Roller of planetary roller screw pair

A planetary roller and screw pair technology, applied in the direction of belts/chains/gears, mechanical equipment, transmission devices, etc., can solve the problems of unfavorable synchronous rolling forming rollers, waste of materials, low efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

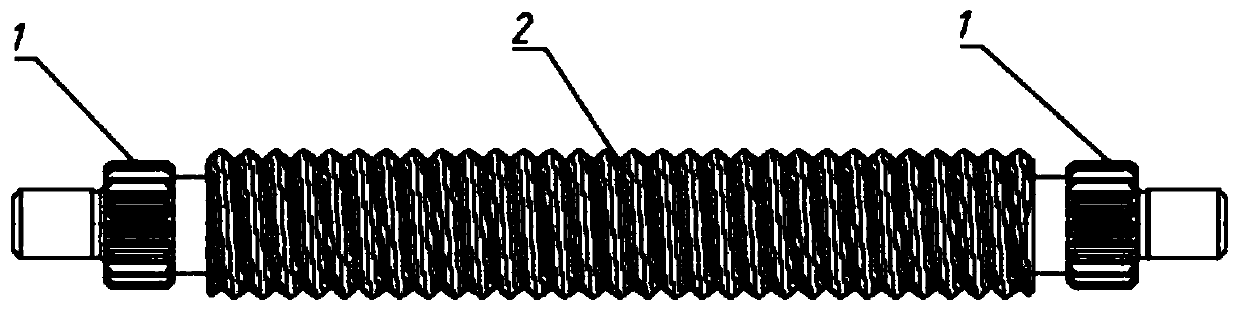

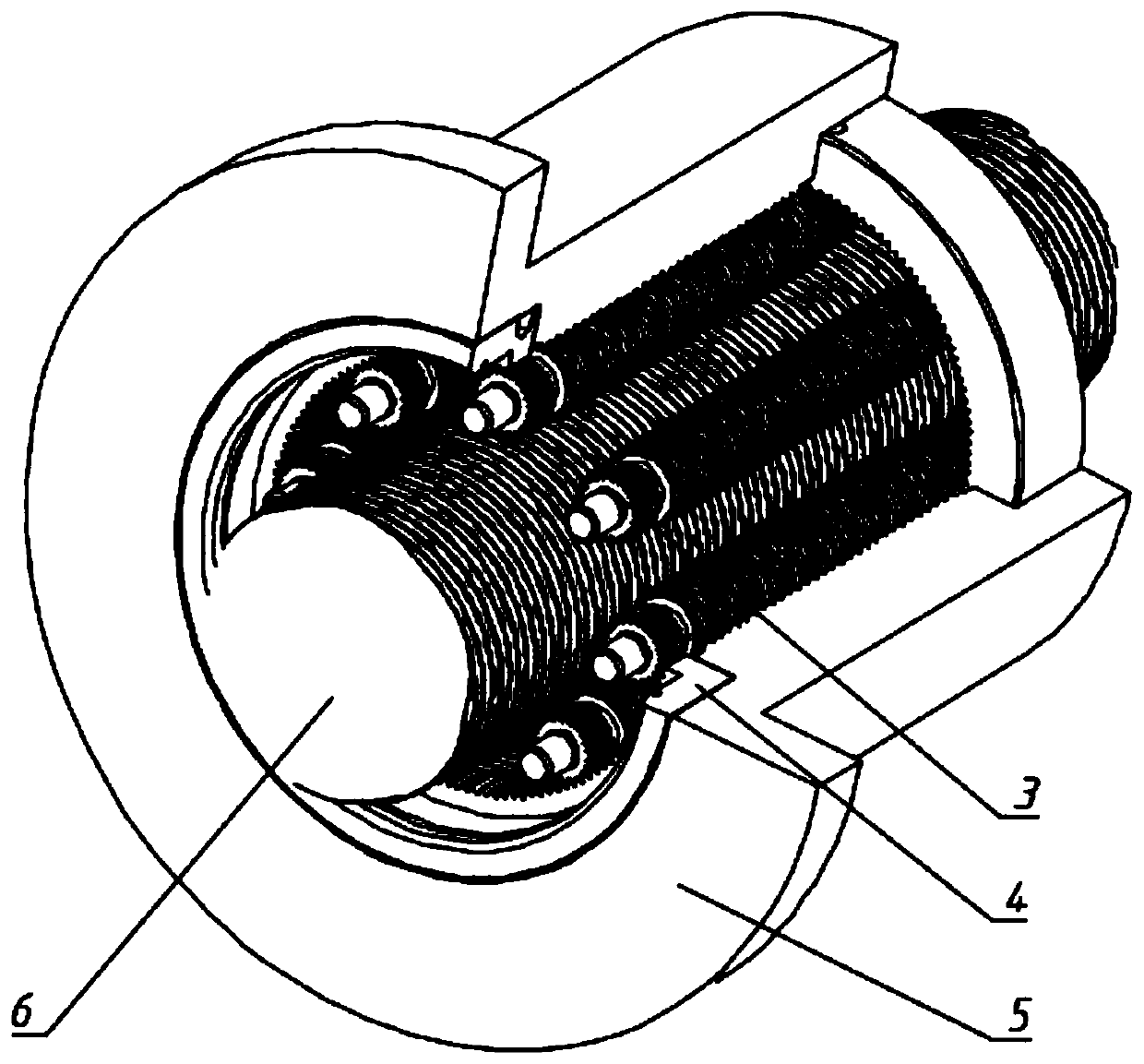

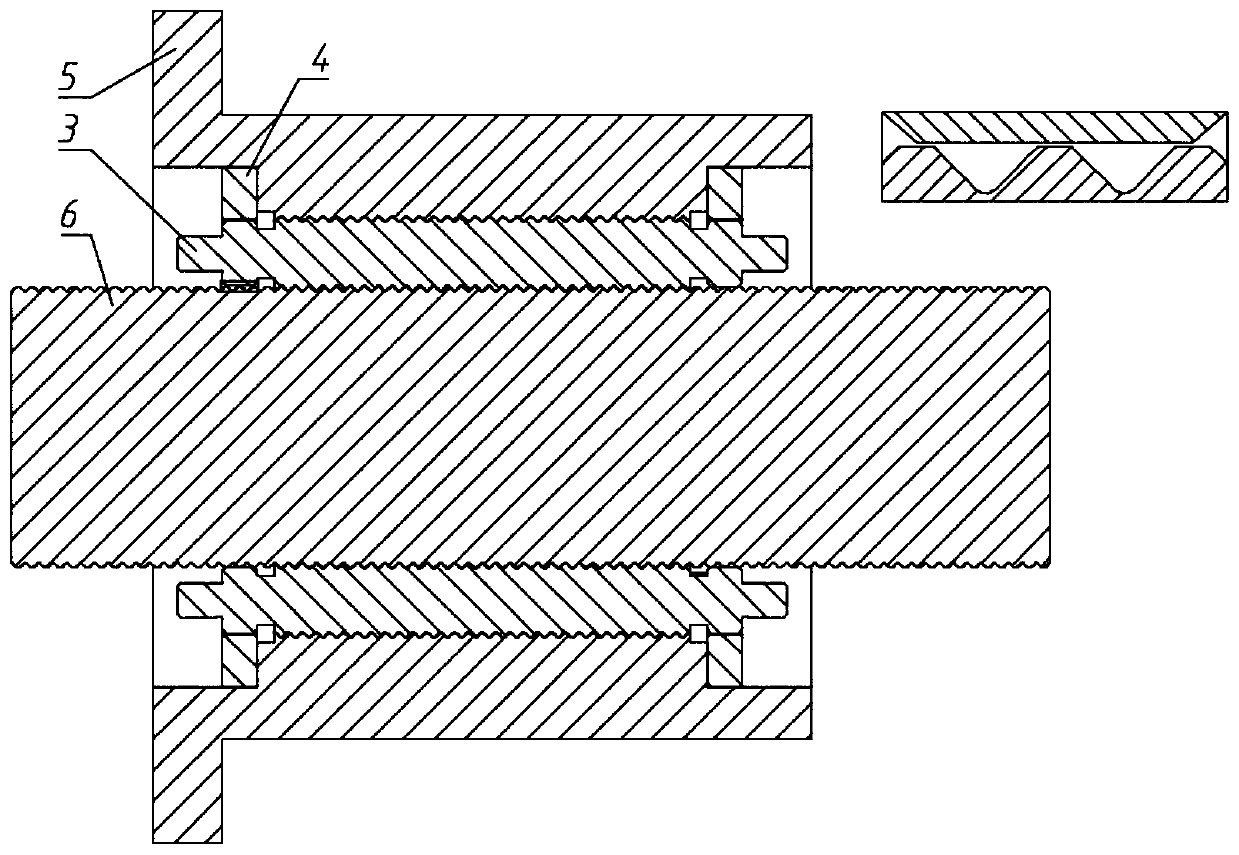

[0042] Embodiment 1, with reference to figure 1 , figure 2 and image 3 , for the standard planetary roller screw, the radius r of the addendum circle of the gear section structure at both ends of the roller a1 Reduced, no physical contact with the first lead screw, and the transmission ratio i of the roller gear and the ring gear conforms to the motion relationship of the roller, the first lead screw and the first nut in the planetary roller screw;

[0043] If it is a standard planetary roller screw pair, the implementation method of the gear segment structure of the rollers of the planetary roller screw pair is as follows:

[0044] The radius of the addendum circle of the gear segment structure 1 at both ends of the roller 3 is Its relationship with the first lead screw 6 is: Where a is the center distance between the roller 3 and the first lead screw 6, r a is the thread outer diameter parameter of the lead screw 6;

[0045] Take the number of teeth of the gear seg...

Embodiment 2

[0055] Embodiment 2, with reference to figure 1 and Figure 4 , in the reverse planetary roller screw, the radius r of the addendum circle of the gear section structure at both ends a1 Reduced, no physical contact with the internal thread of the second nut, the transmission ratio i of the roller gear and the gear ring conforms to the motion relationship of the roller in the planetary roller screw, the second screw and the second nut.

[0056] If it is a reverse planetary roller screw pair, the implementation method of the gear segment structure 1 at both ends of the planetary roller screw roller is as follows:

[0057] Take the radius of the addendum circle of the gear segment structure 1 at both ends of the roller 3 as Its relation with the second nut 9 is: Wherein a is the center distance between the roller 3 and the second lead screw 8, is the thread major diameter parameter of the second nut 9;

[0058] Take the number of teeth of gear segment structure 1 and gear ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com