Apparatus for commutator processing

A commutator and I-shaped technology is applied in the field of commutator processing devices, which can solve the problems of high cost and low benefit, and achieve the effects of reducing difficulty and complexity, improving efficiency and machining accuracy, and reducing production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0026] Examples:

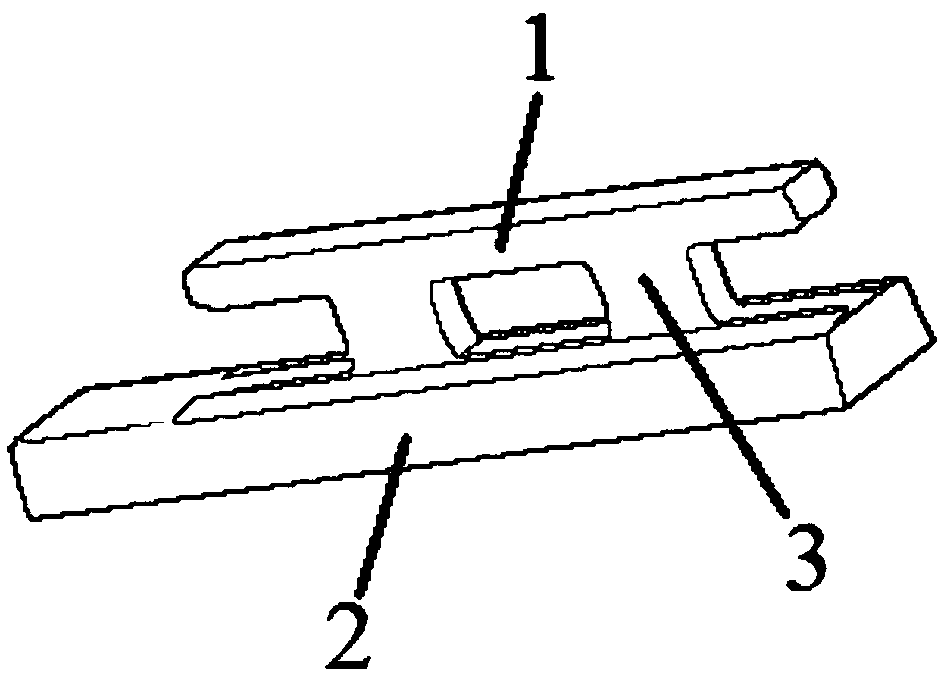

[0027] Such as figure 1 As shown, the commutator segment includes a first elongated portion 1, a second elongated portion 2 arranged side by side, and a connecting portion 3 arranged between the first elongated portion 1 and the second elongated portion 2.

