Machining method and system for novel conical composite material electric pole

The technology of a composite material and a processing method is applied in the field of a new composite material conical electric pole processing method and its processing system, which can solve the problems of insufficient strength and rigidity performance of the conical electric pole, difficulty in construction, transportation, operation and maintenance, and high production costs. problems, to achieve the effect of simple and fast winding steps, improved overall physical and chemical properties, and high pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

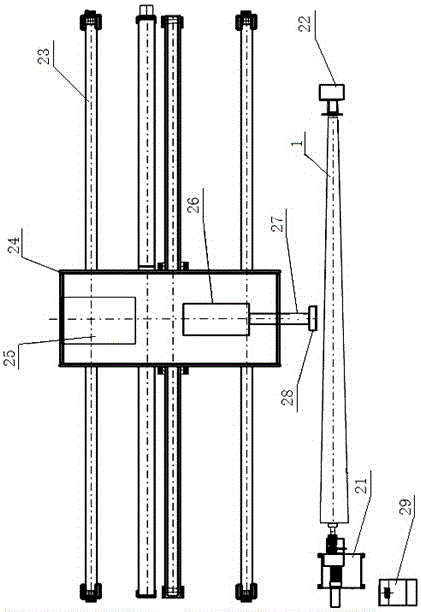

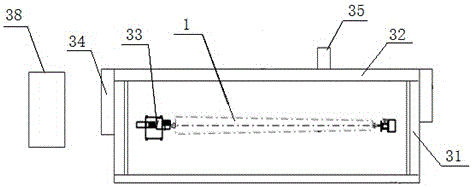

[0045] The processing method of the novel composite tapered electric pole specifically includes the following steps:

[0046] (1), preparation of inner glue and outer glue:

[0047] The raw materials include material A with polyol system and material B with isocyanate system, see formula (1) mix material A and material B at 20-25°C for 10-20 minutes to obtain the inner layer glue; see formula (2) Mix and react material A and material B at 20-25°C for 20-30 minutes to obtain the outer layer glue;

[0048] R-OH+Ar-NCO=Ar-NH-COOR-R(1);

[0049] R-OH+R'-NCO=R'-NH-COOR-R(2);

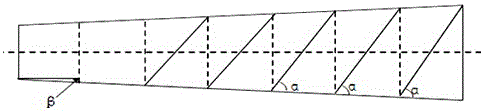

[0050] (2) Winding molding, that is, using a winding system to wind the glass fiber soaked in the inner layer glue or the outer layer glue on the pole mold core, the Young's modulus of the glass fiber is ≥81Gpa, and the tensile strength of the original fiber is ≥3750MPa , the strength of the dipped yarn is ≥2495.7MPa, the modulus of the dipped yarn is ≥85.3GPa, and the interlayer shear strength is ≥49.8MPa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com