Patents

Literature

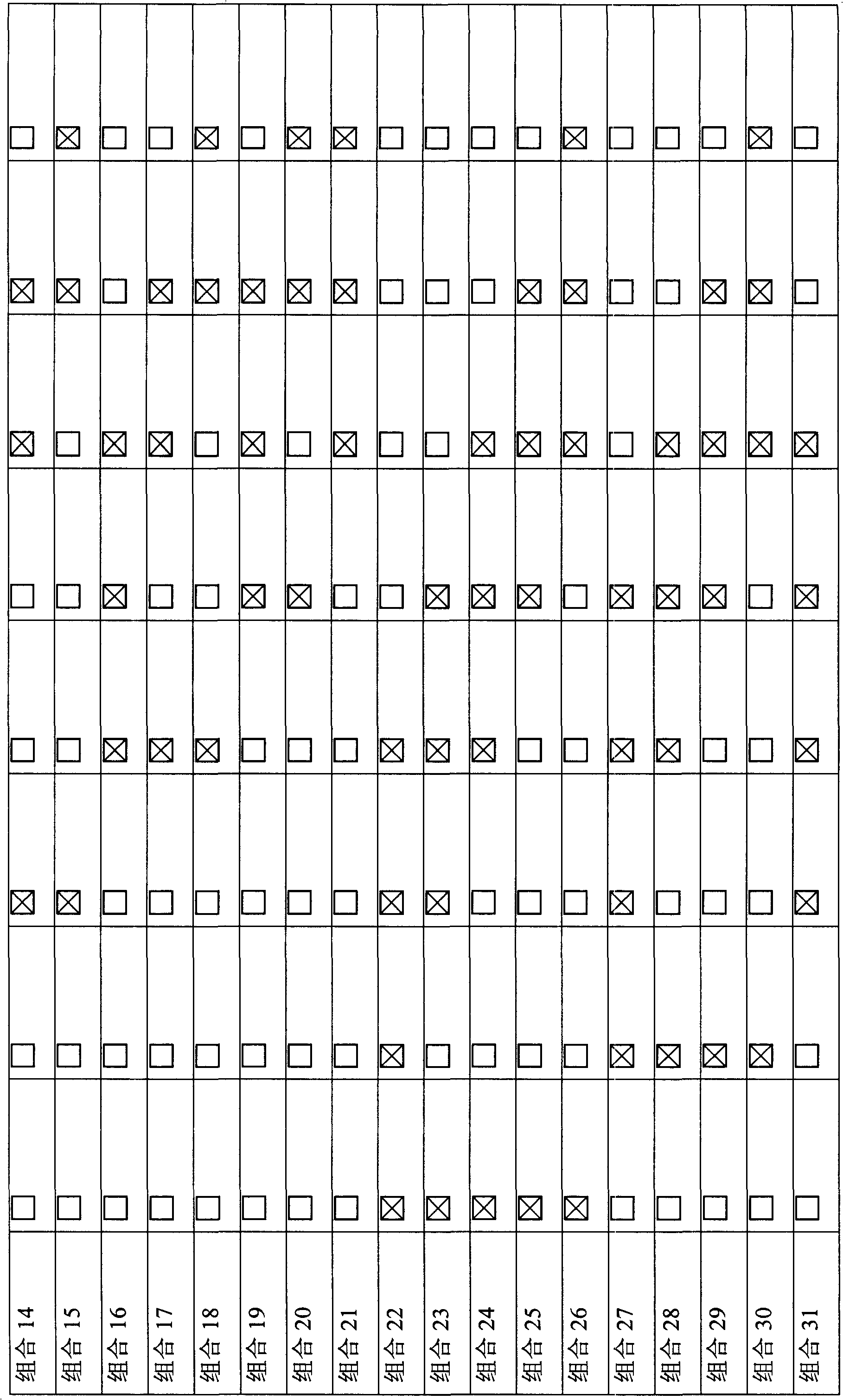

31results about How to "Improve quality monitoring" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

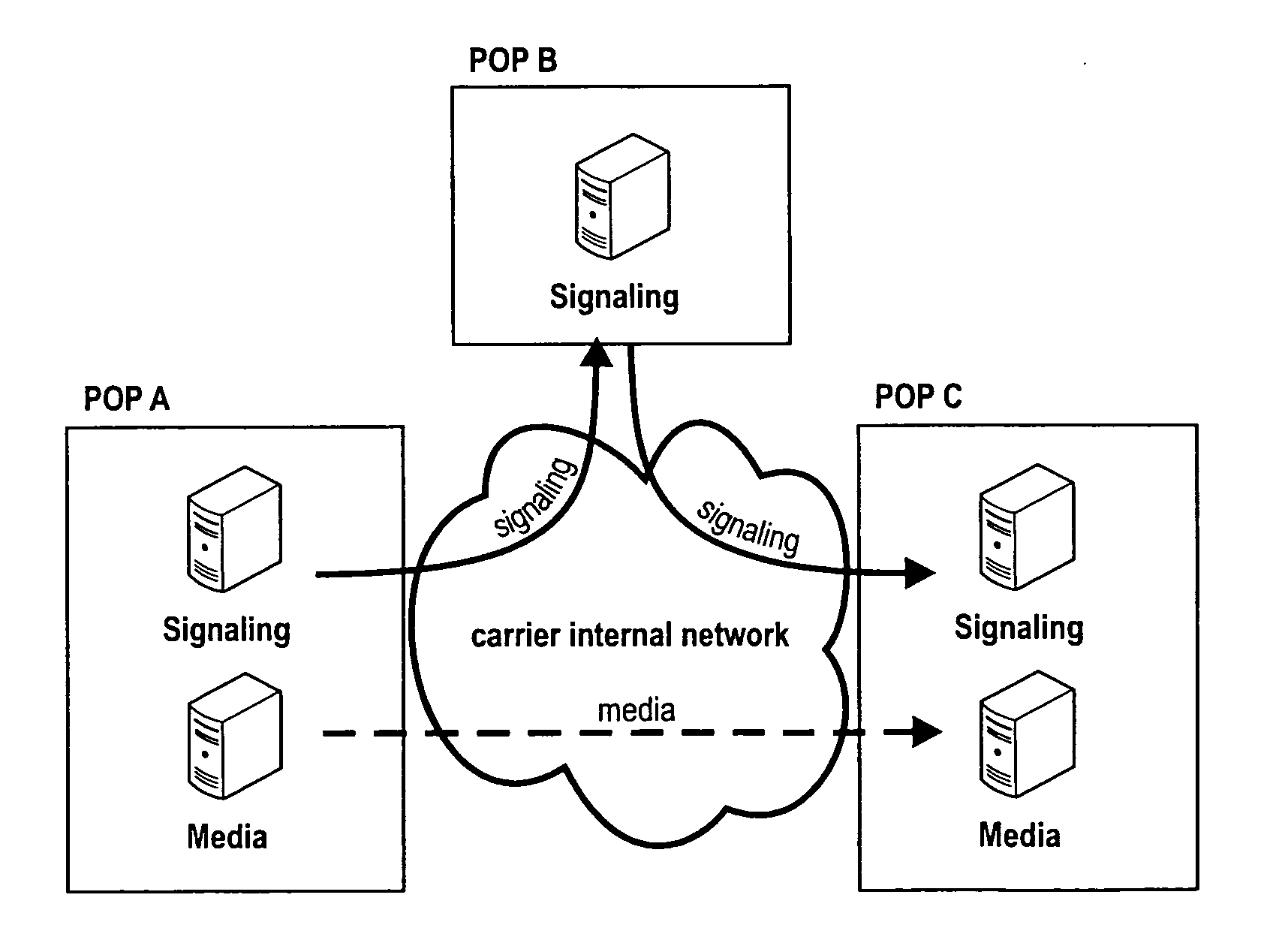

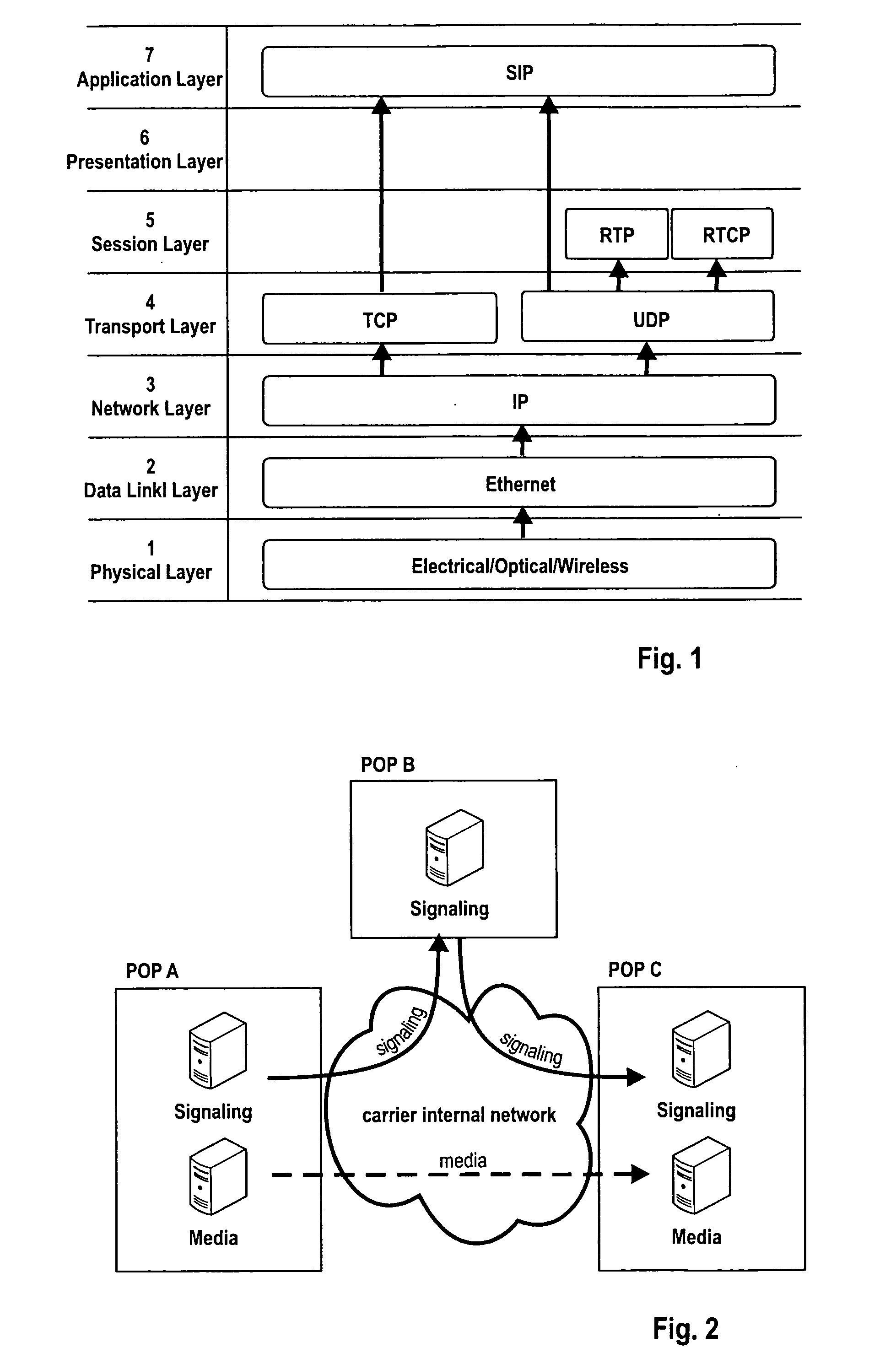

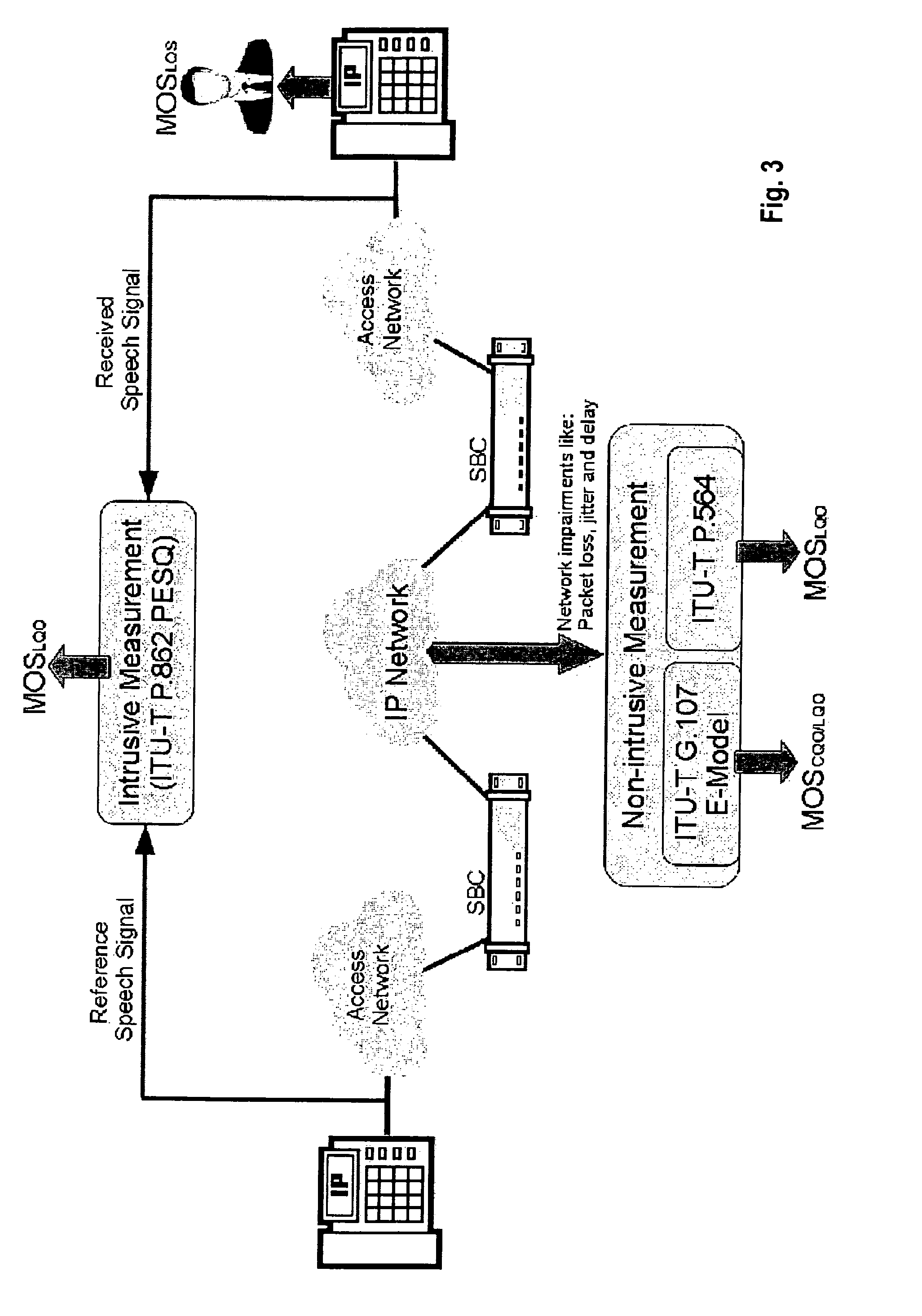

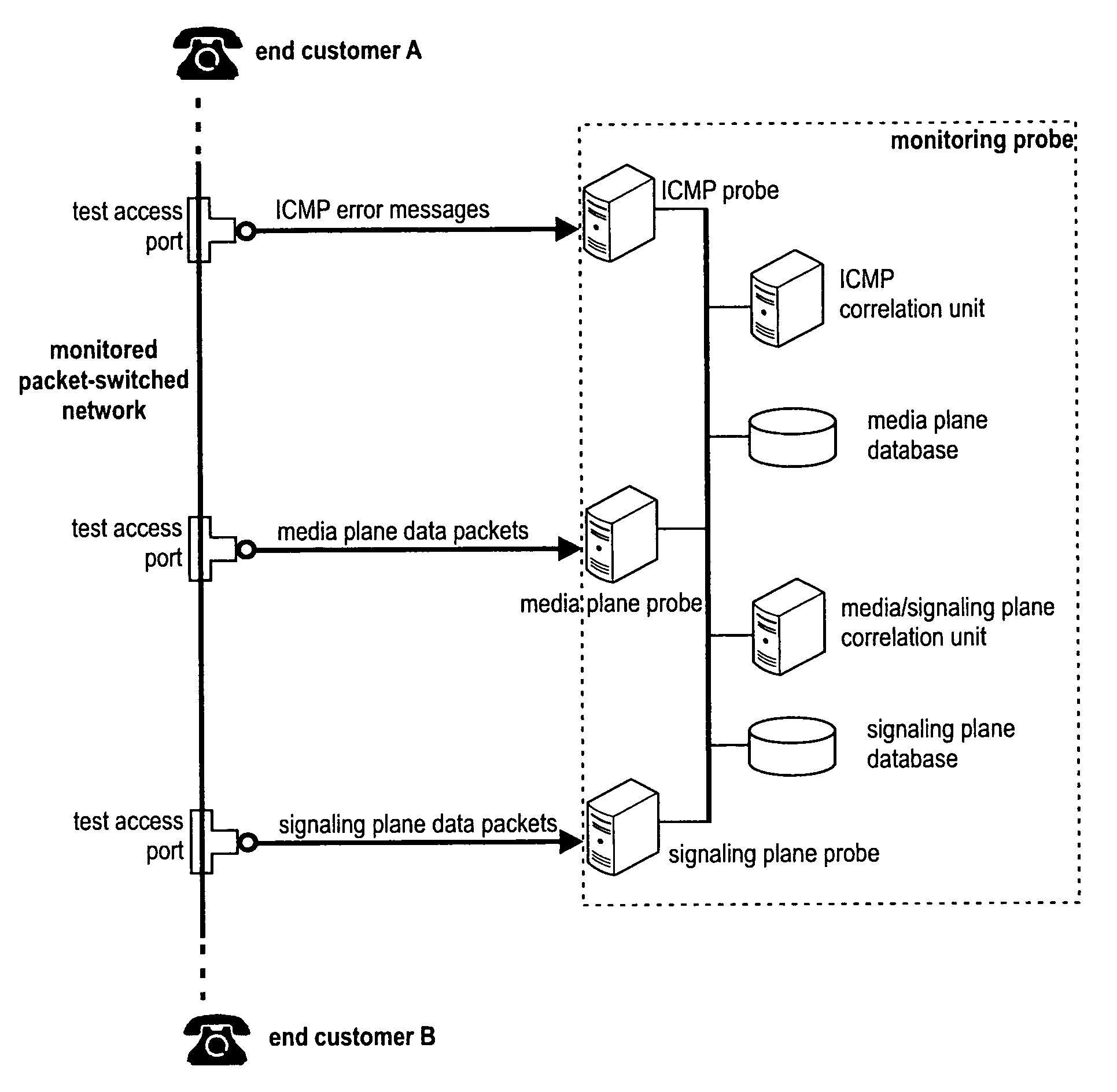

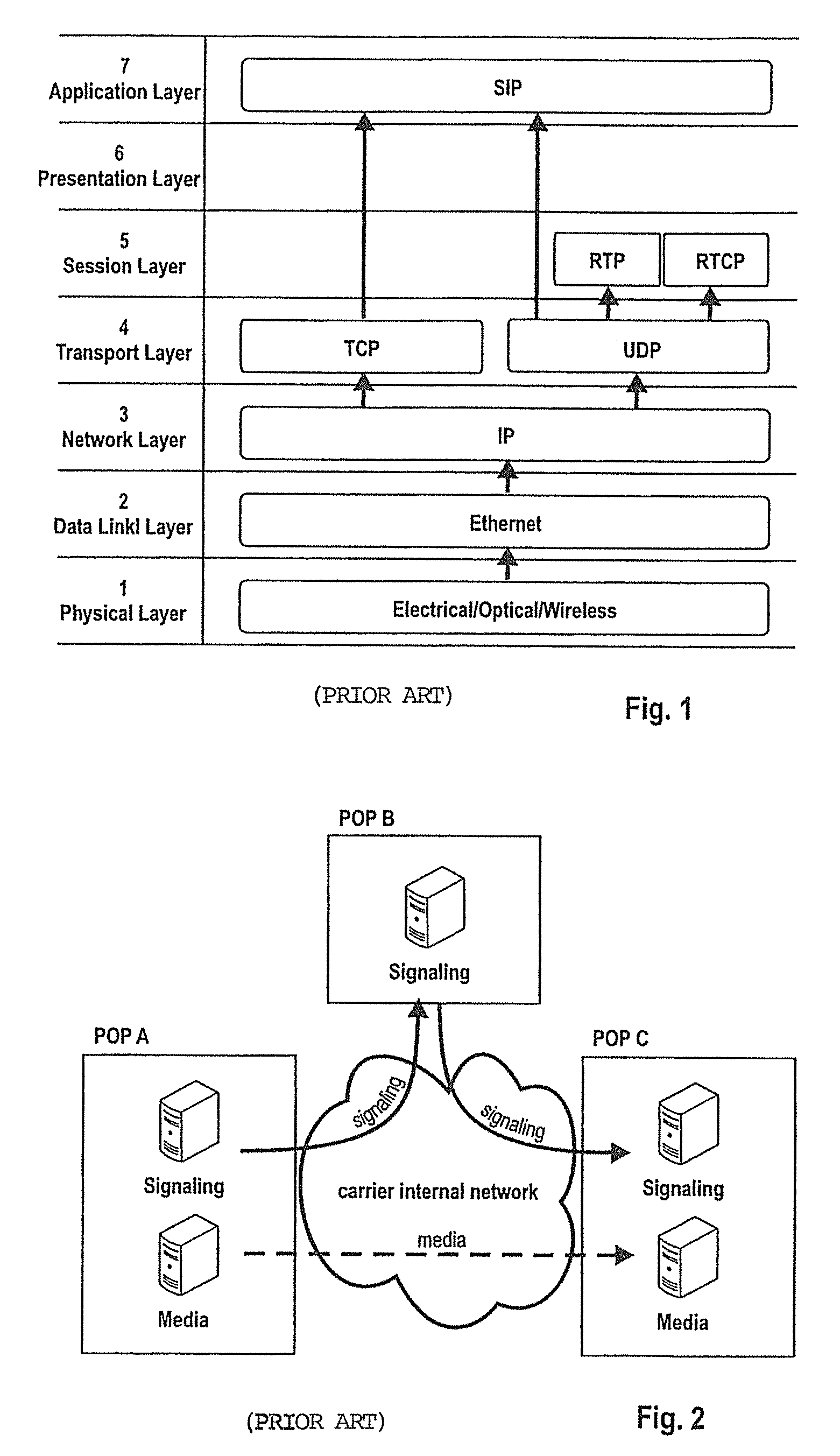

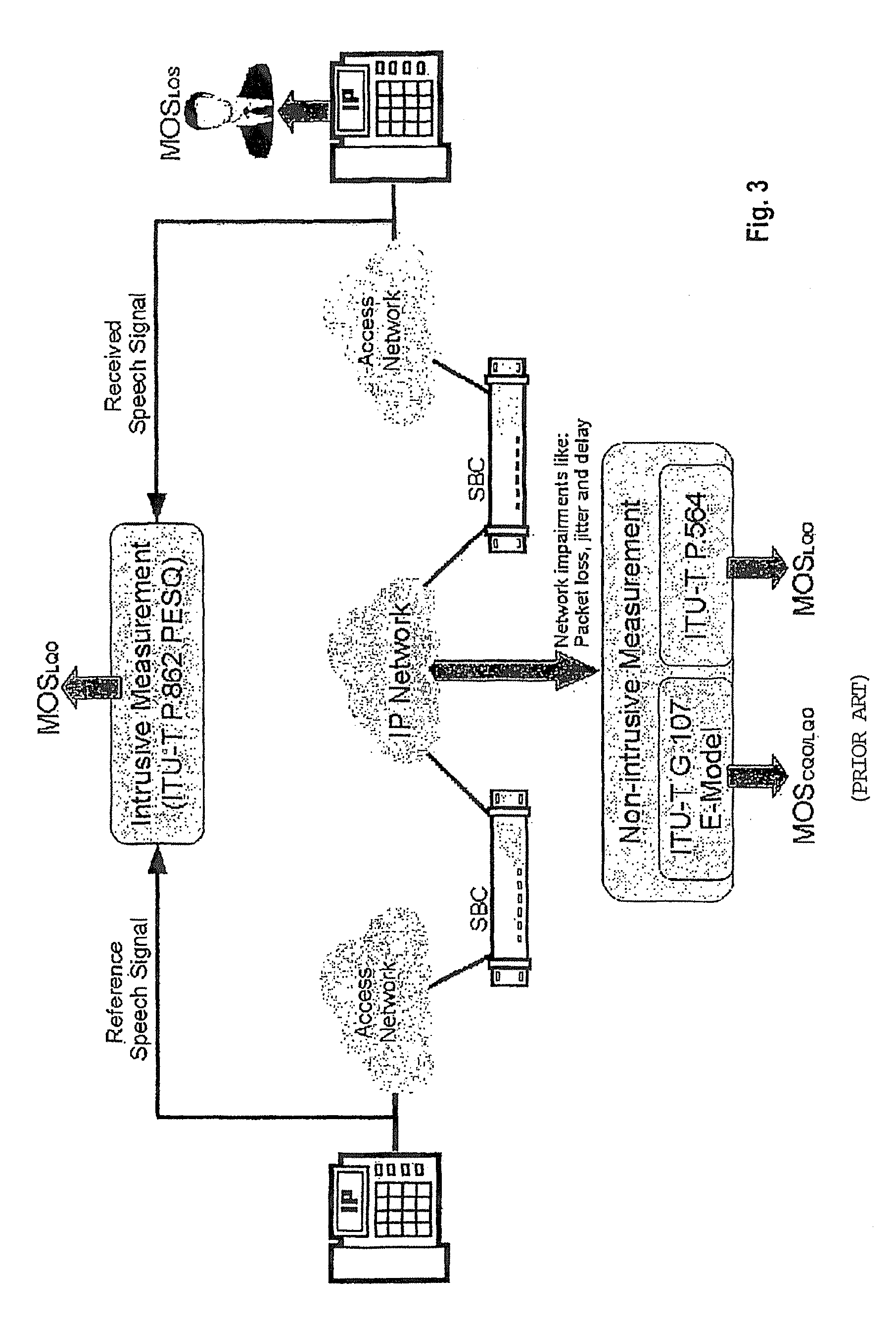

VOIP quality measurement enhancements using the internet control message protocol

ActiveUS20130329595A1Improve quality monitoringError preventionTransmission systemsCommunication endpointTTEthernet

This invention relates to a method for enhancing the quality information of a VoIP session by deducting information from received ICMP messages, in addition to quality information already collected from media streams and / or signaling streams of the same VoIP session. ICMP messages passing on the network link are monitored and correlated with an existing and ongoing VoIP session, i.e. media stream, already monitored by a media plane monitoring unit. A data record for the media stream(s) is expanded with information from the ICMP messages, thus giving a better and more complete quality feedback of the media stream reception at the two communication endpoints.

Owner:VOIPFUTURE

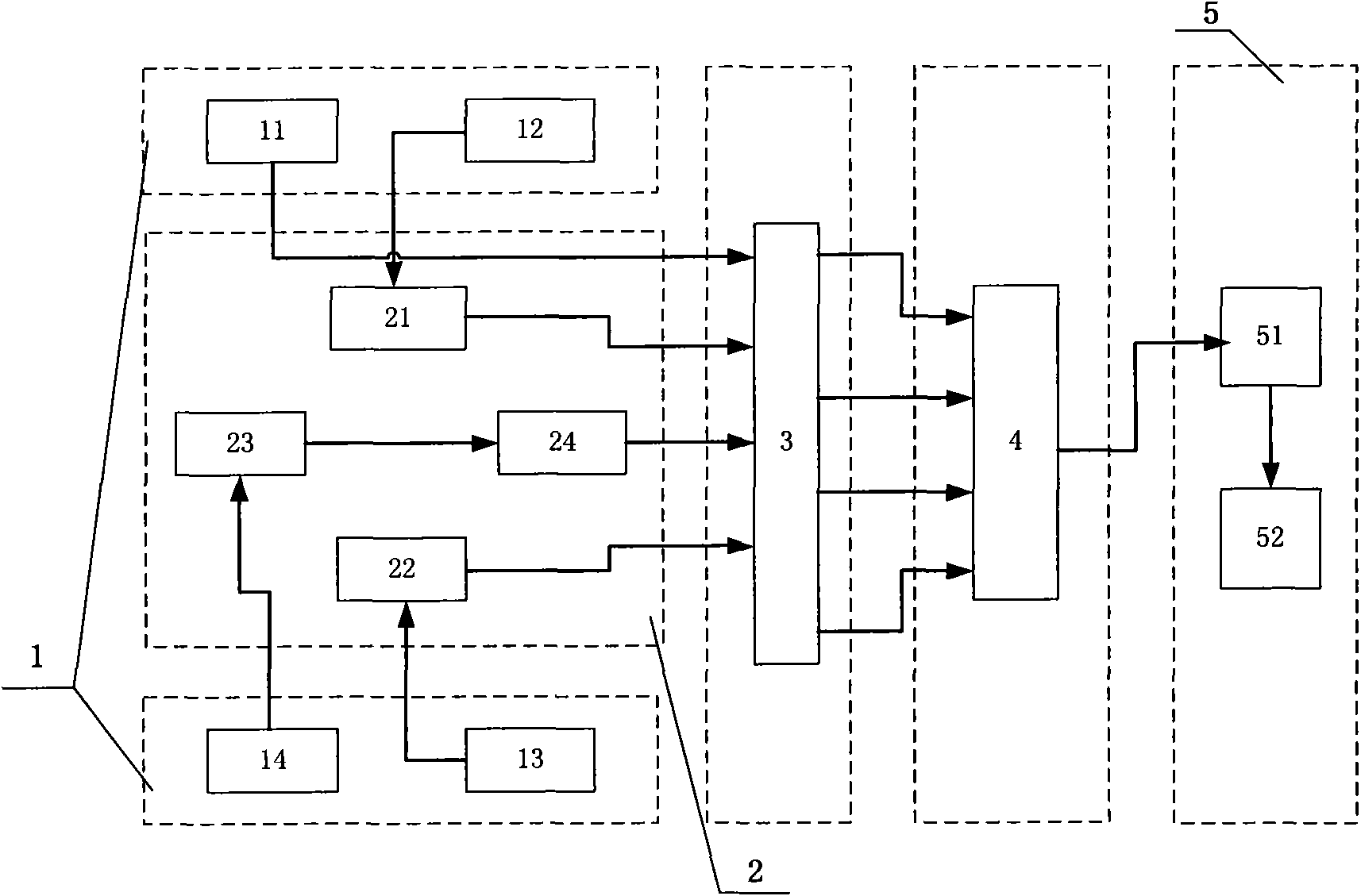

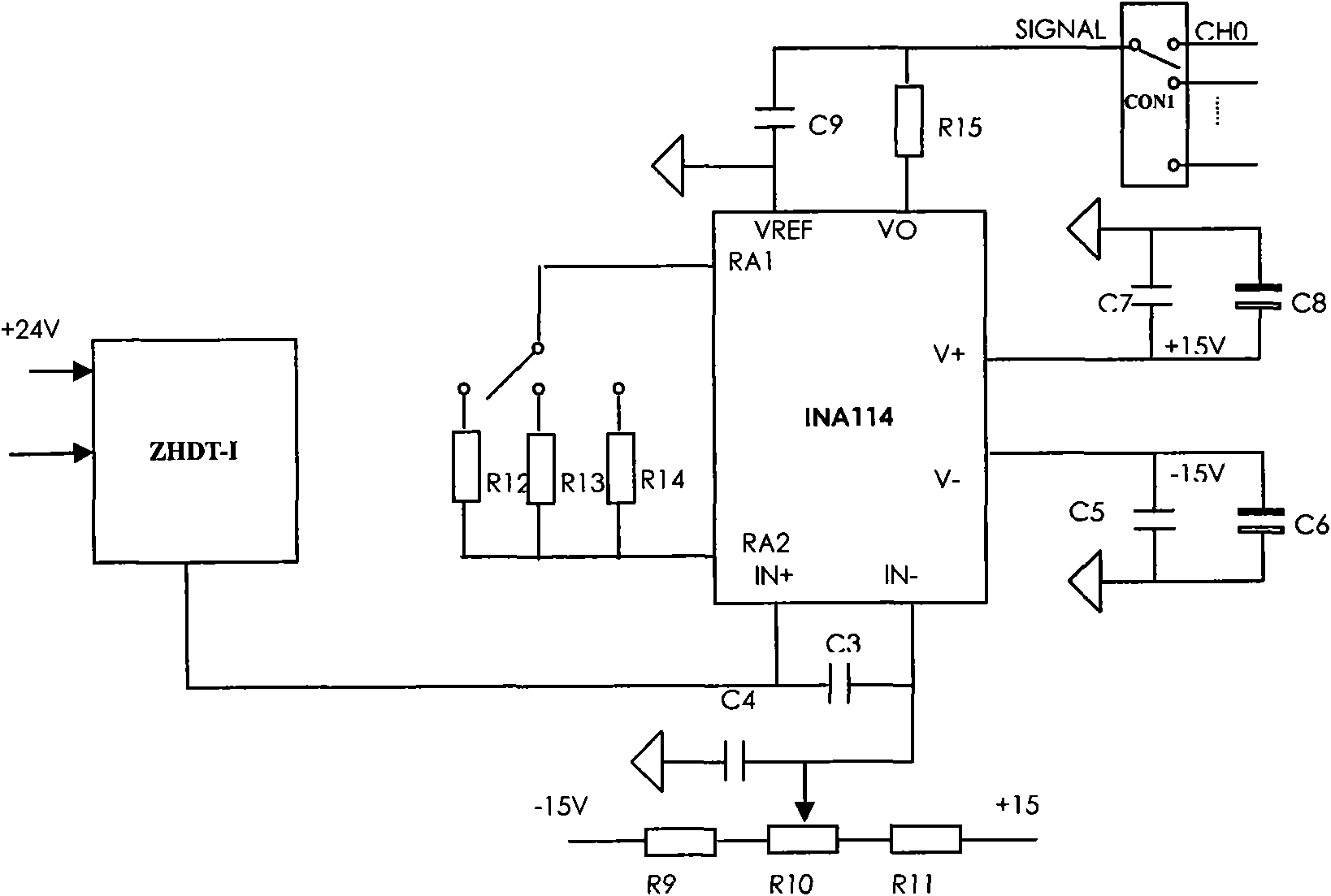

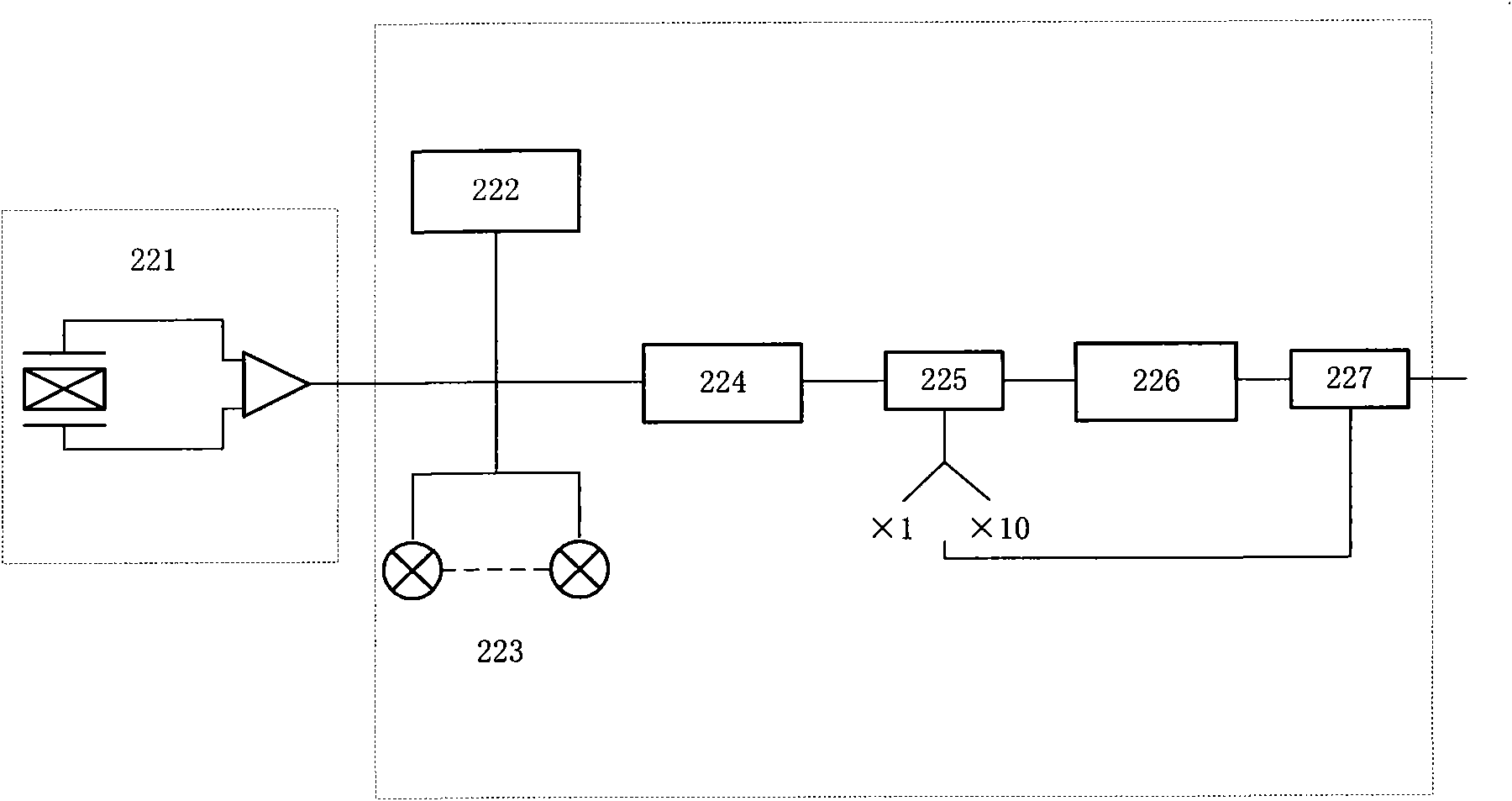

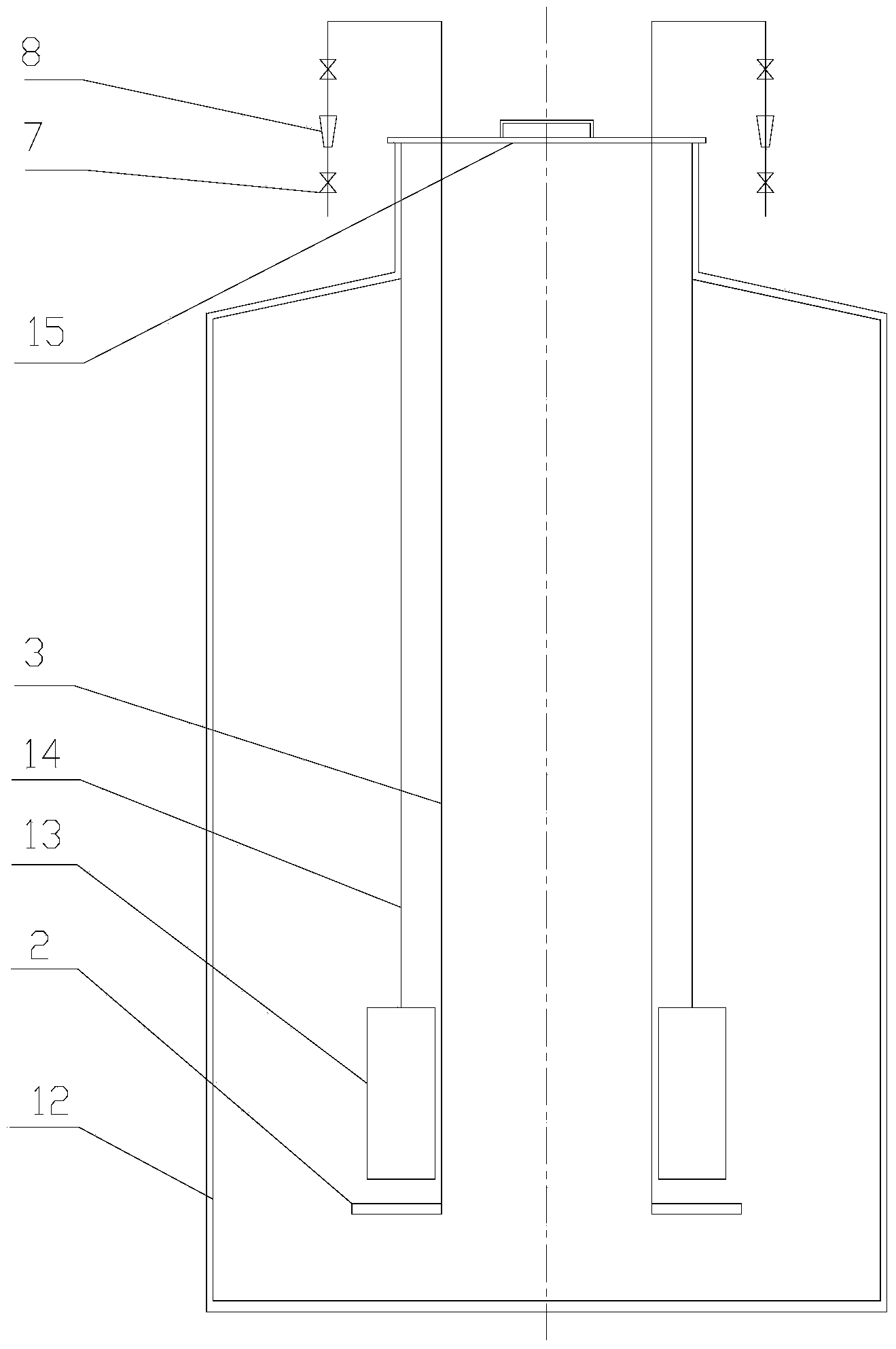

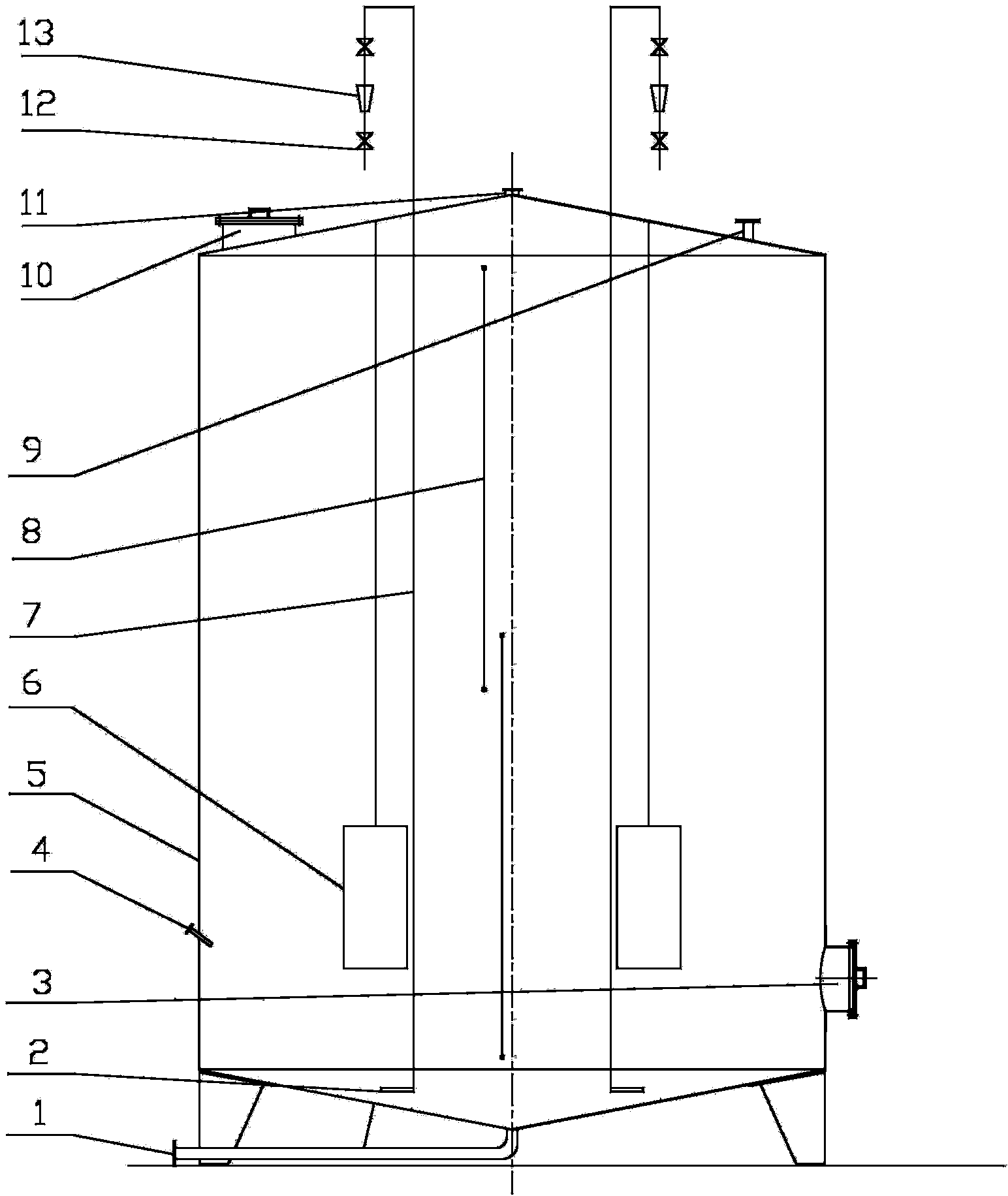

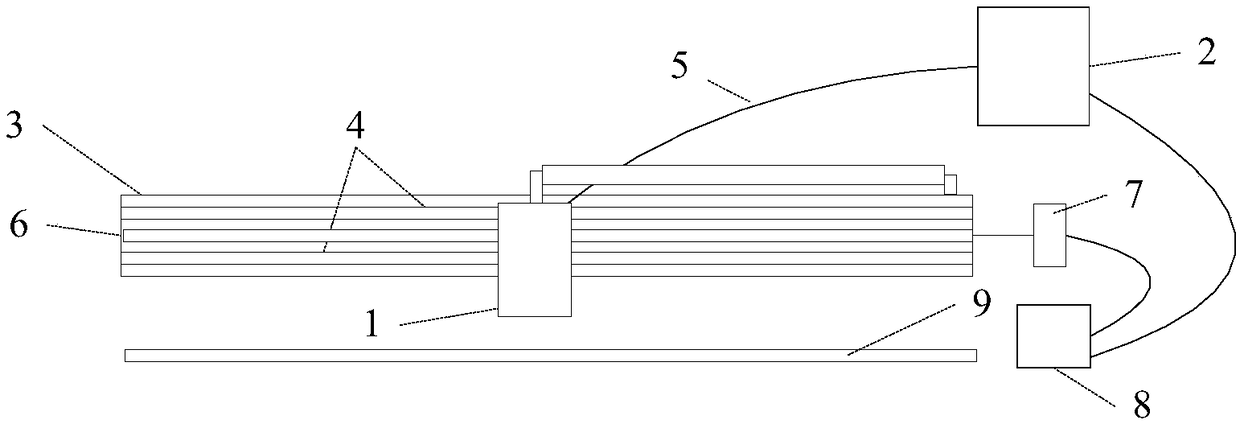

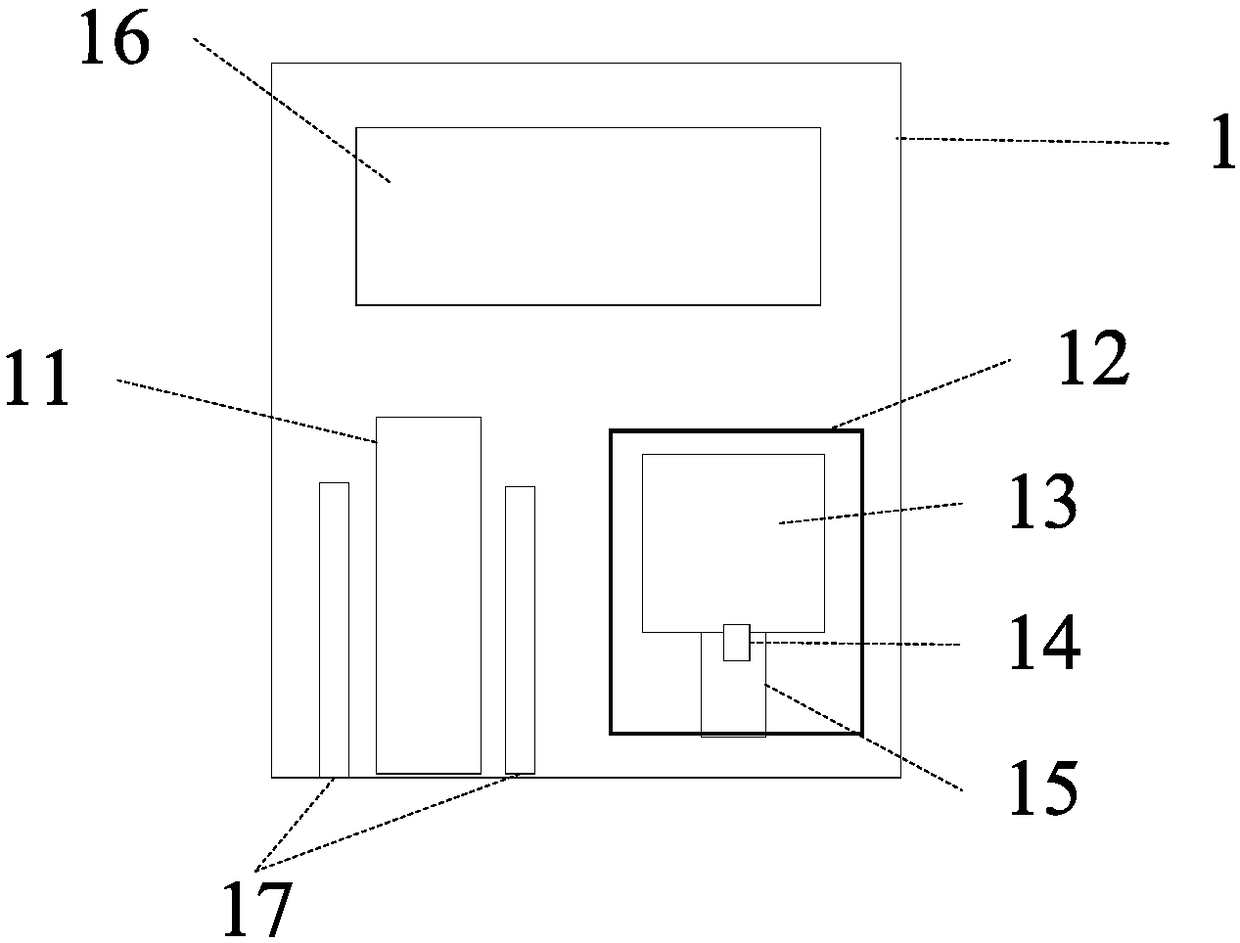

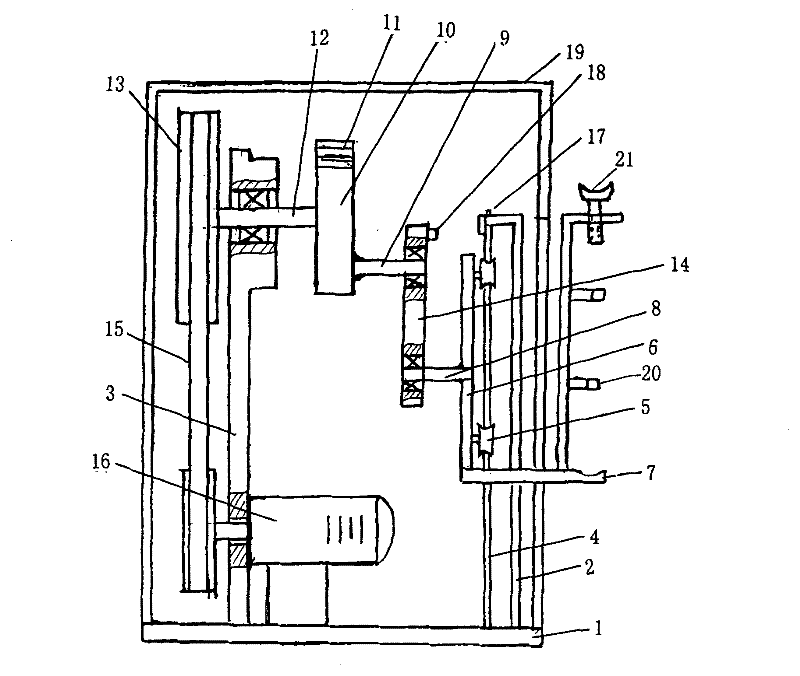

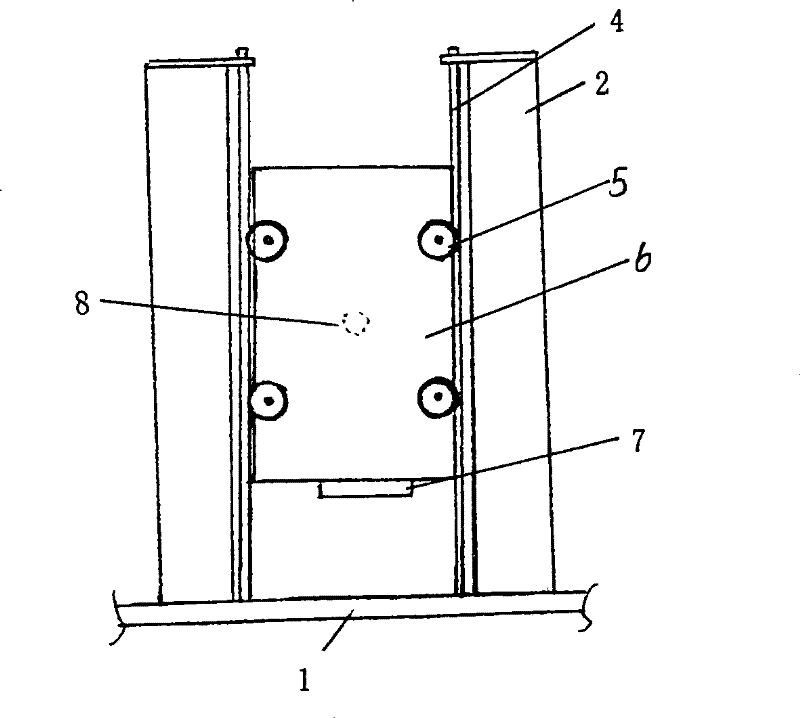

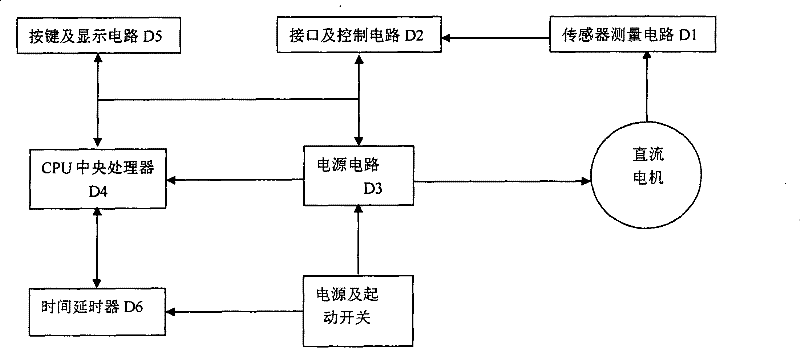

External grinding multiparameter integrated quality monitoring device and method

InactiveCN101670553AExpand the scope of monitoringEnable integrated monitoringRevolution surface grinding machinesGrinding feed controlPower sensorAudio power amplifier

The invention discloses an external grinding multiparameter integrated quality monitoring device. A signal collection device of the external grinding multiparameter integrated quality monitoring device comprises a power sensor, a displacement sensor, an acceleration sensor and a sound emission sensor; a filter amplifier comprises a collection plate, a constant current adapter, a preamplifier and apreamplifier power supply separation annunciator; the power sensor is connected with a wiring terminal plate; the displacement sensor is connected with the collection plate; the acceleration sensor is connected with the constant current adapter; the sound emission sensor is connected with the preamplifier which is connected with the preamplifier power supply separation annunciator; the collectionplate, the constant current adapter and the preamplifier power supply annunciator are respectively connected with the wiring terminal plate which is connected with a data collection card; and the data collection card is connected with a signal analysis and display device. The invention can establish coupling relation between related status characteristic parameters and product quality indexes during grinding so as to direct the adjustment of grinding technological parameters, thereby improving the reliability of quality monitor and judgment.