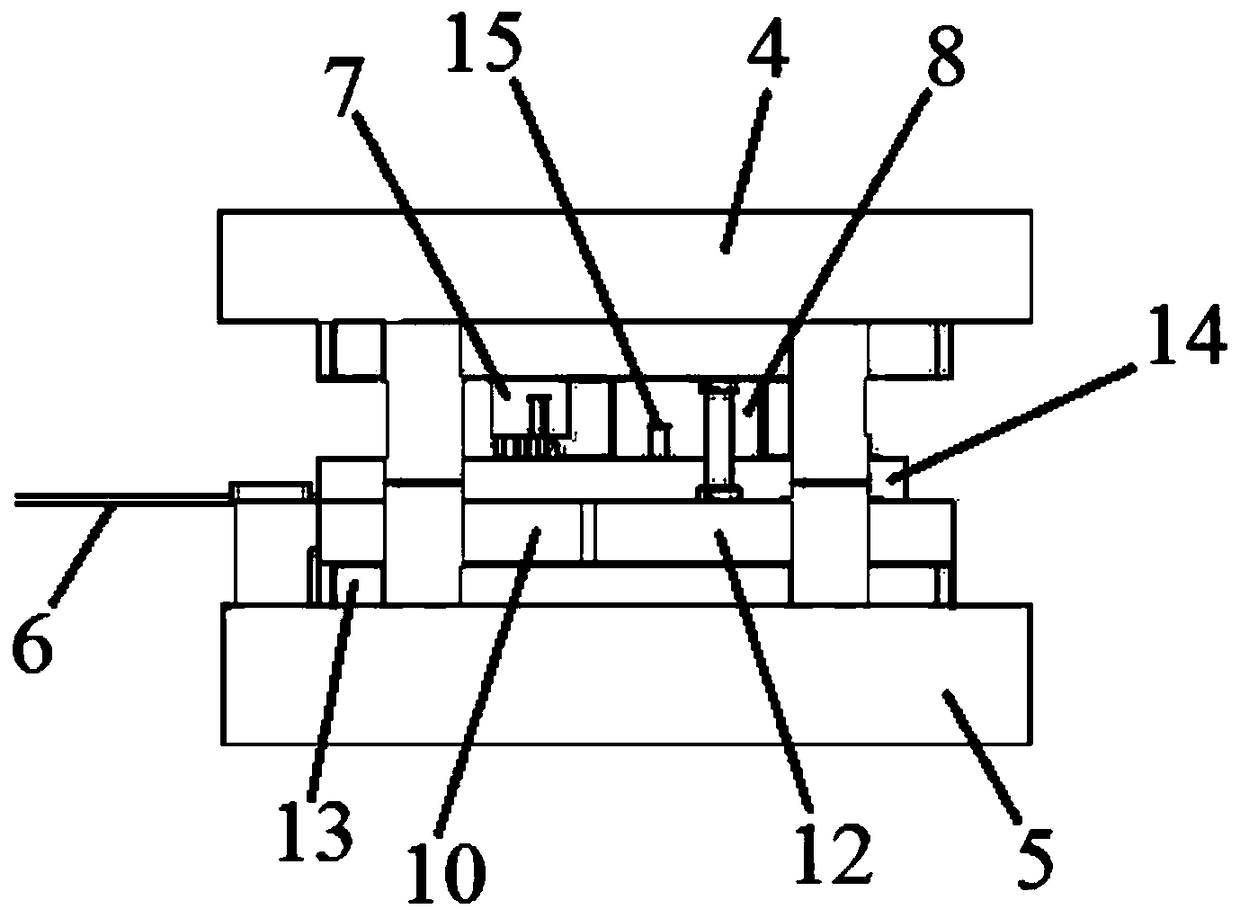

[0028] Such as figure 2 The device shown for processing the commutator includes an upper mold base 4 and a lower mold base 5 adapted to the upper mold base 4. The upper mold base 4 and the lower mold base 5 move along the direction of the profile 6 A press forming unit 7 and a punching unit 8 are arranged in sequence. The end face of the profile 6 is an I-shape.

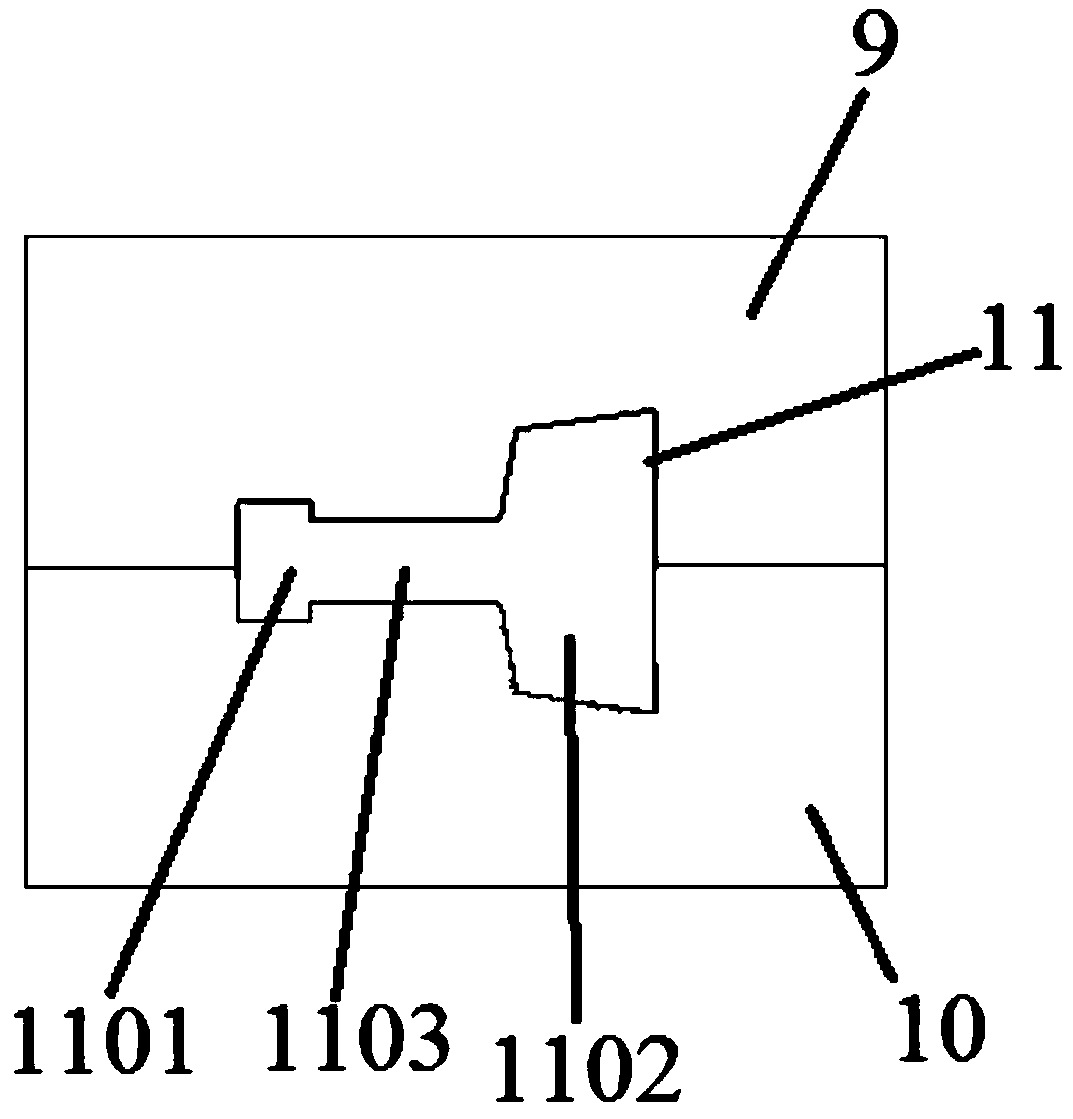

[0029] Such as image 3 As shown, the press forming unit 7 includes an upper pressing plate 9 arranged at the bottom of the upper mold base 4 and a lower pressing plate 10 arranged on the lower mold base 5 and located below the upper pressing plate 9, and between the upper pressing plate 9 and the lower pressing plate 10 is provided with The cavity...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap