Pneumatic pin puller

A pin puller and airway technology, which is applied in the field of pneumatic pin pullers, can solve the problems of large operating space for hydraulic sources, affect normal use, and high labor intensity, and achieve the effects of easy portability, small use space, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

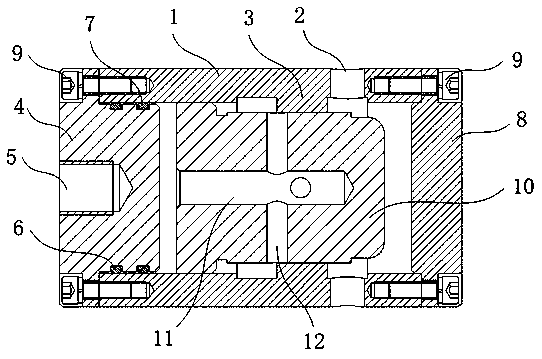

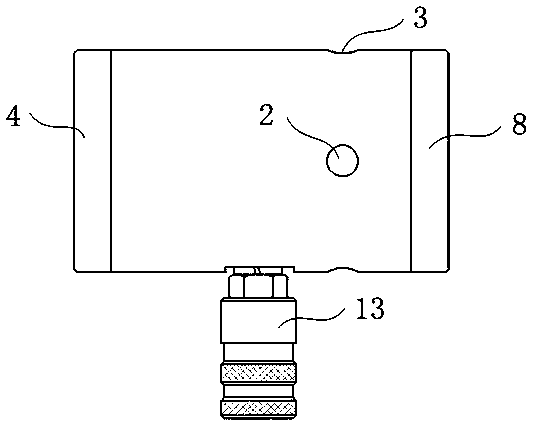

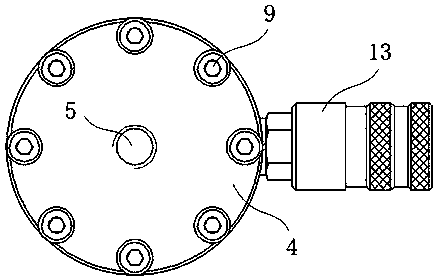

[0020] like Figure 1-3 As shown, the present invention discloses a pneumatic pin puller, which includes a cylinder body 1, a pulling disc 4, an impact disc 8 and a piston hammer 10. The cylinder body 1 is a cylindrical cylinder body, and the front and rear ends of the cylinder body 1 are respectively The drawing plate 4 and the impact plate 8 are installed and fixed by a number of hexagon socket head cap screws 9 at equal intervals in a ring, and the middle part of the cylinder body 1 is connected with a quick air exchange joint 13, and the cylinder body between the quick air exchange joint 13 and the impact plate 8 1 is provided with two sets of vent holes 2 perpendicular to each other, a set of limit protrusions 3 are provided on the inner wall ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com