Timing chain tensioning device, engine and automobile

A technology of chain tensioning device and engine cylinder head, which is applied in the direction of engine components, machines/engines, transmissions, etc. It can solve the problems of unable to measure the amount of elongation of the timing chain wear, reduce maintenance costs, ensure phase accuracy, The effect of reducing detection time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

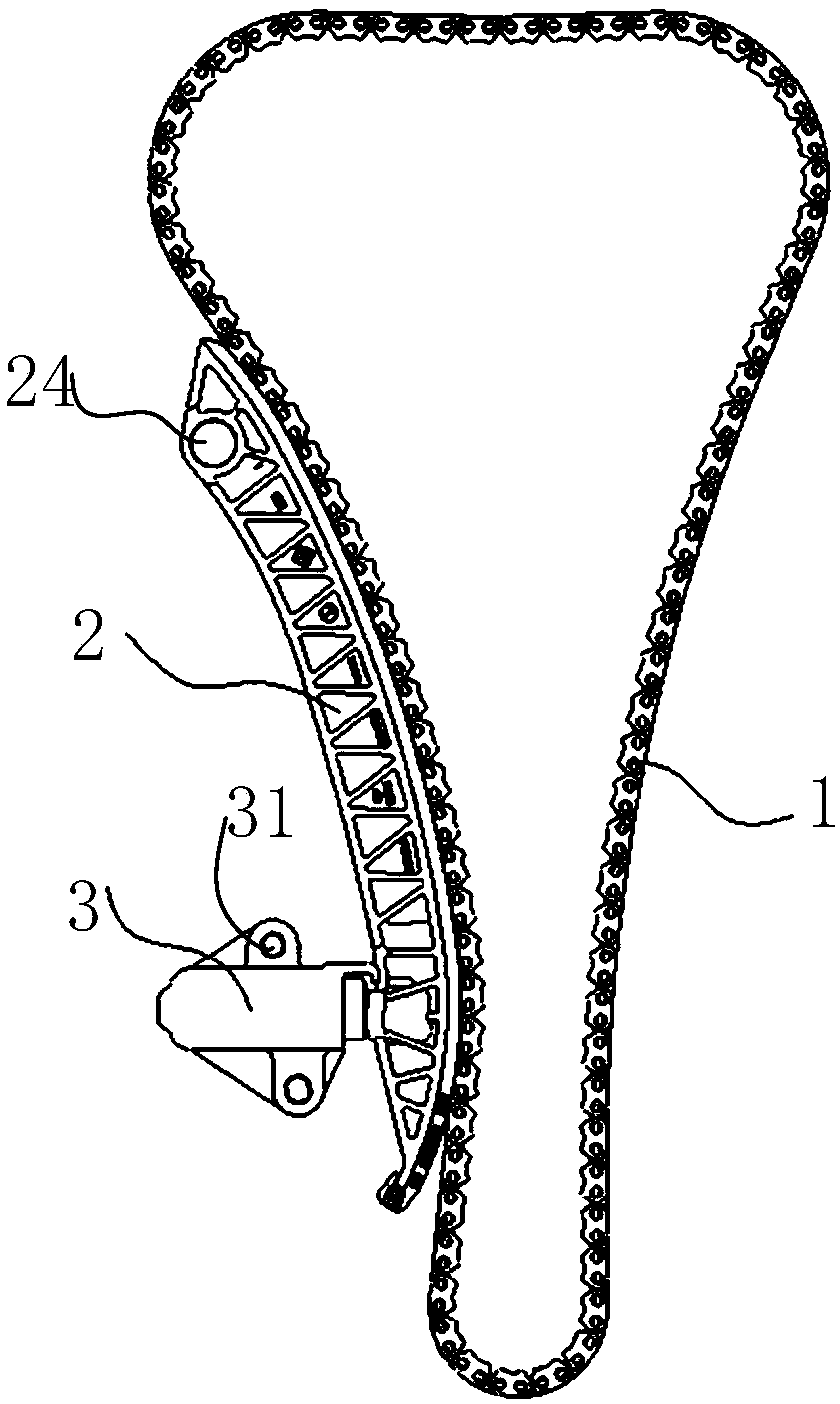

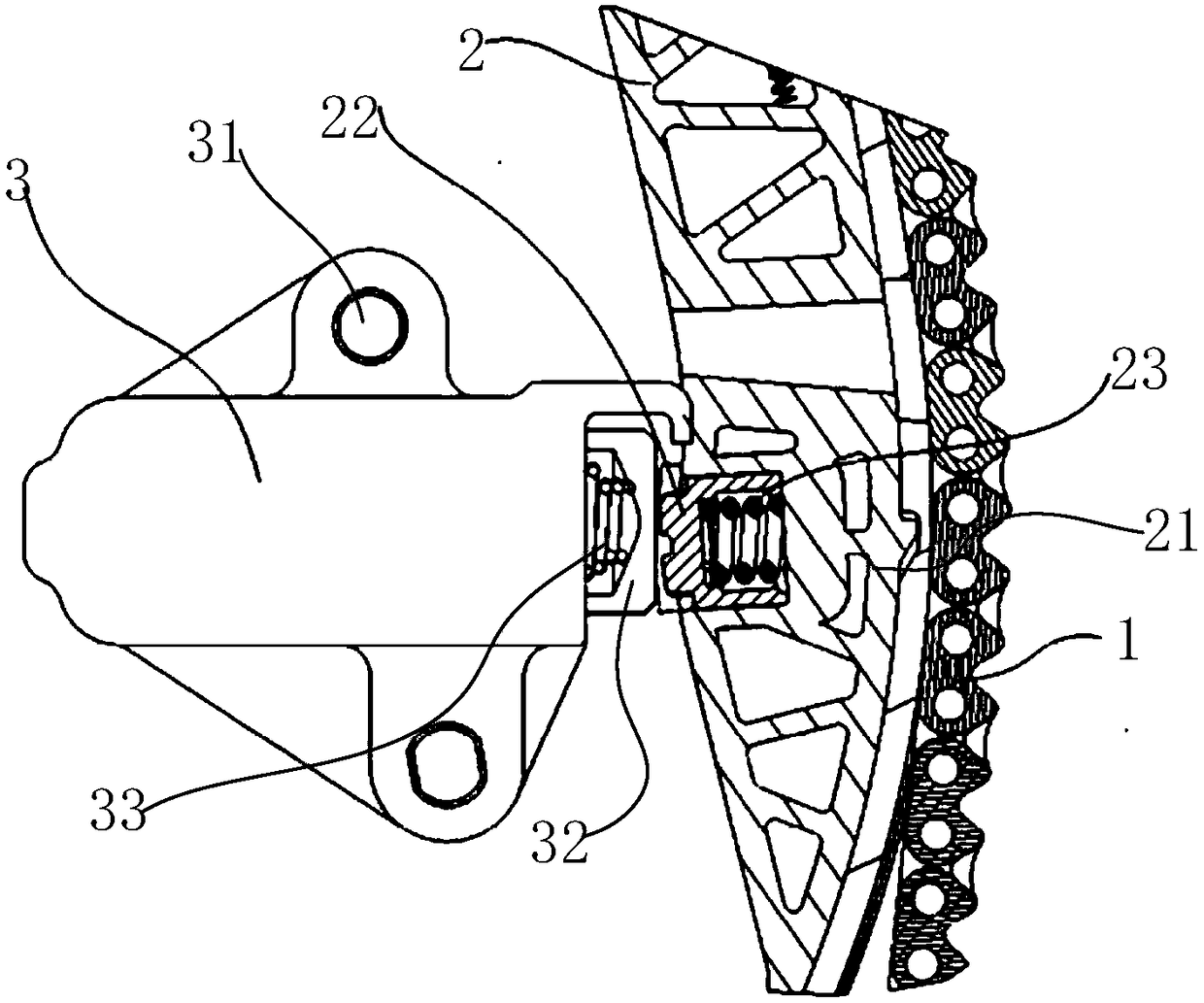