Owner:ZHEJIANG UNIV +1

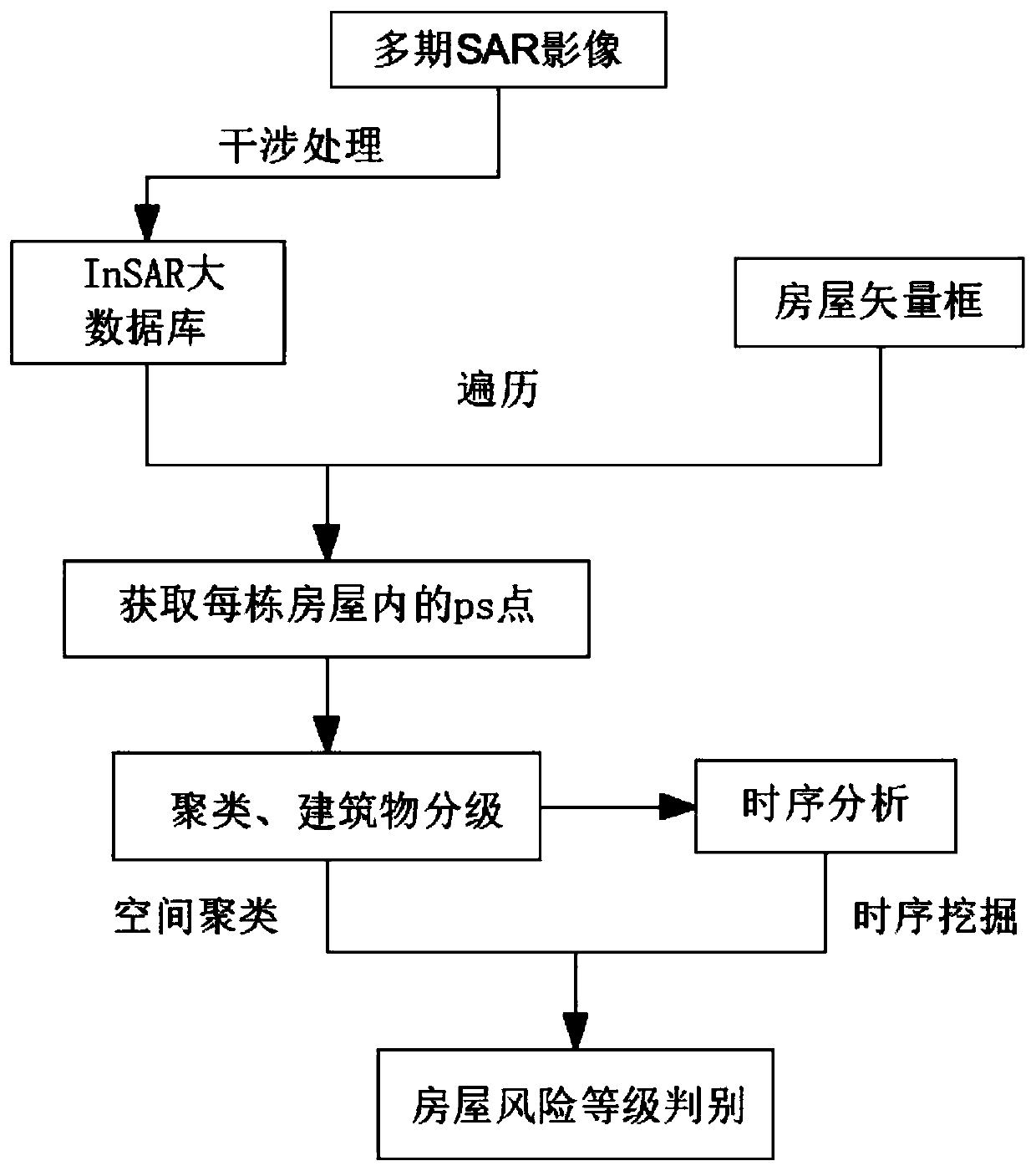

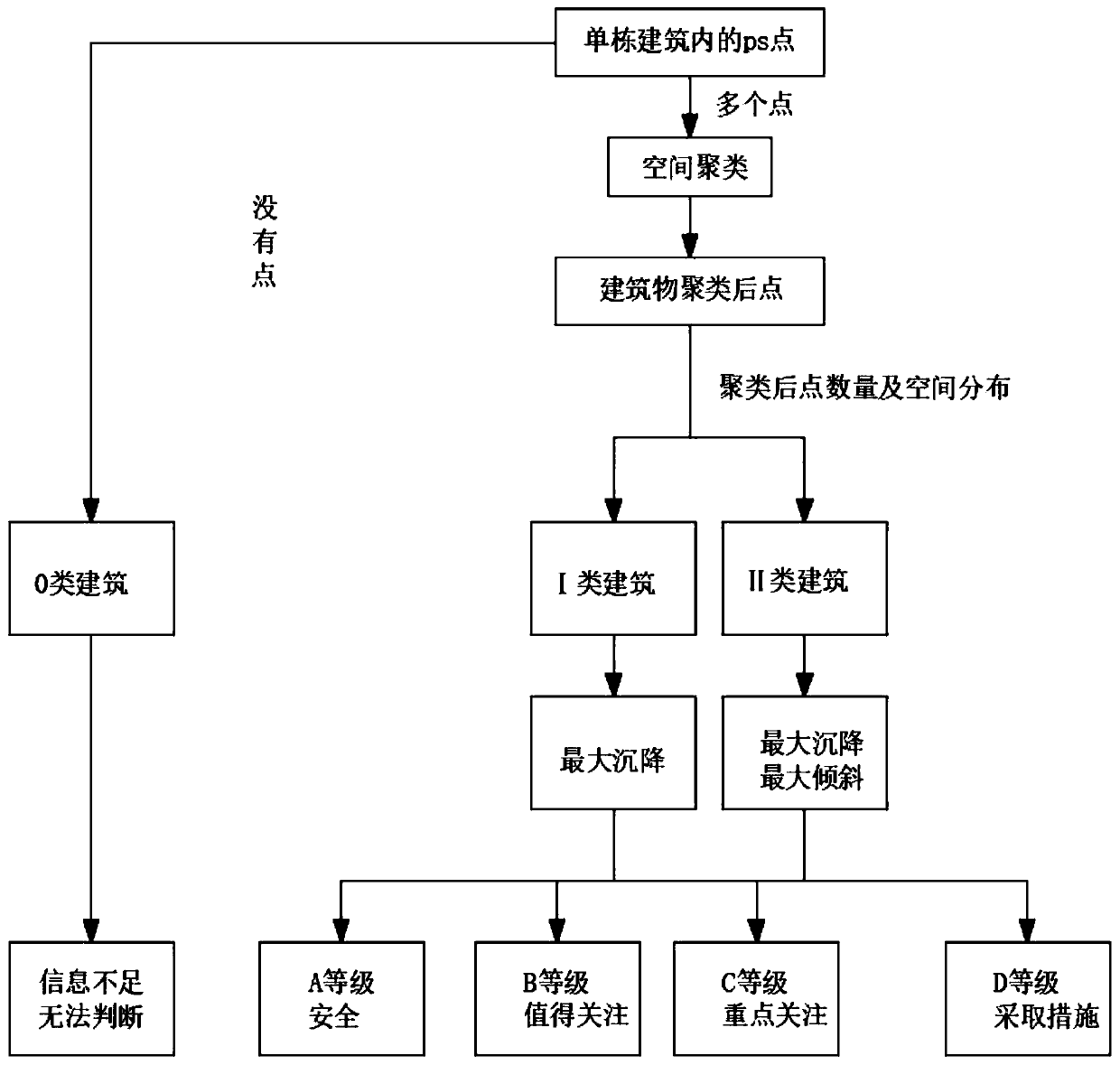

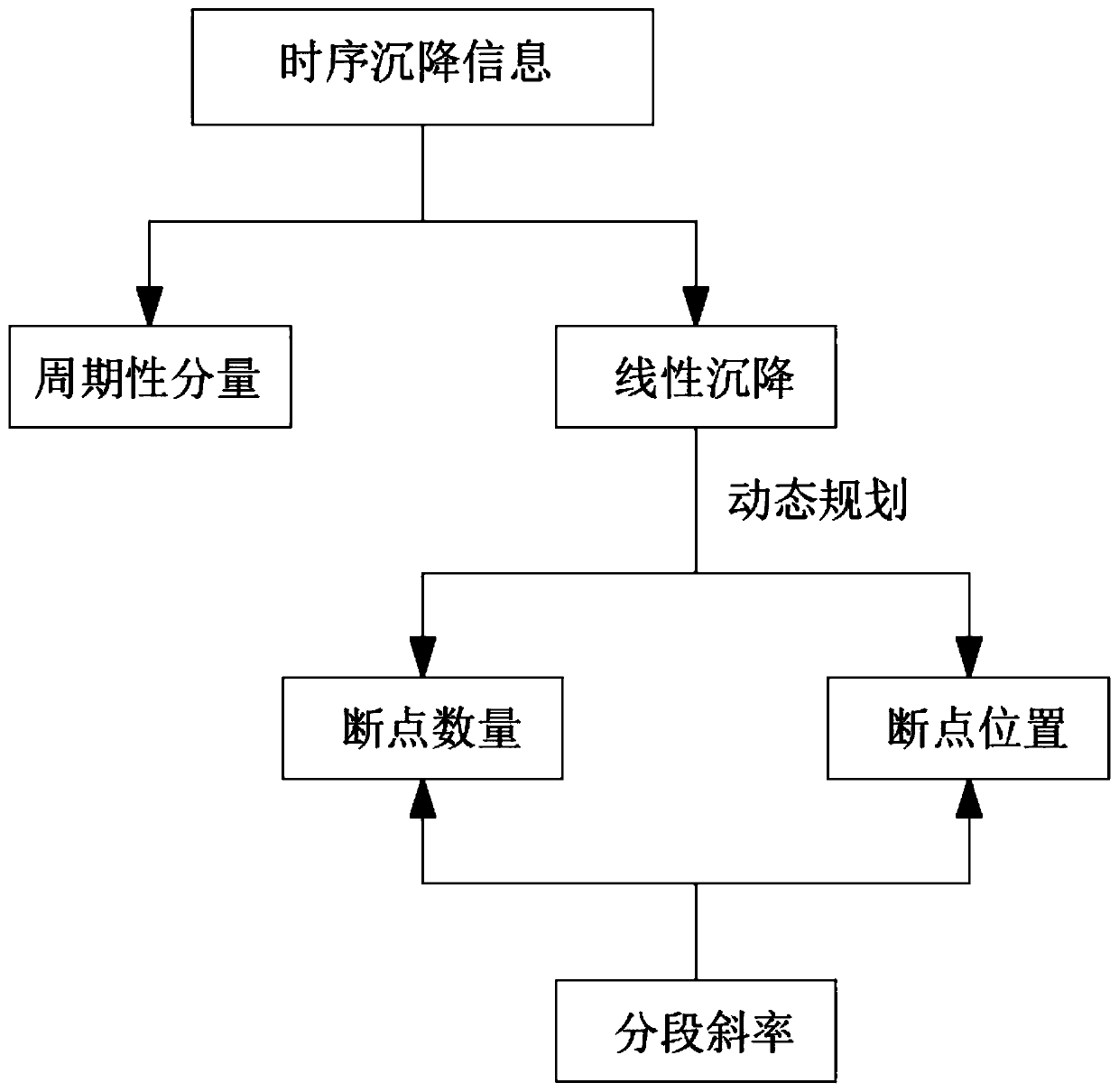

House risk assessment method based on PS-InSAR technology

InactiveCN109991601AAutomatic real-time issuanceQuick issueHeight/levelling measurementUsing wave/particle radiation meansAlgorithmRadar

The invention discloses a house risk assessment method based on the PS-InSAR technology in the technical field of interferometric synthetic aperture radar. The method includes the following steps: obtaining PS points on the surface of a house by using N SAR image data based on the permanent scatterer-interferometric synthetic aperture radar technology; clustering the PS points in a single house according to the historical settlement information and spatial distribution of the PS points, wherein the clustered points can well represent the settlement condition of the small area; for the clustered points in the single house, calculating the inclination rate between the point pairs, carrying out comparison to obtain the maximum inclination, and obtaining an inclination history curve as the evaluation basis for the hazard level of the house; and in the time dimension, decomposing an inclination timing curve into two main components by means of a signal processing method: regular periodic deformation and piecewise linear deformation; and after removing periodic components, analyzing the speed change of each identified time partition to detect abnormal speed and acceleration, and evaluating the stability of the house by integrating the house type, maximum cumulative settlement and inclination rate.

Owner:北京东方至远科技股份有限公司

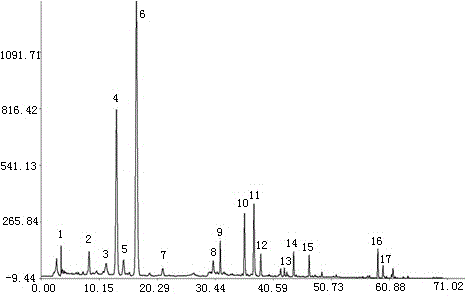

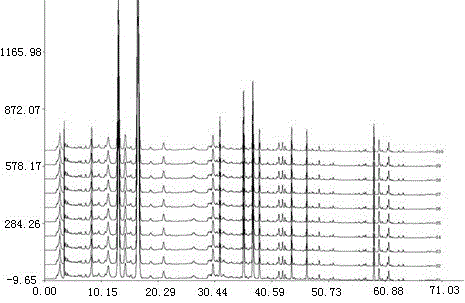

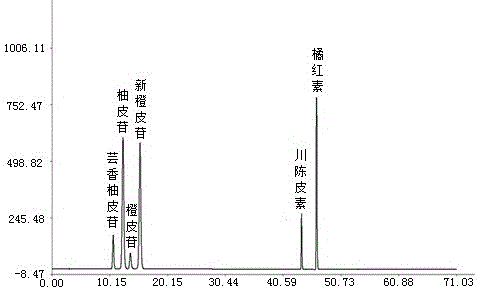

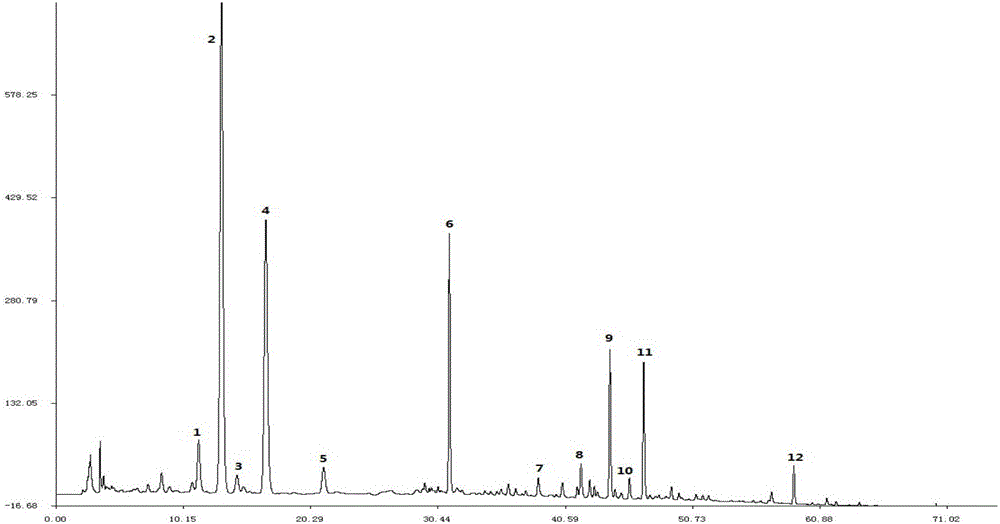

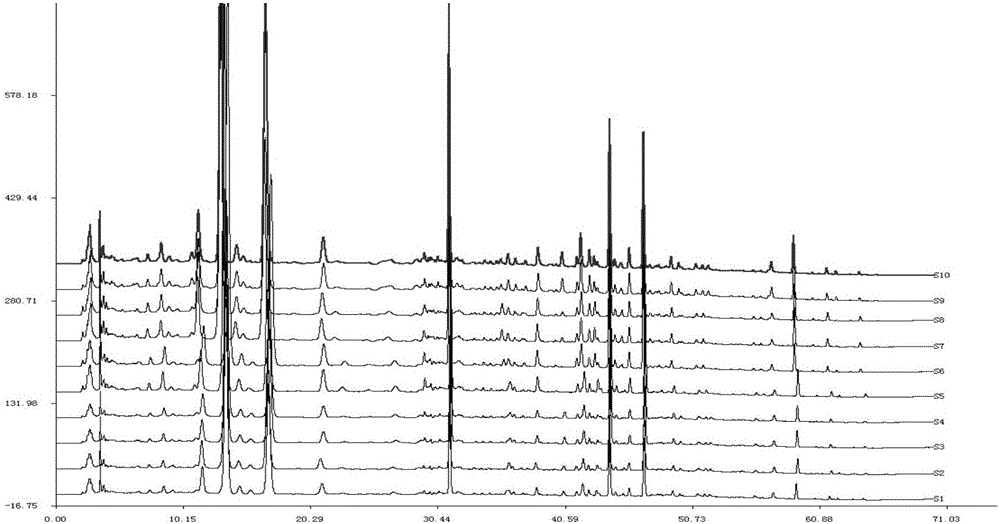

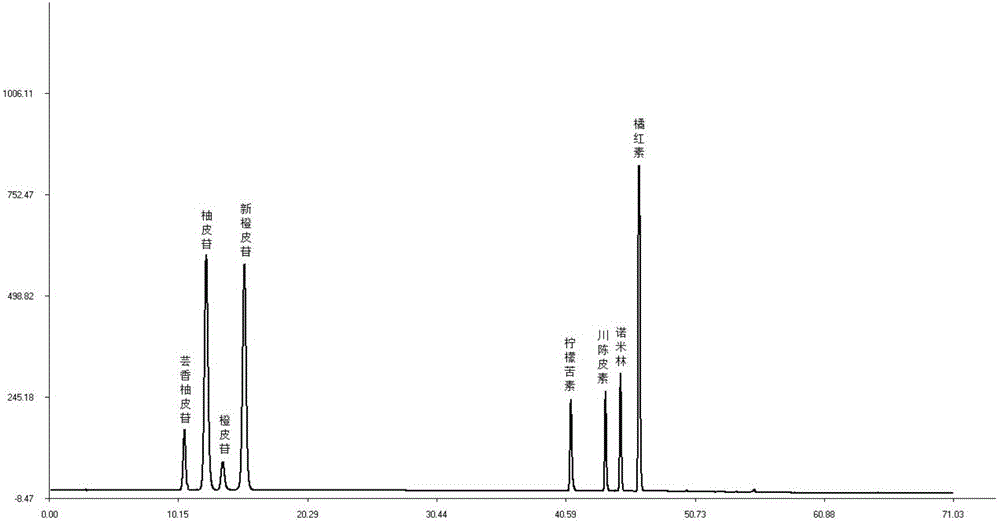

Detection method for fructus aurantii immaturus medicine finger-print, and standard finger-print

InactiveCN106525988AEnhanced visual comparisonImprove quality monitoringComponent separationMedicinal herbsBiomedical engineering

The invention discloses a detection method for a fructus aurantii immaturus medicine finger-print, a standard finger-print thereof, and application of the fructus aurantii immaturus medicine finger-print or the standard finger-print in identifying fructus aurantii immaturus medicines. The method comprises the following steps: (1) taking the fructus aurantii immaturus medicines, smashing into medium-granularity powder, precisely weighting, adding methyl alcohol, carrying out extraction, and taking subsequent filtrate to obtain a solution of a sample for testing; (2) preparing reference substance solution; (3) respectively precisely absorbing the solution of the sample for testing and the reference substance solution, and injecting into a high performance liquid chromatograph to measure, so as to obtain the fructus aurantii immaturus finger-print. The measurement method disclosed by the invention has the advantages of convenience in operation, good repeatability and stability, high accuracy and high specificity, and has an active function on guiding production feeding and guaranteeing quality reliability, and characteristic ingredients are integrally kept. The fructus aurantii immaturus medicine finger-print established by the method can be used for effectively monitoring the quality of the fructus aurantii immaturus medicines and identifying fakes from originals.

