Virtual instrument-based indirect ZigBee IoT welding power supply parameter measuring device

A welding power source and virtual instrument technology, applied in the field of ZigBee IoT welding power source parameter indirect measurement device, can solve problems such as difficulty in grasping the accuracy of welding parameters of welding equipment, difficulty in equipment scheduling and allocation management, and welding parameters not meeting process requirements, etc. Achieve the effect of improving workshop productivity, simple structure and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] In order to further understand the content, features and effects of the present invention, the following examples are given, and detailed descriptions are given below with reference to the accompanying drawings.

[0047] The structure of the present invention will be described in detail below in conjunction with the accompanying drawings.

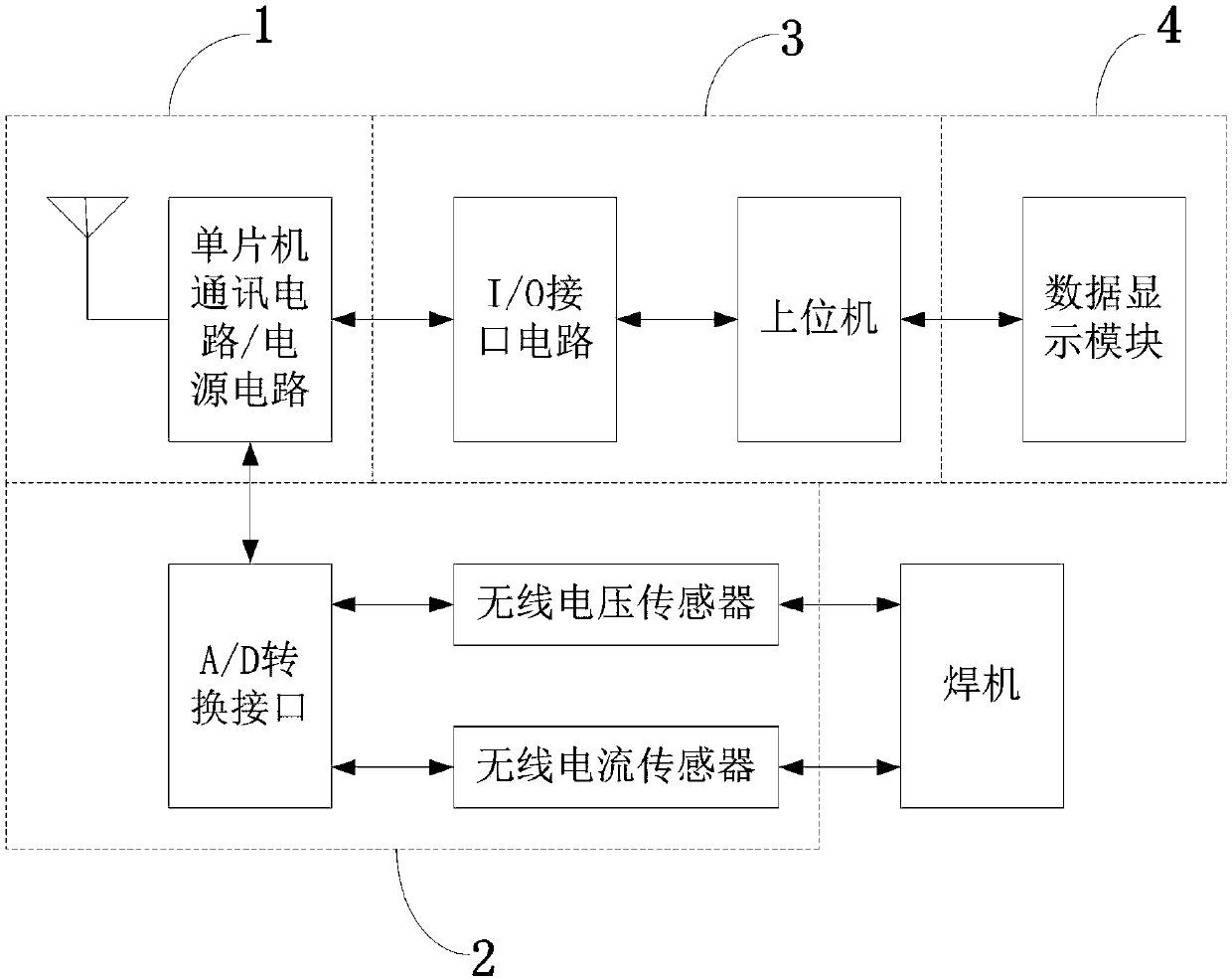

[0048] Such as figure 1 As shown, the ZigBee Internet of Things welding power supply parameter analysis and management system based on virtual instruments provided by the embodiment of the present invention includes: ZigBee wireless network transmission module 1, data acquisition module 2, data collection and storage module 3, and data display module 4.

[0049] A ZigBee wireless network transmitting module 1 for transmitting wireless signals.

[0050] Data acquisition module 2 for parameter welding acquisition.

[0051] A data collection storage module 3 for data collection and storage.

[0052] A data display module 4 for displa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com