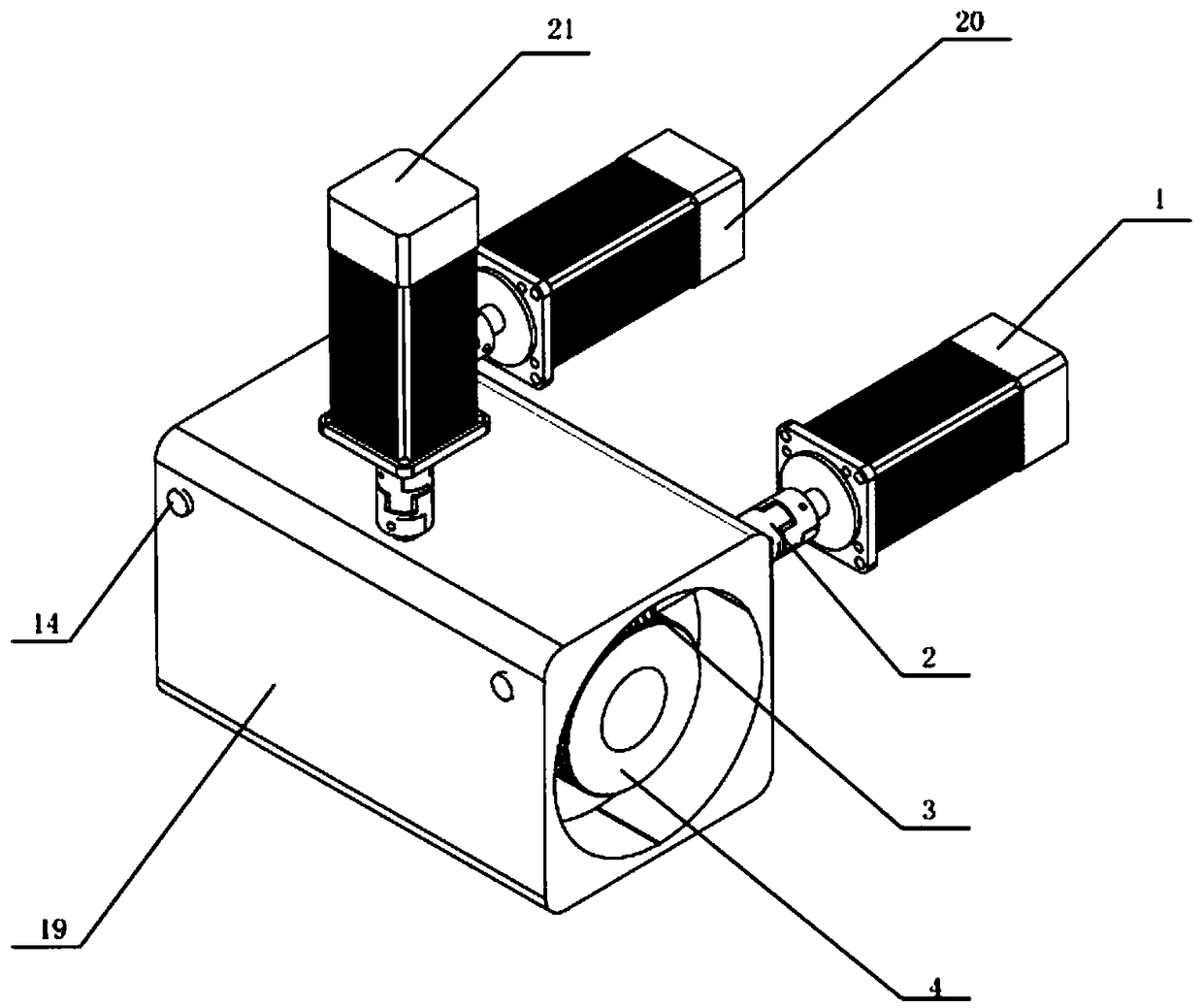

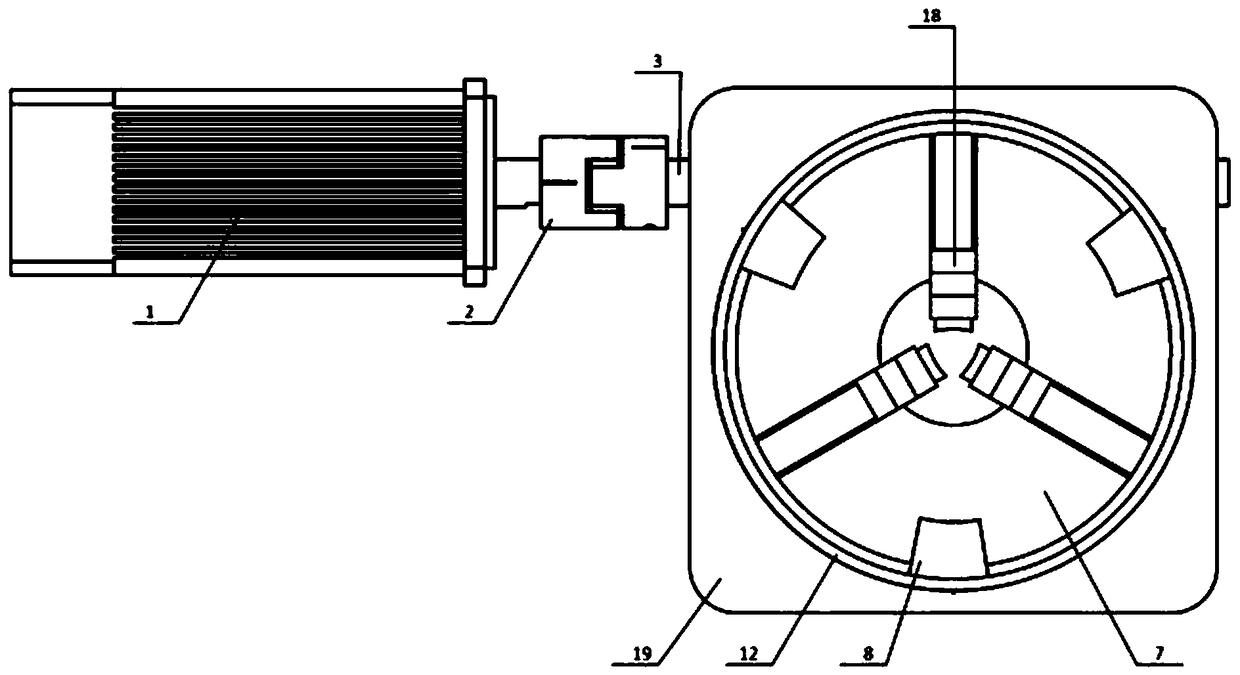

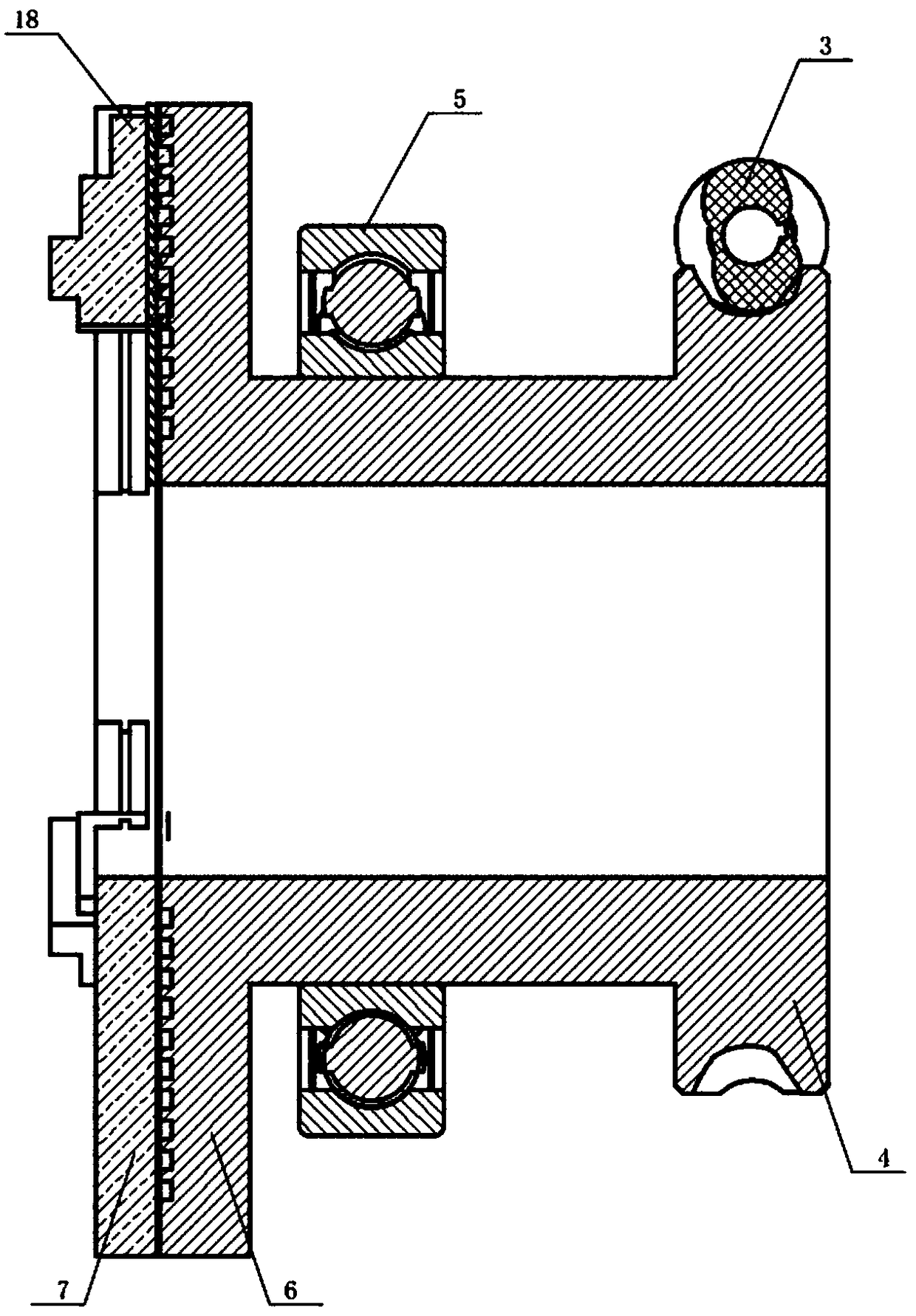

[0036] Figure 1~6 As shown, a pressure-holding cutting device for natural gas hydrate sampling pipes is provided, including a hollow tubular outer cylinder 19 for pressure-holding, as well as an advancing and retreating knife mechanism, a circumferential rotation mechanism and a clamping mechanism; wherein,

[0037] The advance and retreat mechanism includes an advance and retreat motor 20, a coupling, an advance and retreat worm 14, an advance and retreat worm wheel 13, an advance and retreat bearing 15 and a cutting spiral groove disc 11, and the advance and retreat bearing 15 is sleeved on the outside of the hollow tubular first connector ; The advancing and retreating knife worm wheel 13 and the cutting helical groove disc 11 are both annular, and both are fixedly mounted on the two ends of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com