External grinding multiparameter integrated quality monitoring device and method

A technology of cylindrical grinding and quality monitoring, which is applied to the parts of grinding machine tools, grinding/polishing equipment, and machine tools designed for grinding the rotating surface of workpieces, etc., to expand the monitoring range, reduce the quantity and rework rate, and improve Effect on Yield and Production Efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

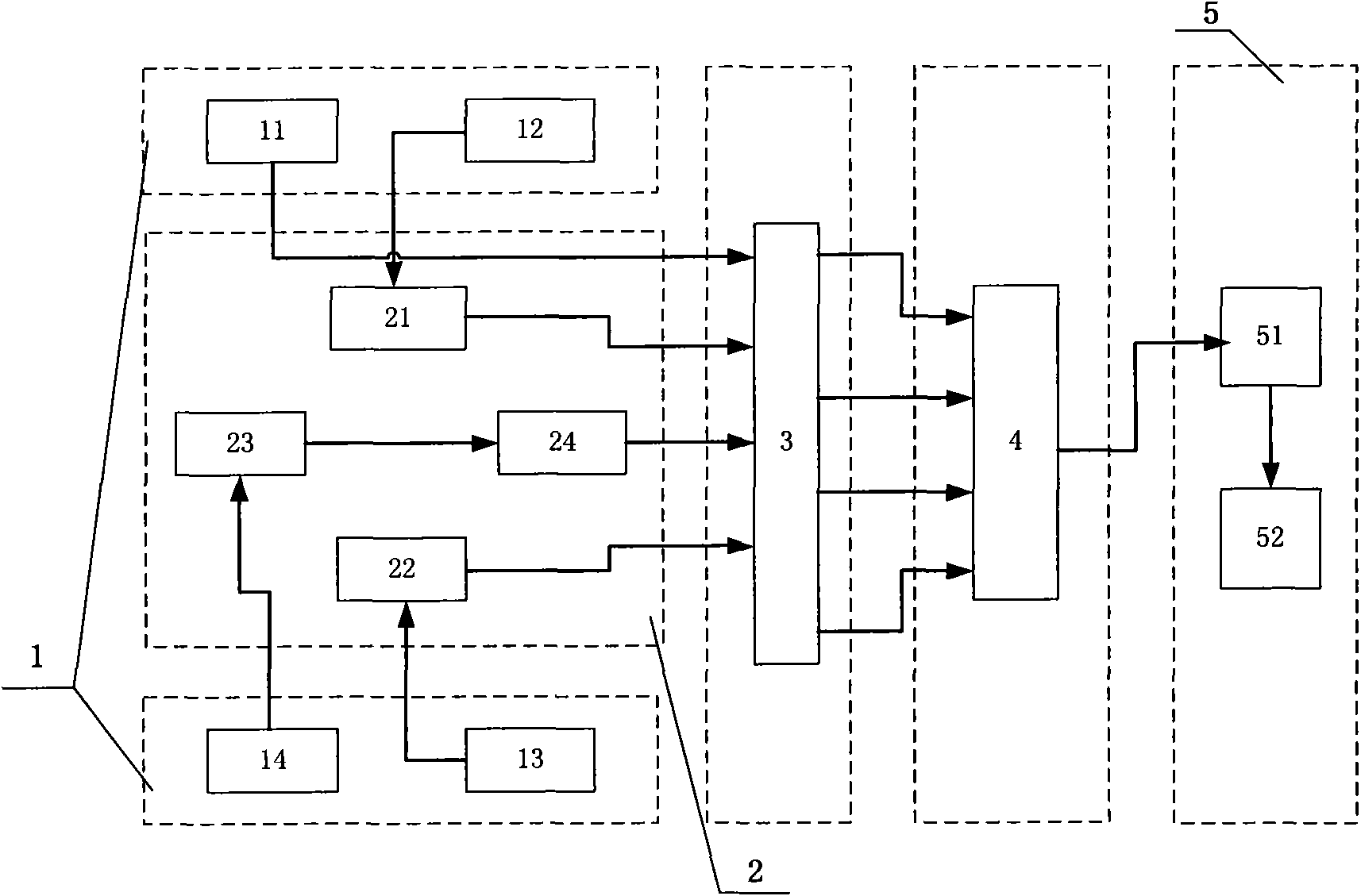

[0022] like figure 1 As shown, the structure of the cylindrical grinding multi-parameter integrated quality monitoring device of the present invention mainly includes the following parts:

