Detection device for polyethylene ball valve

A technology of testing equipment and polyethylene balls, which is applied in the testing of mechanical parts, testing of fluid tightness, testing of machine/structural parts, etc., can solve problems such as poor torque accuracy, and achieve improved production efficiency, simple operation, and automation high degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

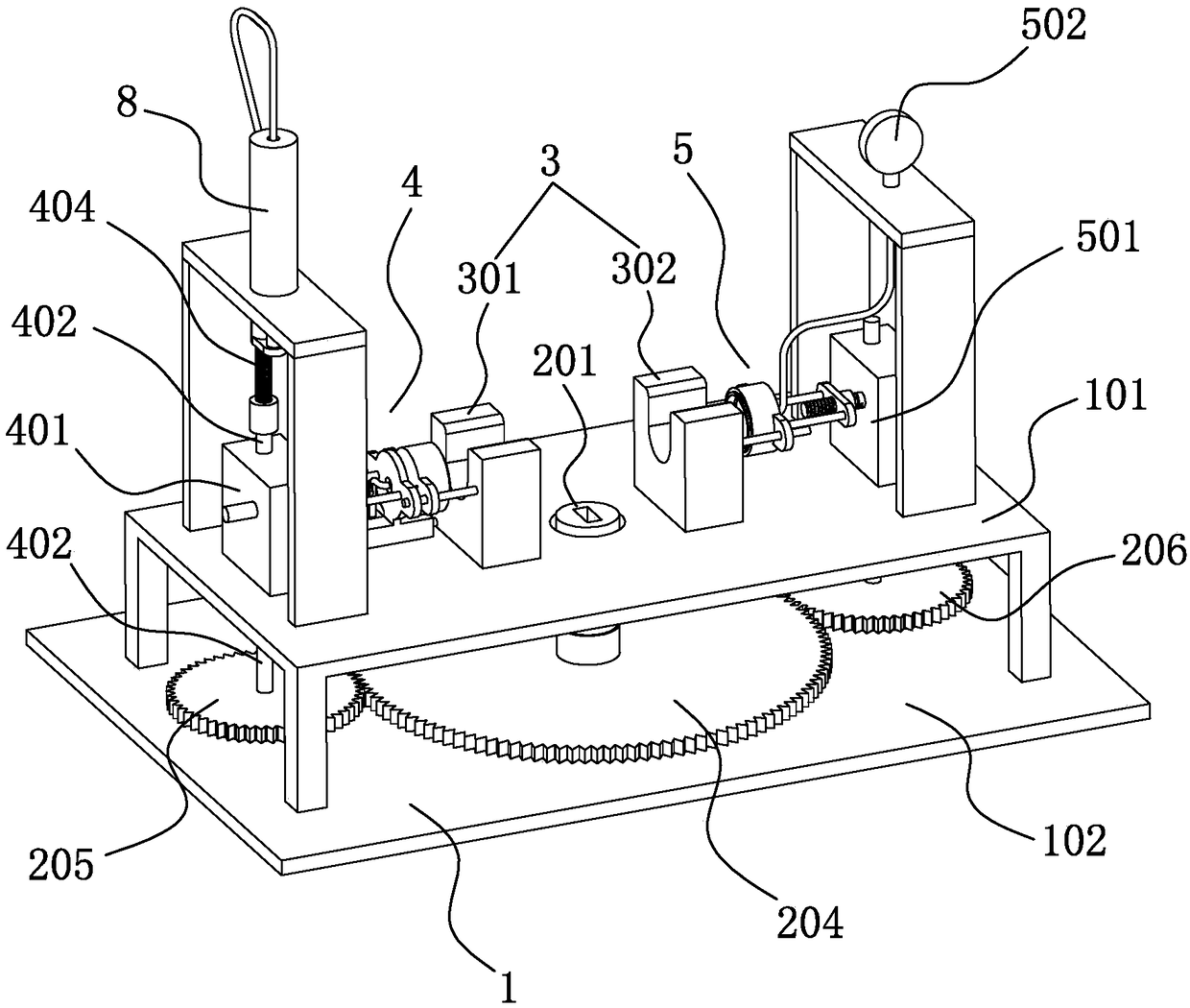

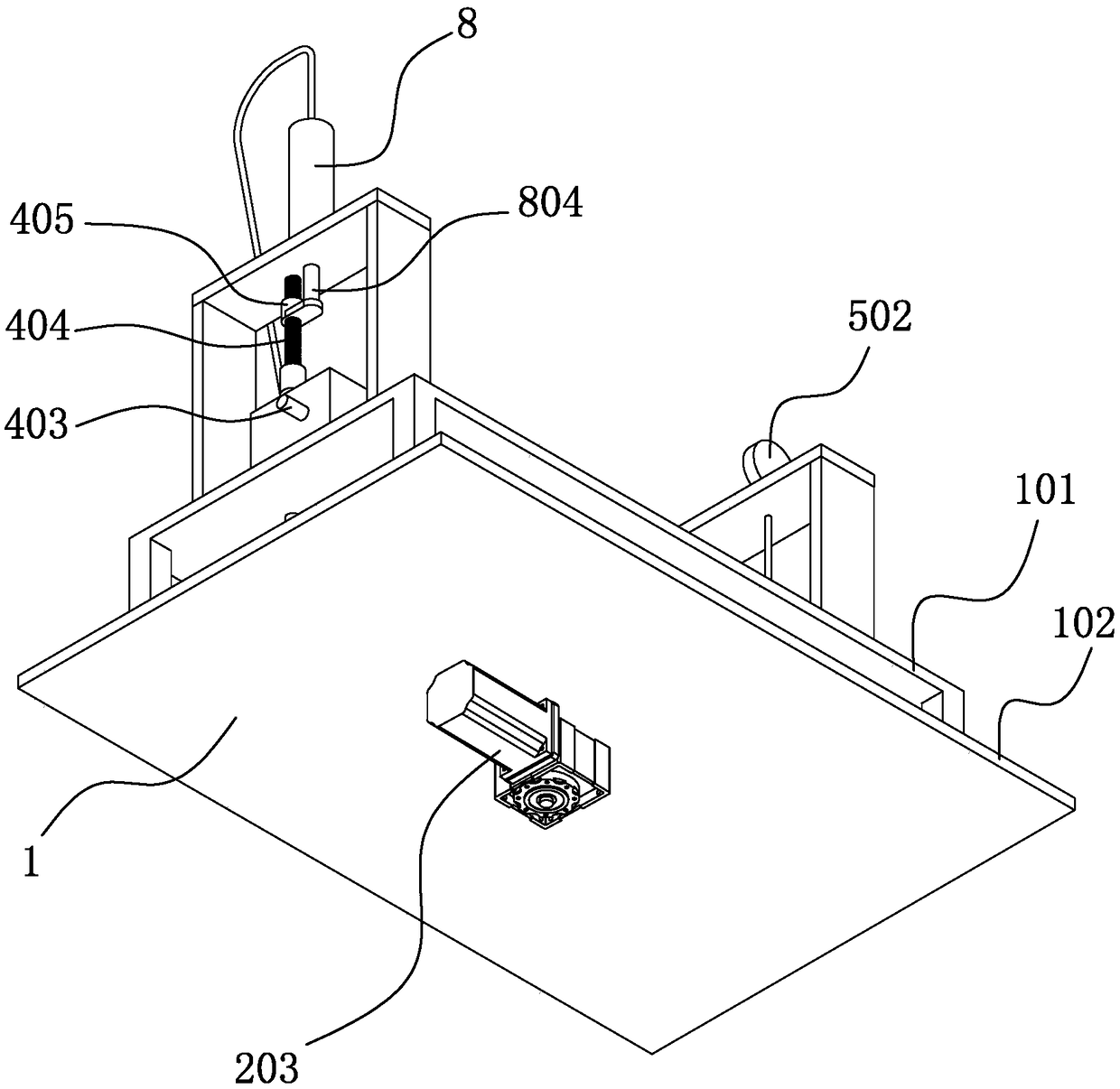

