Adjustable siphon on drying cylinder

A siphon and adjustable technology, applied in the field of siphon, can solve problems such as inability to achieve the effect, and achieve the effect of the best siphon effect and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

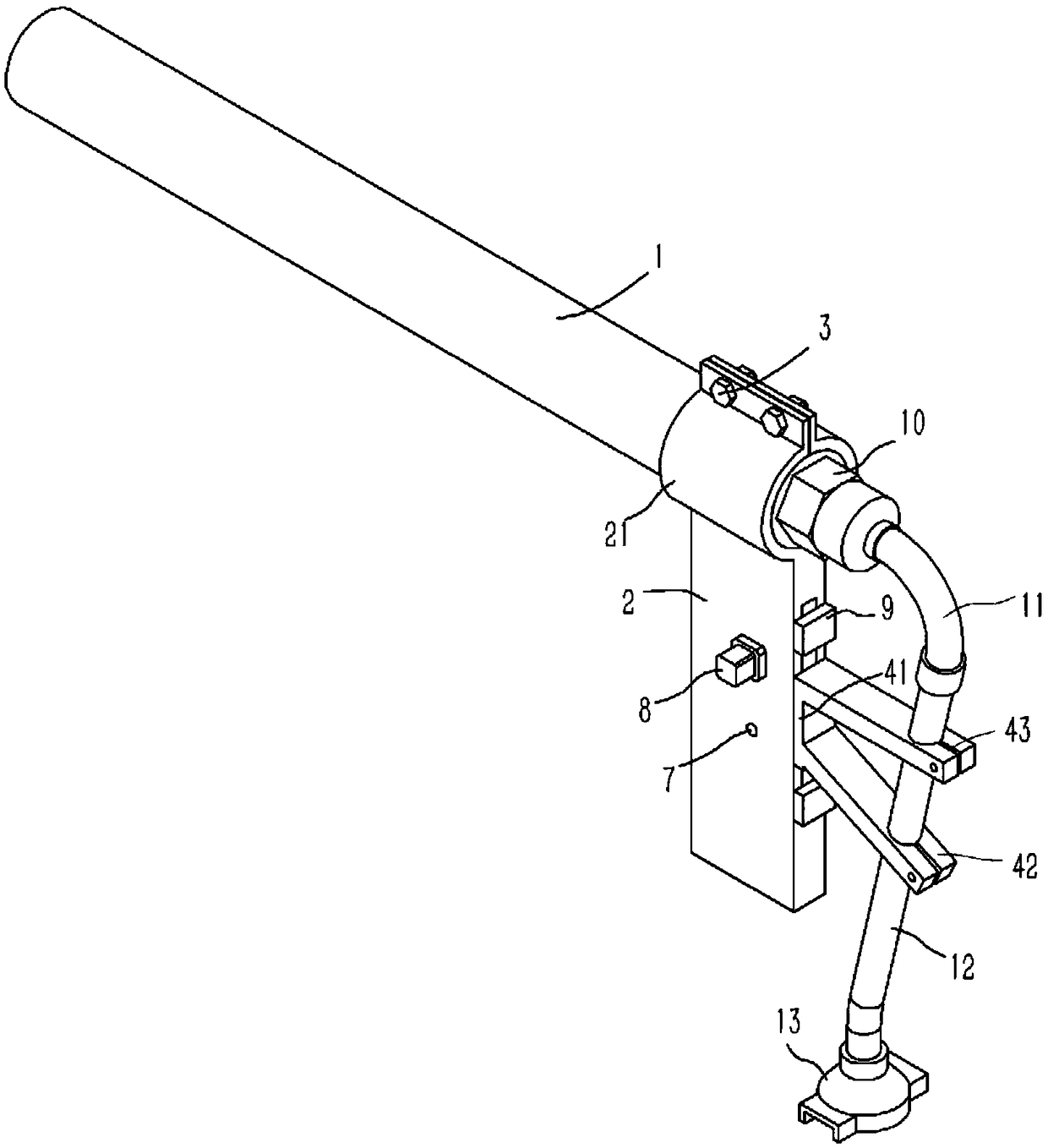

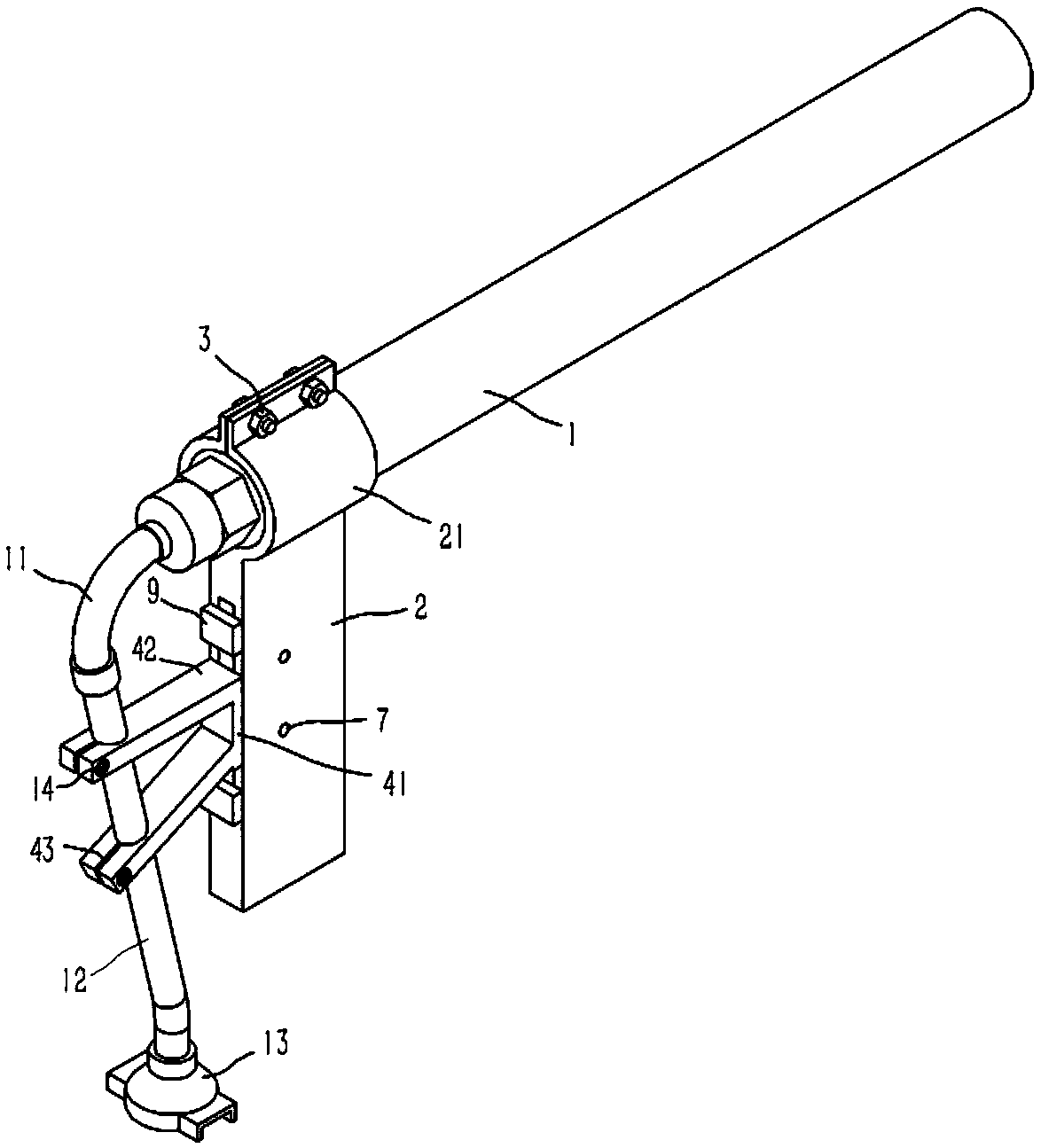

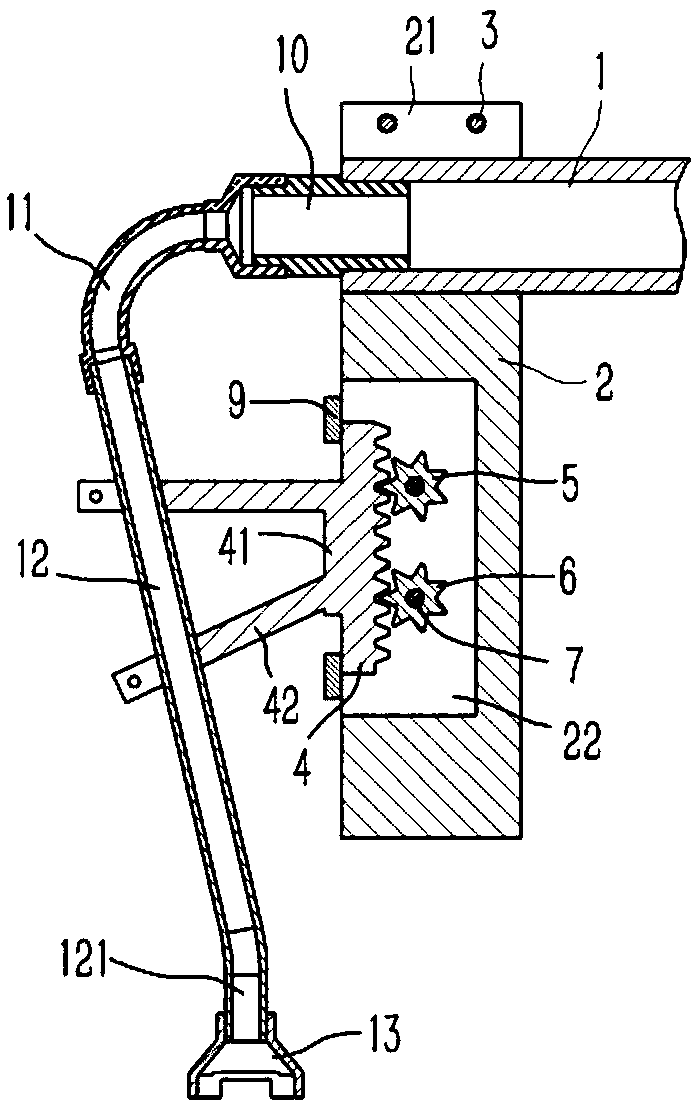

[0016] Example: see Figures 1 to 3 As shown, an adjustable siphon on a drying cylinder includes a horizontal main drain pipe 1, the inner end of the main drain pipe 1 is screwed with a connector 10, and the connector 10 is screwed with a metal hose 11, the metal hose The lower end of 11 is screwed with an inclined siphon pipe 12, and the lower end of the siphon pipe 12 is bent to form a vertical connecting pipe 121; An arc-shaped piece 21, the piece 21 is fixed on the main drainpipe 1 through the bolt assembly 3; the end surface of the fixed bracket 2 near the end of the siphon pipe 12 is formed with a slot 22, and the slot 22 of the fixed bracket 2 A vertical rack 4 is plugged in, the middle part of the rack 4 is formed with a baffle 41, the baffle 41 leans against the end face of the fixed bracket 2 near the end of the siphon tube 12, and the upper and lower ends of the slot 22 of the fixed bracket 2 are fixed with Block 9, block 9 leans against the upper and lower ends of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com