Integrated type pressing-twisting compound sensor measuring device for multifunctional bolt fastening analysis system

A composite sensor and analysis system technology, applied in the field of integrated pressure-torque composite sensor measurement device, can solve problems such as incomplete specifications, long purchase time, incompatibility of controllers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

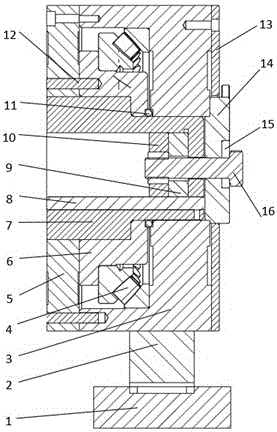

[0020] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

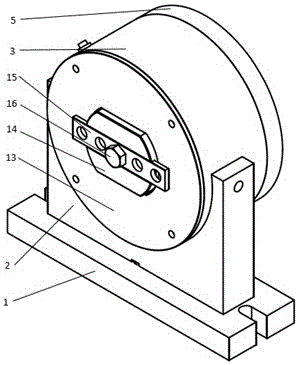

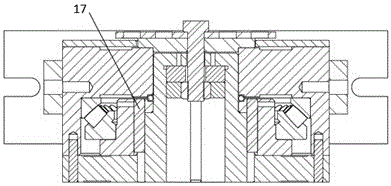

[0021] see Figure 1-3 , which is a multifunctional bolt fastening analysis system integrated pressure-torsion compound sensor measuring device of the present invention. As shown in the figure: it includes seat plate 1, installation vertical plate 2, load sensor 3, self-centering roller bearing 4, disc static torque sensor 5, bearing sleeve 6, stop sleeve 7, long stop pin 8, Round gasket 9, stop ferrule 10, sealing ring 11, positioning pin 12, outer stop plate 13, stop plate 14, bolt washer 15, bolt 16 and short stop pin 17; of which: self-centering roller The outer ring of the bearing 4 is matched with the positioning hole of the load sensor 3 and installed in place; the end surface of the short stop pin 17 is aligned with the small end surface of the load bearing sleeve 6 and then matched with the positioning pin hole on the small end surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com