Owner:HUNAN HANSEN PHARMACEUTICAL CO LTD

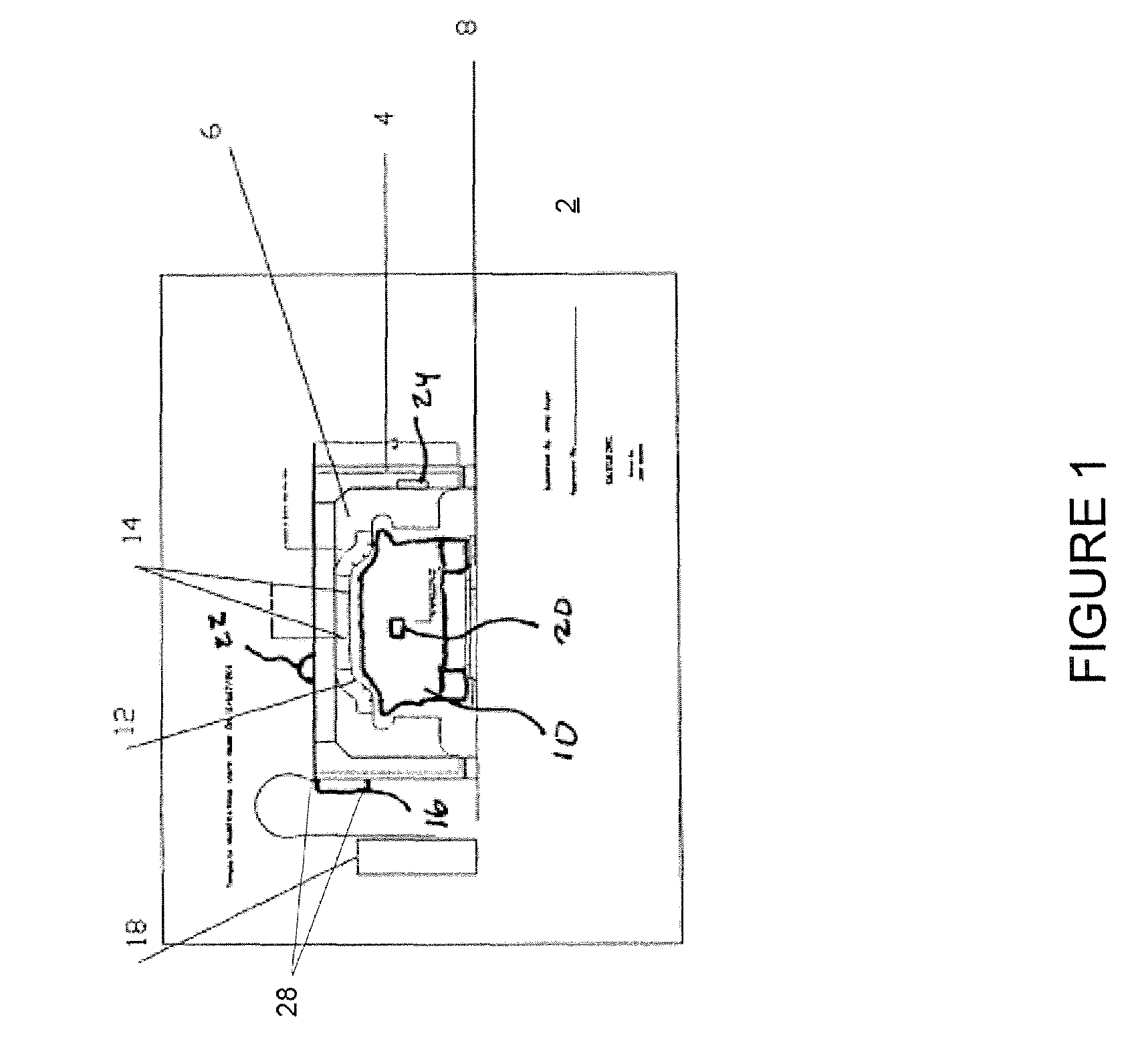

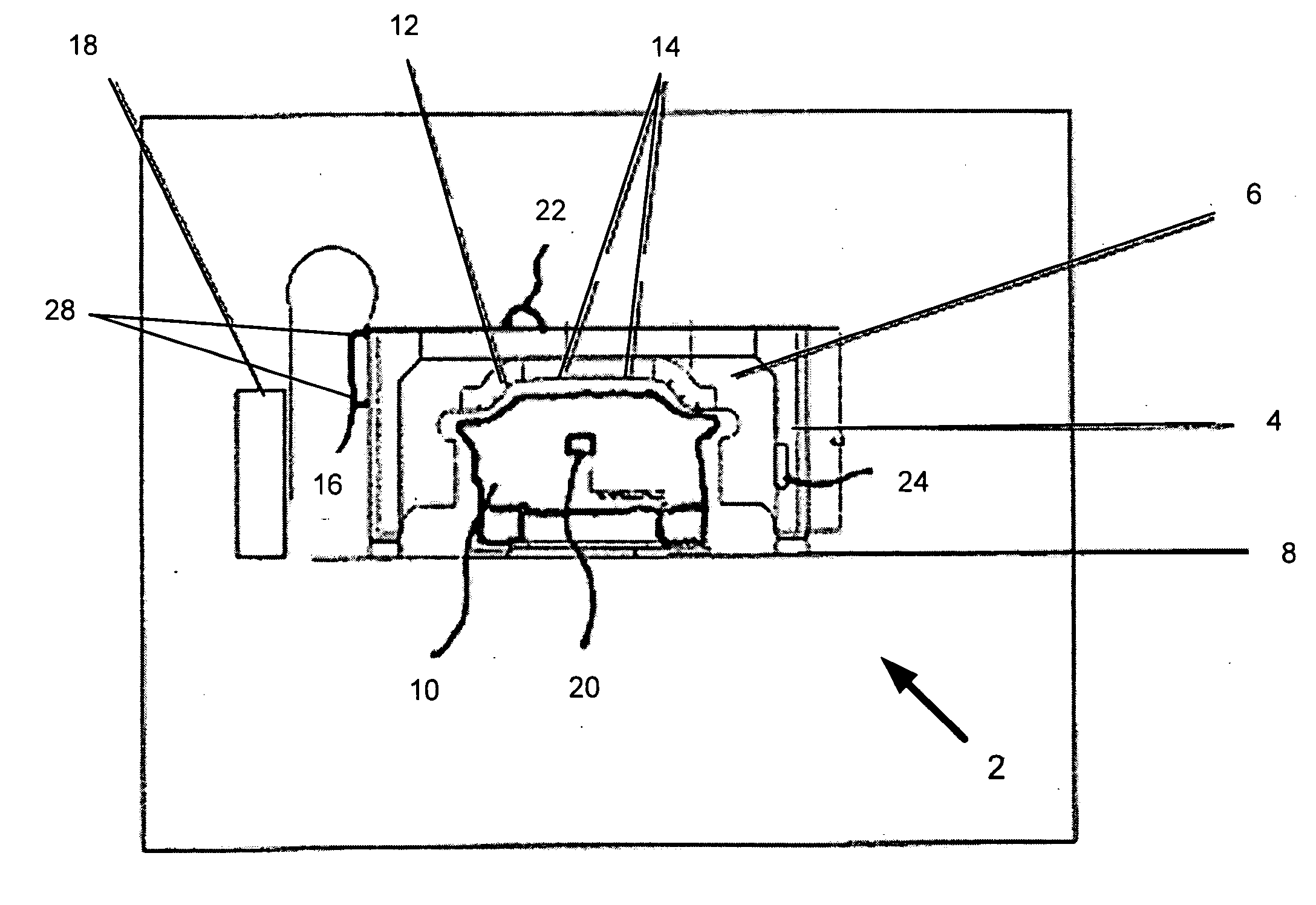

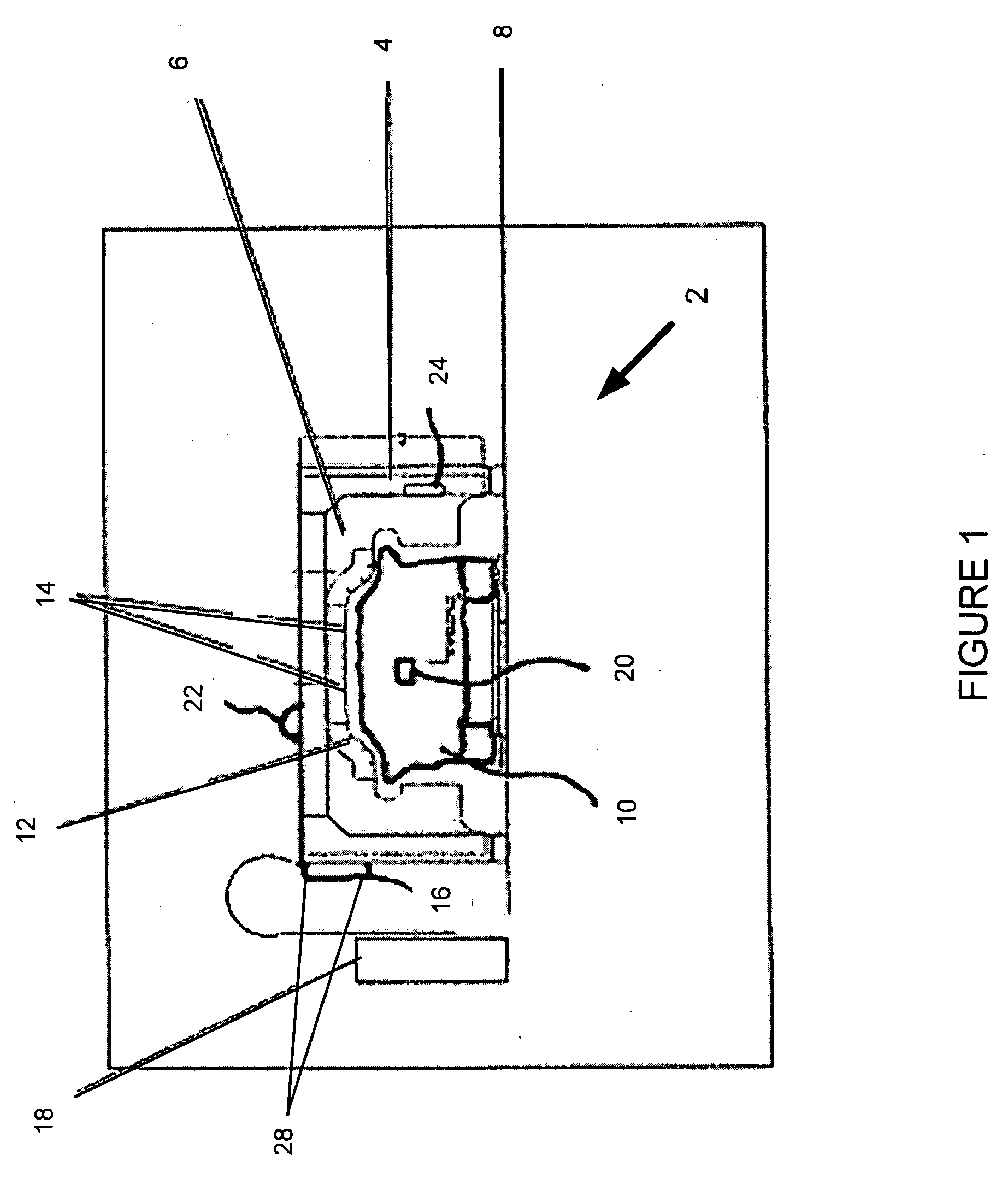

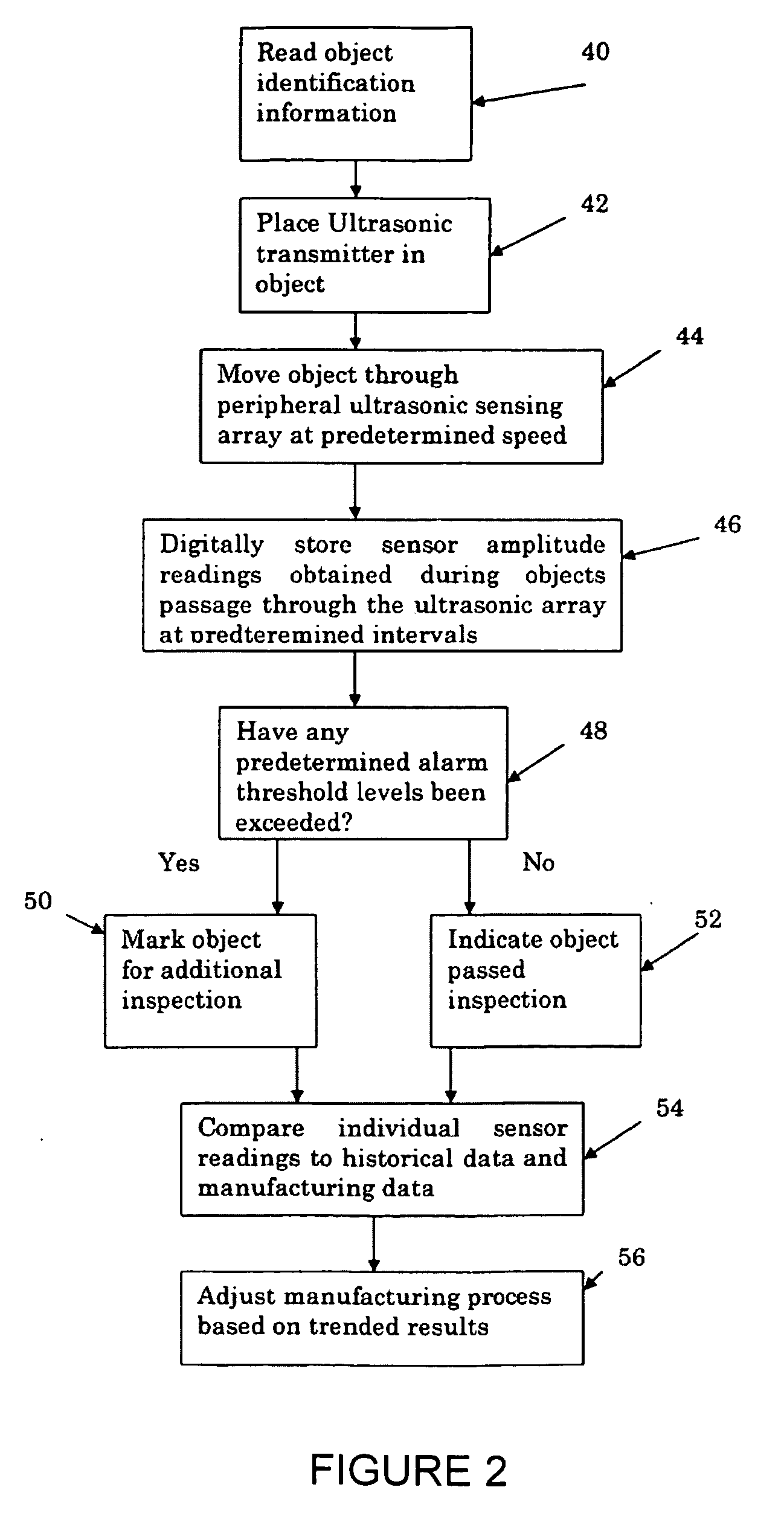

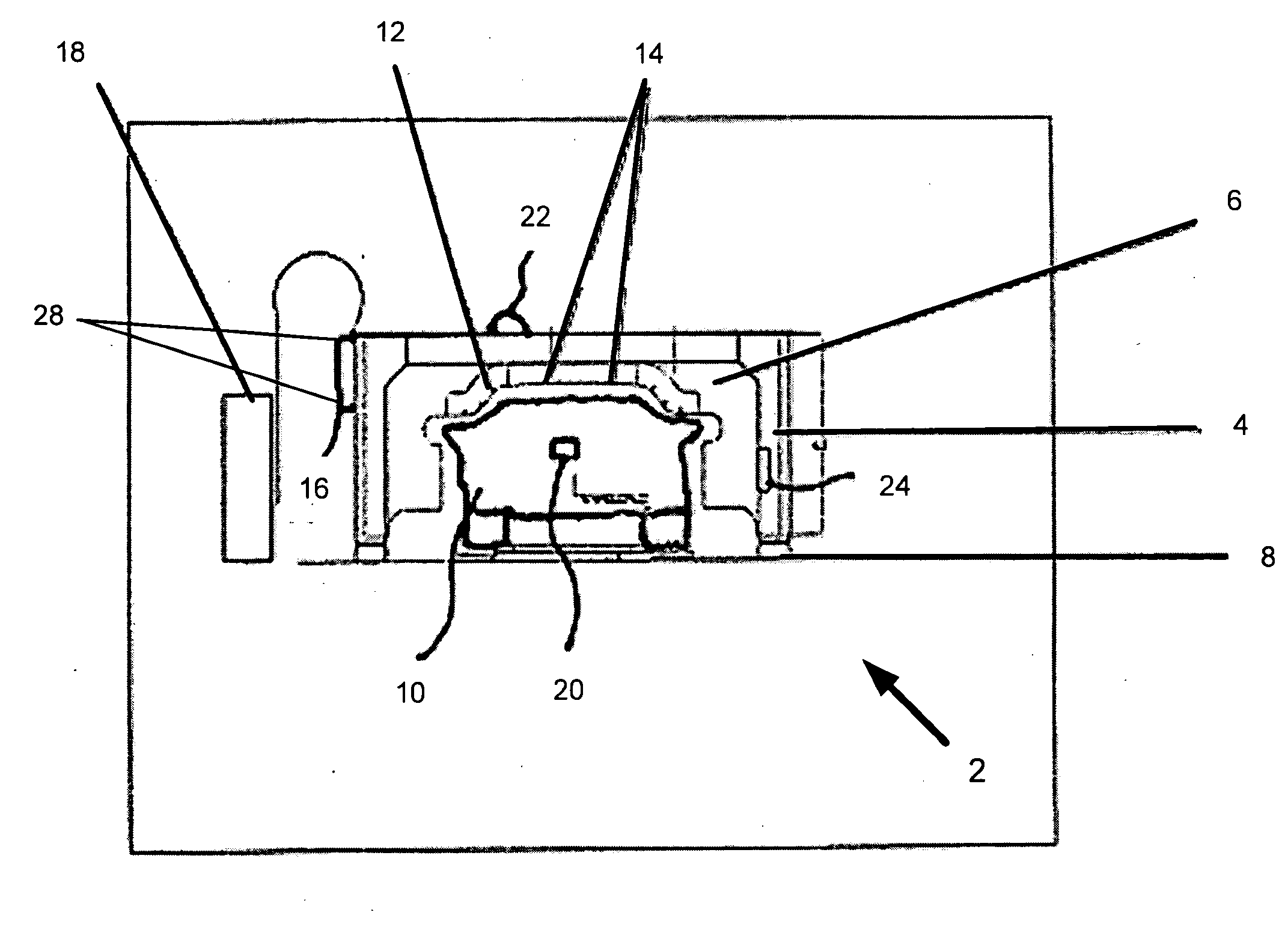

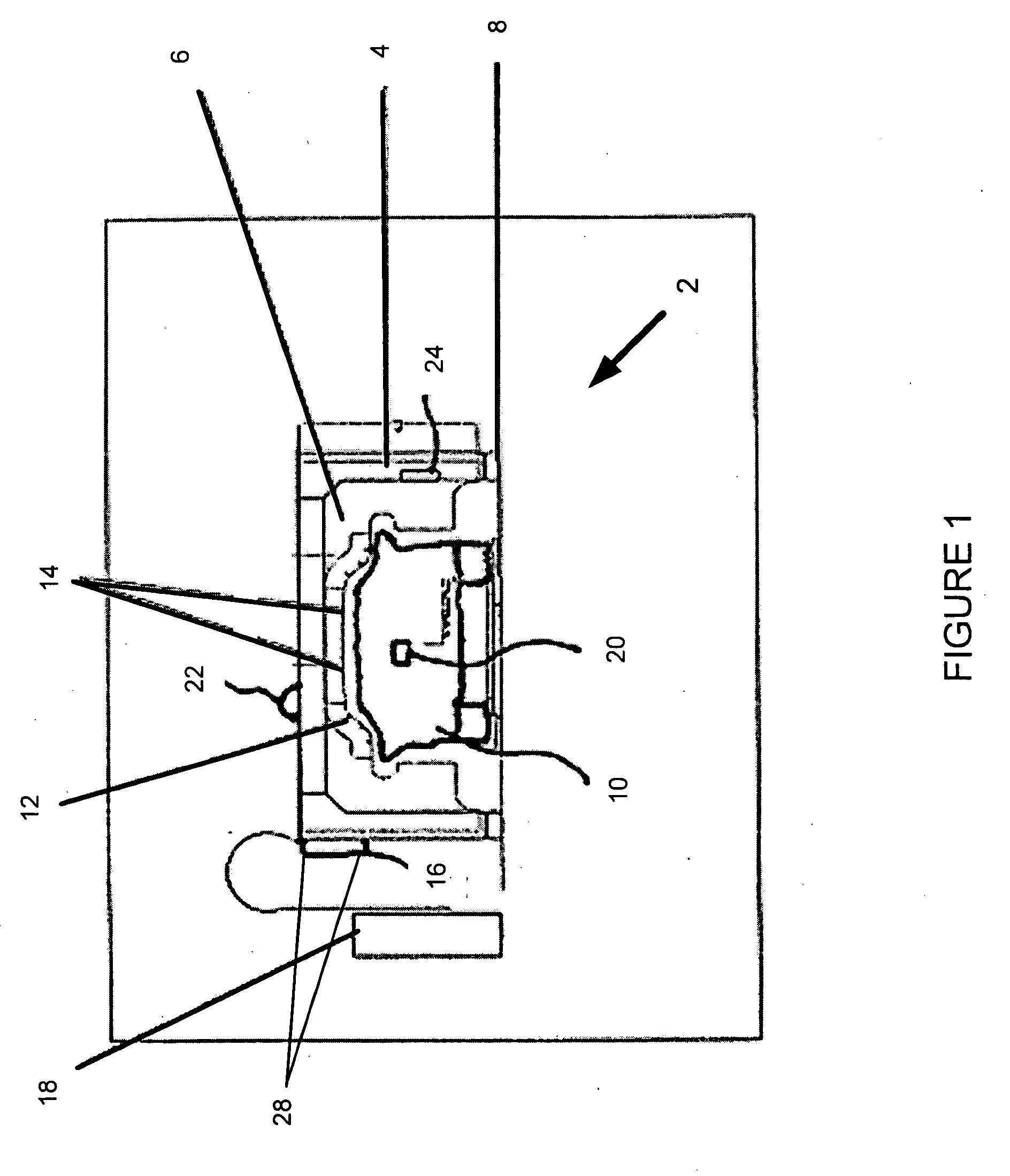

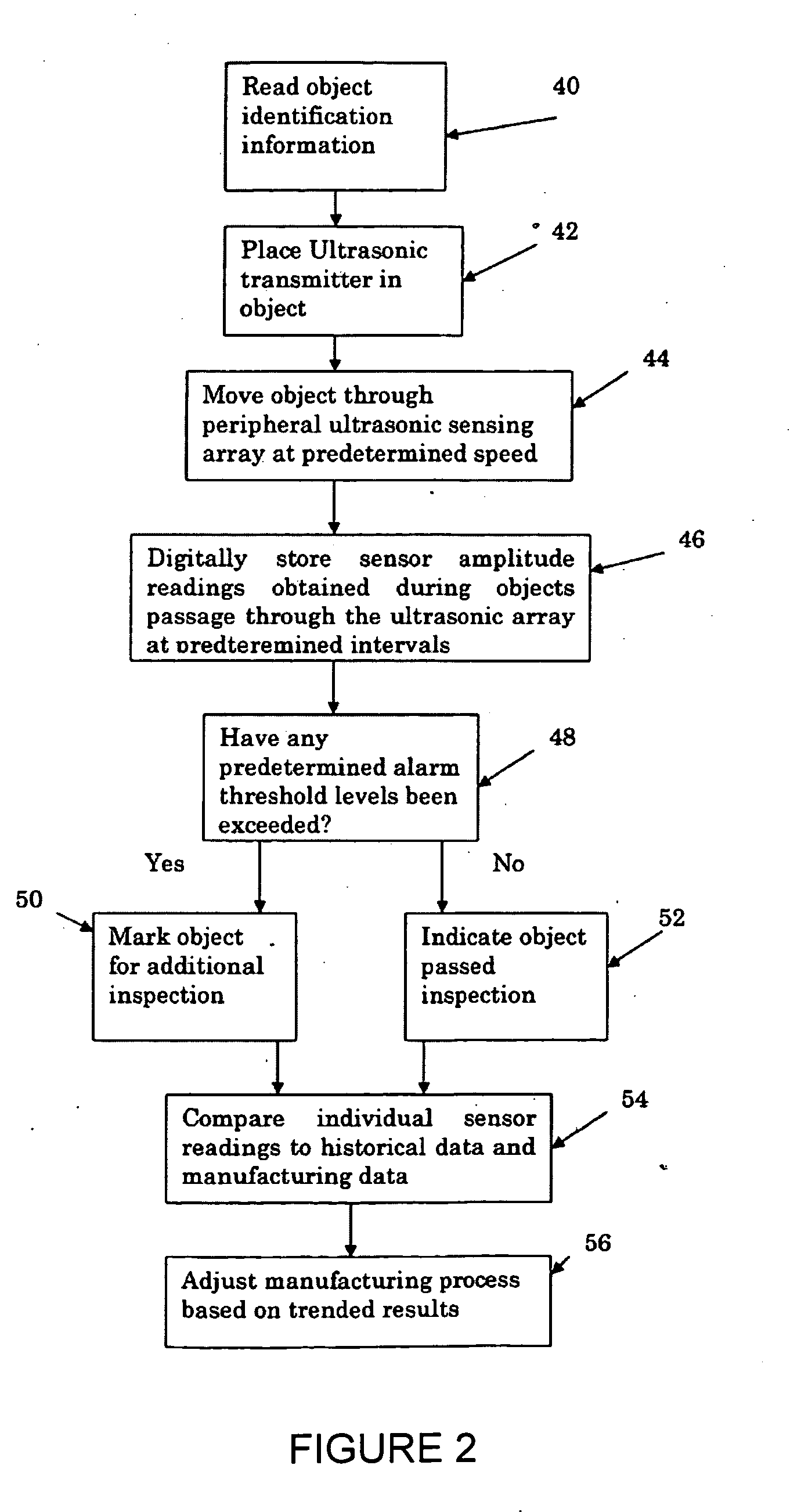

Peripheral ultrasonic sensing array system and method

InactiveUS7387026B1Improve quality monitoringReliable resultsAnalysing fluids using sonic/ultrasonic/infrasonic wavesDetection of fluid at leakage pointJet aeroplaneUltrasonic sensor

An improved system and method for detecting leaks in substantially enclosed objects such as automobiles, airplanes, tanks, etc. uses an ultrasonic transmitter and an array of ultrasonic sensors positioned around the inner periphery of a cut out silhouette that corresponds to an outline of the objects under test. The silhouette is mounted in a frame that is designed to minimize ultrasonic reflections and preserve any amplitude information received by the ultrasonic sensors. As the objects are passed through the frame, ultrasonic amplitude readings obtained from the sensors are processed to determine if they are representative of a defective or leaking object. The position of the leak is determined by examining the amplitude of the individual sensor readings. The system is particularly well adapted for use in detecting defects in automobiles on an assembly line without interrupting the assembly process or damaging the car.

Owner:GAYLE JAMES EDWARD MR

Detection method of fructus aurantii medicine material fingerprint and standard fingerprint

InactiveCN106525989AEnhanced visual comparisonImprove quality monitoringComponent separationFingerprintTest sample

The invention discloses a detection method of a fructus aurantii medicine material fingerprint and a standard fingerprint, and application of the fructus aurantii medicine material fingerprint or the standard fingerprint in identifying a fructus aurantii medicine material. The method includes the steps that firstly, the fructus aurantii medicine material is obtained and smashed into coarse powder and precisely weighed, methyl alcohol is added, extraction is conducted, a subsequent filtrate obtained, and a test sample solution is obtained; secondly, a reference substance solution is prepared; thirdly, the test sample solution and the reference substance solution are precisely sucked and injected into a high performance liquid chromatograph respectively to be measured, and the fructus aurantii fingerprint is obtained. The measurement method is easy and convenient to operate, characteristic components are maintained completely, repeatability and stability are good, precision is high, specificity is high, and the method plays a positive role in guiding production charging and guaranteeing quality reliability. The fructus aurantii medicine material fingerprint built through the method can be effectively used for monitoring the quality of the fructus aurantii medicine material and identifying whether the fructus aurantii medicine material is true or fake.

