Liquid level detection device for water treatment tank equipment

A technology for liquid level detection and water treatment tanks, which is applied in the direction of measuring devices, valve devices, mechanical equipment, etc., can solve problems such as liquid leakage, poor sealing, and affect the detection effect, and achieve the effect of improving sealing and preventing liquid leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

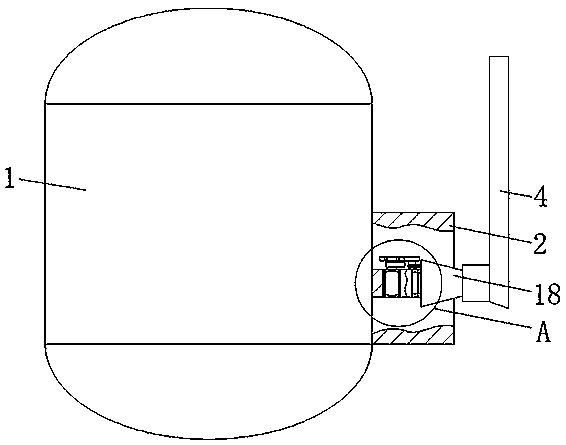

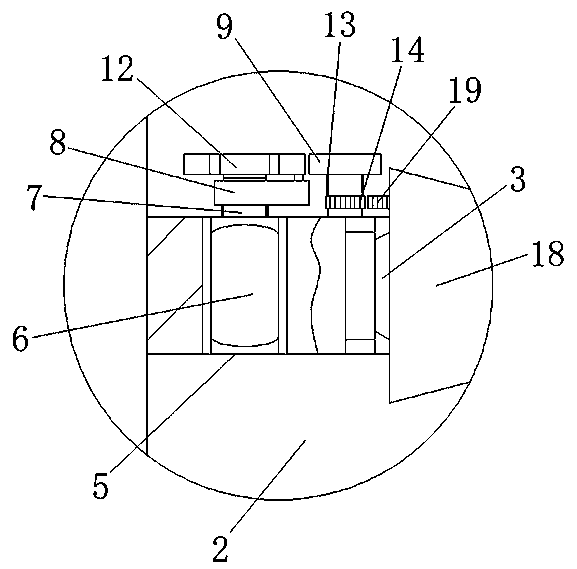

[0039] refer to Figure 1-2 , a liquid level detection device for water treatment tank equipment, comprising a tank body 1, an installation box 2, a communication pipe 3, and a liquid level pipe 4, the bottom end of the tank body 1 is connected with a communication pipe 3 through the installation box 2, and the communication pipe 3 The liquid level pipe 4 at the end far away from the installation box 2 is connected with the liquid level pipe 4. There is a liquid level indicator scale on the liquid level pipe 4. There is a conduction mechanism inside the installation box 2. One end of the conduction mechanism is connected with the tank body 1 and conducts The other end of the mechanism is sealed and connected with the connecting pipe 3, and the connecting pipe 3 is connected with a one-way valve; through the connecting pipe 3, the liquid in the tank body 1 is introduced into the liquid level pipe 4, and the existence of the conducting mechanism is beneficial to realize the liqui...

Embodiment 2

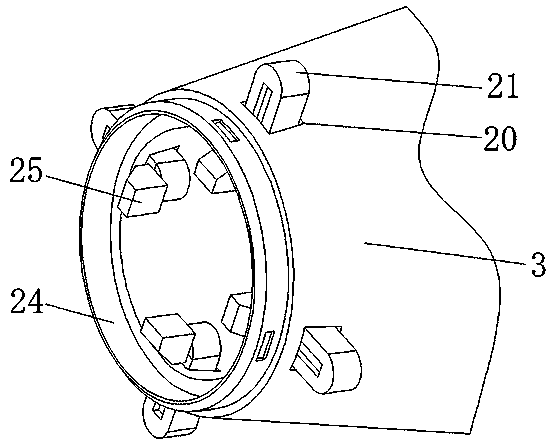

[0041] refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , a liquid level detection device for water treatment tank equipment, comprising a tank body 1, an installation box 2, a communication pipe 3, and a liquid level pipe 4, the bottom end of the tank body 1 is connected with a communication pipe 3 through the installation box 2, and the communication pipe 3 The liquid level pipe 4 at the end far away from the installation box 2 is connected with the liquid level pipe 4. There is a liquid level indicator scale on the liquid level pipe 4. There is a conduction mechanism inside the installation box 2. One end of the conduction mechanism is connected with the tank body 1 and conducts The other end of the mechanism is sealed and connected with the connecting pipe 3, and the connecting pipe 3 is connected with a one-way valve; through the connecting pipe 3, the liquid in the tank body 1 is introduced into the liquid level pipe 4, and the existence of the conduct...

Embodiment 3

[0046] refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 8 , a liquid level detection device for water treatment tank equipment, comprising a tank body 1, an installation box 2, a communication pipe 3, and a liquid level pipe 4, the bottom end of the tank body 1 is connected with a communication pipe 3 through the installation box 2, and the communication pipe 3 The liquid level pipe 4 at the end far away from the installation box 2 is connected with the liquid level pipe 4. There is a liquid level indicator scale on the liquid level pipe 4. There is a conduction mechanism inside the installation box 2. One end of the conduction mechanism is connected with the tank body 1 and conducts The other end of the mechanism is sealed and connected with the connecting pipe 3, and the connecting pipe 3 is connected with a one-way valve; through the connecting pipe 3, the liquid in the tank body 1 is introduced into the liquid level pipe 4, and the existence of the conduct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com