Dry and wet polishing equipment for automobile bumper

A technology for automobile bumpers and equipment, which is applied to grinding/polishing equipment, metal processing equipment, grinders, etc., can solve the problems of uneven surface grinding, manual spraying of cleaning fluid, low bumper processing efficiency, etc., and achieve the grinding effect. Good, quality-improving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below by means of specific embodiments:

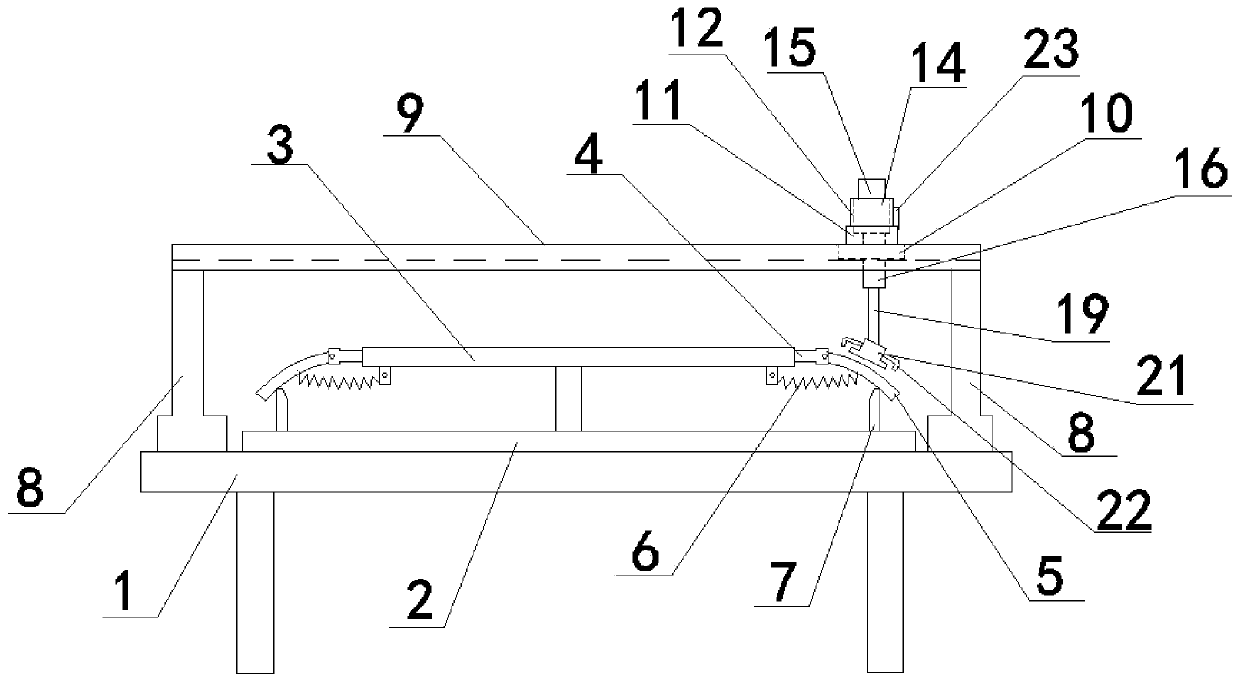

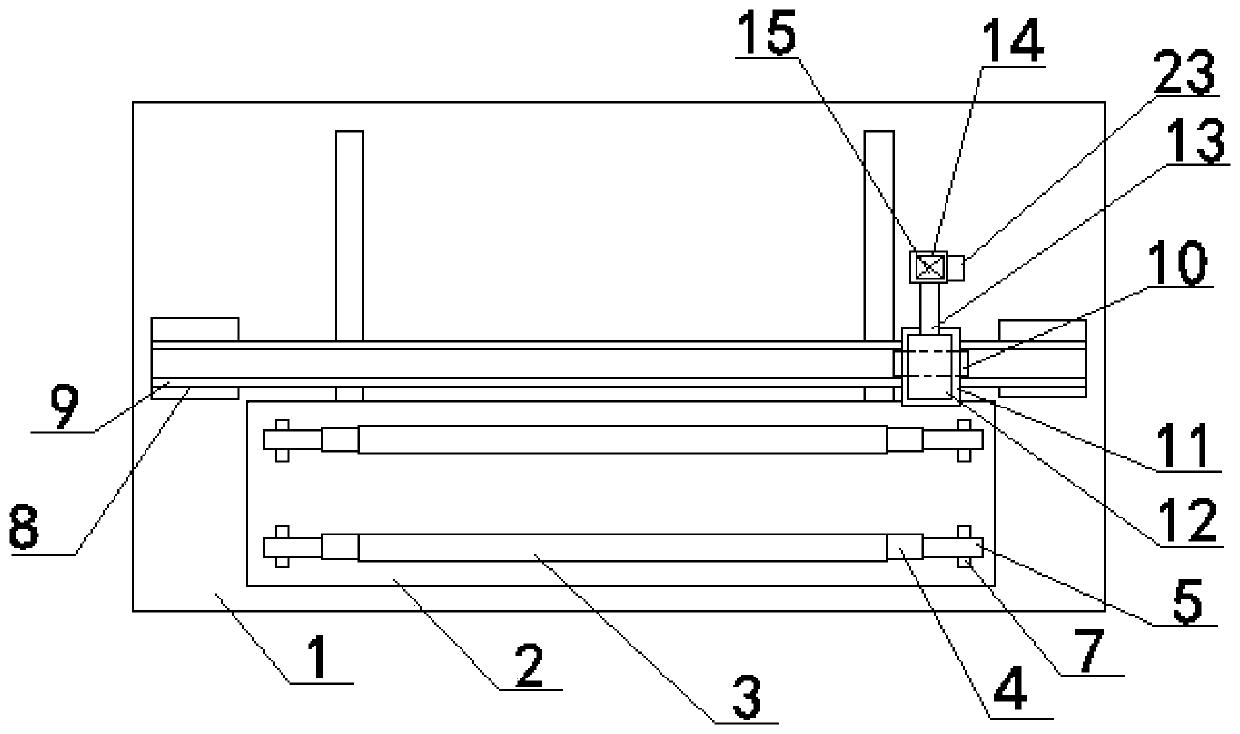

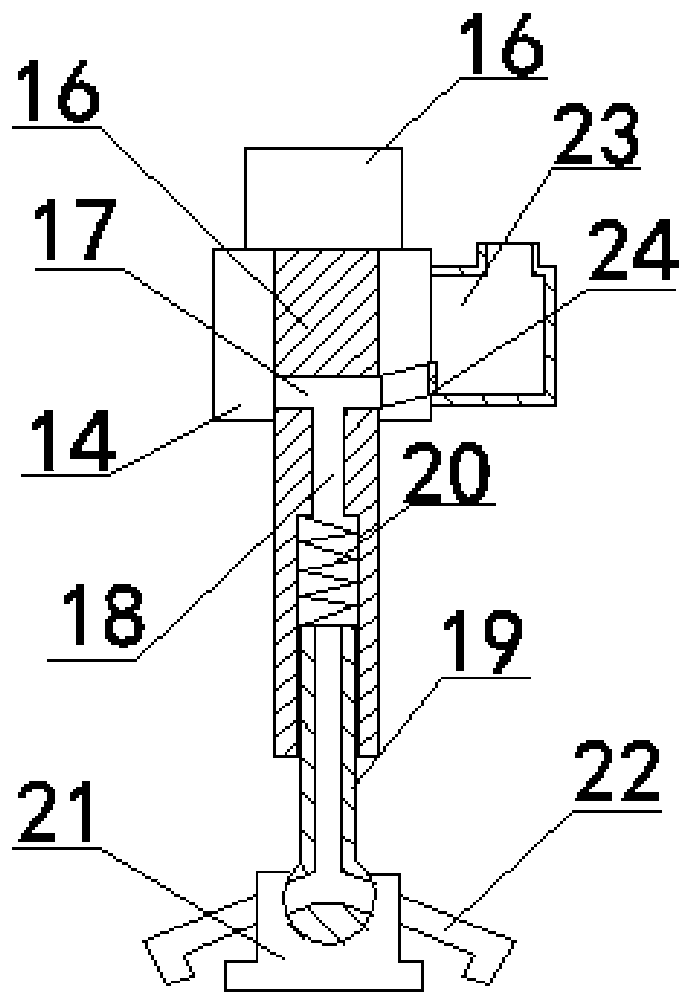

[0020] The reference numerals in the accompanying drawings of the specification include: workbench 1, push platform 2, shelf rod 3, pull rod 4, feed rod 5, first spring 6, limit baffle 7, fixed pile 8, guide rail 9, straight line Motor 10, first slide table 11, cylinder 12, push rod 13, polishing box 14, first motor 15, rotating shaft 16, through hole 17, chamber 18, long rod 19, second spring 20, polishing head 21, spray Pipe 22, liquid storage tank 23, flow valve adjustment 24.

[0021] The embodiment is basically as Figure 1 to Figure 3 As shown, a kind of automobile bumper dry, wet polishing equipment, comprises workbench 1, and workbench 1 is slidably connected with push platform 2, and push platform 2 is fixedly connected with two frame rods 3, and described two frame materials The rod 3 is symmetrically arranged along the central axis of the push table 2, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com