A coating fixture for physical vapor deposition

A technology of physical vapor deposition and fixtures, which is applied in the field of workpiece fixtures, can solve problems that do not meet the quality, efficiency and economy of enterprises, prolong the production cycle of enterprises, and poor flexibility of fixtures, so as to facilitate popularization and application, reduce processing costs, and reduce Effect of Coating Cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with specific embodiments and accompanying drawings, so as to help understand the content of the present invention.

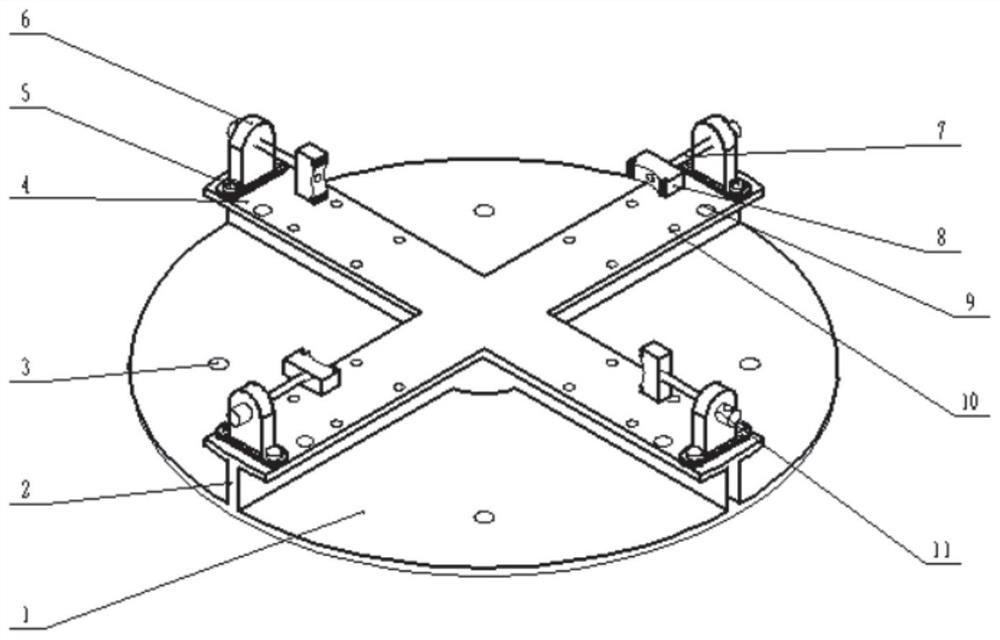

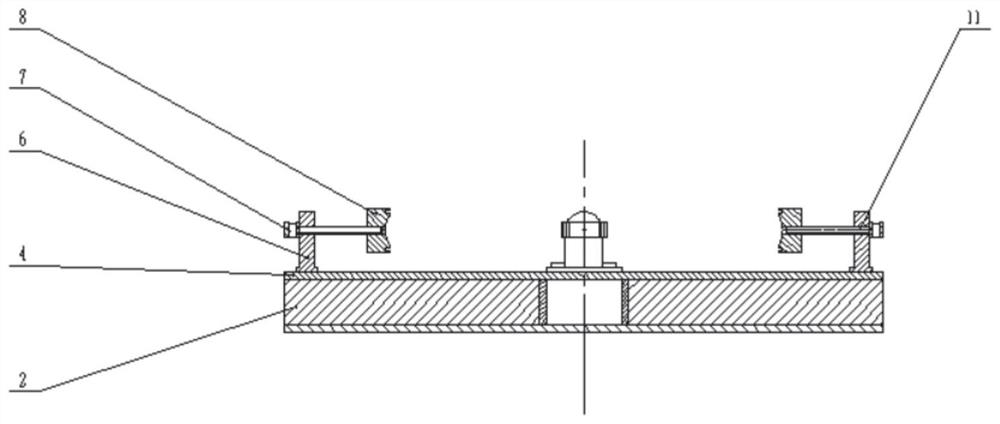

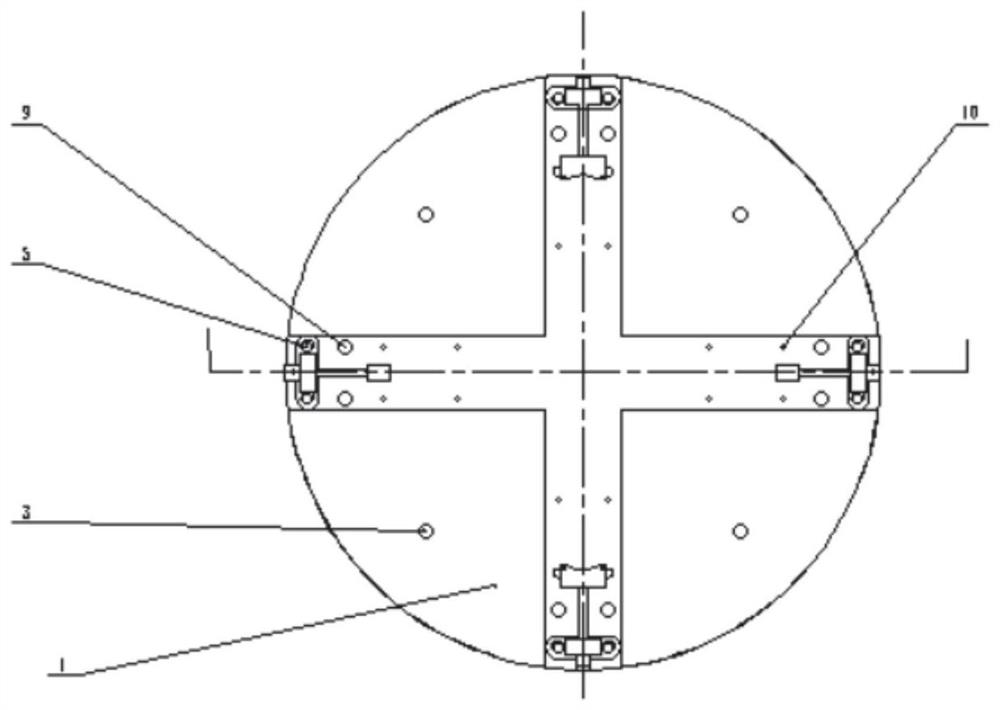

[0023] Such as Figure 1-3 Shown are the axonometric view, front full section view and top view of a coating fixture for physical vapor deposition provided by the present invention, respectively. The coating fixture for physical vapor deposition includes a base 1, a substrate 4 for carrying workpieces, and a rib 2 arranged between the base 1 and the substrate 4 for connecting the base 1 and the substrate 4, and simultaneously supporting the substrate 4. The rib 2 has a certain height. , to ensure the quality of film deposition at the bottom of the furnace chamber. The upper surface of the base plate 4 is cross-shaped, and clamping devices are fixedly connected above the four ends thereof. The clamping device is composed of a support 6, a push bolt 7 and a contact 8. The support 6 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com