High-precision offshore wind turbine hoisting and mounting ship

An offshore fan, high-precision technology, used in ship accessories, transportation and packaging, cargo handling equipment and other directions, can solve problems such as difficulty, low installation accuracy, low lifting capacity, etc., to achieve short construction period, low construction difficulty, The effect of solving installation difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0042] Embodiments of the present invention include the following steps:

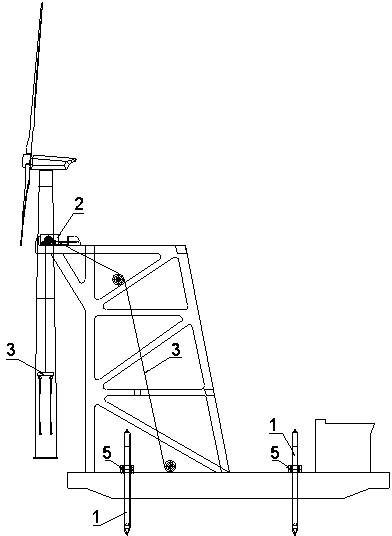

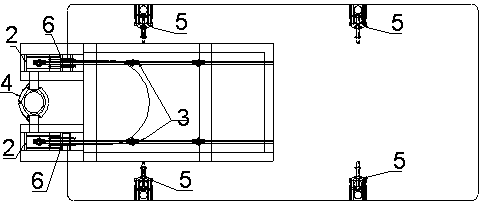

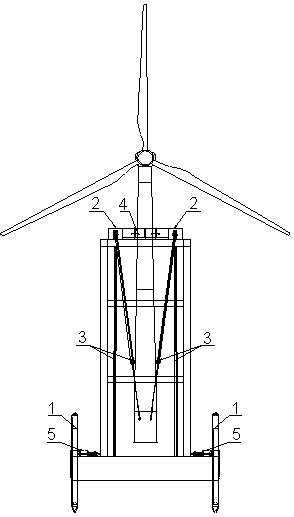

[0043] (1) Initial positioning of the ship. After hoisting the wind turbine on the ship, drive to the installation foundation of the wind turbine, and perform preliminary alignment with the installation foundation of the wind turbine. After the lower end of the wind turbine tower is roughly aligned with the foundation of the wind turbine, use the ship's pile leg positioning system 1 to insert the positioning pile into the seabed . Fix the hull to prevent the tide from shifting the hull.

[0044] (2) Precise positioning of the fan. After the positioning pile is inserted into the seabed to achieve preliminary positioning, use the lateral ship moving device 5 of the pile leg positioning system 1 to adjust the left and right (horizontal) movement of the wind turbine. The left and right movement stroke is about 2.4m, and the moving speed is about 1m / min ;Use the longitudinal adjuster 6 on the platform pos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com