Rotatable tray type cable bridge

A cable tray and tray-type technology, applied in the direction of electrical components, etc., can solve the problems of cumbersome transportation and inflexible installation, and achieve the effects of flexible connection, effective heat dissipation, and avoiding heat accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

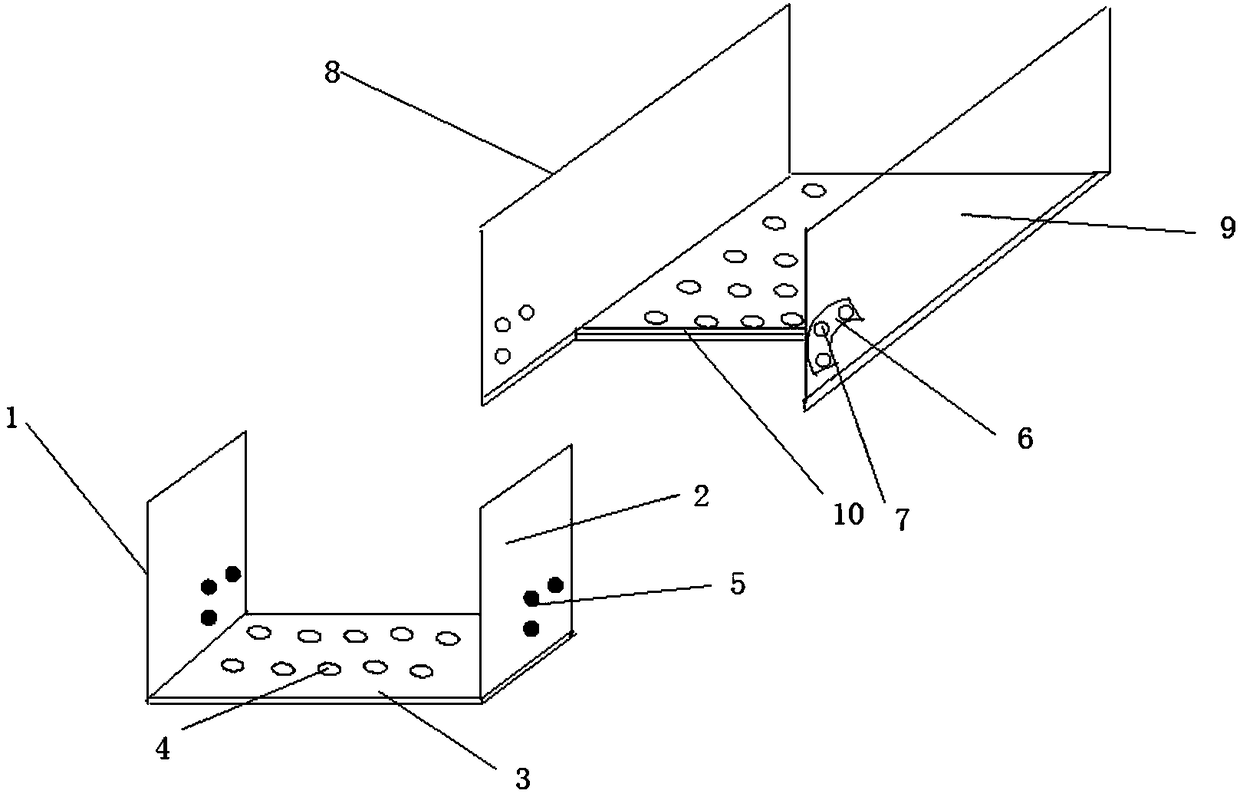

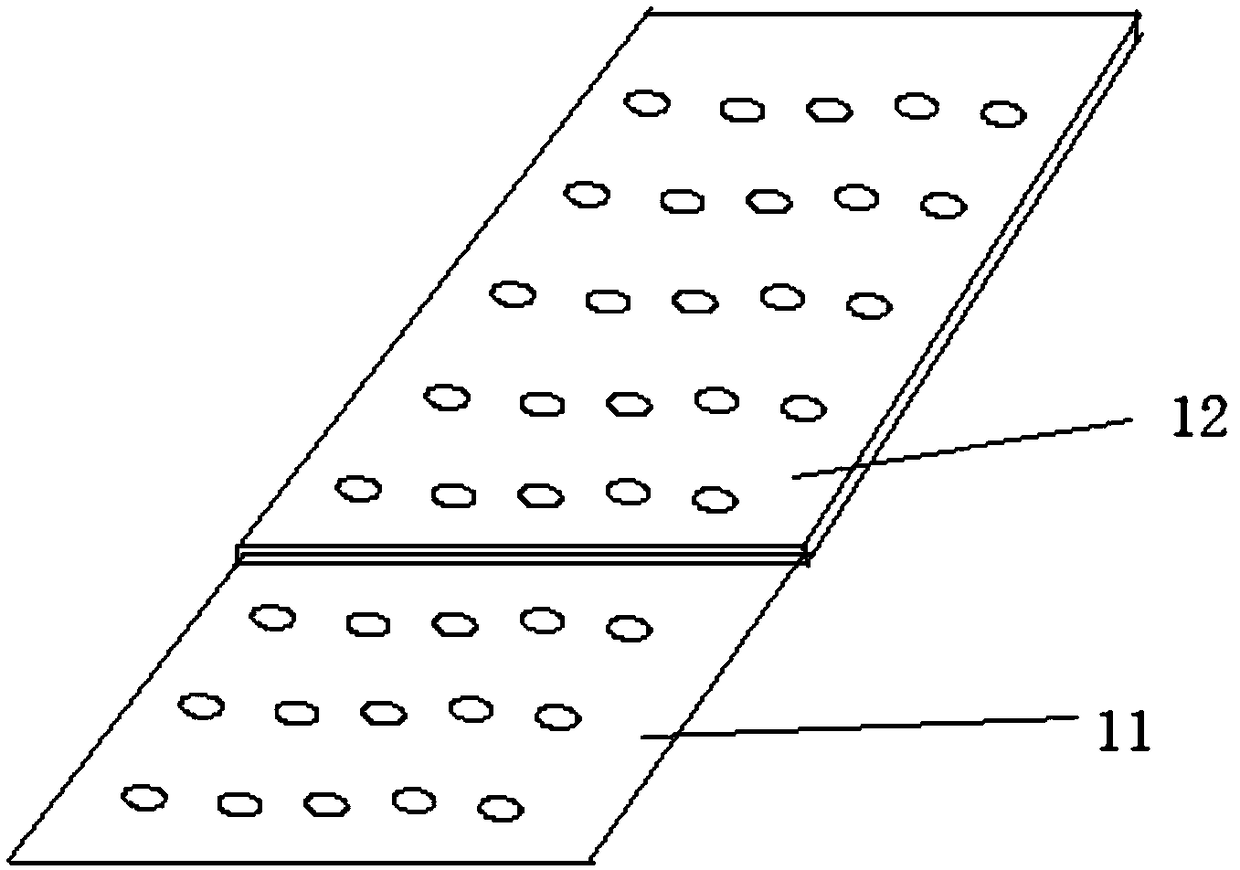

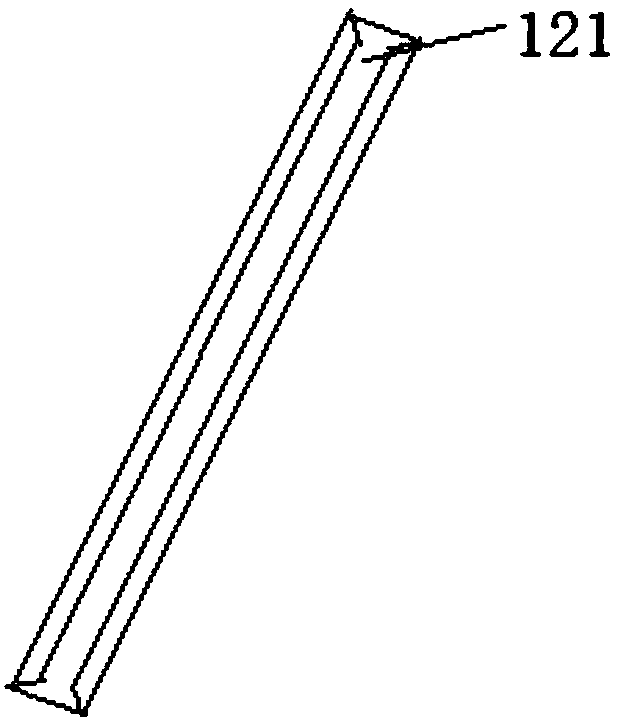

[0017] Such as Figure 1 to Figure 4 As shown, a rotatable tray-type cable bridge of the present invention includes a first bridge body and a second bridge body. The first bridge body includes the first left baffle 1 and the first right baffle 2, and the first left baffle 1 and the first right baffle 2 are all provided with connecting bolts 5, and the connecting bolts 5 include a connecting shell 51, a connecting rod 53 and the connecting spring 52 arranged between the connecting shell 51 and the connecting rod 53, the first bottom plate 3 is arranged between the first left fender 1 and the first right fender 2, and the first bottom plate 3 is a hollow structure. The second bridge body include...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap