Oil discharging device

A technology of oil discharge device and protruding position, which is applied in the direction of connections with fluid cut-off devices, pipes/pipe joints/fittings, passing components, etc., which can solve the problem of slow oil discharge speed, reduce oil discharge time and improve Oil discharge efficiency and the effect of increasing the flow area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

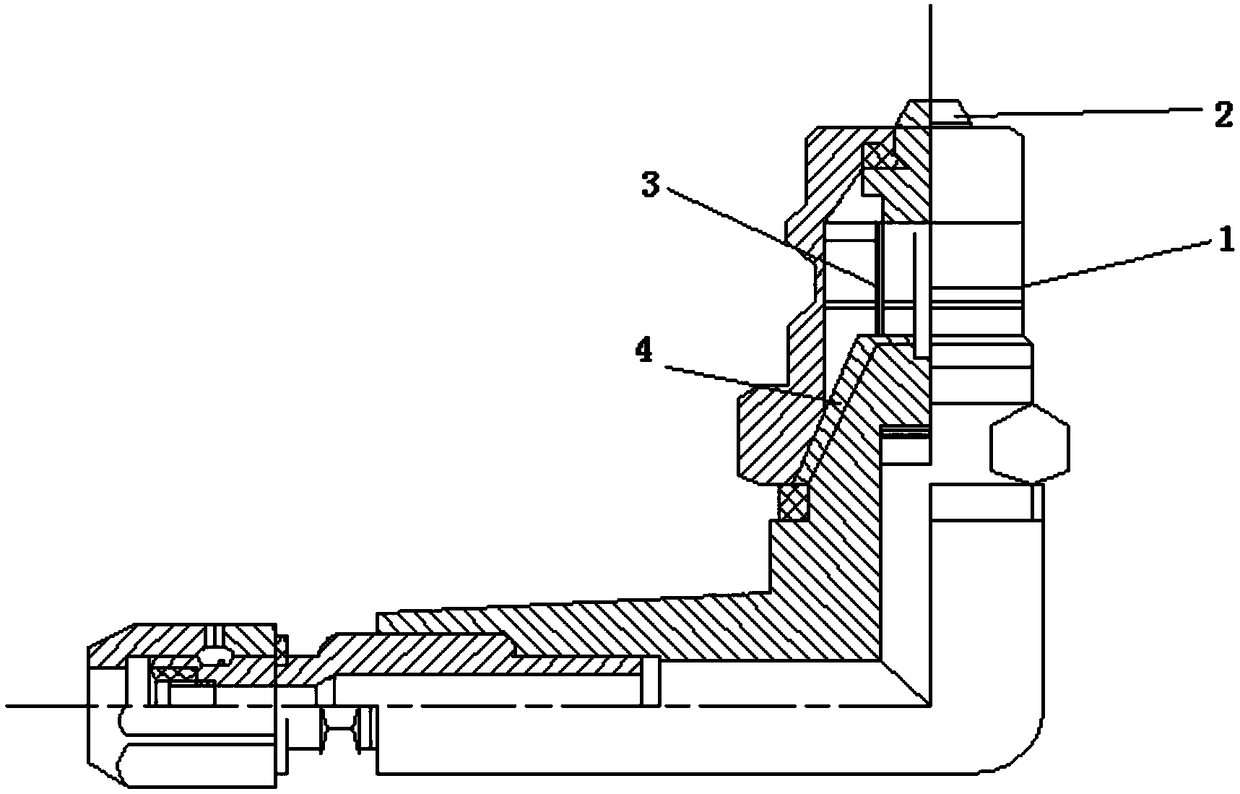

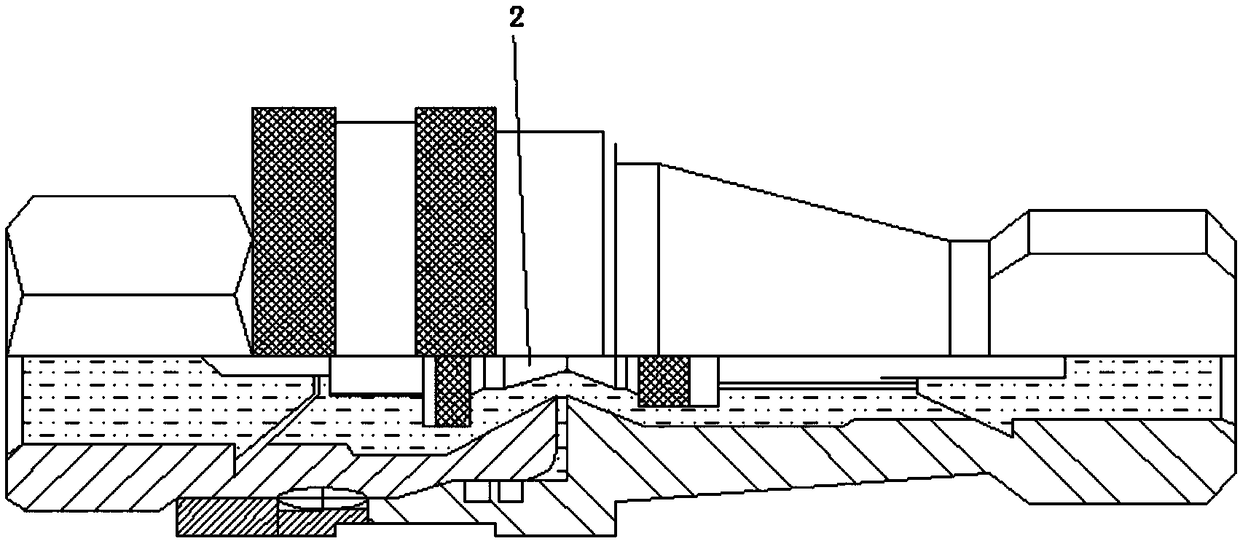

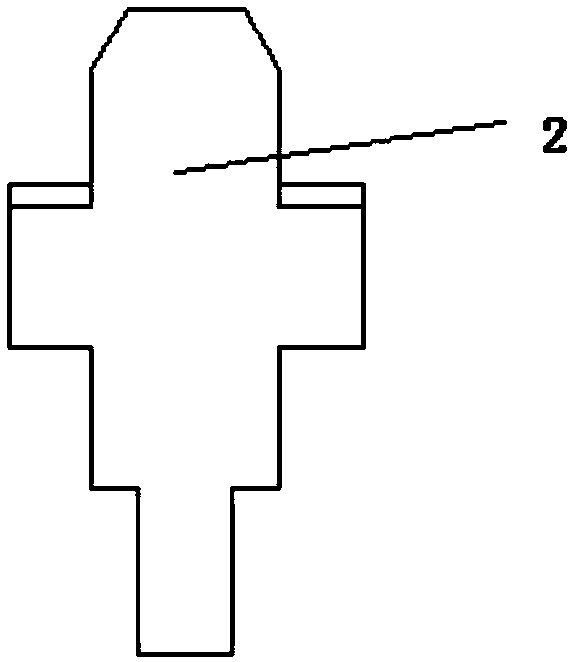

[0040] This embodiment provides an oil discharge device for discharging refrigerated oil and oil stains in a vacuum tube, comprising: a female joint sealingly connected with the vacuum pump tube, and a male joint that can be butted with the female joint. The female connector in this embodiment is as figure 1 As shown, the female joint includes a female joint housing 1, a first valve core 2, and a first biasing member 3. The female joint housing 1 has a first through cavity, and the first valve core 2 can be A retracted position and a first protruding position are set in the first through cavity so as to move, and the biasing force of the first biasing member 3 acts on the first valve core 2, so that the first A valve core 2 is in the first biasing member 3 of the first extended position, and when the first valve core 2 is in the first extended position, it forms a seal with the first through cavity, and the first When the spool 2 moves to the first retracted position under t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com