Owner:HUNAN HANSEN PHARMACEUTICAL CO LTD

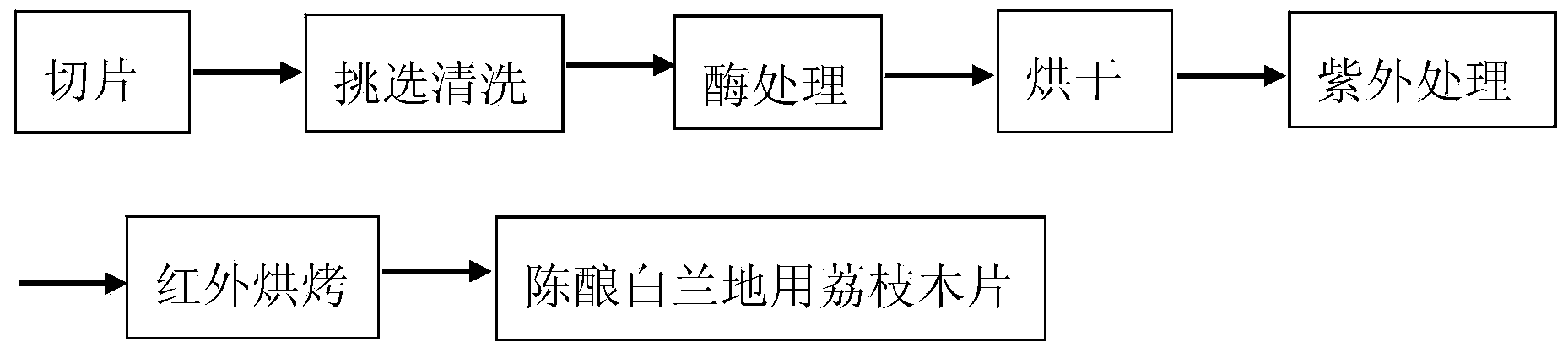

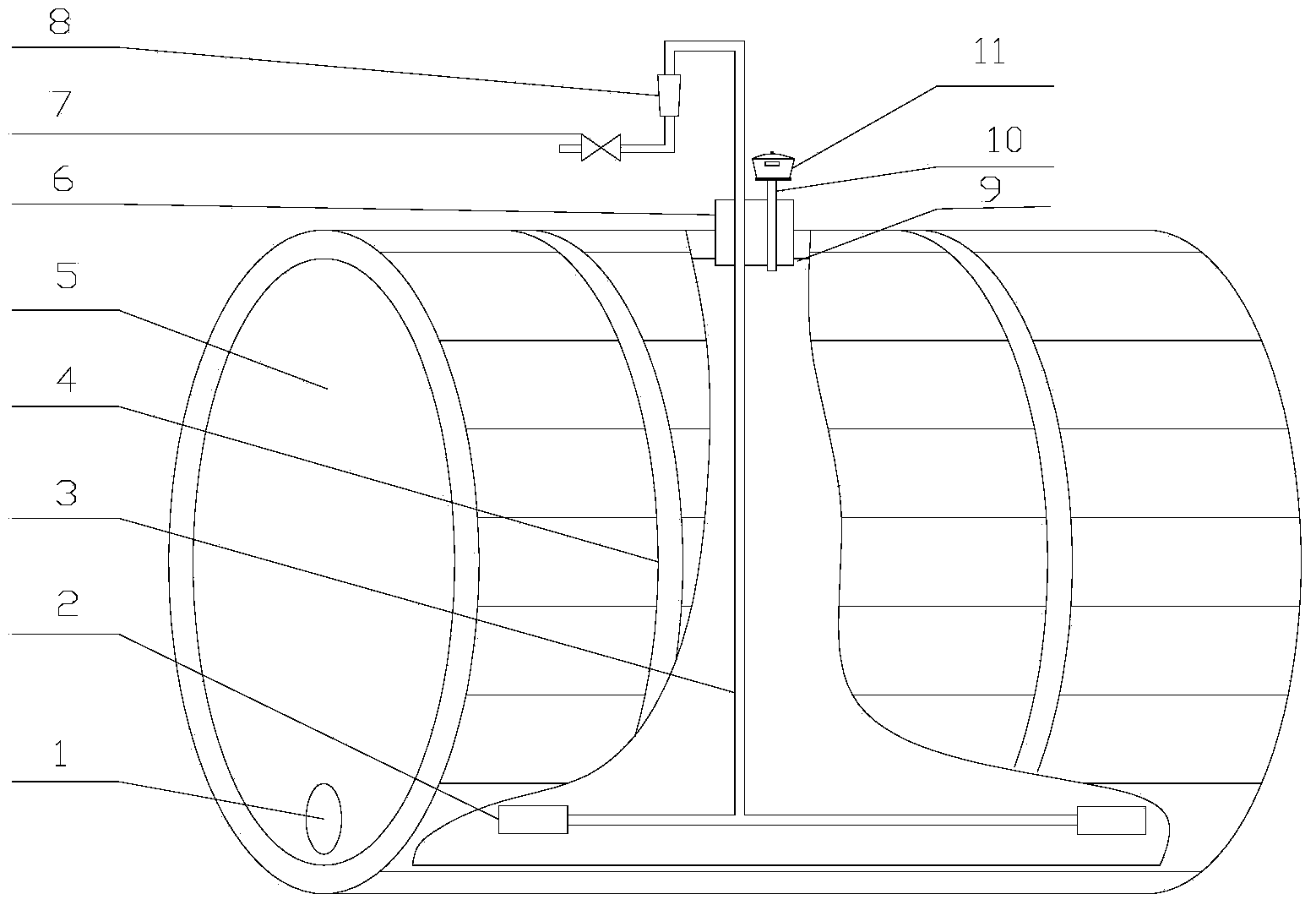

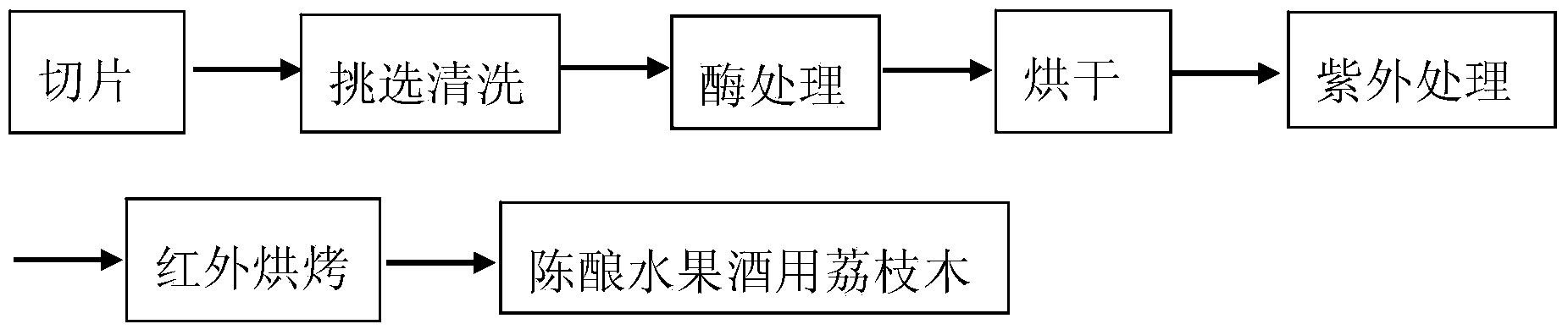

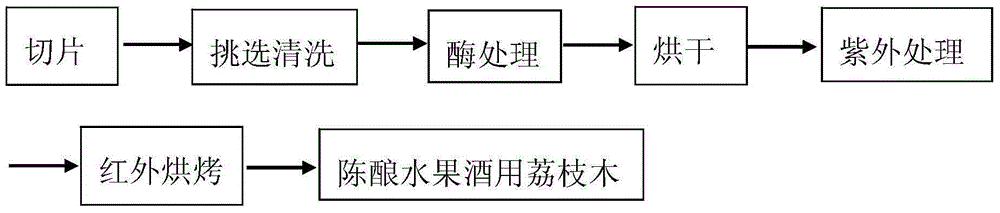

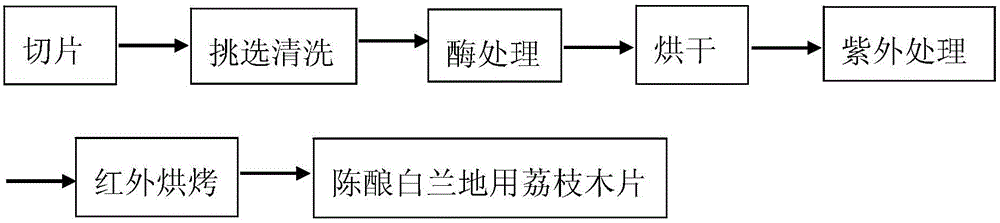

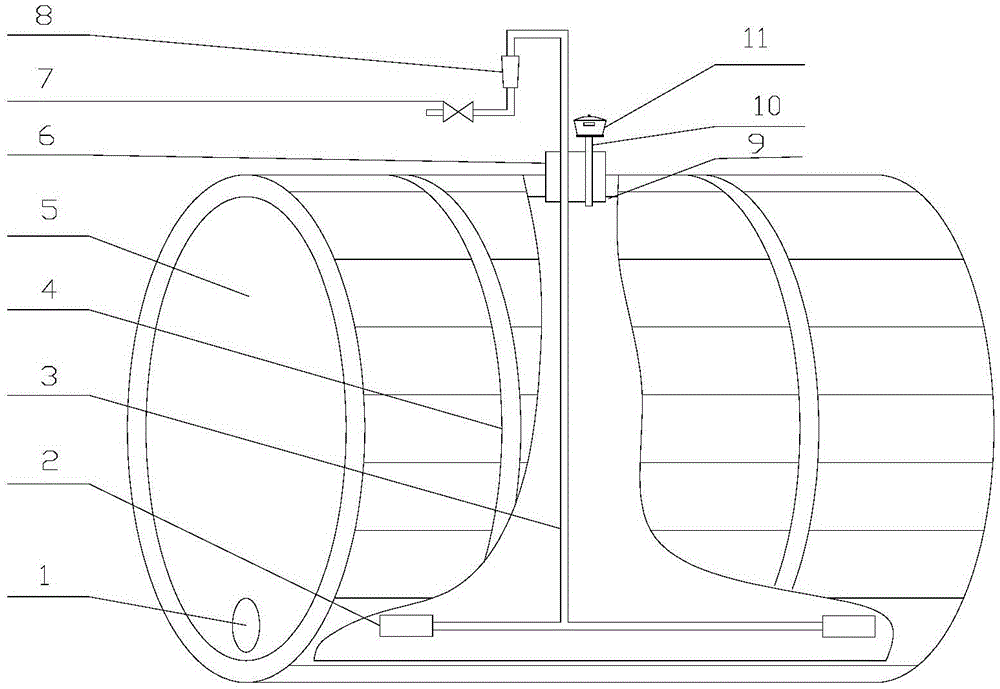

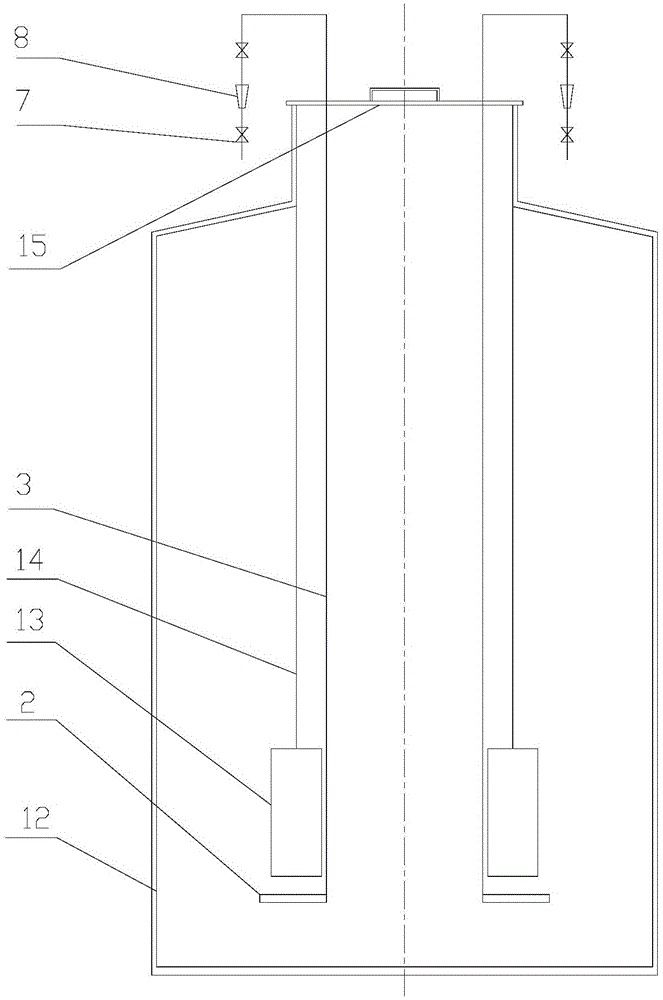

Litchi wood chip for ageing brandy, preparation and application process of litchi wood chip

ActiveCN103659974AQuality improvementReduce lossWood treatment detailsAlcoholic beverage preparationFruit wineAge method

The invention discloses a litchi wood chip for ageing brandy, preparation and application process of the litchi wood chip, and belongs to the field of fruit brandy ageing technology. The invention further discloses a preparation method of the litchi wood chip for ageing brandy, and provides the application process of the litchi wood chip for ageing brandy after the litchi wood chip for ageing brandy is obtained. According to the invention, the novel litchi wood chip for ageing fruit brandy is adopted, the micro-oxygenation technology is utilized, and the litchi wood chip and litchi wood products are combined to enable fruit brandy to mature within relatively short period, and endow the fruit brandy with elegant and comfortable fragrance and soft and rich taste, and the litchi wood chip can be used for ageing various fruit brandy. With adoption of the application process of the litchi wood in ageing brandy, the problems that the existing fruit brandy ageing method consumes longer time, uses a large amount of containers, and is large in labor intensity and great in fruit wine loss, are solved.

Owner:广东省九江酒厂有限公司

Ultrasonic sensing array system and method

InactiveUS20090013763A1Reliable dependable resultImprove quality monitoringDetection of fluid at leakage pointAnalysing solids using sonic/ultrasonic/infrasonic wavesJet aeroplaneUltrasonic sensor

A system and method for detecting leaks in substantially closed objects, such as automobiles, airplanes, tanks, and other vehicles, using an ultrasonic transmitter and an array of ultrasonic sensors or receivers positioned or mounted on a frame. As the objects are passed through the frame, ultrasonic amplitude readings obtained from the sensors are processed to determine if they are representative of a defective or leaking object. The position of the leak may be determined by examining the readings from individual sensors. The system is particularly well-adapted for use in detecting defects and leaks in automobiles on an assembly line without interrupting the assembly process or damaging the automobile.

Owner:GAYLE JAMES EDWARD

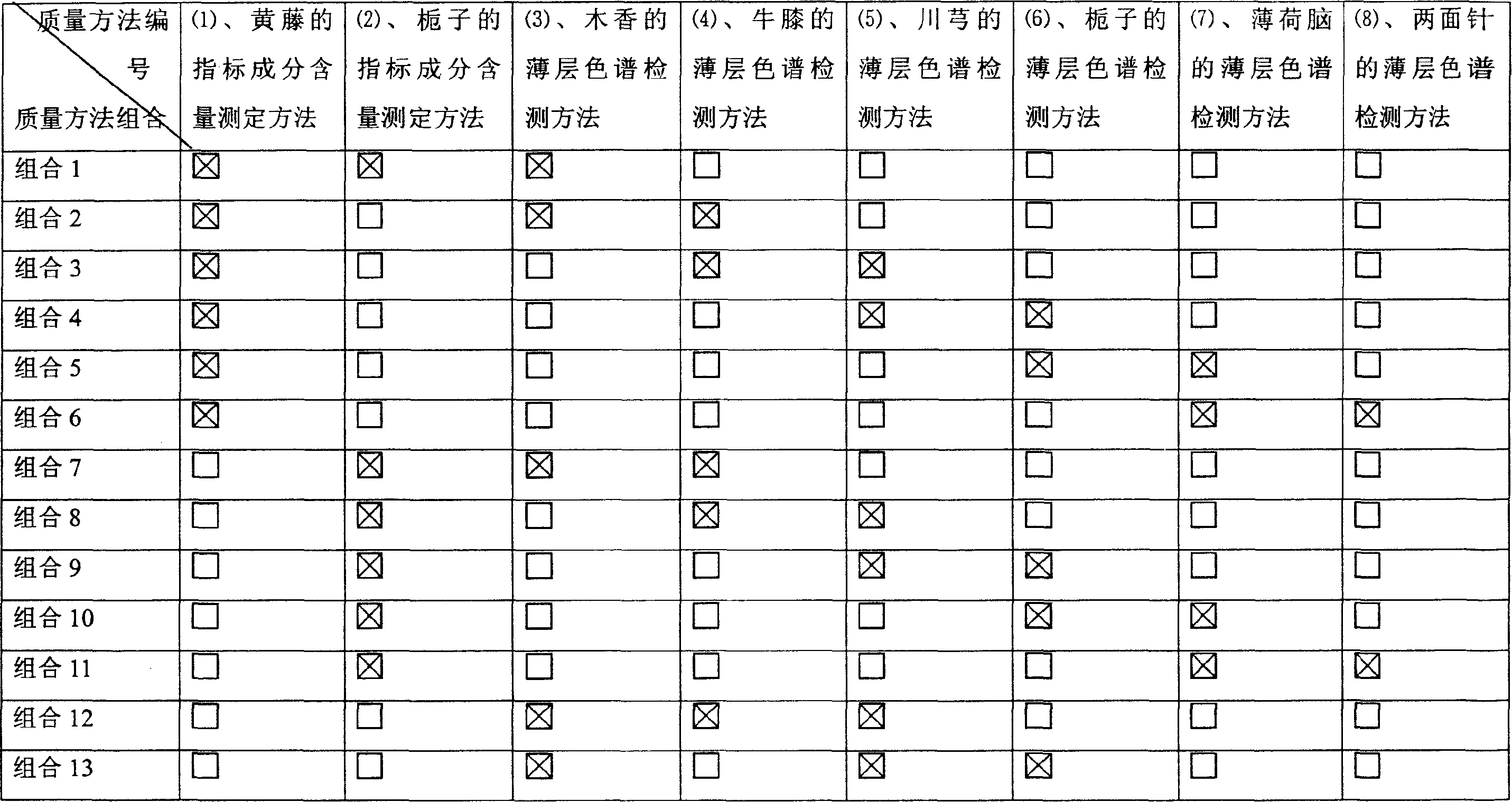

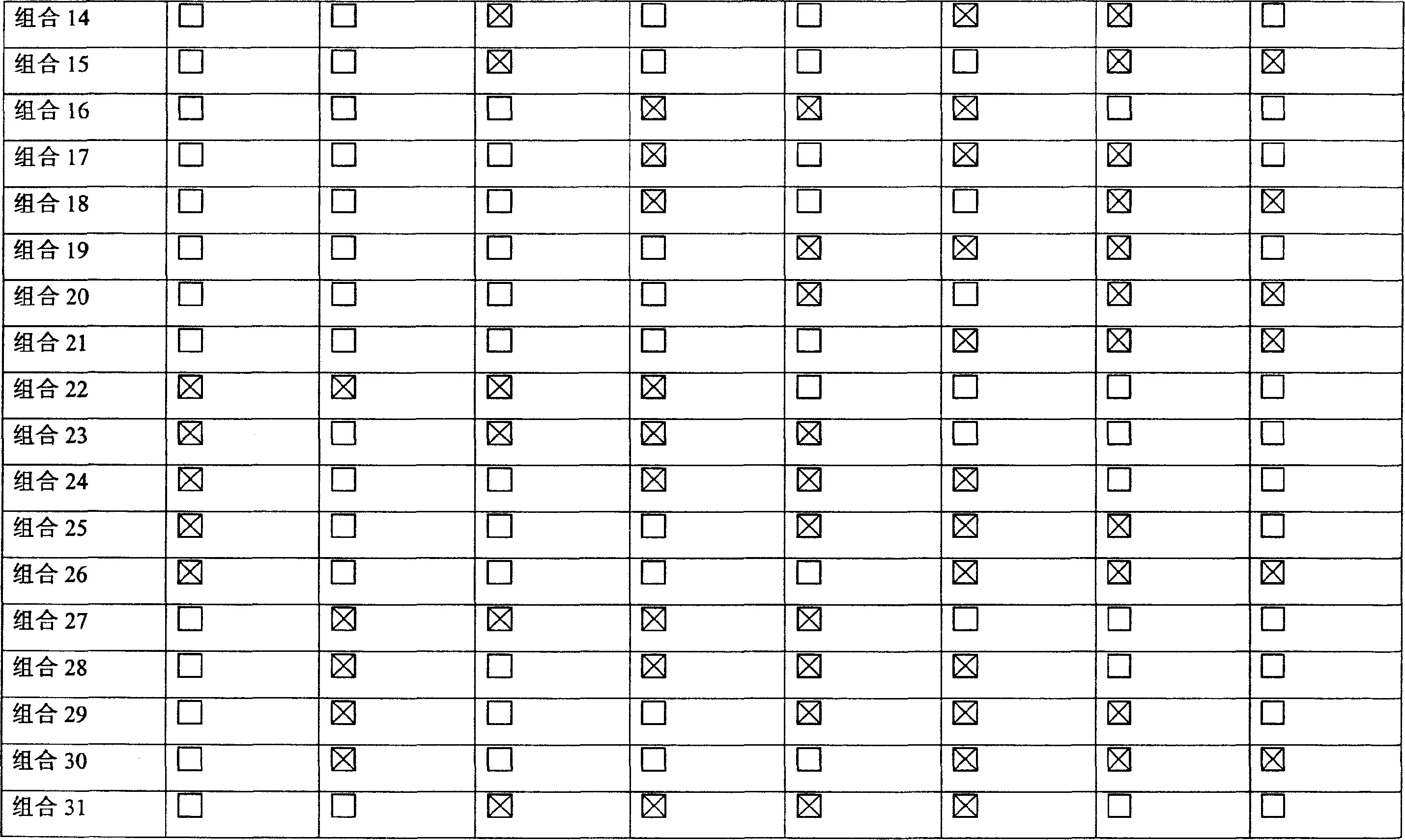

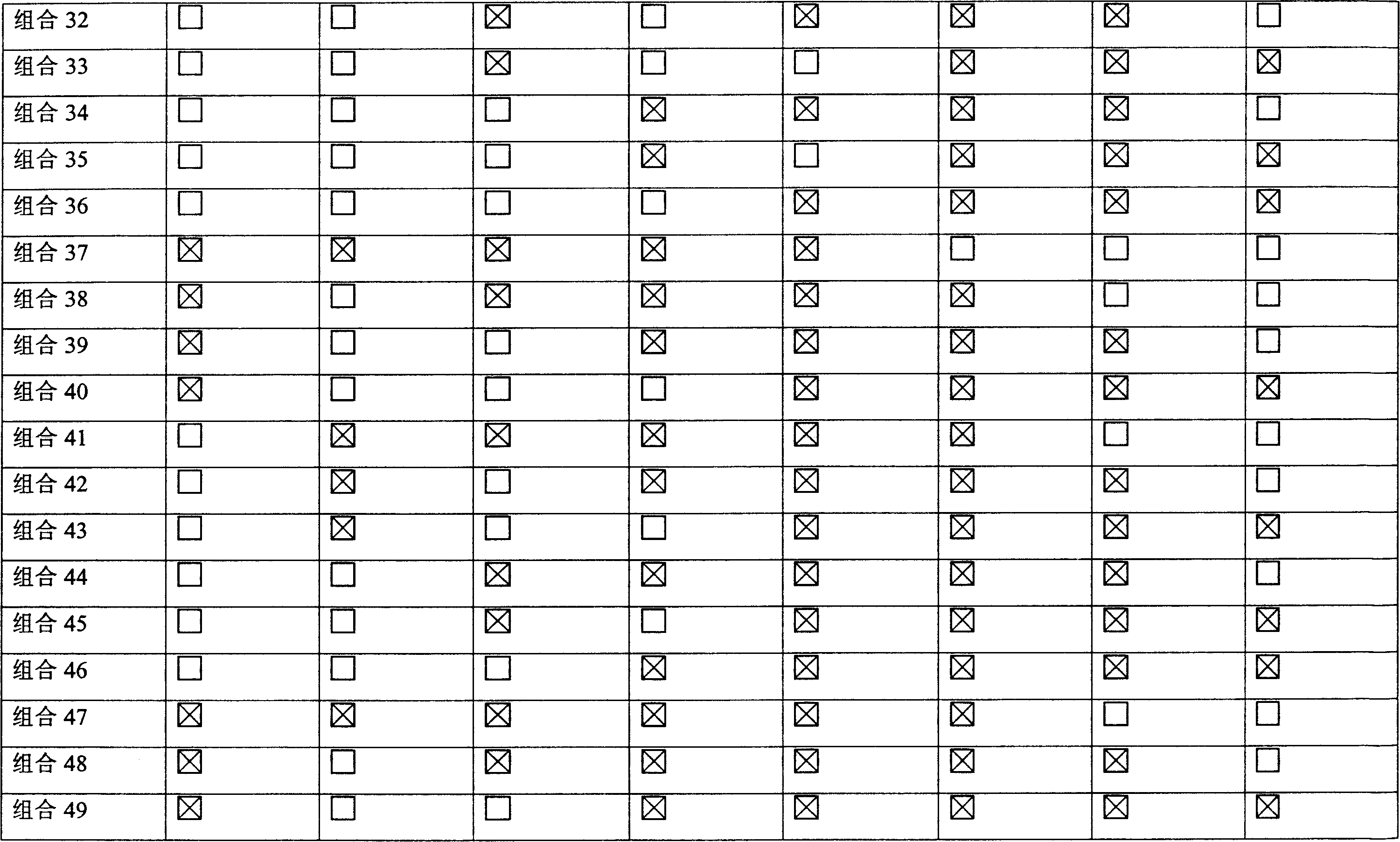

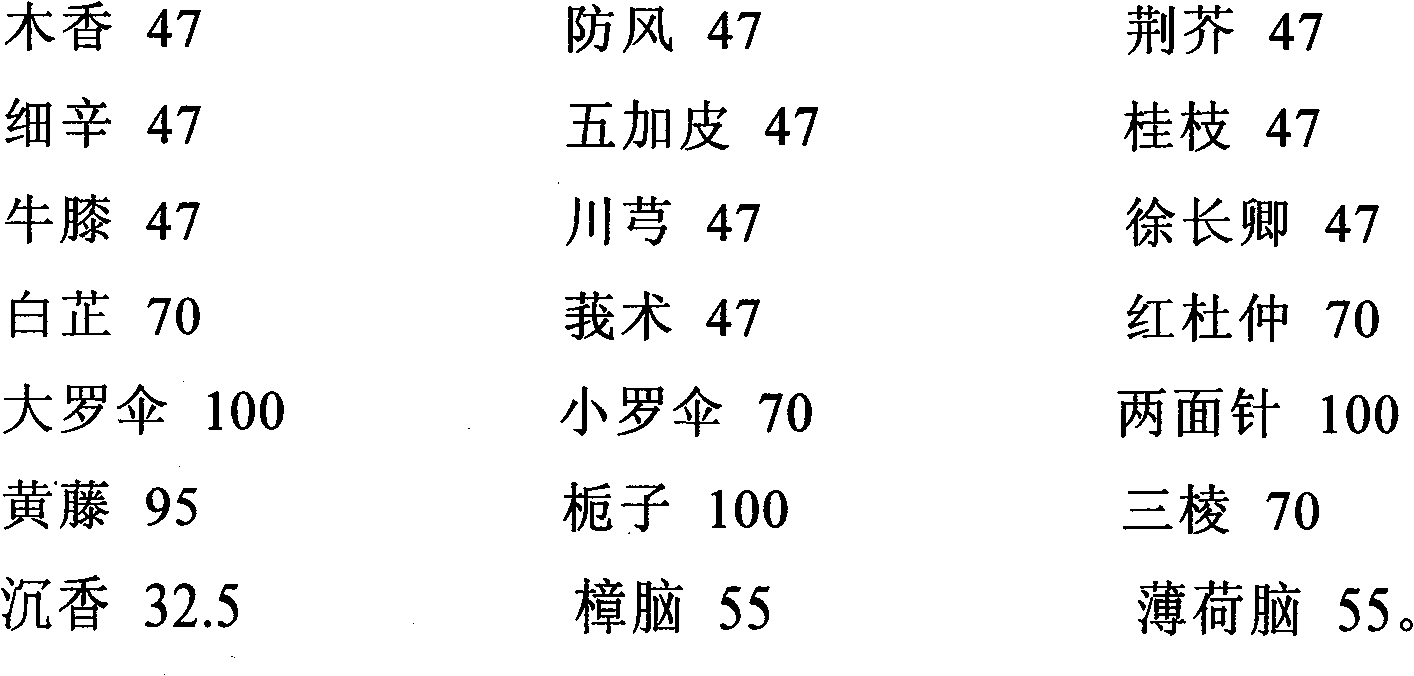

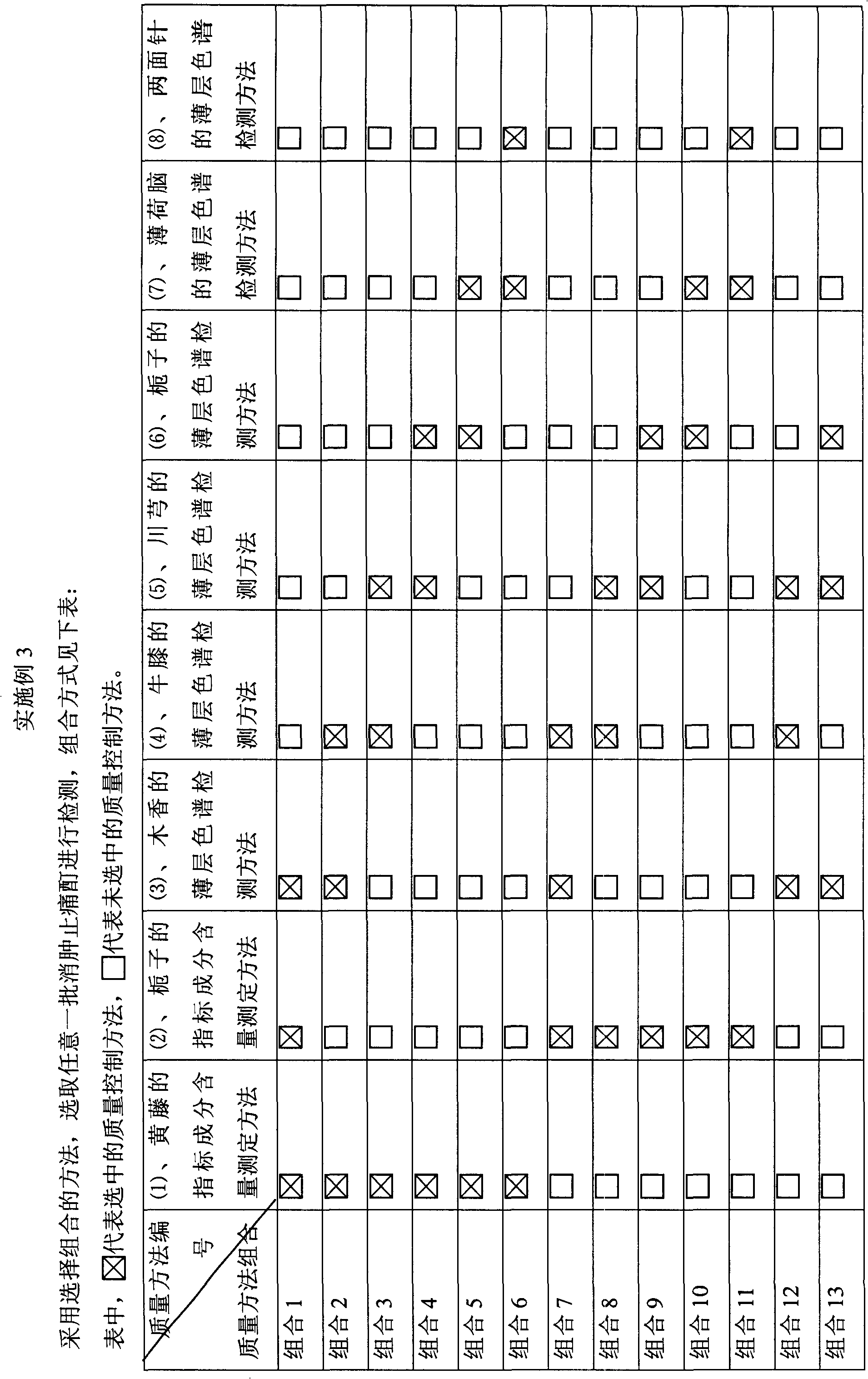

Quality control method of traditional chinese medicine preparation for treating traumatic injury and rheumatism ostealgia

ActiveCN101138594AMeet the needs of quality controlEasy qualityComponent separationAntipyreticInjury causeRheumatism

The present invention discloses a quality control method of Chinese medicine for treating traumatic injuries and rheumatic pain. The present invention combines the index component content mensuration and the thin-layer chromatography detection method for Chinese medicine, so as to achieve the aim of controlling and evaluating the quality of the Chinese medicine. Compared with the traditional quality control method, the method provided by the present invention is more scientific, reasonable and effective. In terms of operation, the method provided by the present invention has the advantages of simple operation, accuracy and reliability, high precision and high practical value.

Owner:广西壮族自治区花红药业集团股份公司

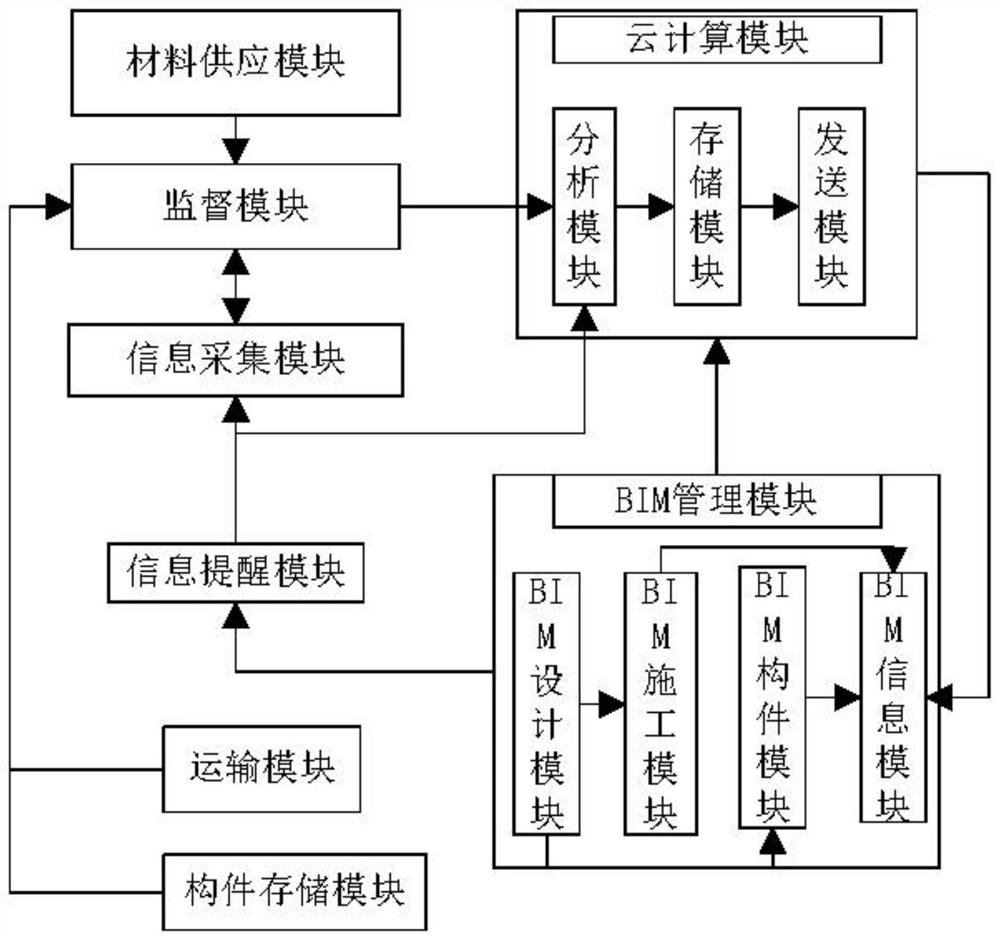

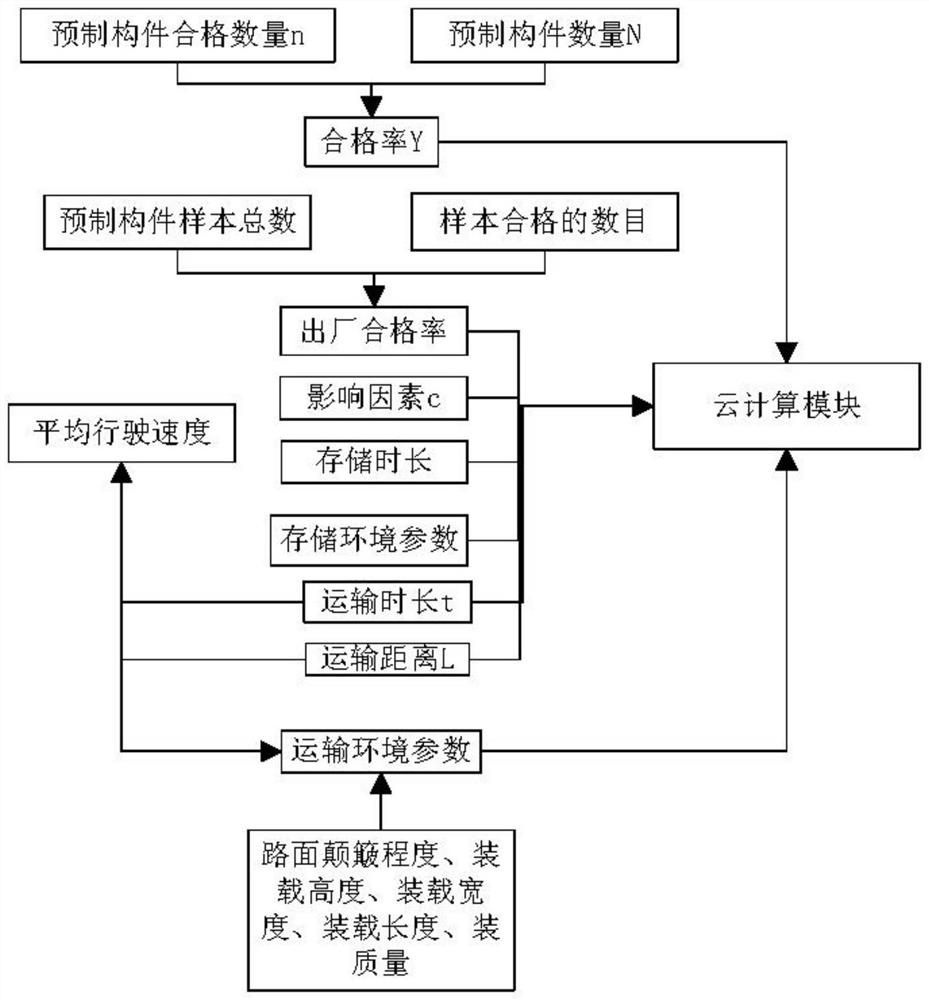

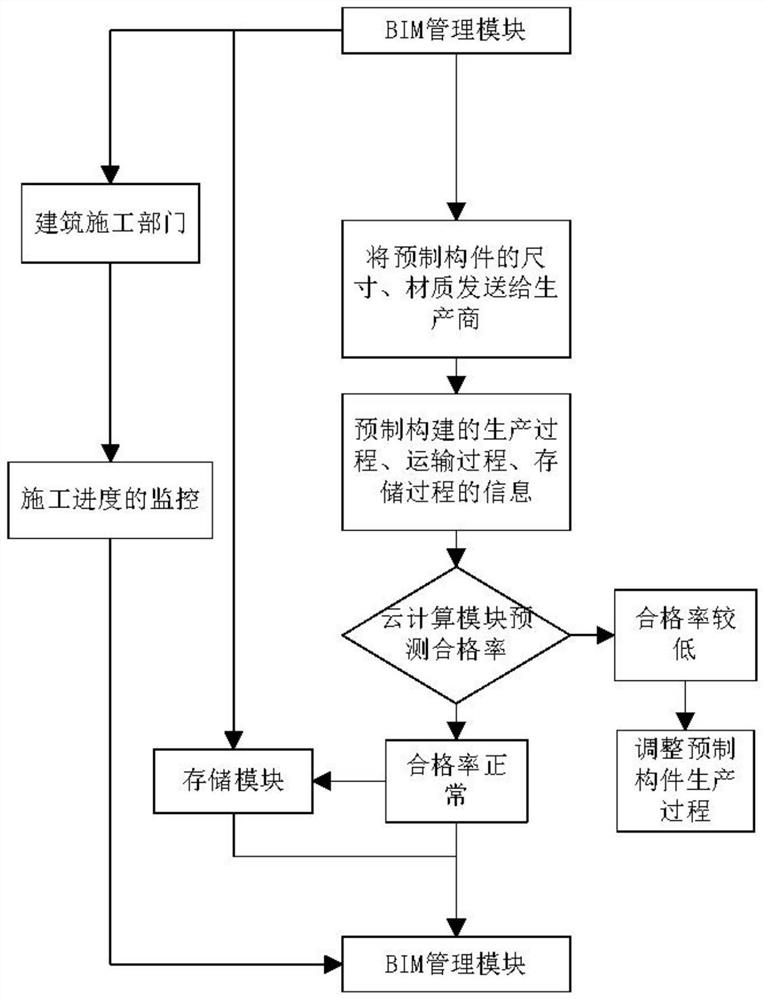

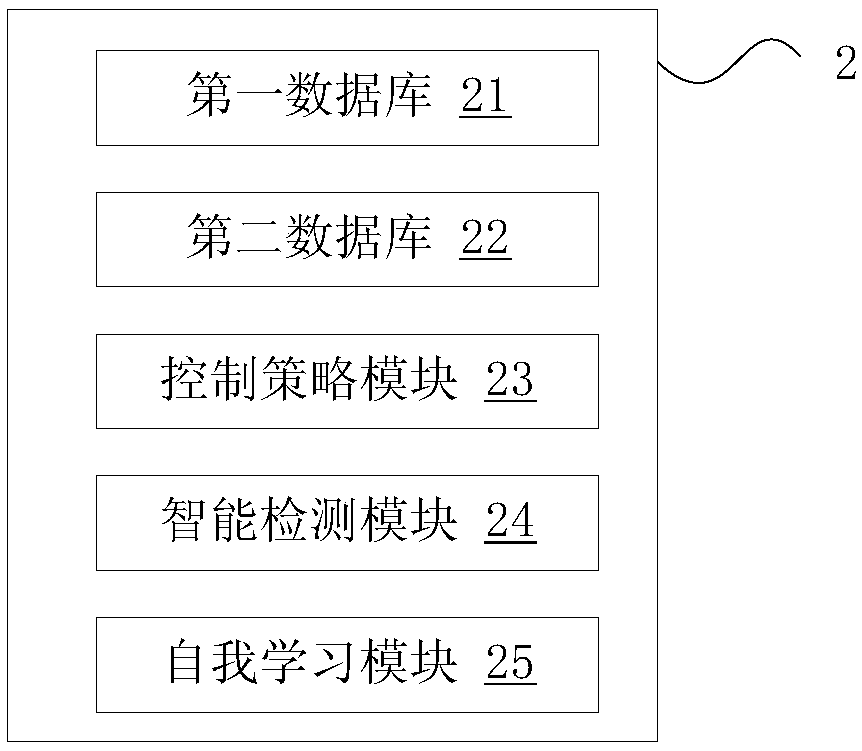

Fabricated building construction quality monitoring system based on Internet of Things

ActiveCN112819338AImprove pass rateSolve the problem of inaccurate forecastsGeometric CADConstraint-based CADConstruction engineeringThe Internet

The invention discloses a fabricated building construction quality monitoring system based on the Internet of Things, which comprises a supervision module, an information acquisition module, an information reminding module, a cloud computing module, a BIM management module and a material supply module, and is characterized in that a designer sends the size and material information of a prefabricated part to a manufacturer of the prefabricated part through the BIM management module; the supervision module receives monitoring information sent by the information acquisition module, transportation information sent by the transportation module, storage information sent by the component storage module and material information sent by the material supply module, and sends the received information to the cloud computing module, and an analysis module of the cloud computing module analyzes and calculates the received information to obtain an analysis result. And the influence of the influence factors of the prefabricated part in each process before hoisting on the qualified rate of the prefabricated part is calculated, and the production of the prefabricated part is adjusted according to the predicted qualified rate, so that the quality supervision strength of the prefabricated part is improved, and the quality monitoring of the prefabricated building is enhanced.

Owner:ZHENGZHOU RAILWAY VOCATIONAL & TECH COLLEGE

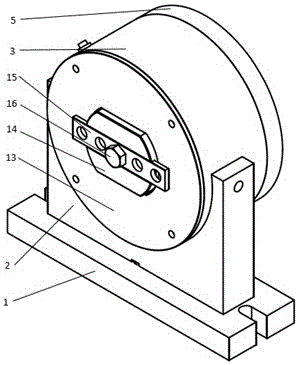

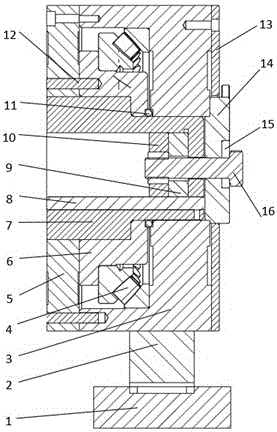

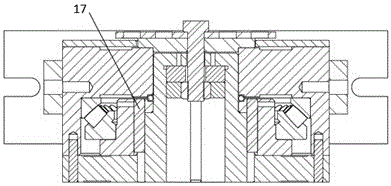

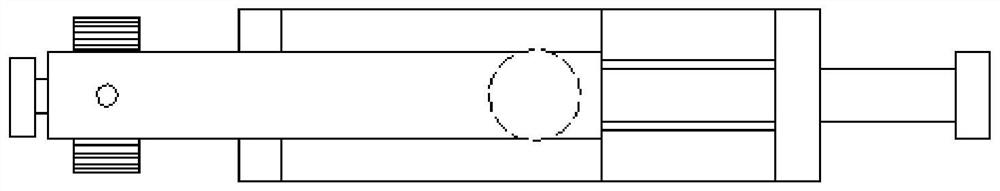

Integrated type pressing-twisting compound sensor measuring device for multifunctional bolt fastening analysis system

PendingCN106644237AReduce the number of fixturesQuality improvementMeasurement of torque/twisting force while tighteningEngineeringTorque sensor

The invention relates to an integrated type pressing-twisting compound sensor measuring device for a multifunctional bolt fastening analysis system. The integrated type pressing-twisting compound sensor measuring device comprises a base plate, a vertical mounting plate, a load sensor, an automatic centering roller bearing, a disc type static torque sensor, a bearing sleeve, a locking sleeve, a long locking pin, a circular washer, a locking ferrule, a sealing ring, a positioning pin, an external stop plate, a stop plate, a bolt gasket, a bolt and a short locking pin. According to the invention, the integration of a pressure load sensor and a plate type torque sensor can be realized, so that the pressing-twisting compound sensor relying on import in the long term, high cost, limited size and long supply period can be replaced. A split type sensor set can be replaced, so that the quantity of the test clamps can be greatly reduced and the operation is more convenient.

Owner:SHANGHAI BAIROE TEST INSTR

Litchi wood chip for ageing fruit wine, preparation and application process of litchi wood chip

ActiveCN103659975AUnique aromaHighlight featuresWood treatment detailsAlcoholic beverage preparationFruit wineAge method

The invention discloses a litchi wood chip for ageing fruit wine, preparation and application process of the litchi wood chip, and belongs to the field of fruit wine ageing technology. The invention further provides a preparation method of the litchi wood chip for ageing fruit wine, wherein novel ageing wood (accelerant) litchi wood is prepared to litchi wood chip for ageing fruit wine. The invention also provides the application process of the litchi wood chip for ageing fruit wine. According to the invention, the novel litchi wood chip for ageing fruit wine is adopted, the micro-oxygenation technology is utilized, and the litchi wood chip and litchi wood products are combined to enable fruit wine to mature within relatively short period, and endow the fruit wine with elegant and comfortable fragrance and soft and rich taste, and the litchi wood chip can be used for ageing various fruit wines. With adoption of the application process of the litchi wood in ageing fruit wine, the problems that the existing fruit wine ageing method consumes longer time, uses a large amount of containers, and is large in labor intensity and great in fruit wine loss, are solved.

Owner:广东省九江酒厂有限公司

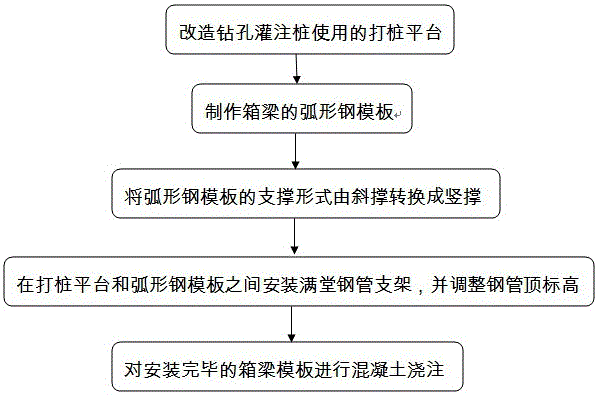

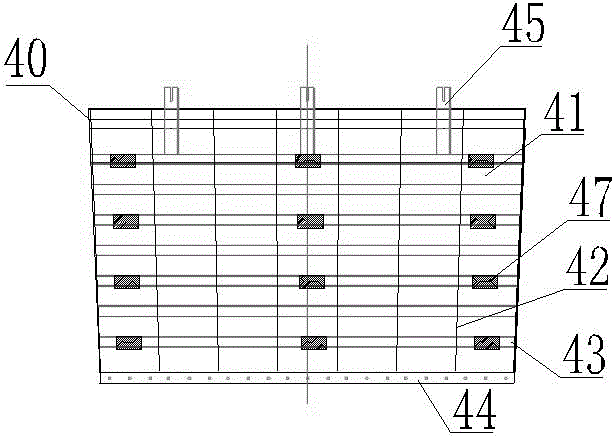

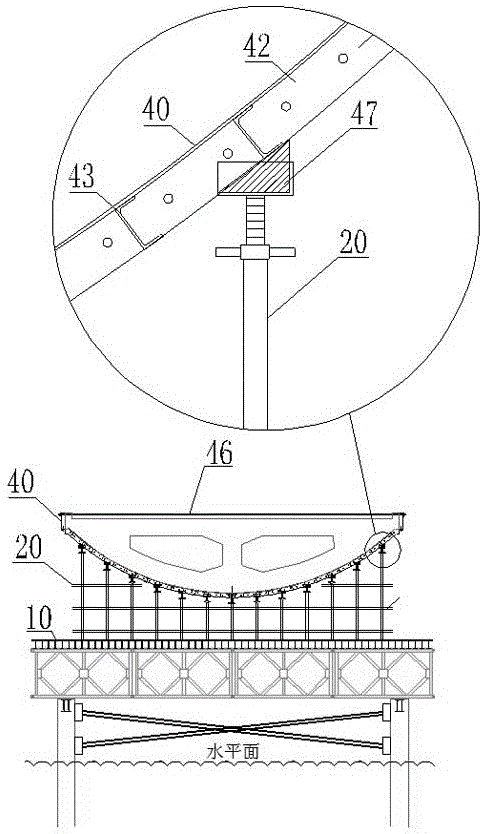

Construction method of curved fish-bellied cast-in-place reinforced concrete box girder above water

ActiveCN105568854BSimple structureImprove economyBridge erection/assemblyBridge materialsReinforced concreteEngineering

A construction method of an overwater curved fish-bellied cast-in-place reinforced concrete box girder comprises steps as follows: a piling platform for a cast-in-place bored pile is modified and taken as a bearing foundation for full-hall steel tube supports; arc-shaped steel formworks of the box girder are manufactured; the bracing form of the arc-shaped steel formworks is changed into vertical bracing from diagonal bracing; the full-hall steel tube supports are mounted between the piling platform and the arc-shaped steel formworks; a mounted box girder formwork is subjected to concrete casting. According to the construction method of the overwater curved fish-bellied cast-in-place reinforced concrete box girder, the piling platform is used as the bearing foundation, the full-hall steel tube supports are erected on the foundation, the structure of the formwork support is optimized by improving the girder formwork, the safety, economy and adaptability of the formwork support are remarkably improved, the construction difficulty is substantially reduced, the construction period is greatly shortened, construction of a fish-bellied special-shaped bridge with a unique model is successfully completed, and a safe, convenient and economical construction technology is provided for construction of similar bridges.

Owner:GUANGZHOU HENGSHENG CONSTR ENG

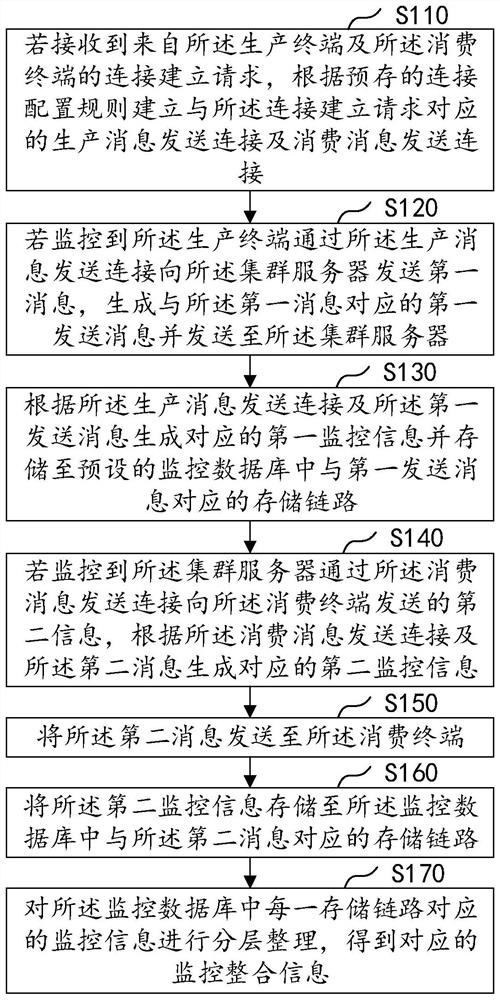

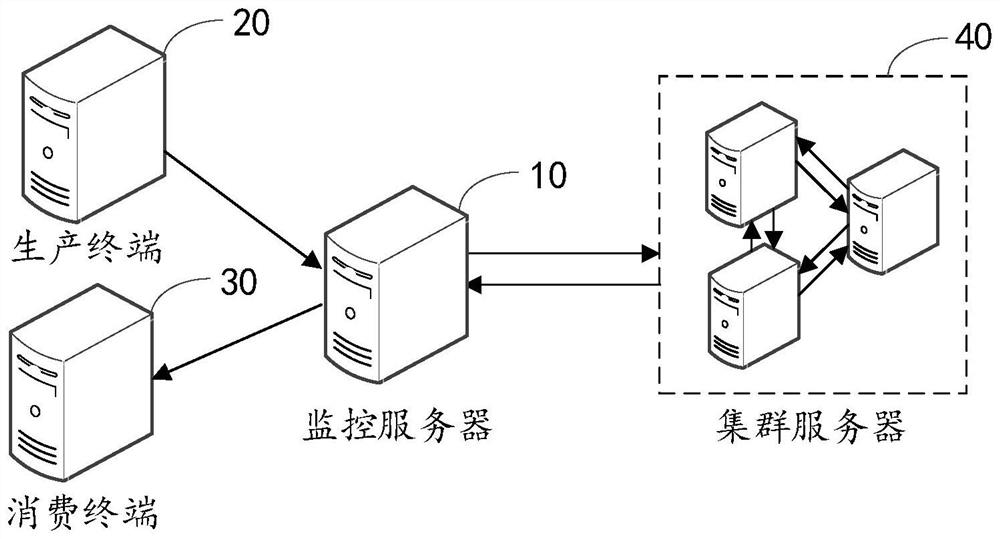

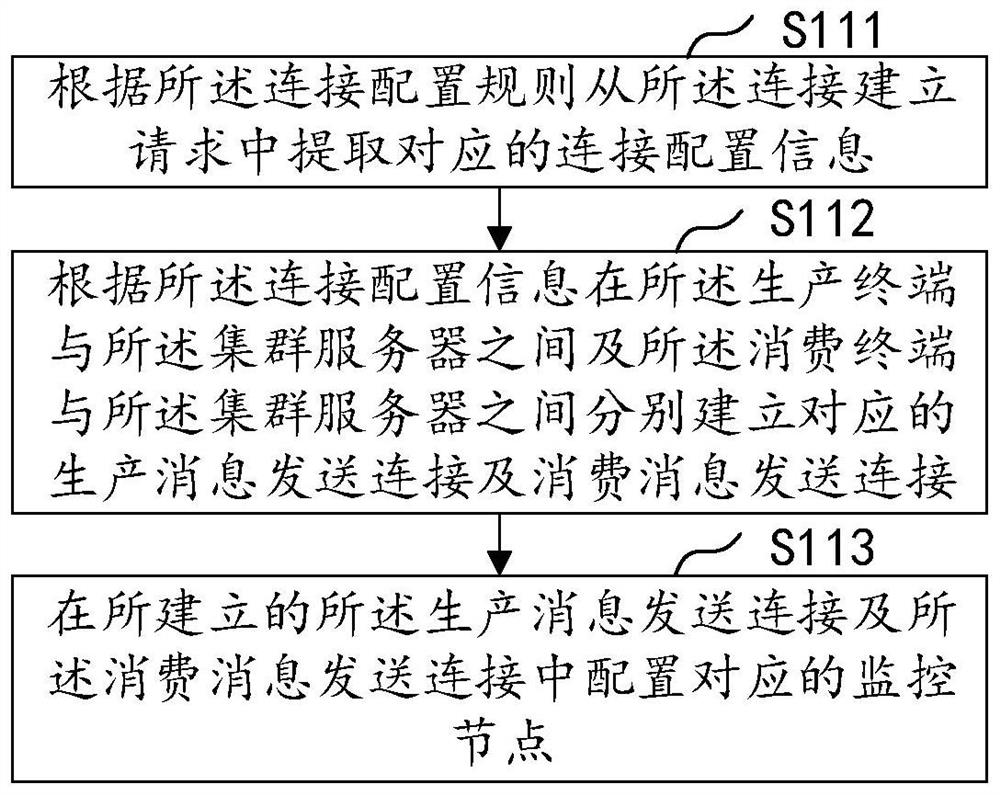

Full-link tracking monitoring method, device and equipment for cluster message and medium

PendingCN114116401AImprove quality monitoringHardware monitoringSoftware simulation/interpretation/emulationEngineeringMessage processing

The invention discloses a full-link tracking monitoring method, device and equipment for cluster messages and a medium, and the method comprises the steps: building corresponding production message sending connection and consumption message sending connection according to a connection configuration rule, monitoring the production message sending connection, generating a first sending message according to a first message transmitted in the production message sending connection, and sending the first sending message to a cluster server, generating first monitoring information and storing the first monitoring information to a corresponding storage link, monitoring consumption message sending connection and generating second monitoring information according to a second message transmitted in the consumption message sending connection, sending the second message and storing the second monitoring information to a storage link corresponding to a monitoring database, and performing hierarchical arrangement on the monitoring information of each storage link to obtain monitoring integration information. The invention belongs to the technical field of server monitoring, the message sending connection is established, the message transmitted in the message sending connection is monitored, the monitoring information is generated according to the transmitted message and stored in the corresponding storage link, and the perfect monitoring information can be obtained to perform high-quality monitoring on the message processing flow.

Owner:PING AN PENSION INSURANCE

Ultrasonic sensing array system and method

InactiveUS20090013764A1Reliable dependable resultImprove quality monitoringDetection of fluid at leakage pointAnalysing solids using sonic/ultrasonic/infrasonic wavesUltrasonic sensorEngineering

Owner:GAYLE JAMES EDWARD

VoIP quality measurement enhancements using the internet control message protocol

This invention relates to a method for enhancing the quality information of a VoIP session by deducting information from received ICMP messages, in addition to quality information already collected from media streams and / or signaling streams of the same VoIP session. ICMP messages passing on the network link are monitored and correlated with an existing and ongoing VoIP session, i.e. media stream, already monitored by a media plane monitoring unit. A data record for the media stream(s) is expanded with information from the ICMP messages, thus giving a better and more complete quality feedback of the media stream reception at the two communication endpoints.

Owner:VOIPFUTURE

Float glass production line cold end stress and thickness detection system

PendingCN108426606AImprove quality monitoringLow costMeasurement devicesGlass productionVertical vibrationProduction line

The invention discloses a float glass production line cold end stress and thickness detection system, which comprises at least one set of servo device, at least one set of industrial visual inspectiondevice, a transporting device, at least one set of compressed gas stamping device and a processor, wherein the at least one set of servo device is used for controlling movement of the industrial visual inspection device; the at least one set of industrial visual inspection device is used for scanning float glass and acquiring stress and / or thickness data information of the float glass; the transporting device is used for enabling detected float glass to translate or move relative to the servo device; the at least one set of compressed gas stamping device is used for applying pressure to the detected float glass to stabilize influences on detection by vertical vibration during the detected float glass transporting process; and the processor is in communication connection with a servo controller and the industrial visual inspection device for generating a control instruction to be sent to the servo controller and receiving the acquired data of the industrial visual inspection device. Thus, synchronous detection on the online stress and the thickness of the float glass can be realized, the detection precision is improved, quality monitoring on float glass processing is enhanced, theprocessing process is optimized, and the intelligent manufacturing level is enhanced.

Owner:湖南科创信息技术股份有限公司

Litchi wood chips for aging fruit wine and its preparation and application technology

ActiveCN103659975BUnique aromaHighlight featuresWood treatment detailsAlcoholic beverage preparationFruit wineLychee fruit

The invention discloses a litchi wood chip for ageing fruit wine, preparation and application process of the litchi wood chip, and belongs to the field of fruit wine ageing technology. The invention further provides a preparation method of the litchi wood chip for ageing fruit wine, wherein novel ageing wood (accelerant) litchi wood is prepared to litchi wood chip for ageing fruit wine. The invention also provides the application process of the litchi wood chip for ageing fruit wine. According to the invention, the novel litchi wood chip for ageing fruit wine is adopted, the micro-oxygenation technology is utilized, and the litchi wood chip and litchi wood products are combined to enable fruit wine to mature within relatively short period, and endow the fruit wine with elegant and comfortable fragrance and soft and rich taste, and the litchi wood chip can be used for ageing various fruit wines. With adoption of the application process of the litchi wood in ageing fruit wine, the problems that the existing fruit wine ageing method consumes longer time, uses a large amount of containers, and is large in labor intensity and great in fruit wine loss, are solved.

