Float glass production line cold end stress and thickness detection system

A float glass and detection system technology, applied in measuring devices, instruments, etc., can solve the problems of cumbersome detection and high hardware cost, and achieve the effects of improving detection accuracy, optimizing processing technology, and improving the level of intelligent manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

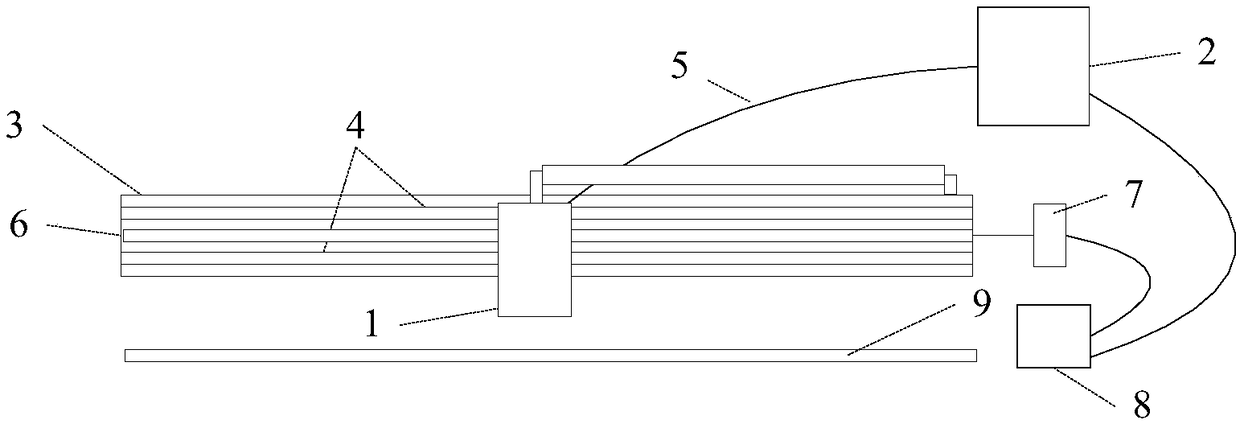

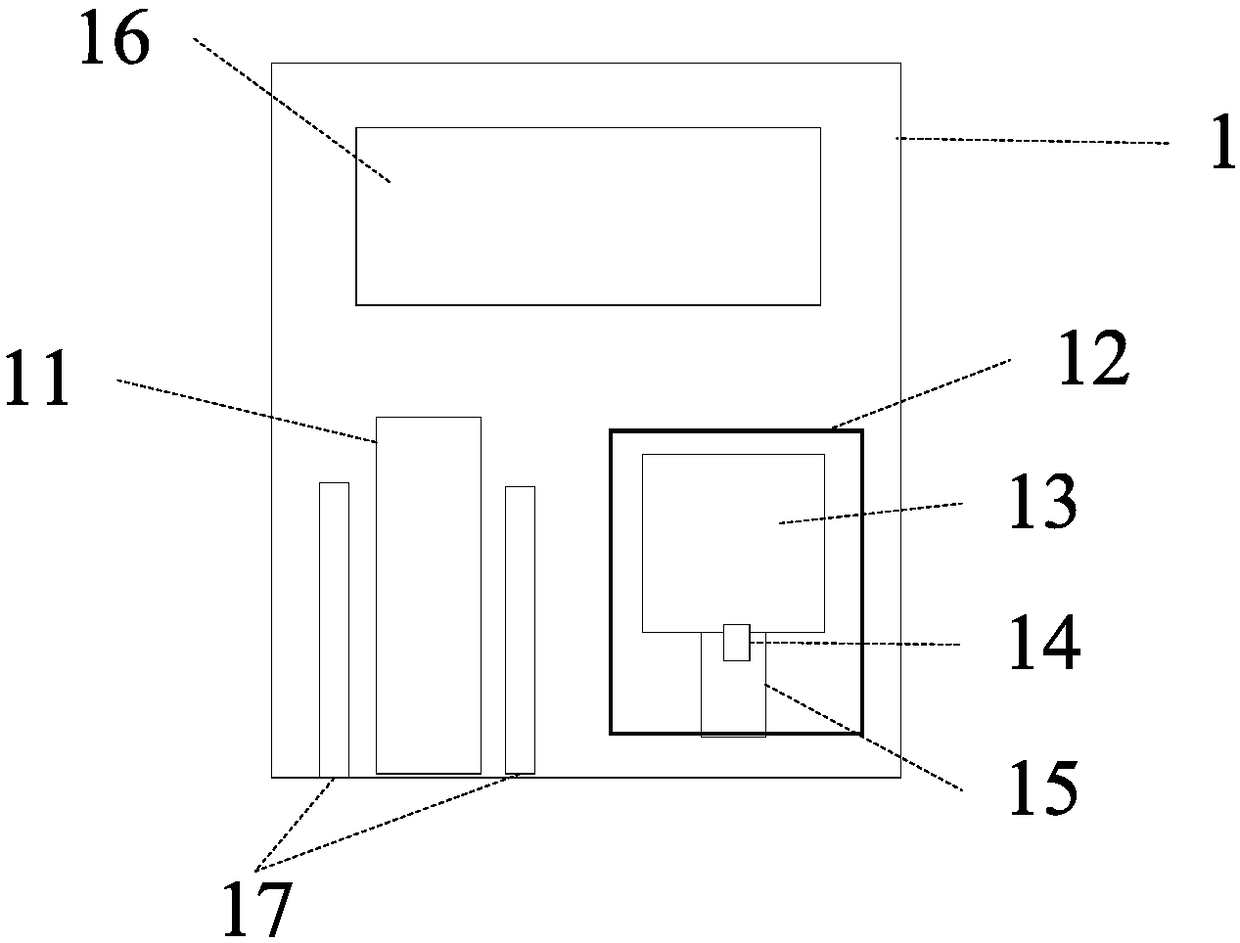

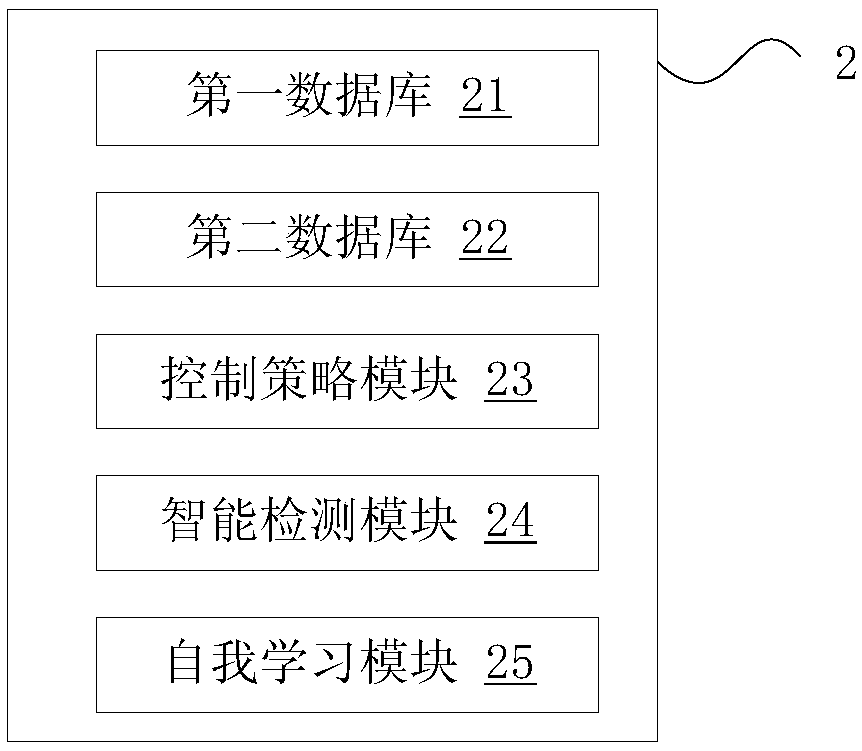

[0049] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

[0050]It should be understood that the drawings and descriptions of this embodiment have been simplified to help clearly understand the system and various components of the present invention by way of example, and at the same time, for the purpose of focusing on describing the present invention, the cold end stress of the float glass production line and the Non-critical components in the thickness detection system. Those skilled in the art will recognize that other components may be desirable and / or necessary in order to practice the invention. However, since these components are well-known in the art, and since they do not contribute to a better understanding of the present invention, no desc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com