Mechanical pressurized air-feeding equipment

An air supply equipment and mechanical pressurization technology, applied in mechanical equipment, liquid variable capacity machinery, machines/engines, etc., can solve the problems of not being able to meet the needs of fire protection, weak wind power, etc., and achieve simple structure, strong wind power, Suitable for large-scale promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

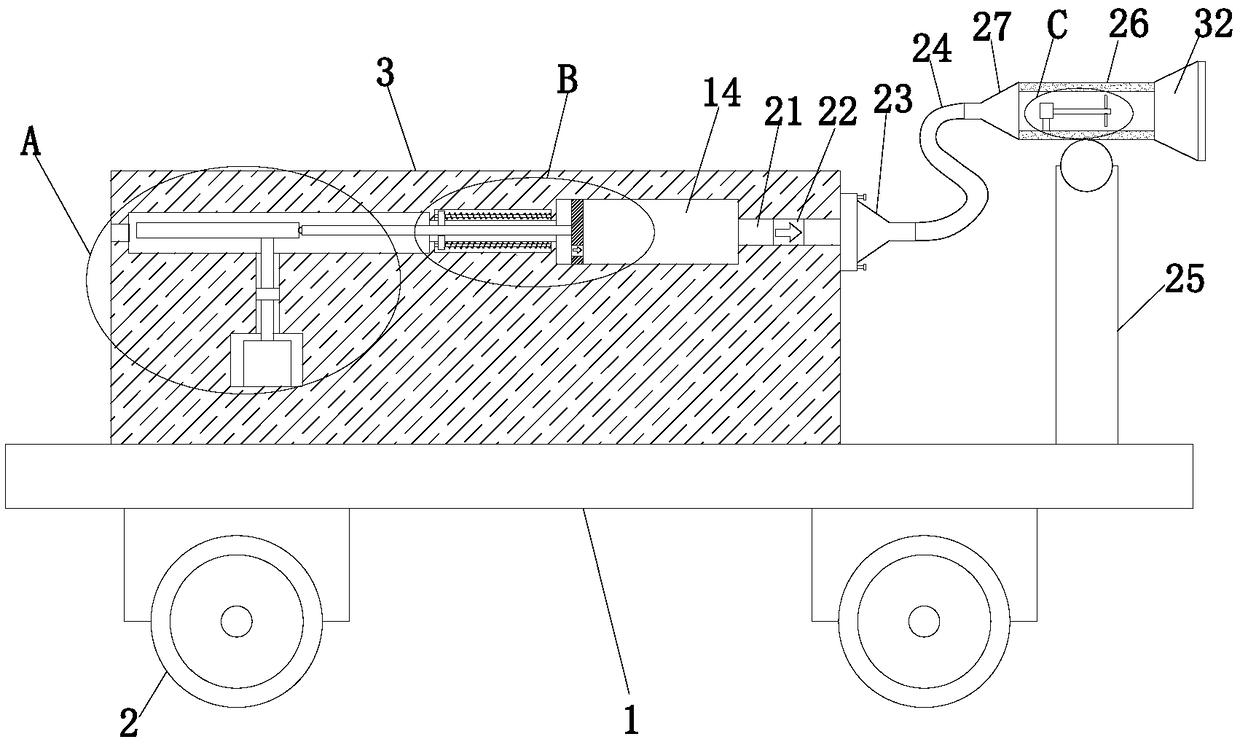

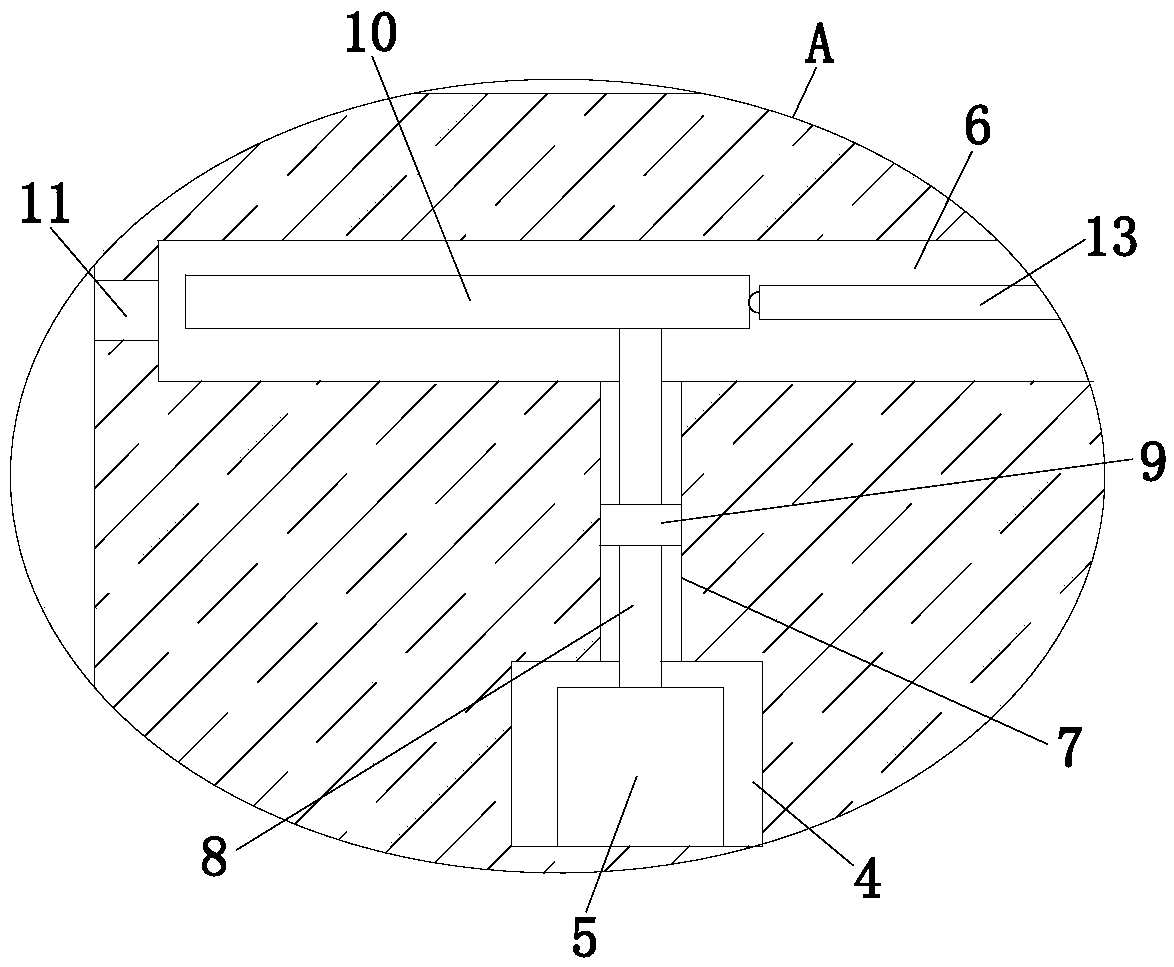

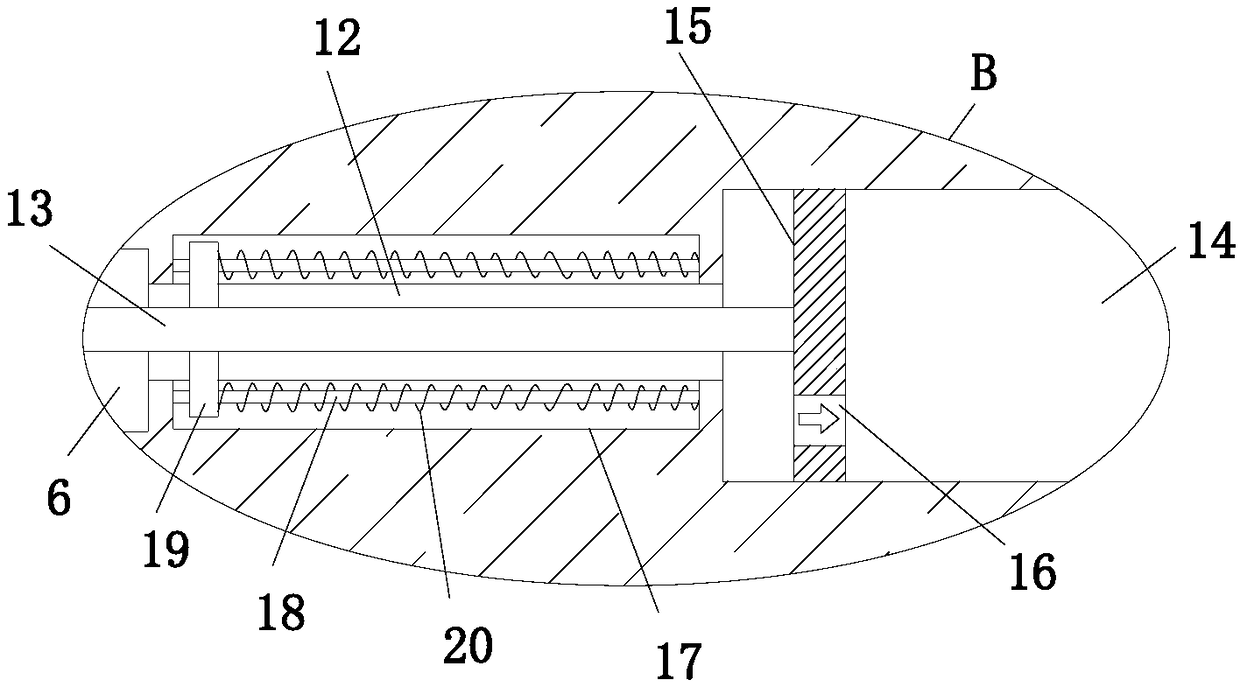

[0025] refer to Figure 1-5 In this embodiment, a mechanically pressurized air supply device is proposed, including a base 1, a plurality of rollers 2 are installed on the bottom side of the base 1, a mounting base 3 is fixedly installed on the top side of the base 1, and a mounting base 3 is provided on the mounting base 3. Motor chamber 4, the first motor 5 is fixedly installed in the motor chamber 4, the mounting base 3 is provided with a cavity 6, the cavity 6 is located above the motor chamber 4, and a through hole 7 is provided on the inner wall of the top side of the motor chamber 4, A rotating shaft 8 is installed in the through hole 7, the bottom end of the rotating shaft 8 extends into the motor cavity 4 and is fixedly connected with the output shaft of the first motor 5, and the top end of the rotating shaft 8 extends into the cavity 6 and a cam 10 is fixedly installed. A pressurized cavity 14 is opened on the base 1, and the pressurized cavity 14 is located on one ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com