Dust removal machine

The technology of a dust collector and a dust removal box is applied in the field of dust collectors, which can solve the problems of low efficiency, complicated work, and large dust removal area, and achieve the effect of simple work and time reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] The equipment that separates dust from flue gas is called dust collector or dust removal equipment. The performance of the dust collector is expressed by the amount of gas that can be handled, the resistance loss when the gas passes through the dust collector, and the dust removal efficiency. At the same time, the price, operation and maintenance costs, service life and difficulty of operation and management of the dust collector are also important factors to consider its performance. Dust collectors are commonly used facilities in boilers and industrial production. It needs to be large, but it is time-consuming and labor-intensive, the efficiency is low, and the follow-up work is complicated.

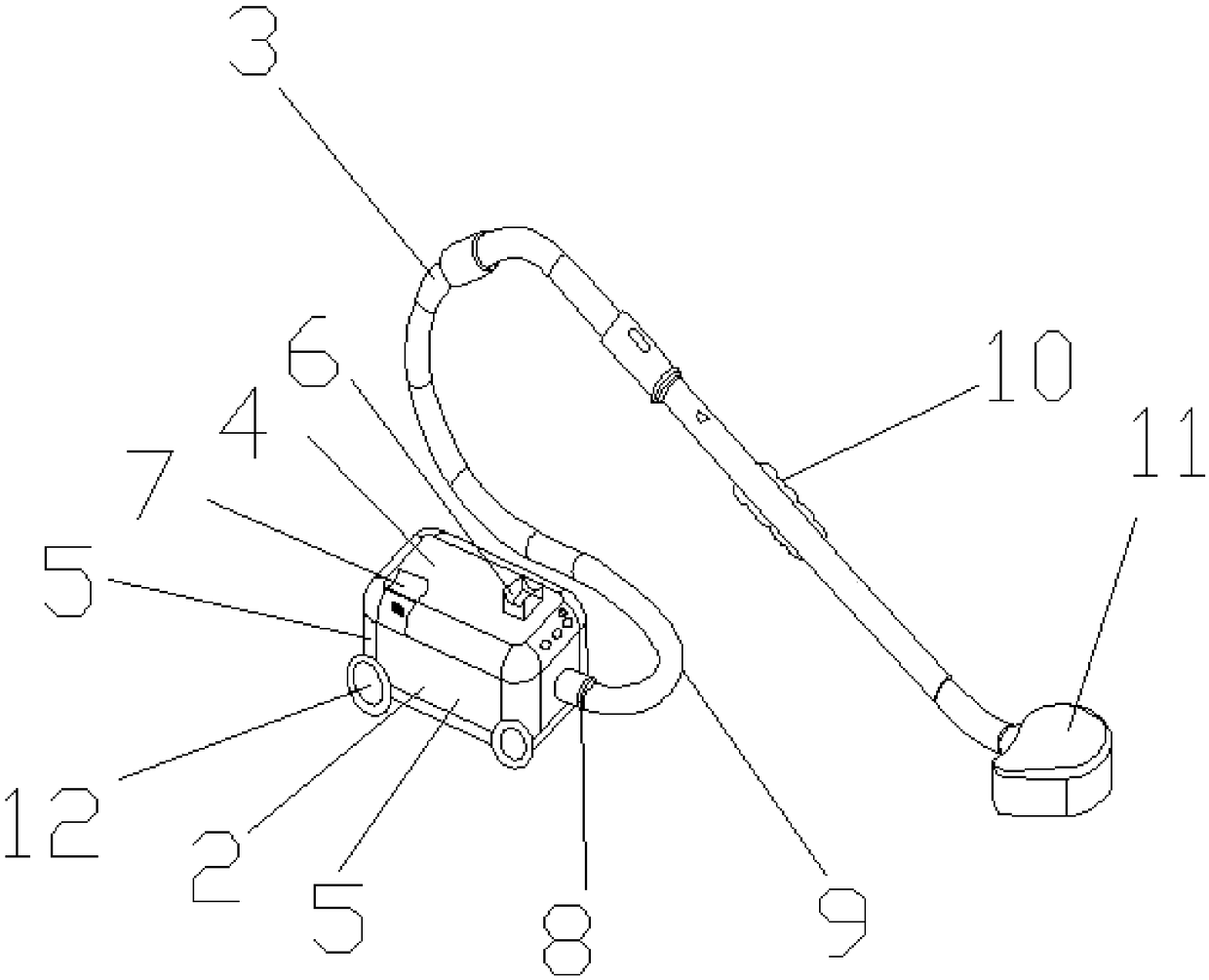

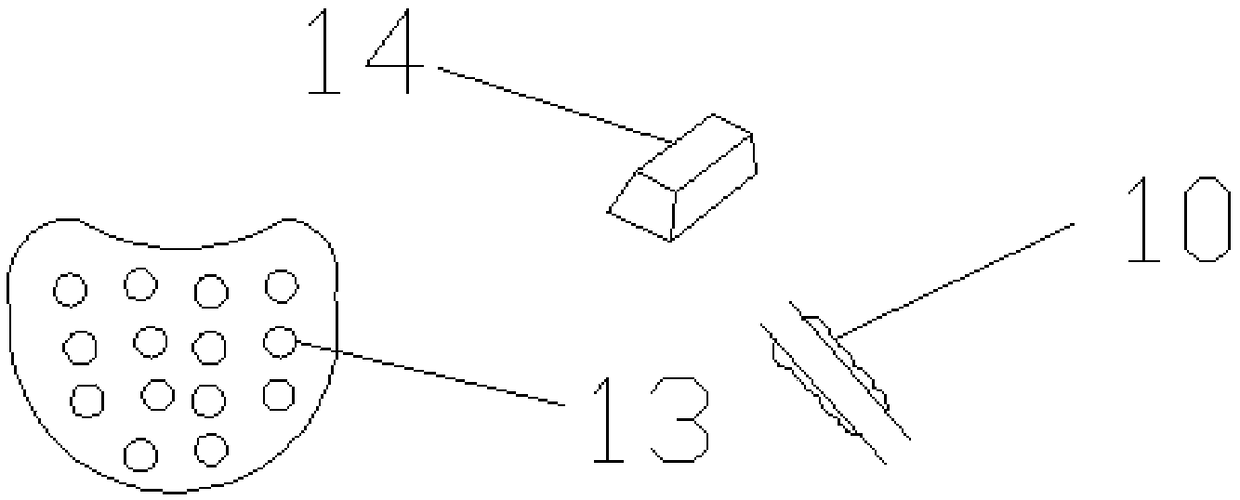

[0014] refer to Figure 1-Figure 2 A dust collector, comprising a frame 1, a dust removal box device 2, and a dust removal pipe device 3, the dust removal box device 2 is connected to the dust removal pipe device 3, and the frame 1 is connected to the dust removal box device 2,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com