Anti-shock packaging box

A packaging box and support plate technology, applied in the field of packaging supplies, can solve the problems of poor display, broken or damaged, and not environmentally friendly, and achieve the effects of good display performance and good shock resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

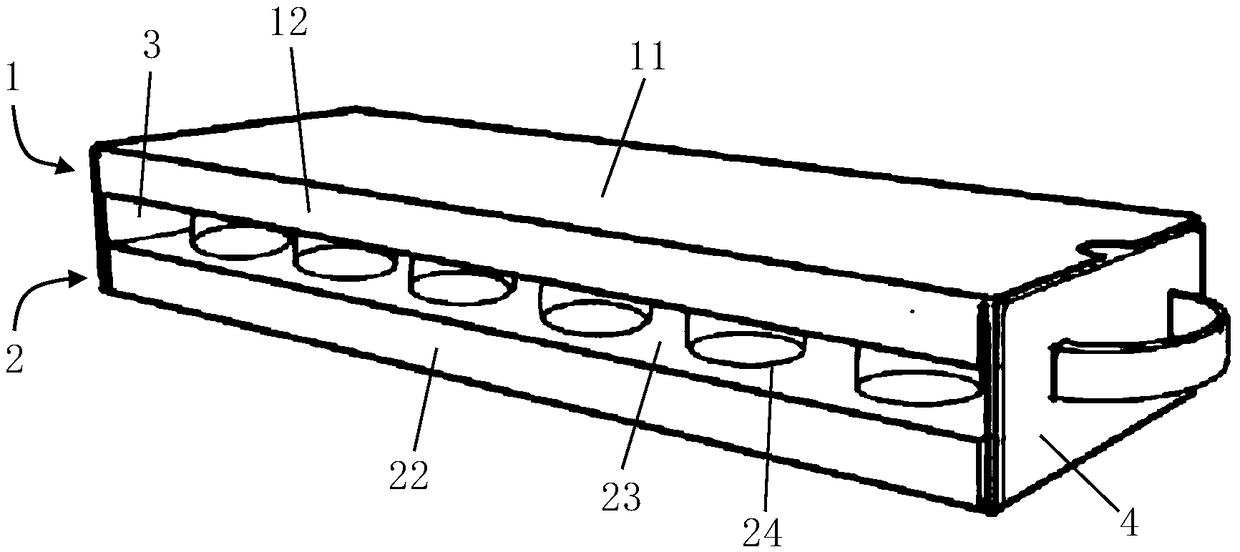

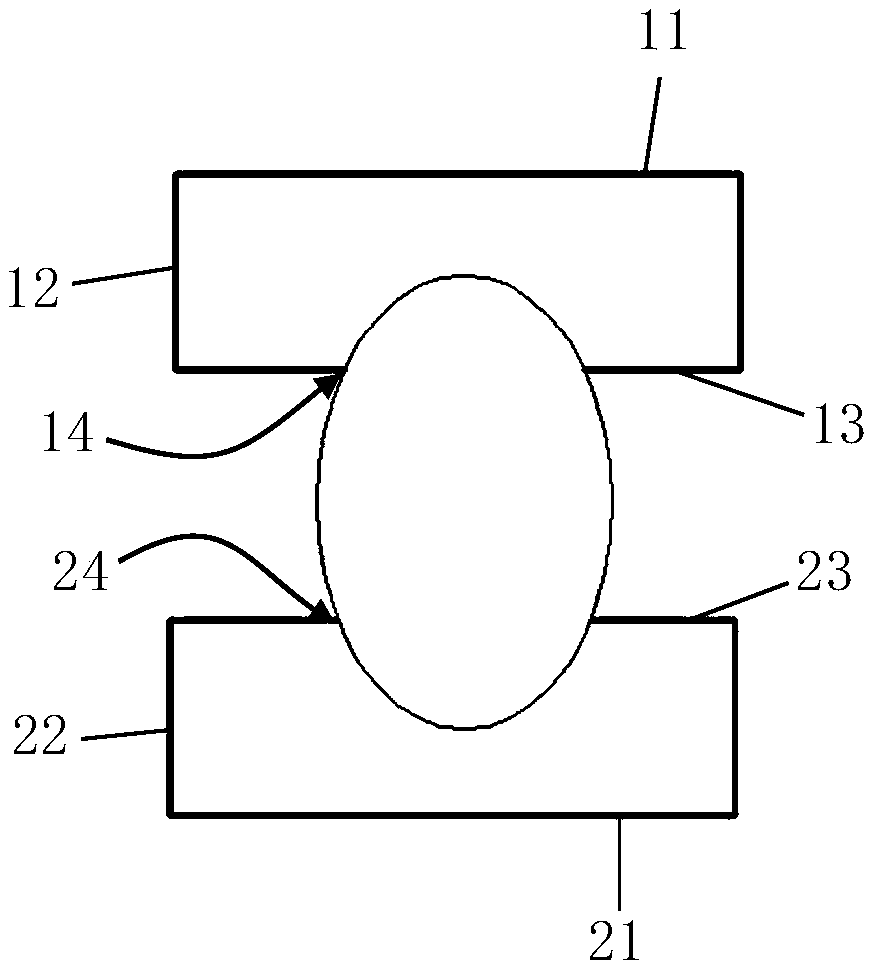

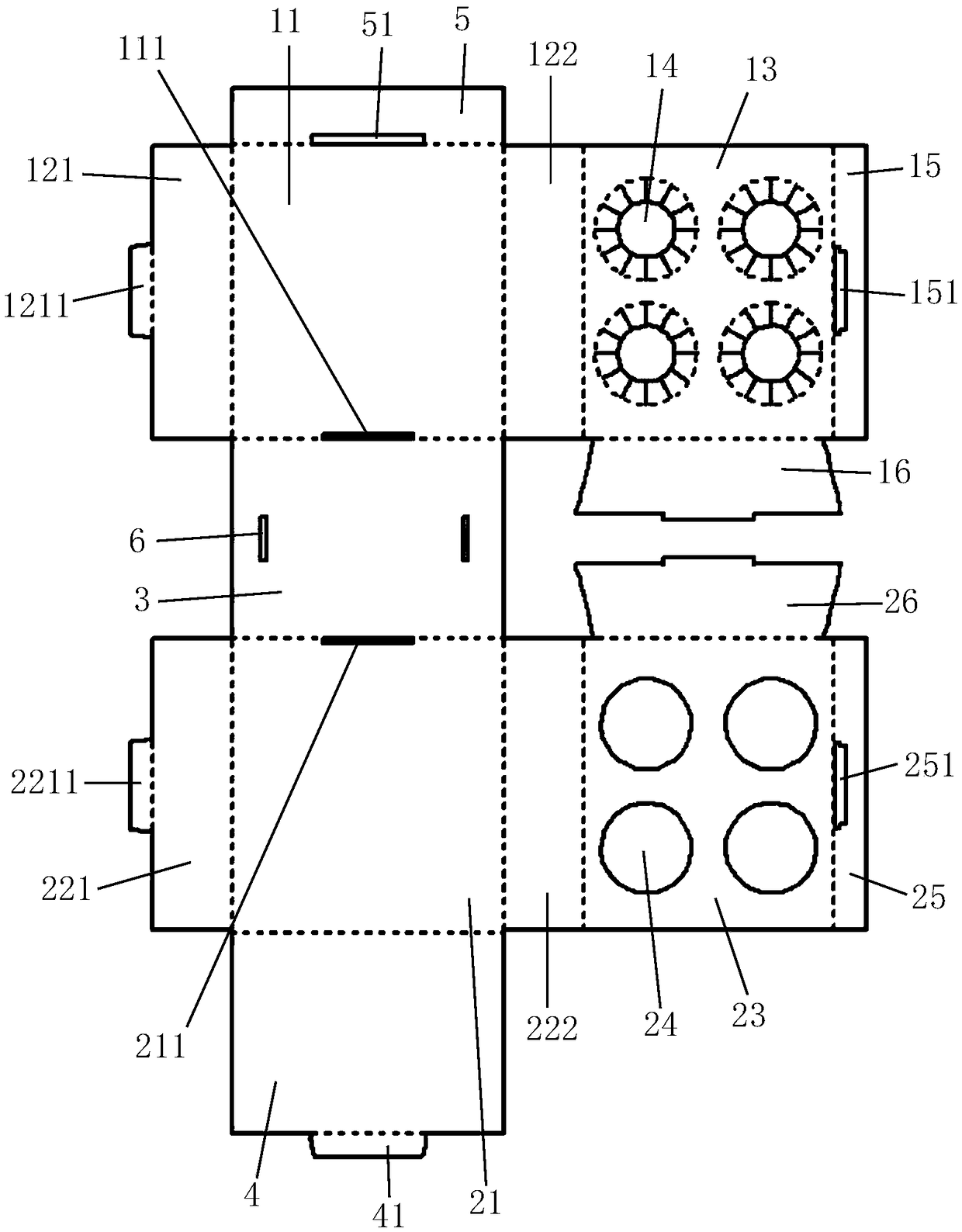

[0040] The board structure provided by this embodiment is as image 3 Shown, comprise upper cover plate 11, the first vertical plate 3 and lower cover plate 21, described upper cover plate 11, the first vertical plate 3 and lower cover plate 21 are longitudinally connected successively (the length direction of paper is longitudinal, the width direction is horizontal), the upper cover plate 11 and the lower cover plate 21 are respectively connected with the first bent plate 5 and the second vertical plate 4 by a fold line away from the side of the first vertical plate 3; the first bent plate 5 and the upper cover A first insertion seam 51 is provided at the connecting fold line of the board 11 , and a first insertion tongue 41 adapted to the first insertion seam 51 is connected to the fold line on the second vertical plate 4 .