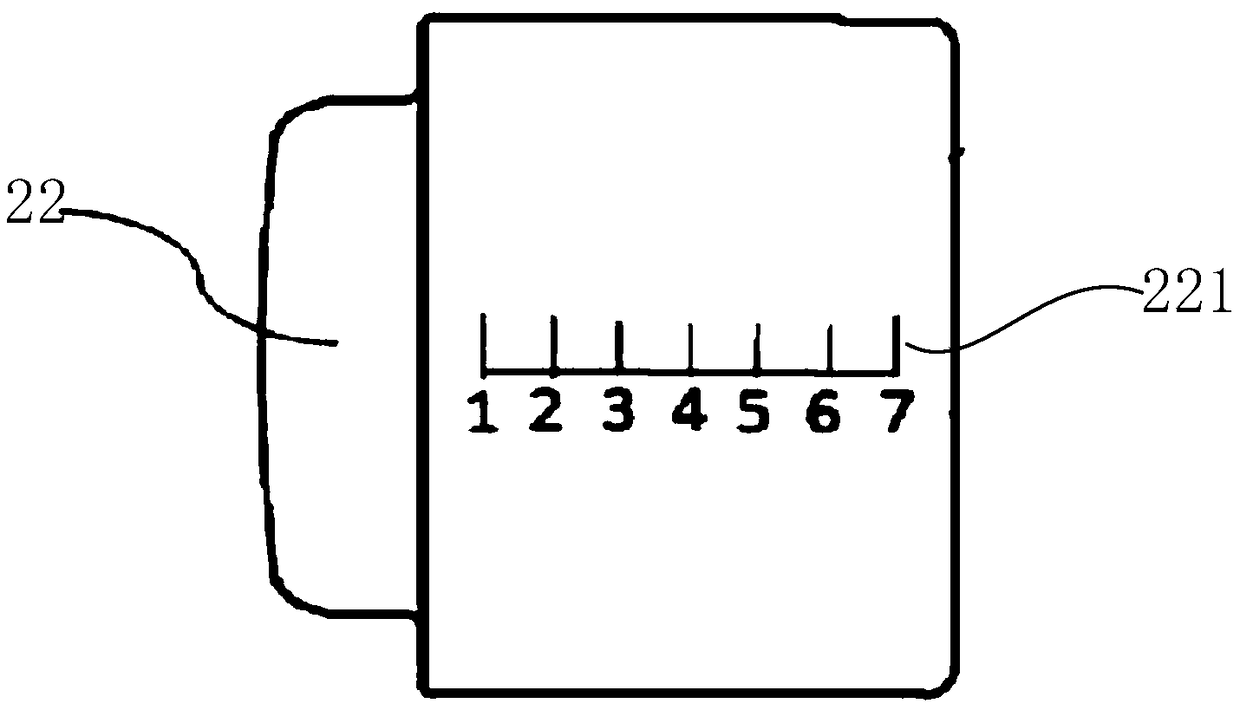

[0022] refer to Figure 1 to Figure 3 , the embodiment of the present invention provides a timing chain tensioning device, which includes a timing chain 1, a tensioning rail 2 and a tensioner 3 abutting against the tensioning rail 2. There is a guide rail 21, and the timing chain 1 is installed in the guide rail 21; the other end surface of the tension rail 2 facing the tensioner 3 is provided with a mounting groove, and a slidable sliding element 22 is embedded in the mounting groove, and the sliding element 22 Abutting against the tensioner 3, the end surface of the sliding element 22 opposite to the groove wall of the installation groove is provided with a scale line 221 for indicating the wear elongation of the timing chain 1; between the sliding element 22 and the groove bottom of the installation groove An elastic element 23 is provided. When the timing chain 1 is worn and elongated, the elastic element 23 pushes the sliding element 22 to slide away from the groove botto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com