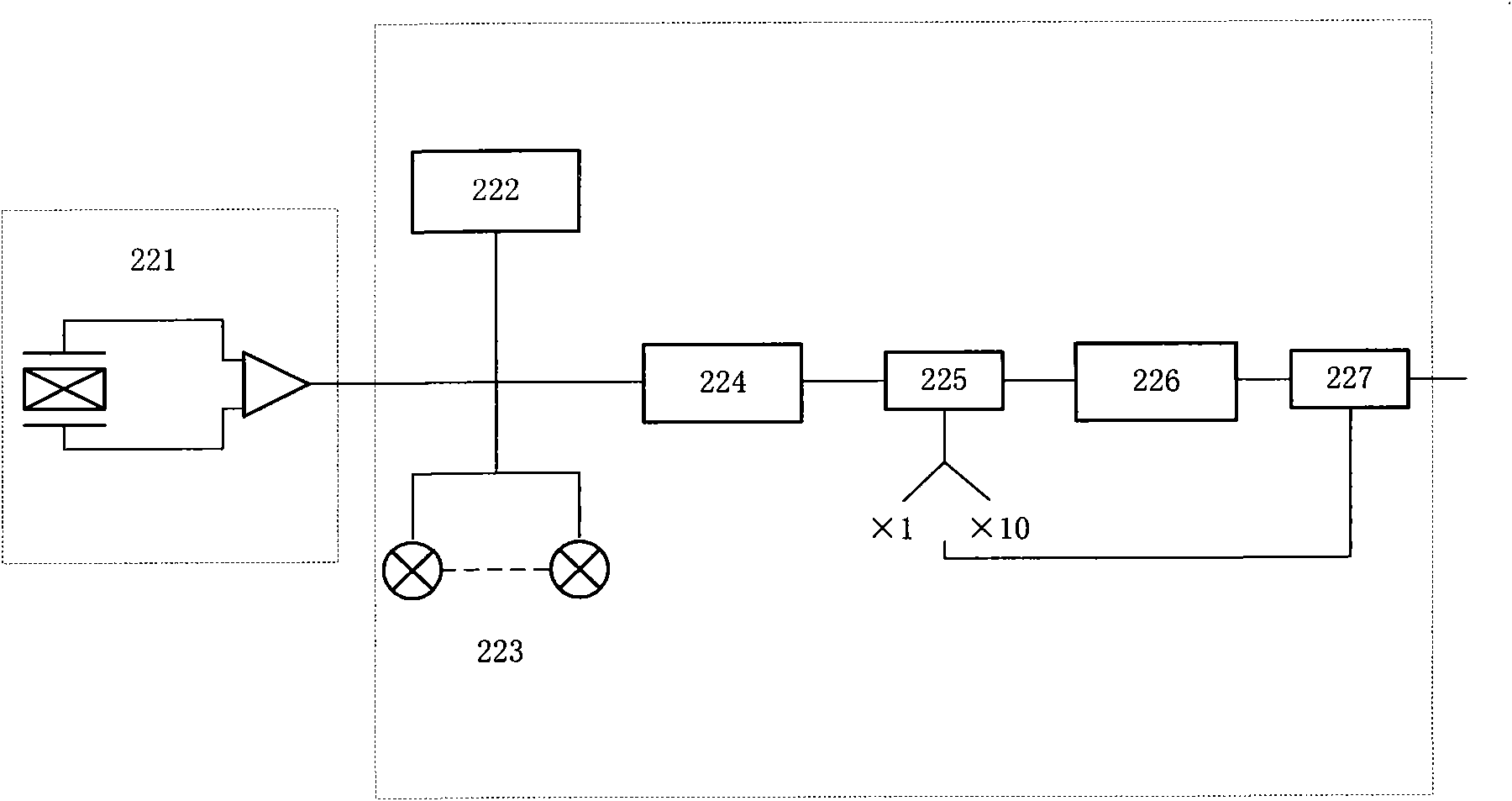

[0023] 1) Signal acquisition device 1: includes four sets of sensors, namely:

