Packaging material coating equipment

A technology for packaging materials and coating equipment, which is applied to devices for coating liquids on surfaces, coatings, pre-treatment surfaces, etc. Firmness and other problems, to achieve the effect of solving the uneven and unstable coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

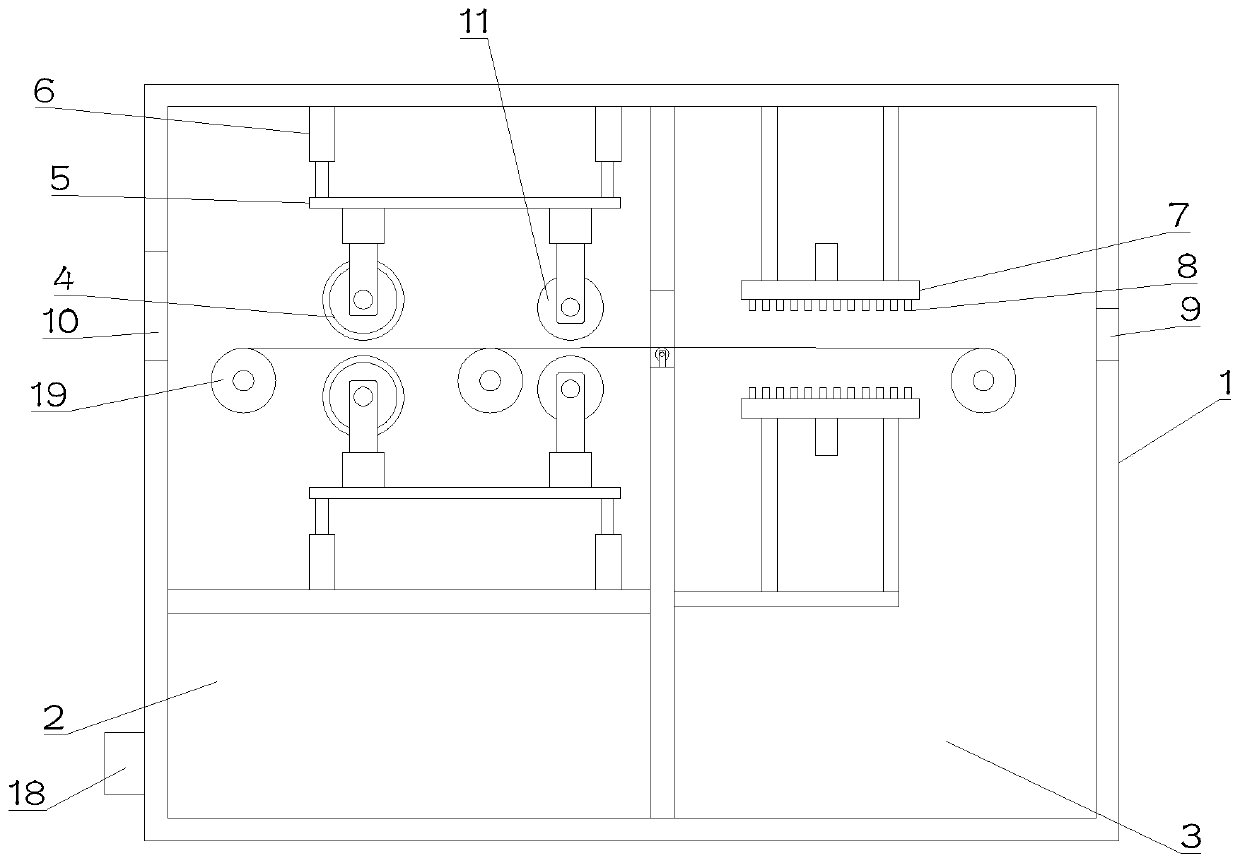

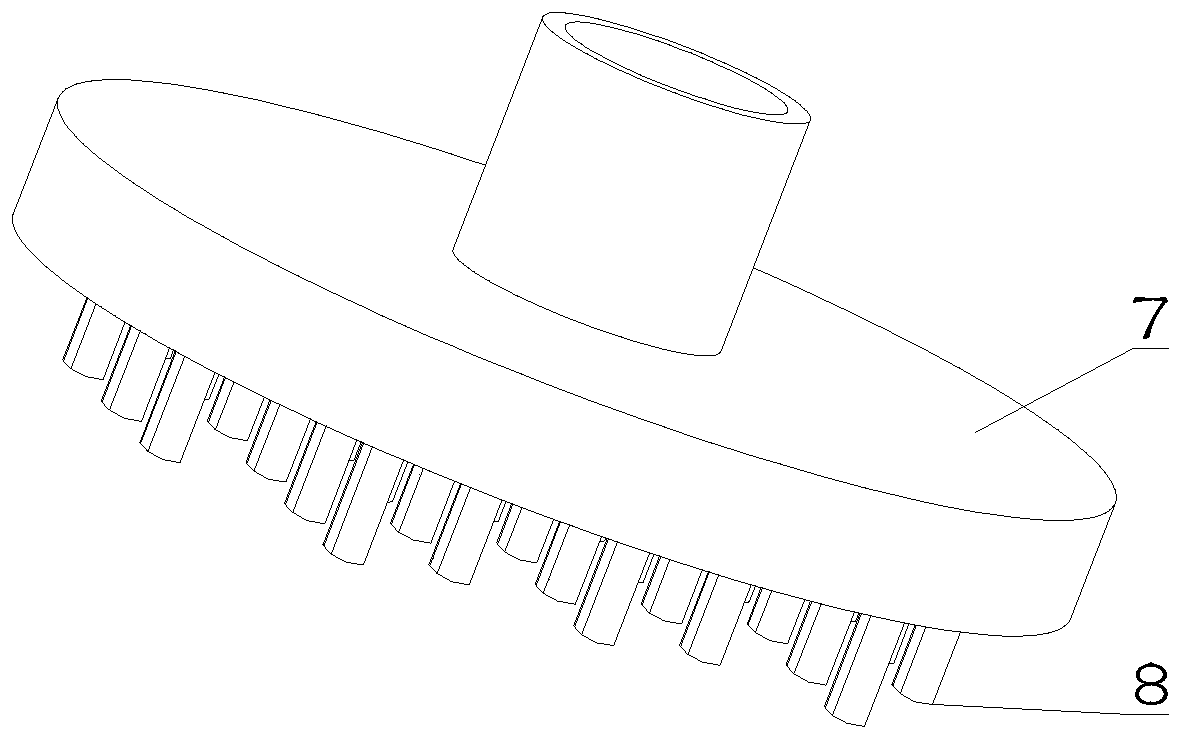

[0020] see Figure 1~3 , in the embodiment 1 of the present invention, a kind of packaging material coating equipment comprises coating main body 1, and the inside of described coating main body 1 is divided into coating cavity 2 and drying cavity 3 with partition board, and coating cavity 2 is set for packaging material For coating, the drying chamber 3 is used to dry the packaging materials; the interior of the coating chamber 2 and the drying chamber 3 are provided with conveying wheels 19 for conveying materials, and the interior of the coating chamber 2 is provided with two sets of cooperating The uniform coating assembly includes a coating wheel 4 and a uniform material wheel 11, and the coating wheel 4 and the uniform material wheel 11 on the two groups of coating uniform components are respectively symmetrically arranged for coating and uniform material to the material; the coating wheel 4 and the equalizing wheel 11 are all installed on the connecting plate 5, the upp...

