Reaction kettle capable of switching heat insulation and heat dissipation

A technology of reactor and kettle body, which is applied in the field of reactor with heat insulation and switchable, can solve the problem of not being able to dissipate heat quickly, and achieve the effect of rapid heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

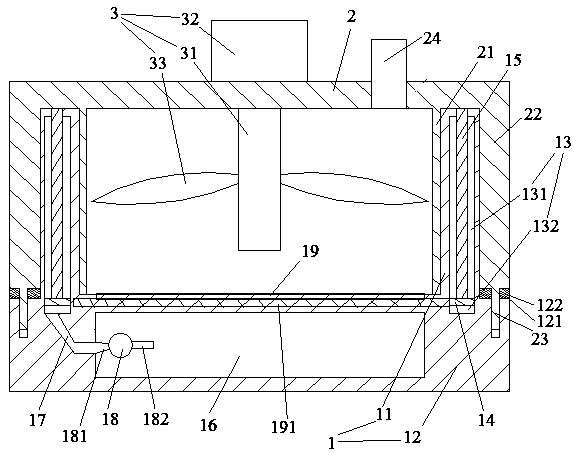

[0013] see figure 1 , a heat-insulated switchable reaction kettle, including a kettle body 1, an upper cover 2 and a stirrer 3.

[0014] The kettle body 1 comprises a kettle body side wall 11 of circular tube structure and a kettle body bottom wall 12 connected to the lower end of the kettle body side wall. The valve body is made of thermally conductive material. Specifically made of metal. The bottom wall of the kettle body is provided with an annular support seat 121 protruding from the side wall of the valve body. A gasket 122 is provided on the annular support seat. An annular cavity 13 extending along the circumference of the valve body is provided in the side wall of the valve body. The distance between the upper end of the annular cavity 13 and the upper end surface of the side wall of the still body is less than 2 cm. The lower end of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com