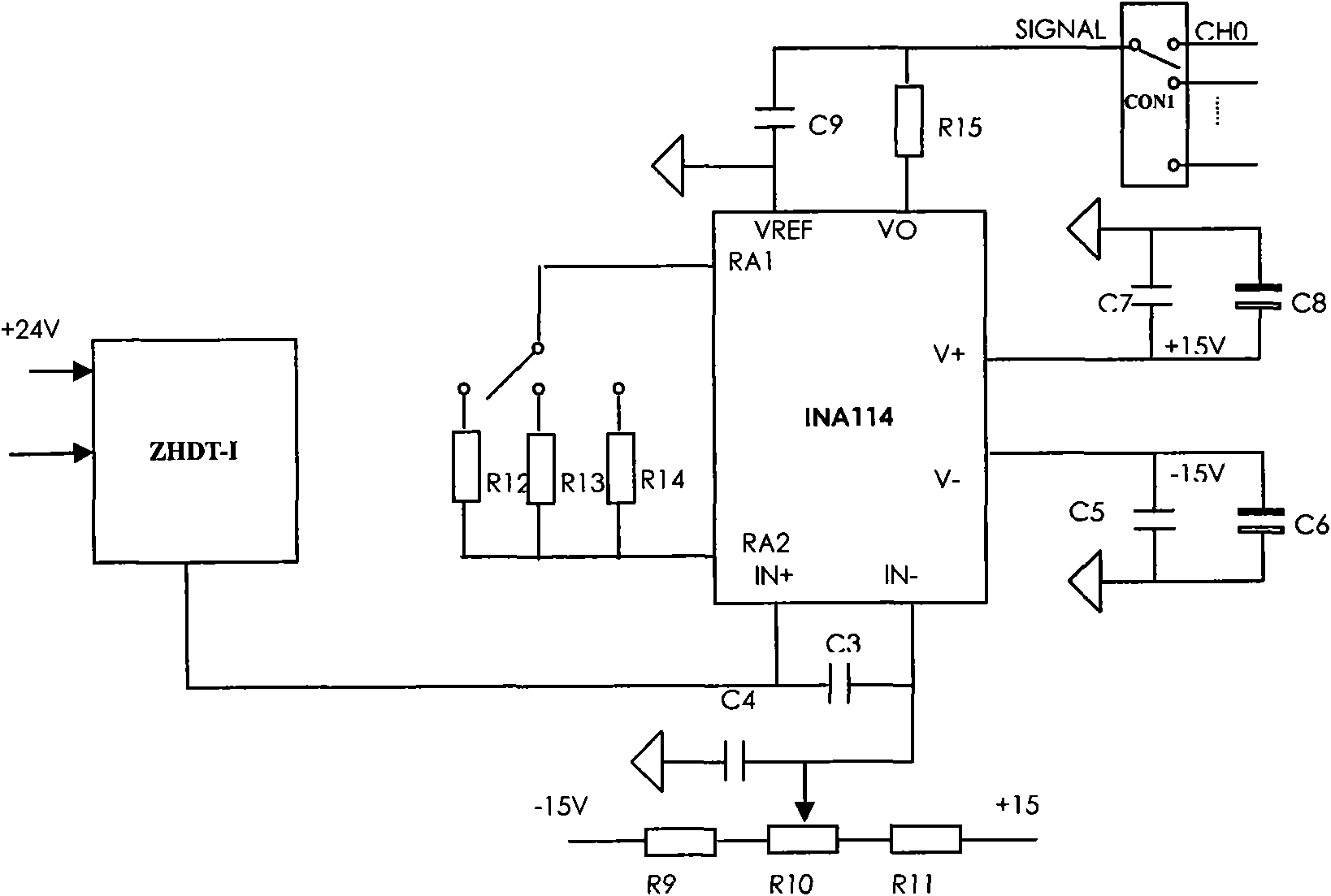

[0024] The displacement sensor 12, the grinding wheel feed displacement sensor used to measure the radial feed displacement of the grinding head, can adopt the LVDT differential pressure variable displacement sensor DG09 produced by Zhongyuan Measuring Instruments. The measuring range of the differential pressure variable displacement sensor is ±5mm, the total stroke is 11mm, the front stroke is 5.1-5.3mm, the linearity error is ±0.5%, the repeatability error is 0.2μm, and the measuring force is 0.7-0.9N. The output end of the displacement sensor is connected to the acquisition board 21 in the filtering and amplifier 2 .

[0025] The power sensor 11 is the main motor power sensor used to measure the power of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com