Embodiment 2

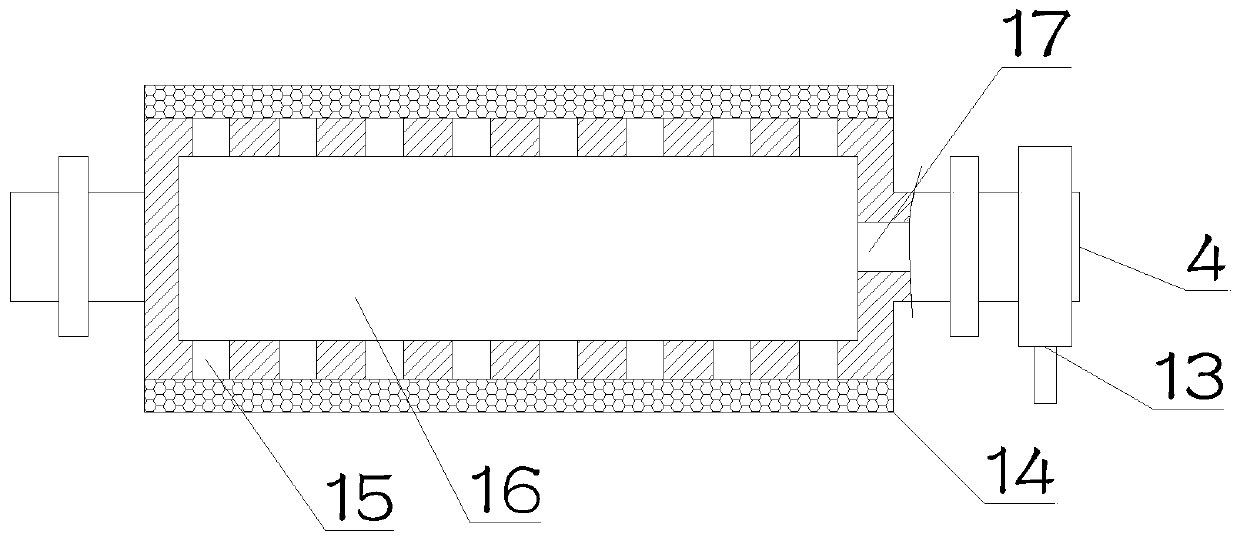

[0024] see Figure 1~3 The main difference between the present embodiment 2 and embodiment 1 is that a rotary joint 13 is also installed on the paint wheel 4, and the rotary joint 13 is externally connected to the paint, and the rotary joint 13 communicates with the feed channel 17 inside the paint wheel 4 , the delivery channel 17 communicates with the material storage chamber 16, so as to facilitate the input of the paint input by the rotary joint 13 into the material storage chamber 16.

[0025] Paint is stored at the bottom of the paint chamber 2, and a feed pump 18 is also installed on the paint chamber 2. The input end of the feed pump 18 is arranged at the bottom of the paint chamber 2, and the output end of the feed pump 18 is arranged on The input end of the rotary joint 13 is convenient for inputting the paint at the bottom of the paint chamber 2 into the paint wheel 4 to paint the packaging material.

[0026] The telescopic cylinder 6 is a hydraulic cylinder, which...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com