Video technology based real time stockyard airborne dust detection and intelligent watering dust depositing device and method

A technology of real-time detection and video technology, which is applied in the direction of program control in TV, closed-circuit television system, sequence/logic controller, etc. It can solve the problem of increasing the moisture content of stockpiled materials, too little watering and dust prevention effect, and affecting the quality of materials and other issues, to achieve the effect of saving hydropower resources and transport capacity resources, approximately uniform location distribution, and saving hydropower resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

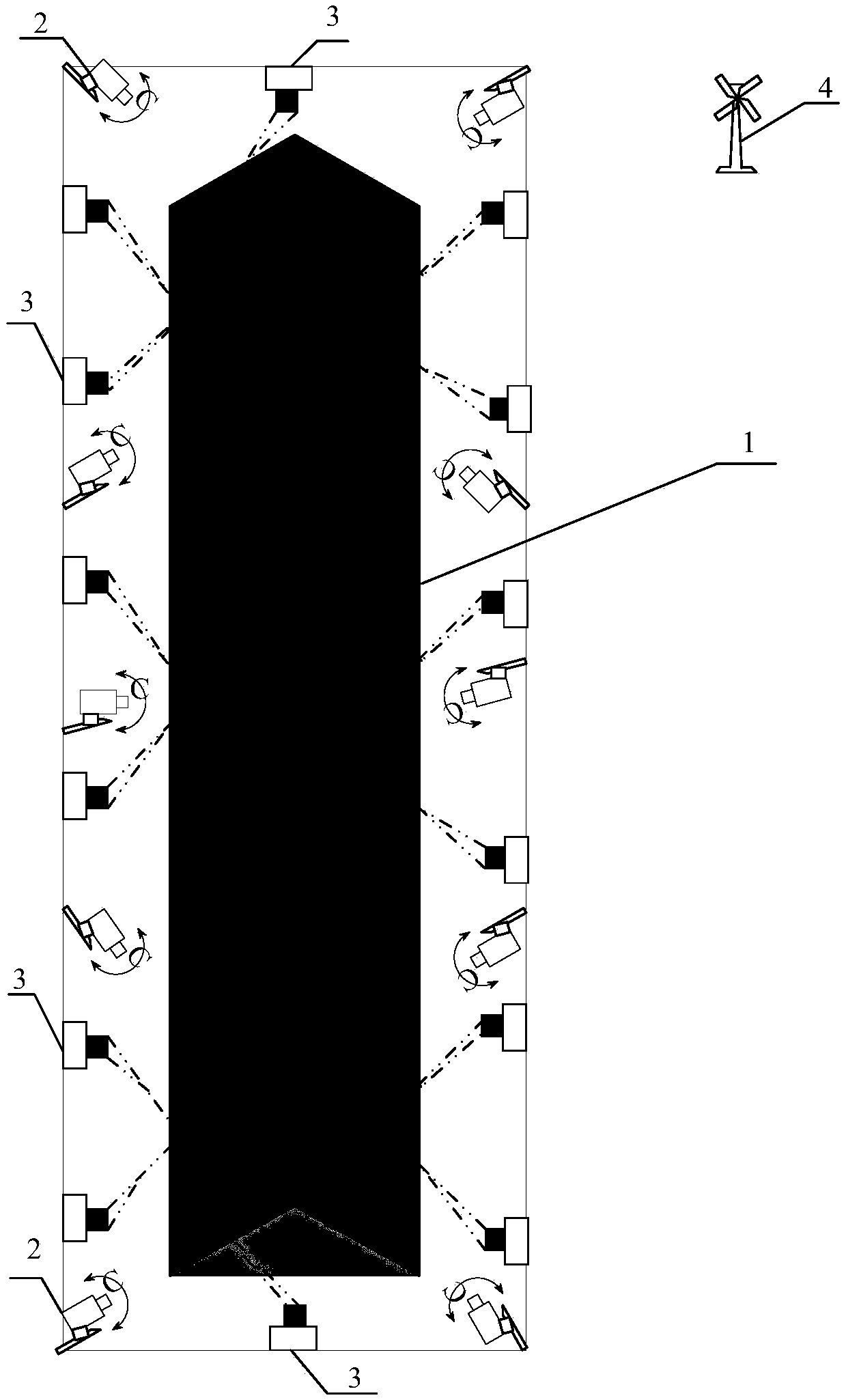

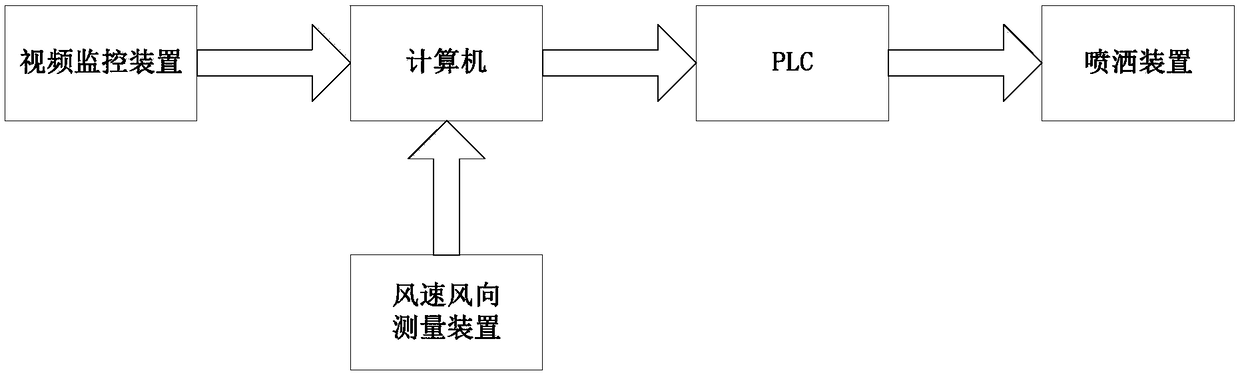

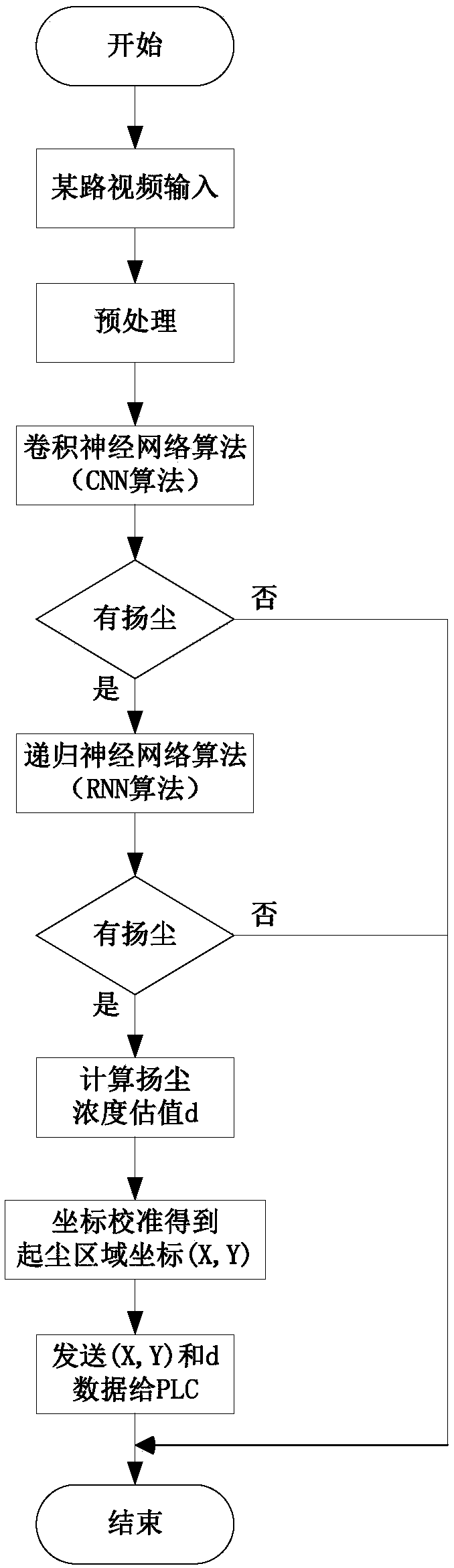

[0036] Such as Figure 1-Figure 2 As shown, a video technology-based real-time detection of dust in a stockyard and an intelligent sprinkler and dust reduction device includes a video monitoring device 2, a wind speed and direction measuring device 4, a PLC, a spraying device 3 and a computer.

[0037]The video monitoring device 2 is specifically set as a high-resolution industrial monitoring camera, and is evenly installed around the stockyard 1, and can carry out real-time video data collection to all dust-generating areas of the stockyard 1. The video monitoring device 2. Communicate with the computer to transmit the video surveillance data to the computer in real time.

[0038] The wind speed and direction measuring device 3 is installed on the high position of the edge of the storage yard 1, which can effectively and accurately measure the real-time wind speed and wind direction of the storage yard, and is equipped with a wireless transmission module to facilitate real-ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com