Manual automobile seat waist-supporting mechanism and operating method thereof

A car seat, manual technology, applied in the direction of the back cushion, etc., can solve the problems of potential safety hazards in the car, small effective stroke, unclear maximum ejection point APEX point of the top waist mechanism, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

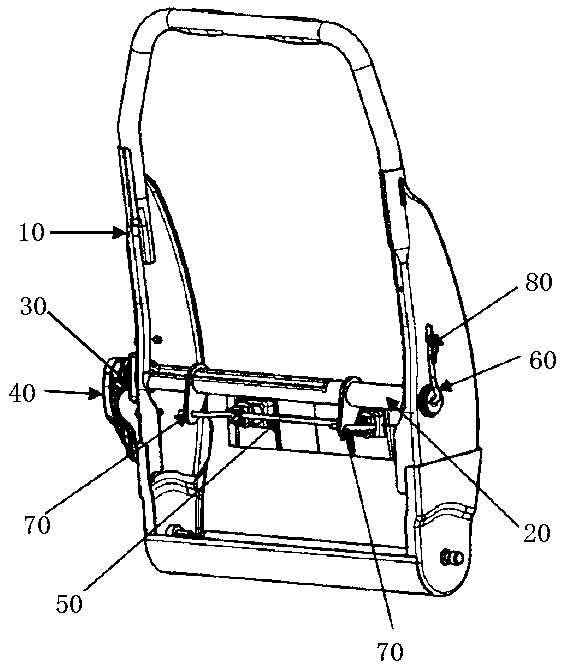

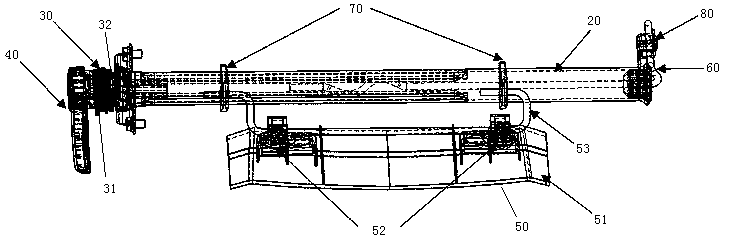

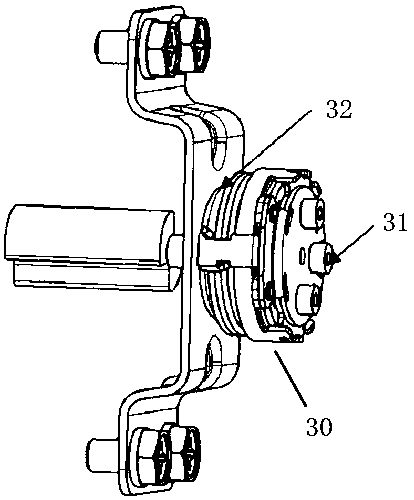

[0024] like Figure 1~3 As shown, a manual car seat backrest mechanism includes a seat back frame 10, a cross bar 20 is arranged on the seat back frame 10, a two-way ratchet mechanism 30 is arranged at one end of the cross bar 20, and one end of the two-way ratchet mechanism 30 is installed on On the cross bar 20, the other end is provided with a ratchet rotating disk 31 for adjusting the direction of rotation of the two-way ratchet mechanism 30 and a coil spring 32 capable of automatically resetting the ratchet rotating disk 31; The handle 40 of the two-way ratchet mechanism 30 is provided with a top waist mechanism 50 in the middle of the cross bar 20, and the other end of the cross bar 20 is provided with a power-assisted torsion bar 60 for the rotation of the cross bar 20 when the top waist mechanism 50 is adjusted. 40, driving the ratchet rotating disc 31 to rotate, the ratchet rotating disc 31 rotating to drive the two-way ratchet mechanism 30 to rotate, and then driving...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com