[0041] In the unfolded panel structure, the two upper bearing panels 12 are the first side panel 121 and the second side panel 122 respectively, and th...

Embodiment 2

[0050] Such as Image 6 As shown, the plate body structure of this embodiment is roughly the same as that of Embodiment 1, the difference is that in this embodiment, positioning inserts 16 are connected with folding lines on both longitudinal sides of the upper support plate 13, and on the corresponding upper cover plate 11 The longitudinal connection fold line is provided with a positioning slot 111 adapted to the positioning insert 16, the positioning insert 26 is connected to the longitudinal both sides of the lower support plate 23 by a fold line, and the longitudinal connection fold line corresponding to the lower cover plate 21 is provided with a positioning slot 111. The positioning slot 211 that the insertion piece 26 is adapted to, when folded, the positioning insertion piece 16 is inserted into the corresponding positioning slot 111 , and the positioning insertion piece 26 is inserted into the corresponding positioning slot 211 .

[0051] Compared with Embodiment 1, ...

Embodiment 3

[0055] Such as Figure 7 As shown, the upper cover plate 11, the first vertical plate 3, the lower cover plate 21, the first bent plate 5, the second vertical plate 4, the first side plate 121, the second side plate 122, the second The structure of the three side plates 221 and the fourth side plate 222 and the connection relationship between them are roughly the same as in Embodiment 1, except that the shape and size of the first bent plate 5 in this embodiment are the same as those of the second vertical plate. 4 have the same shape and size, that is, after folding, the first bent plate 5 is attached to the inner side of the second vertical plate 4 and contacts the lower cover plate 21 to play a supporting role.

[0056] In addition, the upper support plate 13 in this embodiment includes a first upper support plate 131 connected to the first side plate 121 by a fold line, and a second upper support plate 132 connected to the second side plate 122 by a fold line, wherein the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com