Owner:广东省九江酒厂有限公司

Litchi wood chips for aging brandy and its preparation and application technology

ActiveCN103659974BUnique aromaHighlight featuresWood treatment detailsAlcoholic beverage preparationBiotechnologyFruit wine

Owner:广东省九江酒厂有限公司

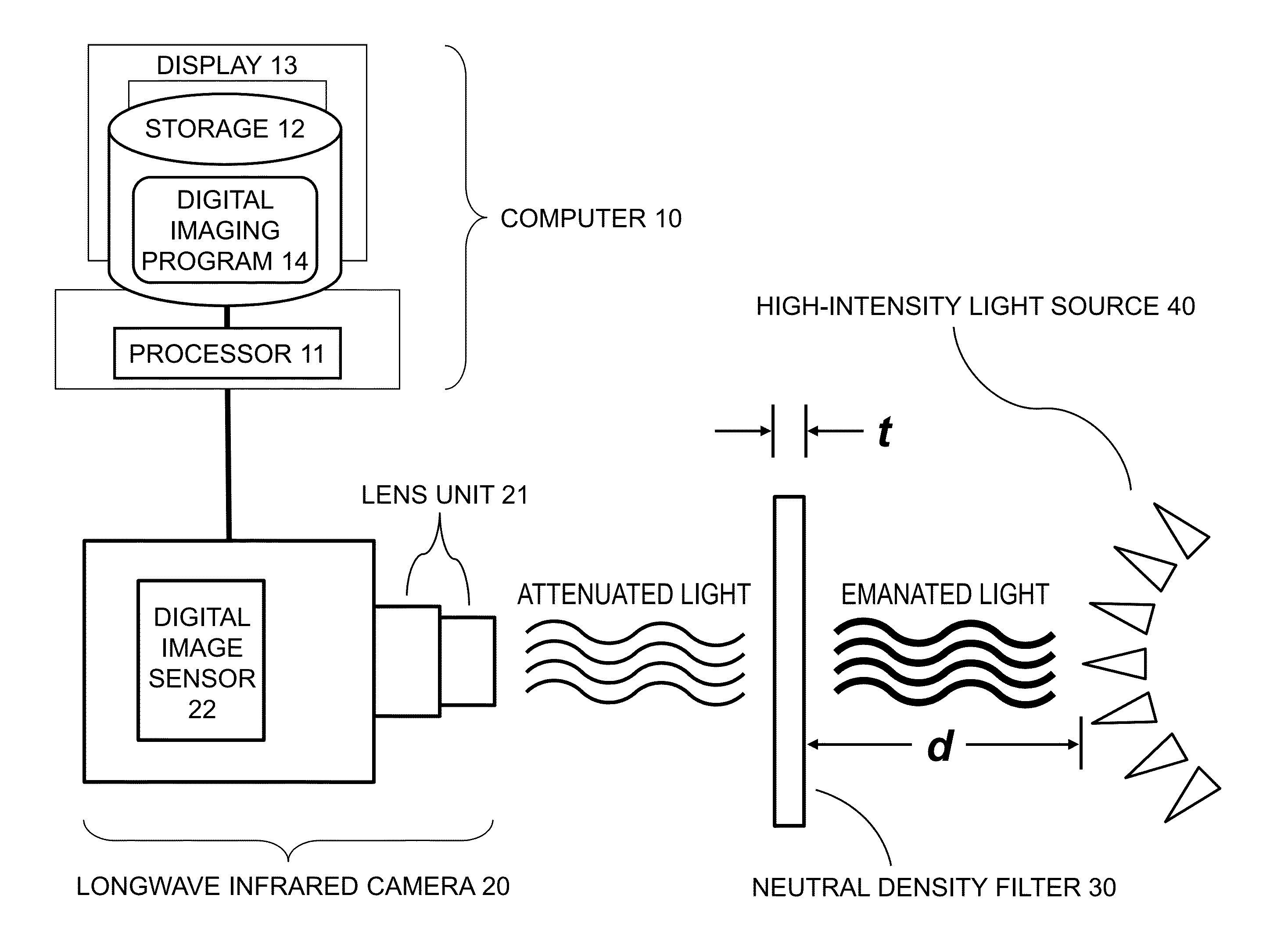

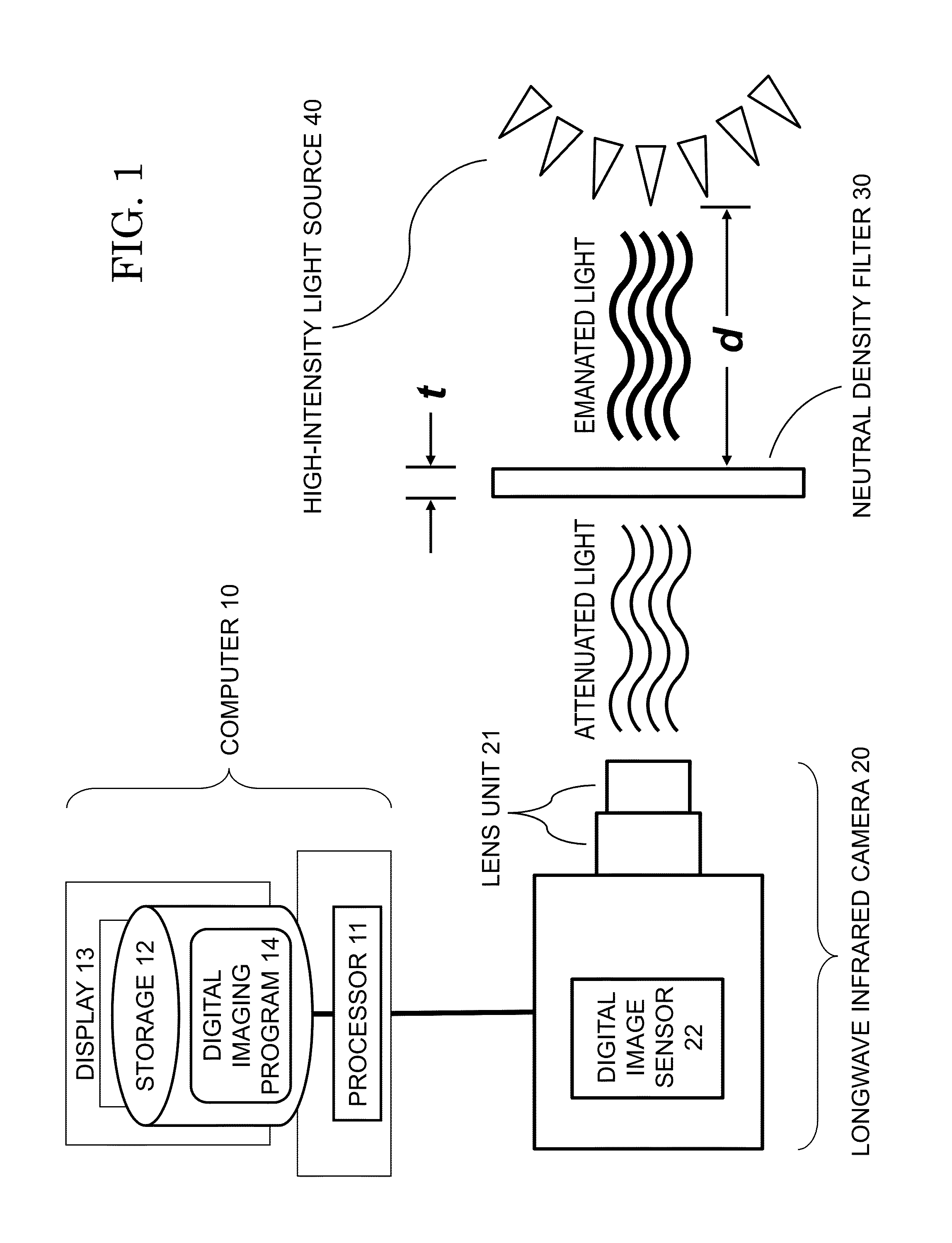

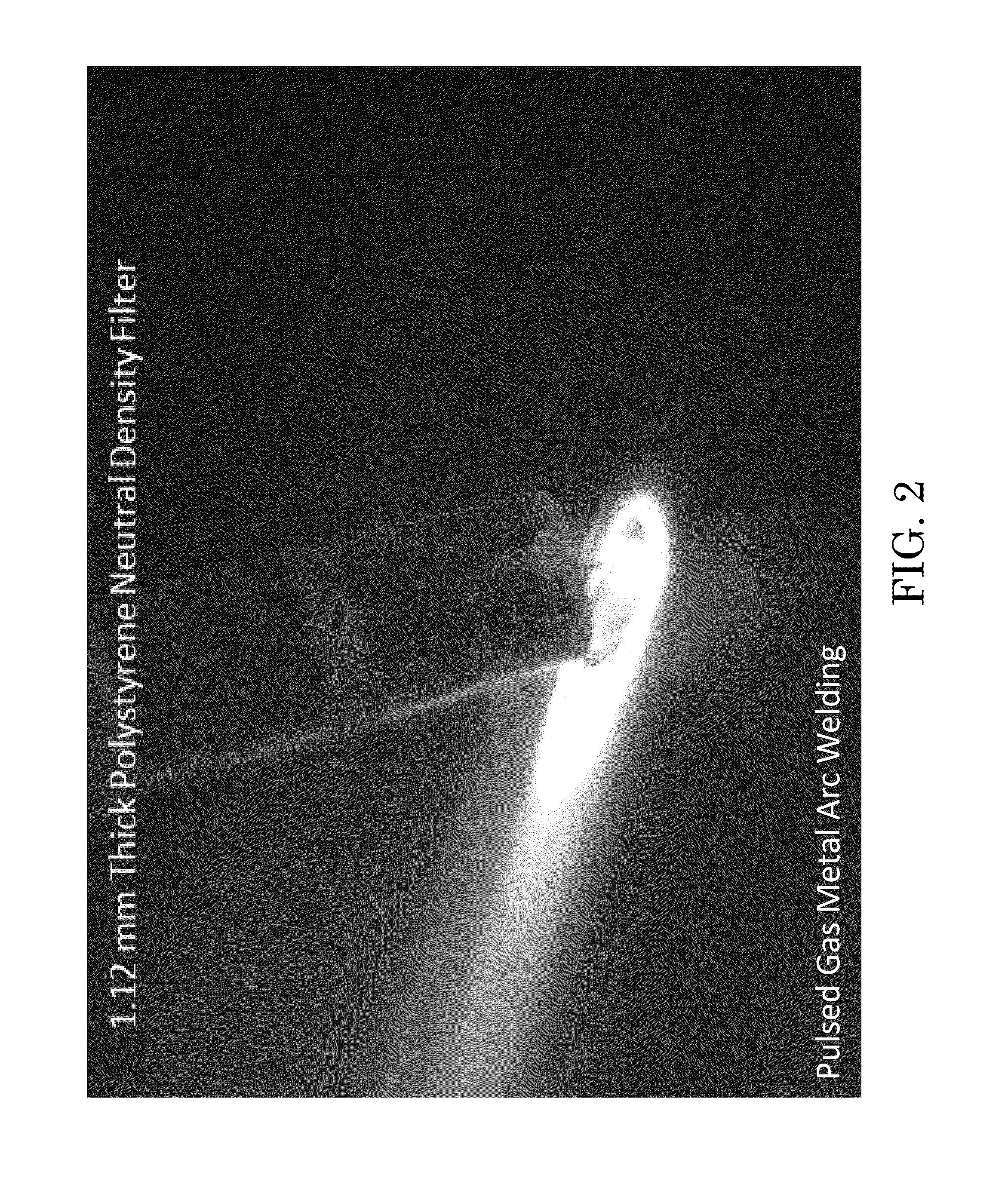

Longwave infrared imaging of a high-temperature, high-intensity light source

ActiveUS9307156B1Reduced intensity of electromagneticReduce saturationTelevision system detailsSensing radiation from gases/flamesThermoplasticPolystyrene

A neutral density (ND) filter made of an LWIR-transmissive, heat-resistant material is interposed between a longwave infrared (LWIR) imager and an entity that is highly emanative of both light and heat. According to exemplary inventive practice, the ND filter is a thermoplastic (e.g., polystyrene) sheet characterized by a thickness in the 1-2 mm range and a thermal conductivity≦0.13 W / m-K. Important parameters of the ND filter include LWIR transmittance (which depends on material and thickness) and thermal conductivity (which depends on material). The quality of the image taken of the entity is affected by the respective degrees of LWIR attenuation by, and heating up of, the ND filter. Accordingly, the material and the thickness of the ND filter are selected to optimize the image, in particular so as to avoid saturation and / or whiting-out of the image due to insufficient LWIR attenuation and / or excessive ND filter temperature.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

Quality control method of traditional chinese medicine preparation for treating traumatic injury and rheumatism ostealgia

ActiveCN101138594BMeet the needs of quality controlEasy qualityComponent separationAntipyreticInjury causeRheumatism

The present invention discloses a quality control method of Chinese medicine for treating traumatic injuries and rheumatic pain. The present invention combines the index component content mensuration and the thin-layer chromatography detection method for Chinese medicine, so as to achieve the aim of controlling and evaluating the quality of the Chinese medicine. Compared with the traditional quality control method, the method provided by the present invention is more scientific, reasonable and effective. In terms of operation, the method provided by the present invention has the advantages ofsimple operation, accuracy and reliability, high precision and high practical value.

Owner:广西壮族自治区花红药业集团股份公司

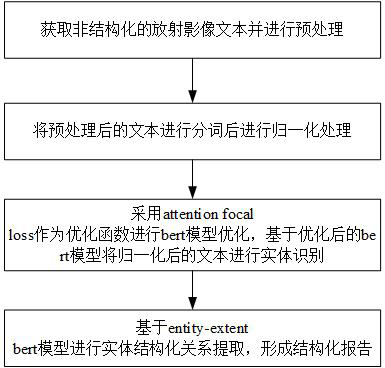

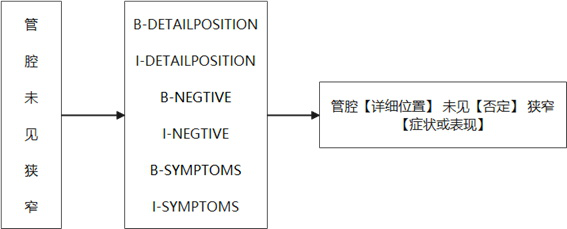

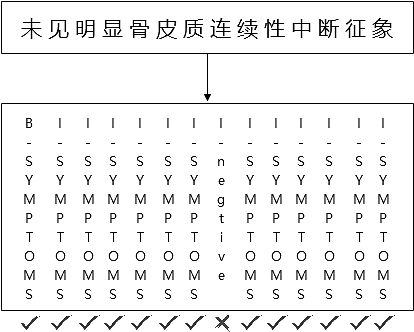

A Method for Structural Extraction of Image Report

ActiveCN114328938BEnhance expressive abilityImprove accuracyNatural language data processingMedical reportsMisclassification errorRelationship extraction

Owner:浙江卡易智慧医疗科技有限公司

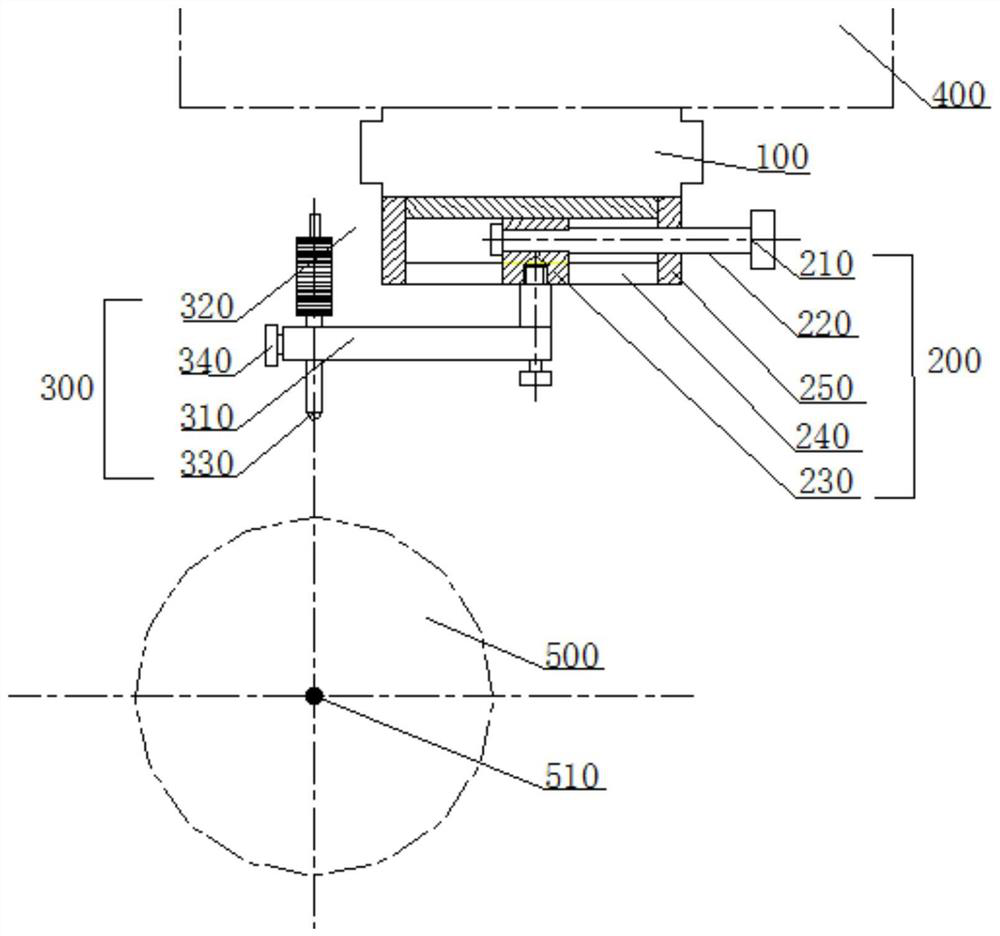

Device for measuring annular groove depth

PendingCN111678485AImprove quality monitoringReduce scrap rateMeasurement/indication equipmentsMechanical measuring arrangementsPhysicsMeasurement device

The invention relates to a device for detecting the depth of an annular groove. The device for detecting the depth of the annular groove comprises a magnetometer base, an adjusting device and a measuring device. The magnetic gauge stand is attracted to a lathe Z-axis ram through the magnetic force of the magnetic gauge stand. The adjusting device is installed on the magnetometer base. The measuring device is installed on the adjusting device. The measuring device can rotate at will; the device is low in production cost, stable in operation, easy to maintain, long in service life and wide in application range. According to the invention, the defect of insufficient measurement precision grade in the prior art is overcome; measurement errors and randomness are large. The invention provides adevice capable of accurately measuring the groove depth in cooperation with a numerical control vertical lathe. The device is simple in structure, wide in application range, convenient to operate, efficient and capable of achieving the measurement tolerance grade of 0.001-0.01, the problem that measurement is not accurate when the depth of the inner circular ring groove and the depth of the outercircular ring groove are measured through a vertical numerical control lathe is solved, and the rejection rate is reduced in the machining process.

Owner:NINGXIA KOCEL MOLD

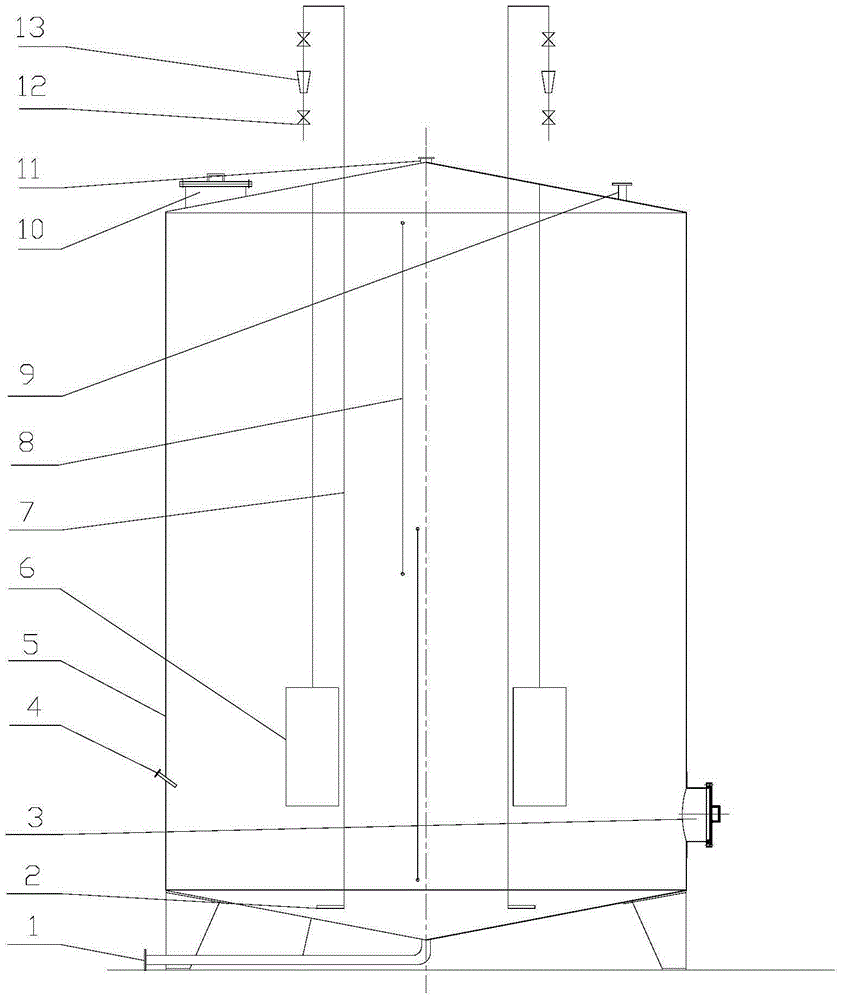

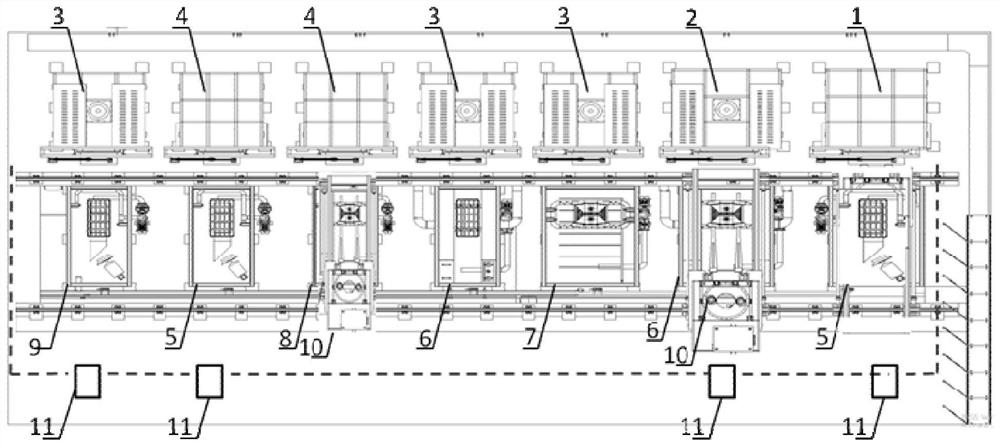

Large flexible heat treatment automatic production line with protective atmosphere and production method

PendingCN114045383AImprove quality consistencyFully automatedFurnace typesHeat treatment process controlTemperingClean water

The invention provides a large flexible heat treatment automatic production line with protective atmosphere and a process thereof. The heat treatment automatic production line can use a computer integrated control management system to realize automatic loading and unloading of a material taking vehicle, automatic execution of heat treatment process parameters, online monitoring and real-time regulation and control. The heat treatment automatic production line comprises: a set of high-temperature quenching heating unit, which is composed of three high-temperature quenching heating furnaces; a tempering heating unit which is composed of four tempering heating furnaces, wherein the heat treatment furnaces are sequentially arranged from right to left as follows: a large high-temperature quenching heating furnace, a large tempering heating furnace, a small tempering heating furnace, a small tempering heating furnace, a small high-temperature quenching heating furnace, a small high-temperature quenching heating furnace and a small tempering heating furnace; and a set of matched high-precision cooling unit which is composed of cooling tanks with different specifications, wherein the cooling tanks are sequentially a clear water tank, an oil tank, a cleaning tank, an oil tank, a saline water tank, a clear water tank and an organic solvent tank from right to left.

Owner:SHANGHAI AEROSPACE EQUIP MFG GENERAL FACTORY

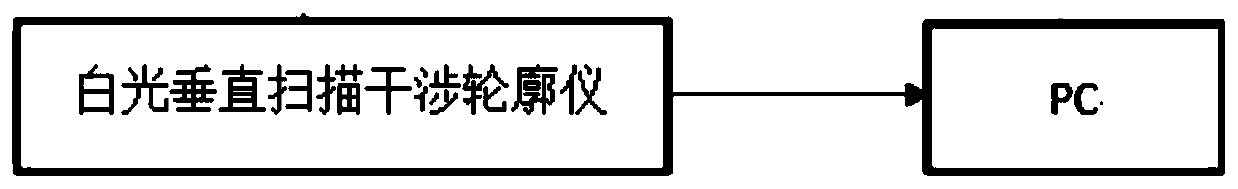

A feature automatic recognition method for laser grooves formed by laser processing

ActiveCN107292924BHigh precisionRealize one-button measurementImage analysisLaser processingImage resolution

The invention proposes a method for automatically recognizing features of a laser groove formed by laser processing, and the method comprises the steps: employing a three-dimensional detection system to obtain a digital image corresponding to a real height, such as a white-light vertical scanning interference contourgraph, wherein the longitudinal resolution of the digital image is less than 1.0nm, and the highest lateral resolution can reach 0.35 microns, i.e., enabling each pixel to be corresponding to one height value. The digital image processing technology is employed for the recognition of the groove, and the width and depth of the groove are calculated. The above detection is carried out after the laser groove is formed by the laser processing, so the detection cannot be affected by the physical impact of laser processing, and the estimation accuracy and reliability of the laser groove can be improved.

Owner:长川科技(苏州)有限公司

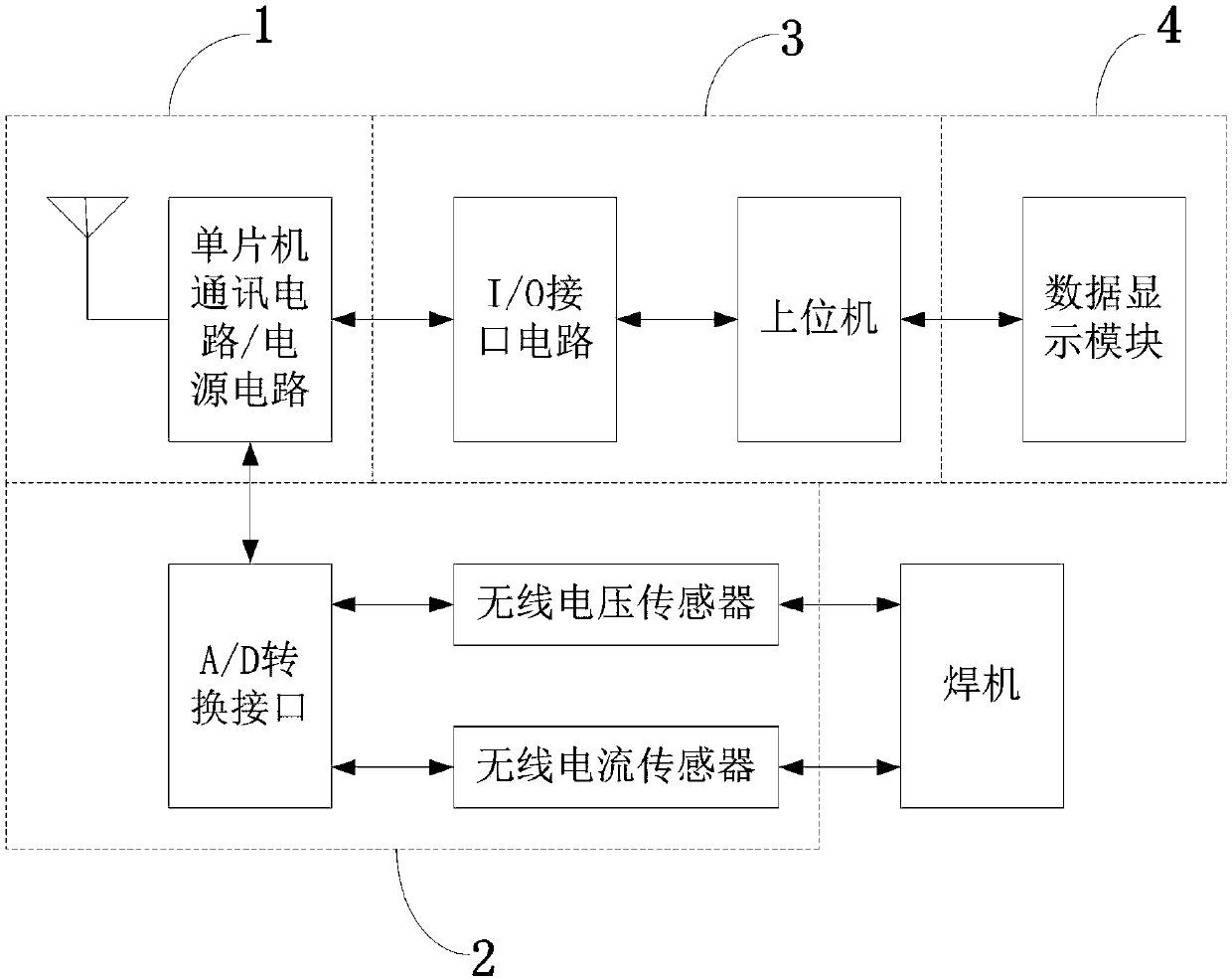

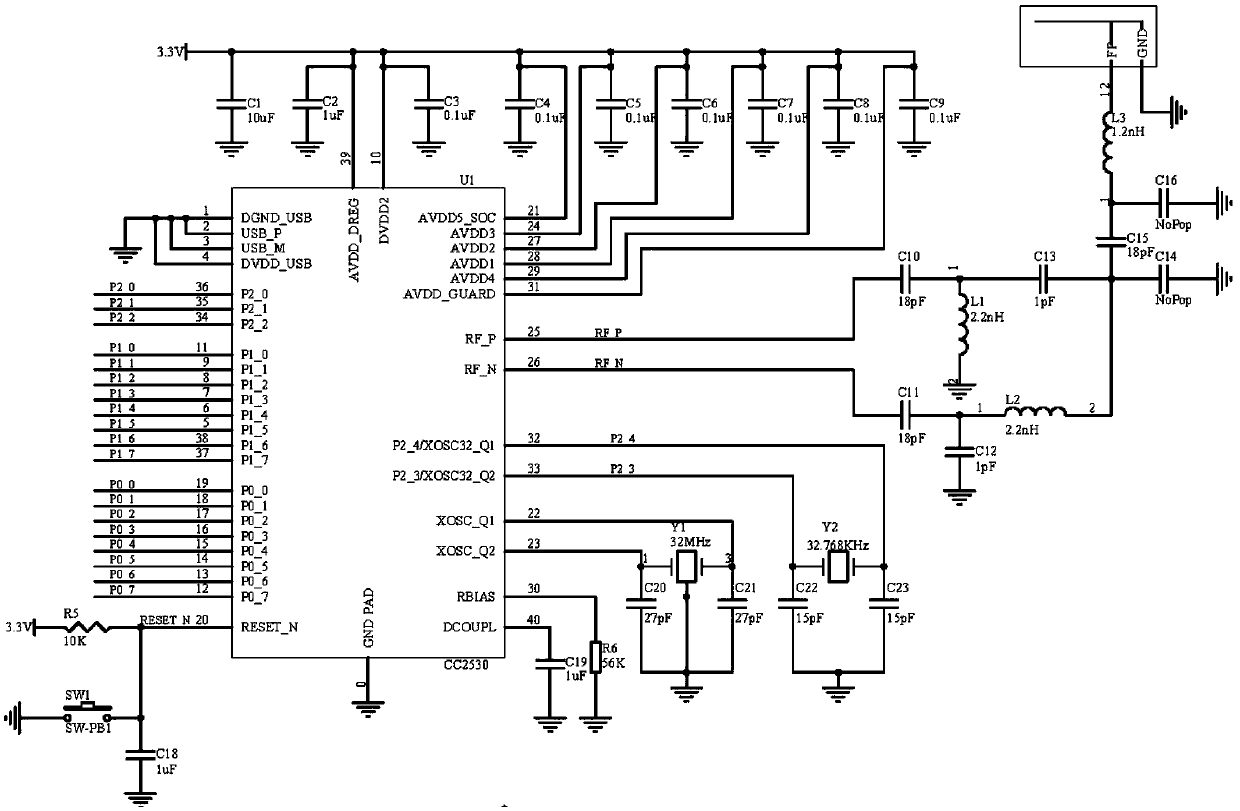

Virtual instrument-based indirect ZigBee IoT welding power supply parameter measuring device

PendingCN109541493AEnables indirect measurementsRealize cluster managementParticular environment based servicesNetwork topologiesData displayWelding power supply

The invention belongs to the technical field of virtual instruments and ZigBee IoT control, and discloses a virtual instrument-based indirect ZigBee IoT welding power supply parameter measuring device. The Virtual instrument-based indirect ZigBee IoT welding power supply parameter measuring device is provided with a ZigBee wireless network transmission module for transmitting wireless signals, a data acquisition module for carrying out welding signal acquisition, a data collection and storage module for carrying out data collection and storage, and a data display module for carrying out data display. Based on a ZigBee IoT self-organizing network technology, the device is low in design cost, simple to mount and suitable for welding parameters wireless sensor terminal modules in industrial fields, and is capable of developing virtual instrument and IoT technology-based workshop welding power supply monitoring systems so as to realize indirect measurement and cluster management of equipment at industrial production site, thereby reducing the management cost and increasing the business productivity.

Owner:CHONGQING IND POLYTECHNIC COLLEGE

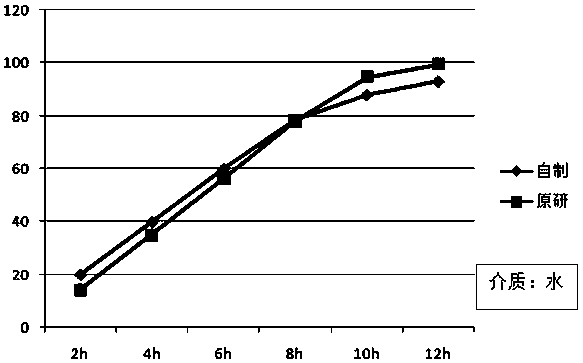

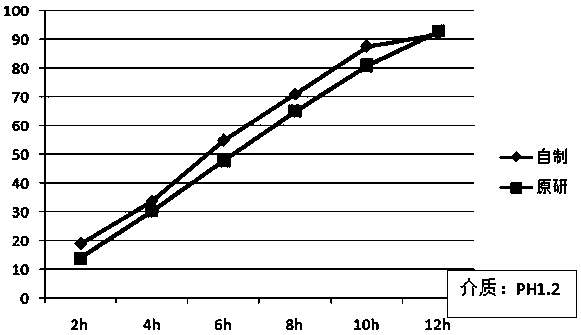

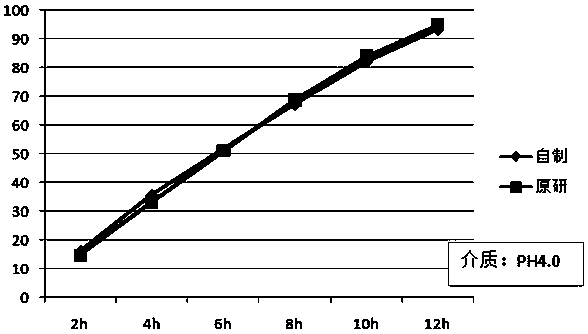

A kind of felodipine sustained-release tablet and preparation method thereof

ActiveCN104997750BAchieve the desired effectSolve the problem of easy exceeding the standardOrganic active ingredientsPharmaceutical delivery mechanismDual releaseWeight gain

The invention provides a felodipine sustained-release tablet, which is prepared by wrapping a sustained-release layer with a sustained-release element tablet. The sustained-release element tablet contains the following components in weight percentage: 1-4% of felodipine, 40% polyoxyethylene as a solubilizer Hydrogenated castor oil accounts for 2-8%, filler 63-72.5%, binder 1-5%, skeleton slow-release material 10-25%, absorbent 1-6%, lubricant 0.2-1.5%; slow-release layer The composition contains the following components by weight percentage: the coating material is ethyl cellulose, and the weight gain is 6-12% of the total weight of the sustained-release tablet; the plasticizer, the weight gain is 0-20% of the weight of the coating material; As for the adhesive, the weight gain is 0-50% of the weight of the coating material; for the coloring agent, the weight gain is 0-10% of the weight of the coating material. The present invention realizes the double sustained release of the preparation by constructing the sustained-release tablet and the coating sustained-release material, fully releases the drug, greatly improves the bioavailability, and meets the requirements of consistency evaluation; and has good reproducibility, high uniformity, and reliable quality. control.

Owner:HANGZHOU CONBA PHARMA

Aviation fuel water reaction automatic test device

InactiveCN101430314BEasy to transportReliable test condition control meansPreparing sample for investigationFuel testingDrive wheelAutomatic test equipment

An automatic test device for water reaction of aviation fuel is characterized in that a front bracket (2) and a rear bracket (3) are installed on the base (1), and a guide rail (4) is installed on the front bracket (3), and the guide rail (4) Cooperate with the slider or pulley (5), the slider or pulley (5) is installed on the skateboard (6), the lower part of the skateboard (6) is connected with the bracket (7), and one end of the connecting pin (8) is fixed on the skateboard (6), the other end is inserted on the rocker arm (14), the other end of the rocker arm (14) is inserted with the connecting rod shaft (9), and the other end of the connecting rod shaft (9) is connected to the drive rod (10) One end of the driving rod (10) is connected to each other, and the other end of the driving rod (10) is equipped with a balance weight (11). The runner (13) that drives it to rotate is installed on it and the runner (13) links to each other with motor (16). The invention has the advantages of simple structure, convenient manufacture, accurate test and good repeatability.

Owner:中国人民解放军南京军区联勤部油料监督处

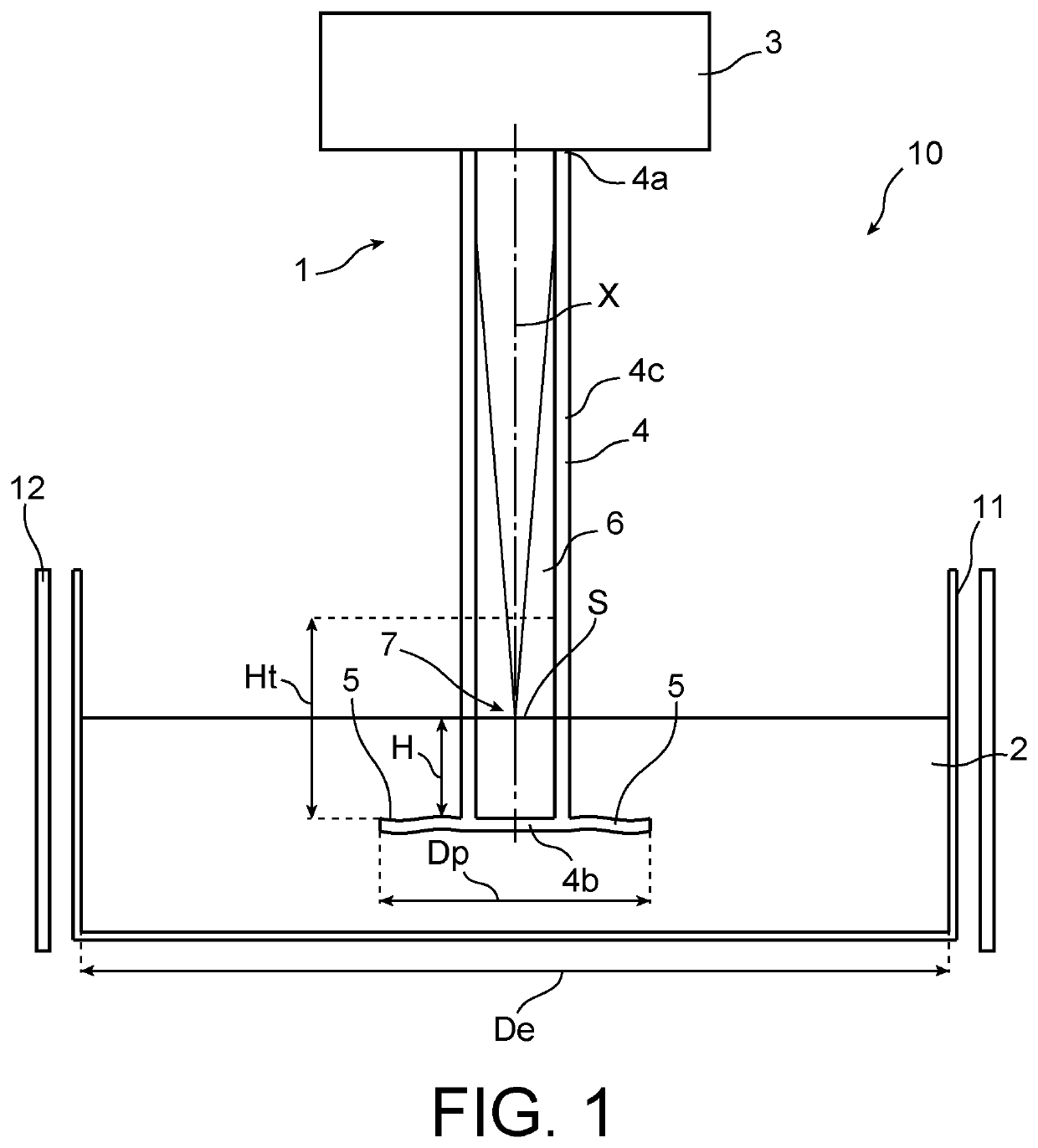

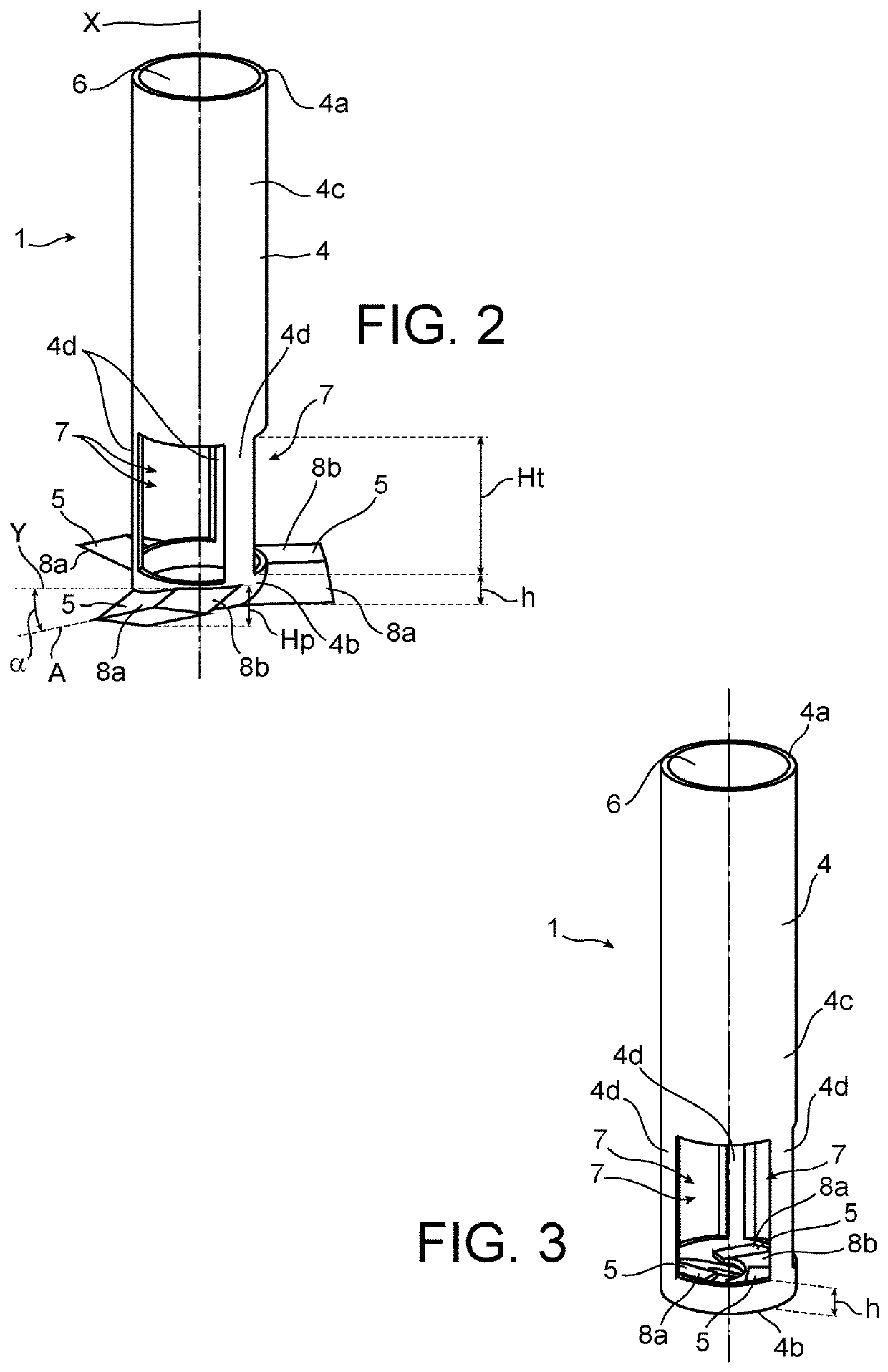

Device for characterising a liquid material

PendingUS20220026368A1Easy to analyzeShorten analysis timeRotary stirring mixersTransportation and packagingEngineeringMechanical engineering

A device for characterising at least one liquid material includes an analysis head and a rotating mechanical mixer. The mixer includes a central part having an internal cavity which forms an analysis chamber, a first end connected to the analysis head, and a plurality of stirring blades which are connected to a second end that is hollow so as to ensure fluid communication between the internal cavity and the liquid bath. The mechanical stirring blades are intended to be totally submerged, the central part comprises one or more openings intended to be partially submerged, and each mechanical stirring blade comprises at least one stirring flange oriented at a non-zero angle of orientation.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

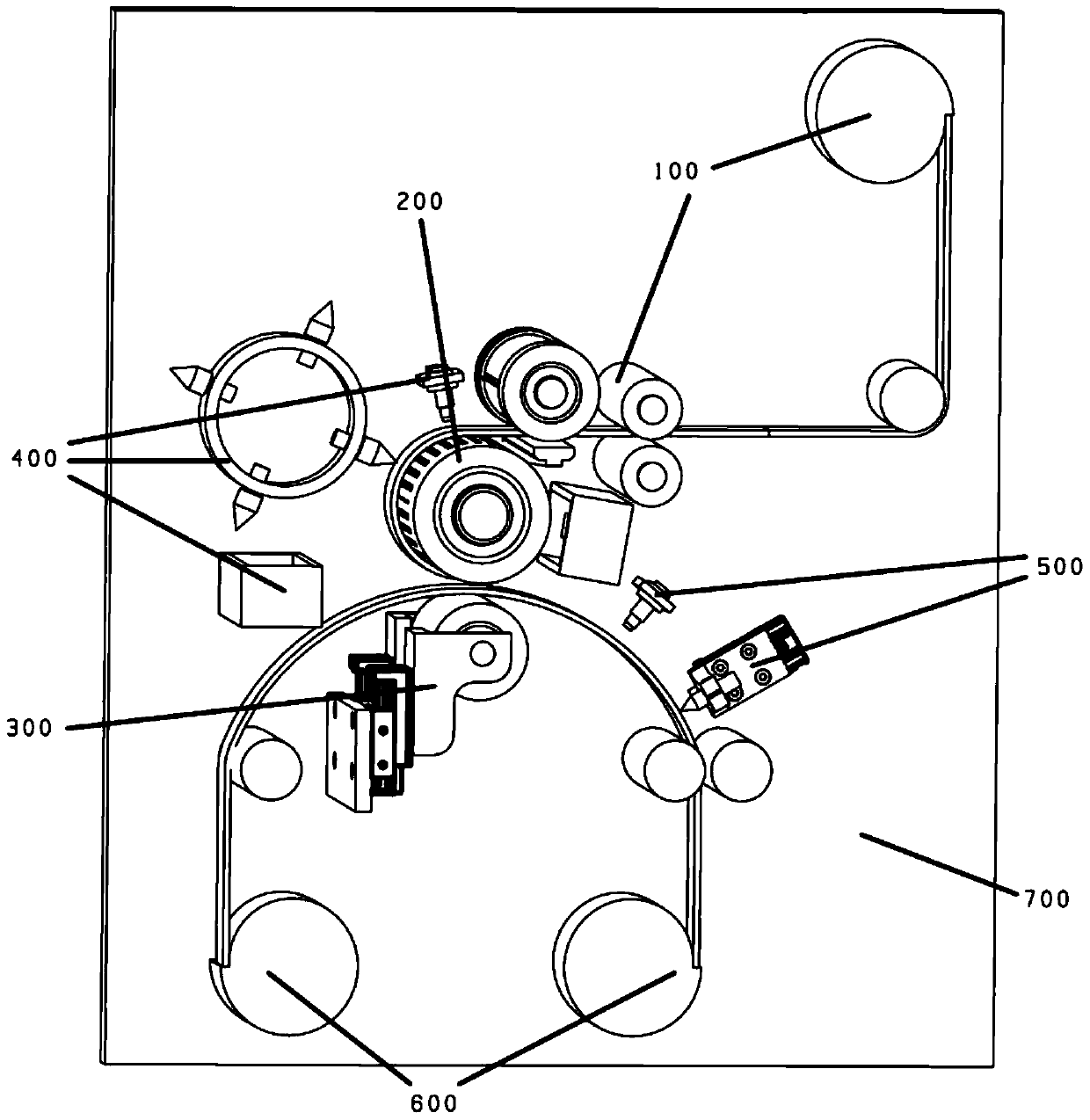

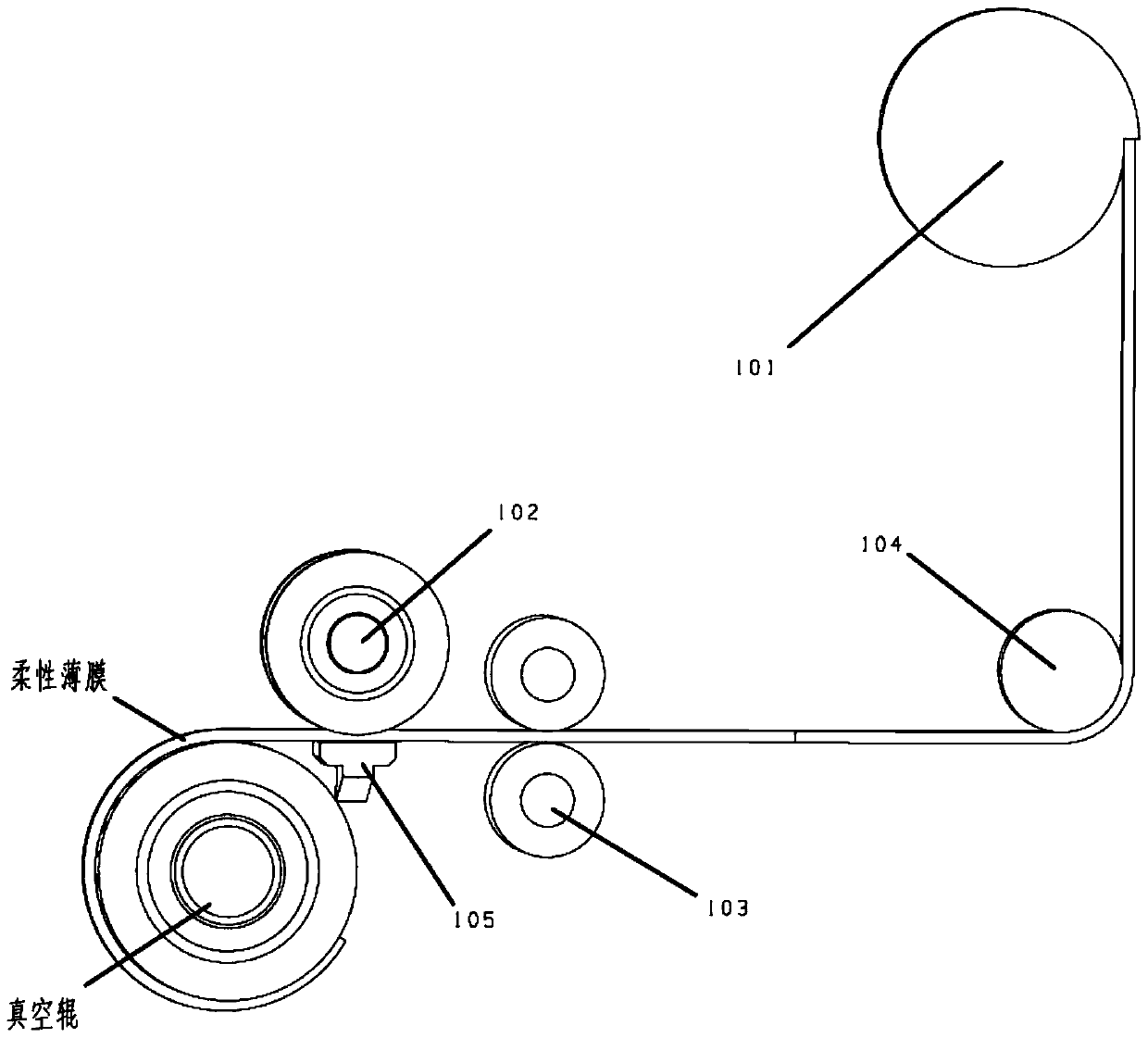

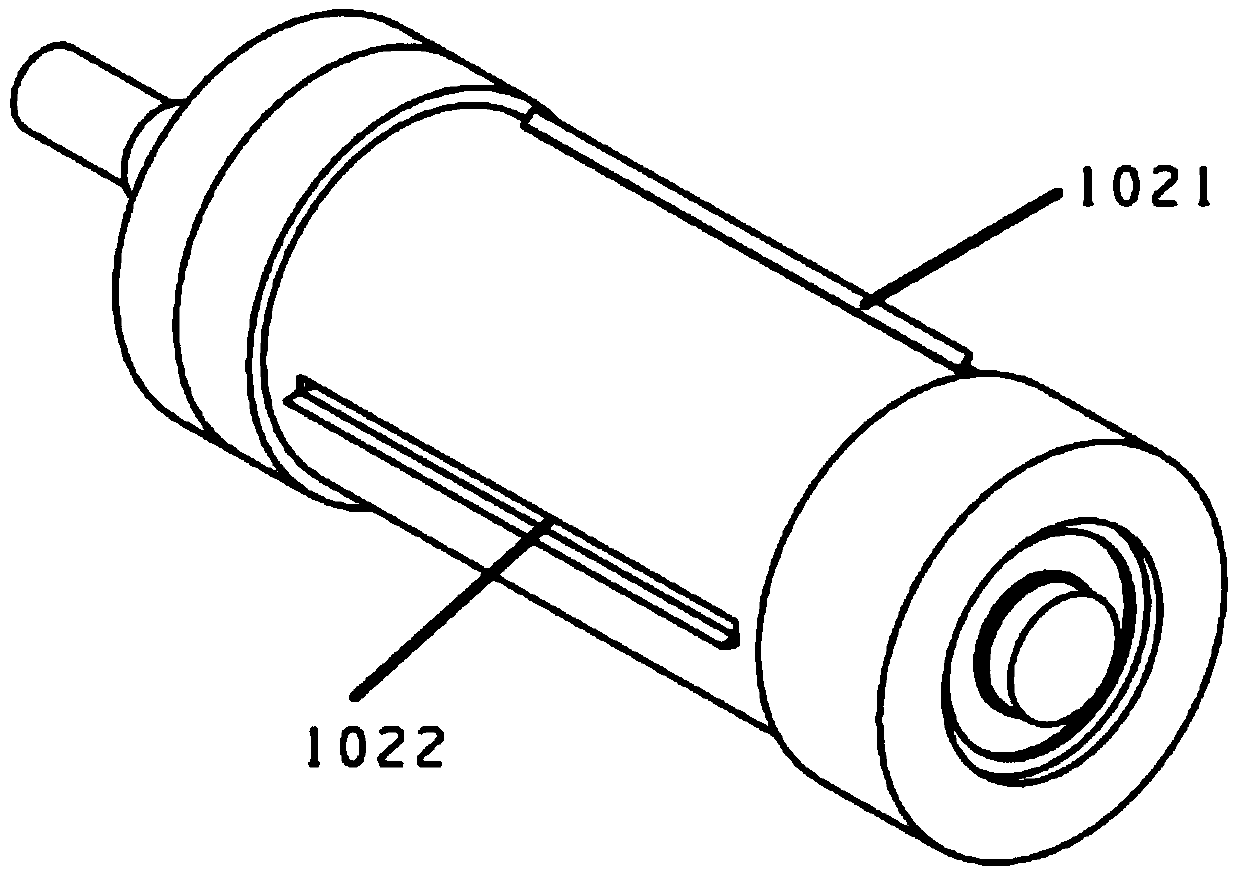

A sheet-by-sheet transfer device suitable for rolling flexible electronic devices

ActiveCN105070674BHigh degree of automationImprove efficiencySemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingEngineeringFlexible electronics

The invention discloses a sheet-by-sheet transfer apparatus suitable for a rolling flexible electronic device. The sheet-by-sheet transfer apparatus comprises a film feeding unit, a carrier tape conveying unit, a vacuum roller adsorption unit, a pressure roller transfer unit and a waste material rejection unit, wherein the film feeding unit is used for feeding motion of a film and performing mold cutting on the film, the film after the mold cutting is driven via the vacuum roller adsorption unit to the pressure roller transfer unit, the film after the mold cutting realizes adhesion and fixation to a carrier tape in the pressure roller transfer unit, and the waste material rejection unit provides multiple real-time detection and rejection operation of a waste material according to condition needs. According to the invention, module units are connected with one another and cooperate together, a high-speed detection transfer process of the rolling flexible electronic device sheet by sheet is realized, and at the same time, the apparatus also has the advantages of good motion stability and reliability and the like.

Owner:HUAZHONG UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com