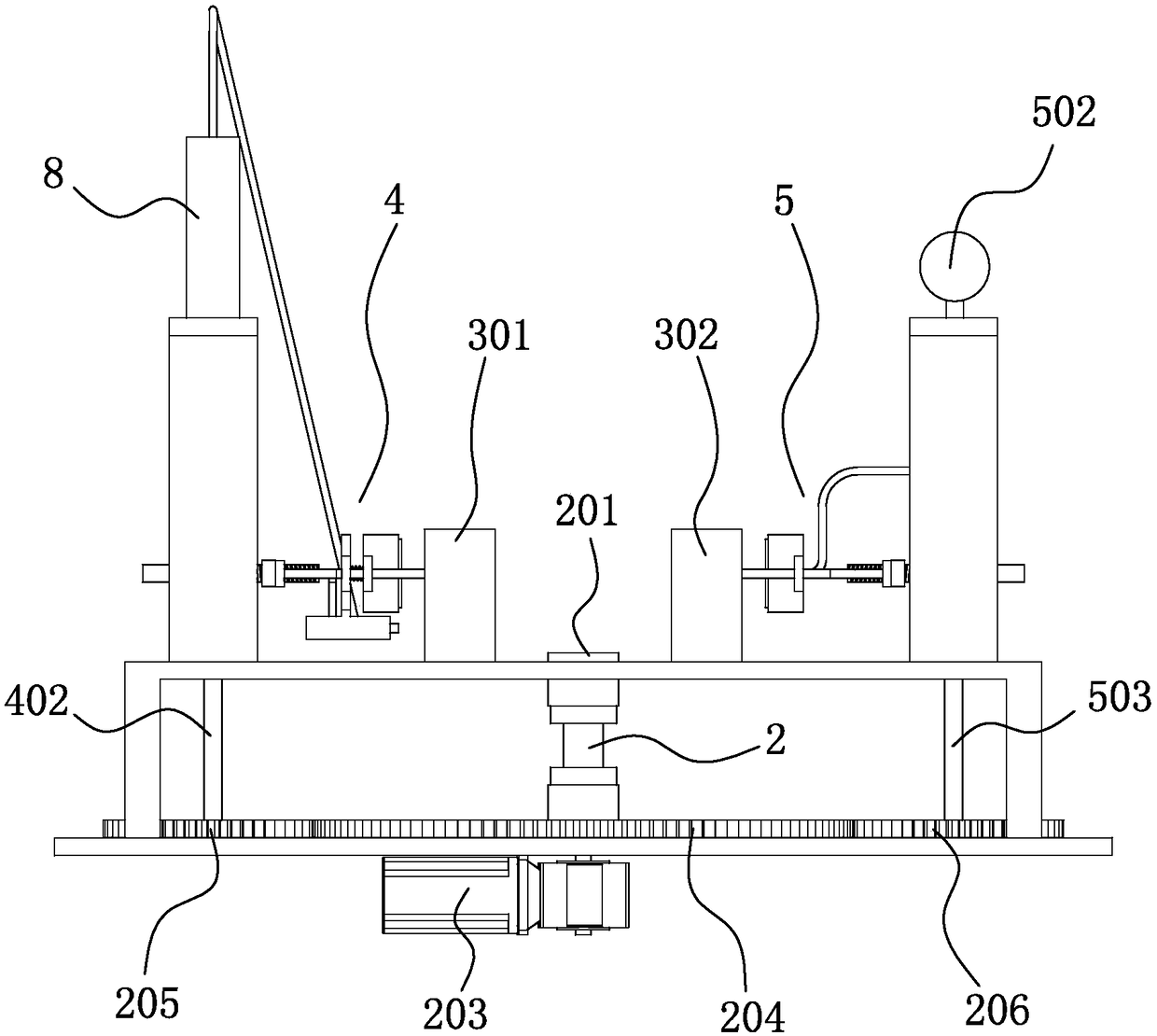

[0029] A kind of detection equipment of polyethylene ball valve, see Figure 1 to Figure 16 , including at least a base 1, a torque sensor 2 and a motor 203, the base 1 includes an upper base plate 101 and a lower base plate 102, the upper base plate 101 is located above the lower base plate 102 and is fixed by several columns between the upper base plate 101 and the lower base plate 102; The torque sensor 2 is located between the upper base plate 101 and the lower base plate 102, the central axis of the torque sensor 2 is longitudinal, the lower end of the torque sensor 2 is driven to rotate by a motor 203, and a valve stem connecting block 201 is fixed at the upper end, the valve stem connecting block The top of 201 is provided with a bar-shaped groove 202 that can be engaged with the ball valve stem 901. The upper bottom plate 101 is provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com