Assembled concrete bridge pier

A prefabricated, concrete technology, applied in the direction of bridges, bridge parts, bridge construction, etc., can solve the problems of shock absorption, poor seismic performance, difficult assembly, and time-consuming, etc., and achieve the effect of enhanced seismic resistance and efficient, convenient and fast assembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

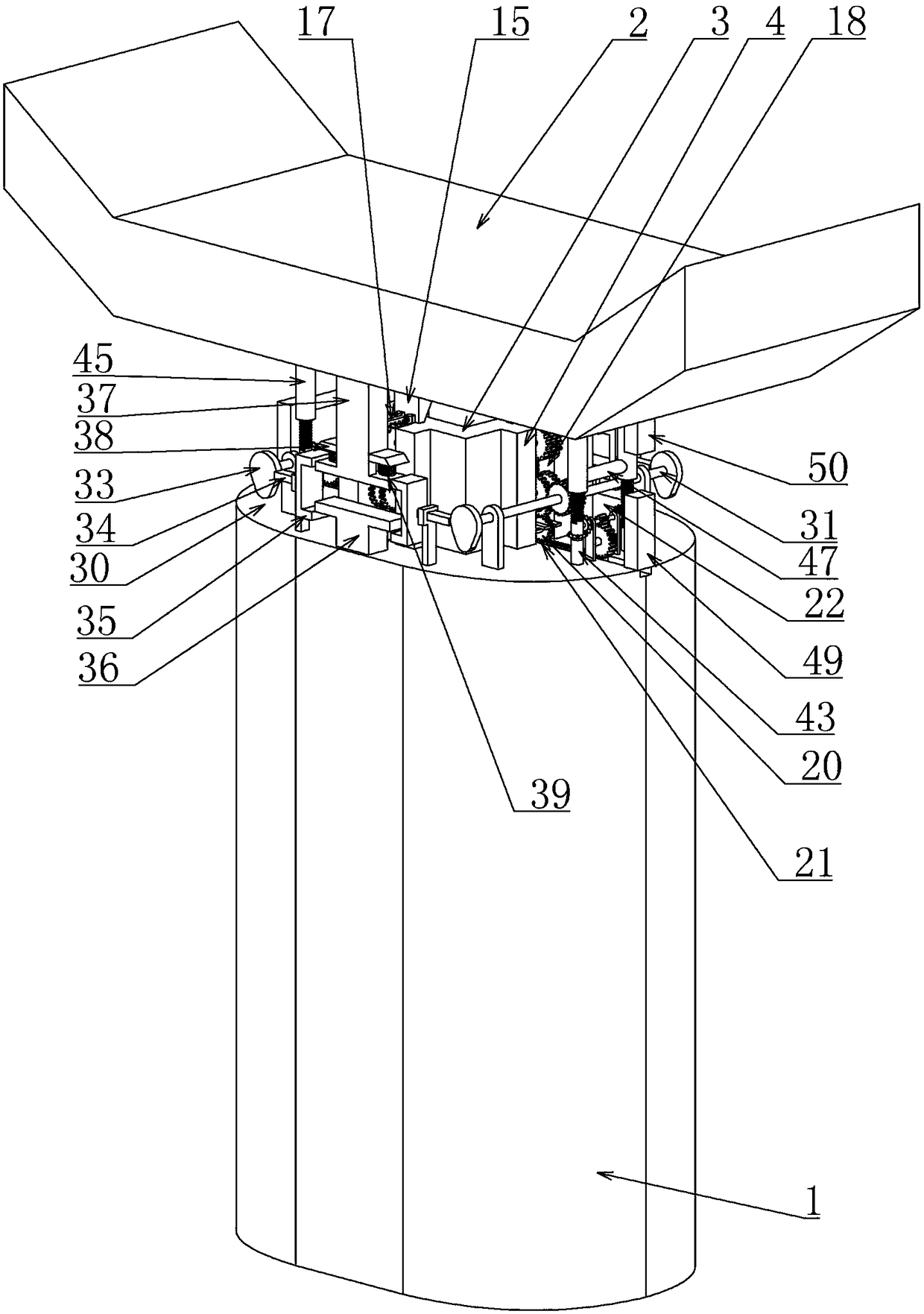

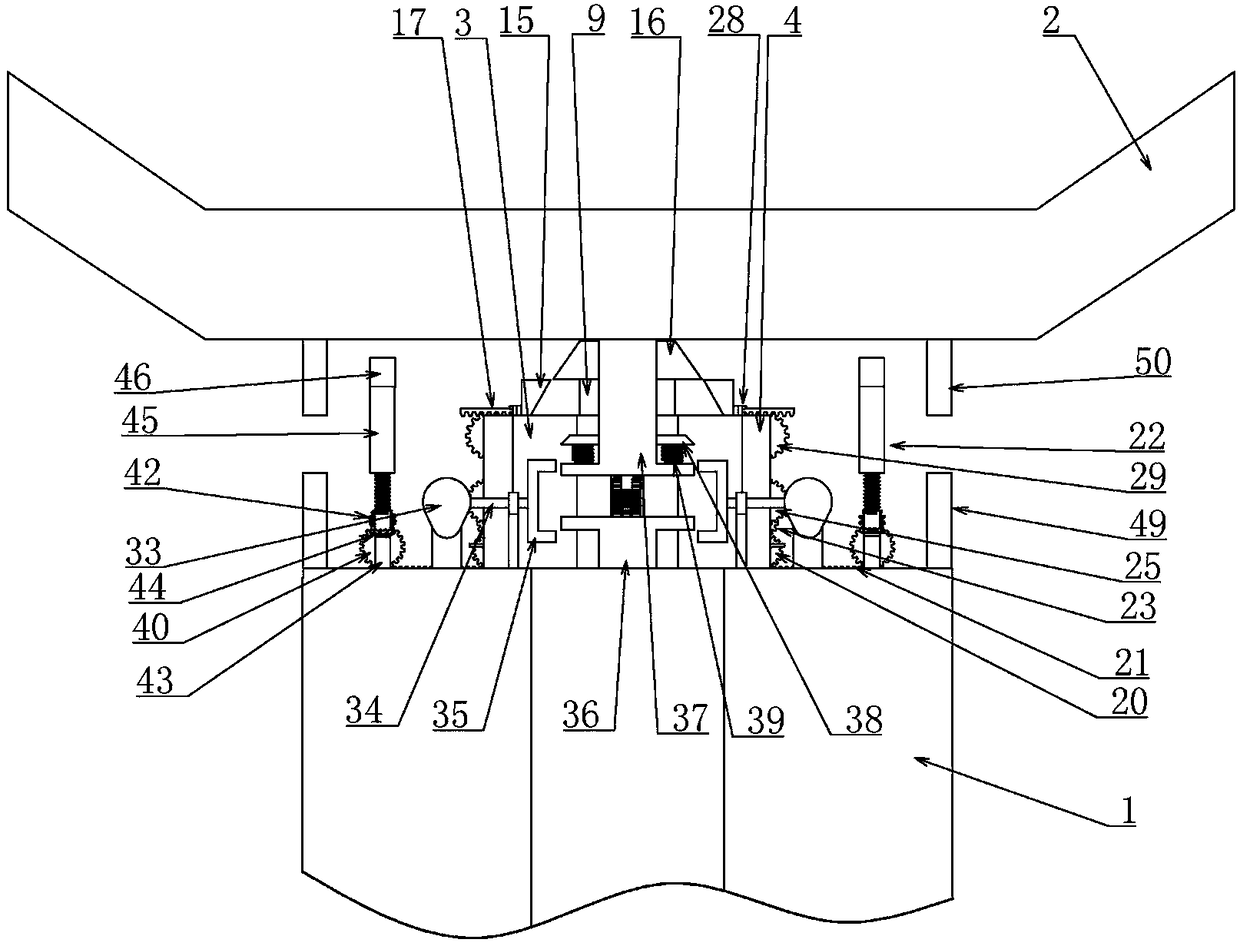

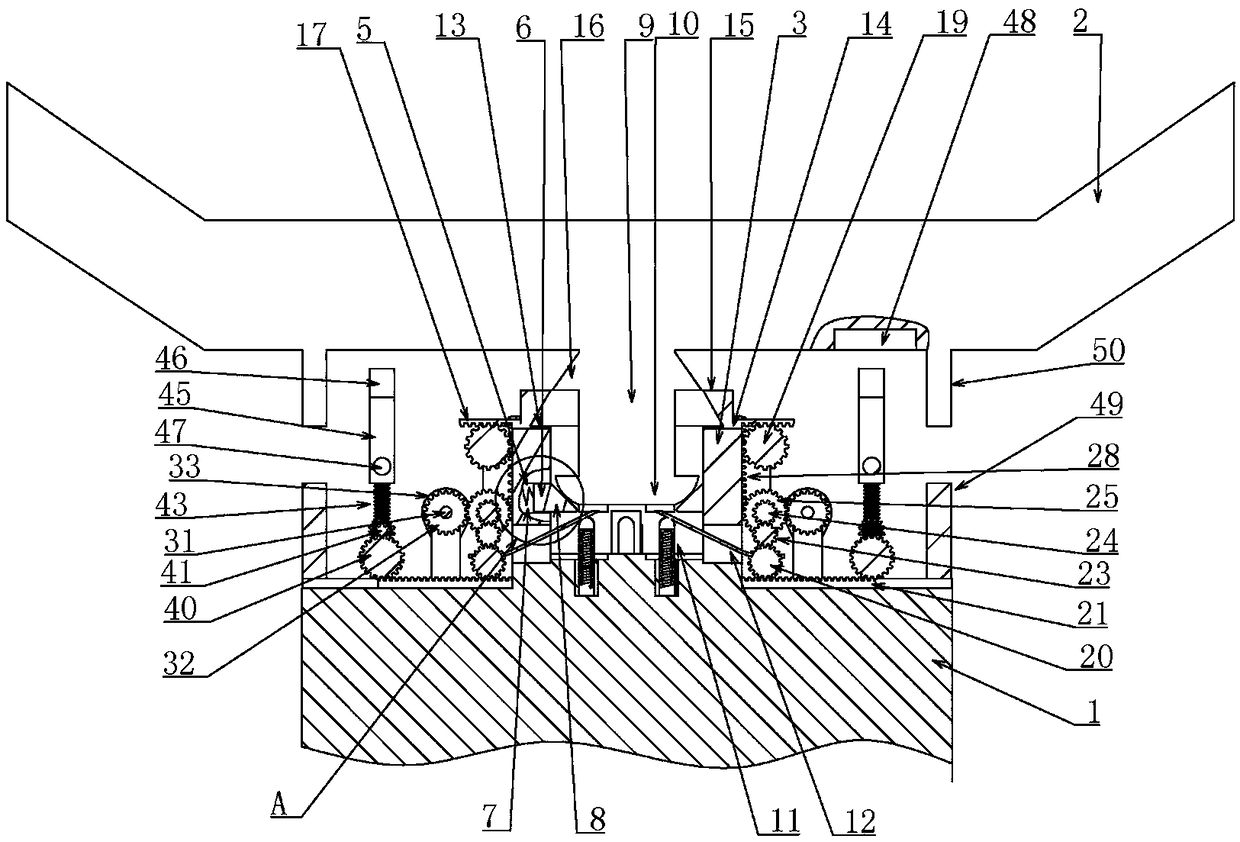

[0027] Embodiment one, combined with the attached Figure 1-9 , prefabricated concrete pier 1, including pier 1 and precast concrete cover beam 2, pier 1 and concrete cover girder 2 need to be assembled, pier 1 and prefabricated concrete cover girder 2 are prefabricated in advance, realizing the three-dimensional intersection operation , which ensures green construction and saves a lot of construction time. It is characterized in that the upper end of the bridge pier 1 is connected with a square support platform 3 opening upwards. Well, in preparation for the assembly with the cover beam 2, two sets of support plates 4 vertically parallel and symmetrically arranged are respectively connected to the outer walls around the support platform 3, and two sets of support plates 4 are respectively arranged on the inner walls around the support platform 3. A group of symmetrically arranged rectangular slideways 5, preferably, the position of the rectangular slideway 5 is selected as fa...

Embodiment 2

[0031] Embodiment two, on the basis of embodiment one, in conjunction with the attached Figure 1-9 , the transmission device 18 includes a first gear 23 placed above the drive gear 20 and rotatably connected between the two support plates 4, combined with the attached Figure 8 , the first gear 23 meshes with the driving gear 20, the driving gear 20 is driven by the rotation of the rotating plate 12, and the upper end of the first gear 23 is meshed with a second gear that is rotatably connected between the two supporting plates 4 24, the two sides of the second gear 24 are coaxially connected with a third gear 25 placed between the two support plates 4, the radius of the second gear 24 is smaller than the radius of the third gear 25, where the second gear 24 and The 3rd gear 25 not only plays the seat of transmission, also plays the effect of amplifying the stroke, expands the rotation stroke that drive gear 20 transmits, makes the stroke of its output larger, also includes o...

Embodiment 3

[0033] Embodiment three, on the basis of embodiment two, in conjunction with appended Figure 1-9 The vertical displacement limiting device 30 includes a rotating shaft 31 that is rotatably connected to the upper end of the pier 1 and extends along the front and rear directions. The rotating shaft 31 is coaxially connected with two sets of fifth gears 32, and the two sets of fifth gears 32 are respectively connected The two groups of third gears 25 on the same side mesh, and the fifth gear 32 is driven by the third gear 25 to provide power input for the rotating shaft 31,

[0034] The front and rear side shaft ends of the rotating shaft 31 are respectively coaxially connected with cams 33, combined with the attached Image 6 , the direction of the protruding end of the cam 33 should be set downwards, the cams 33 are respectively placed in the direction of the front and rear sides of the support platform 3, and the cam 33 is provided with a horizontal sliding connection in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com