Flexible bionic electronic skin and its preparation method

An electronic skin and flexible technology, applied in the field of sensors and bionics, can solve the problems of no pressure sensing and airflow sensing functions, complex preparation methods of conductive films, etc., and achieve the effects of low cost, high sensitivity, and simple processing methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

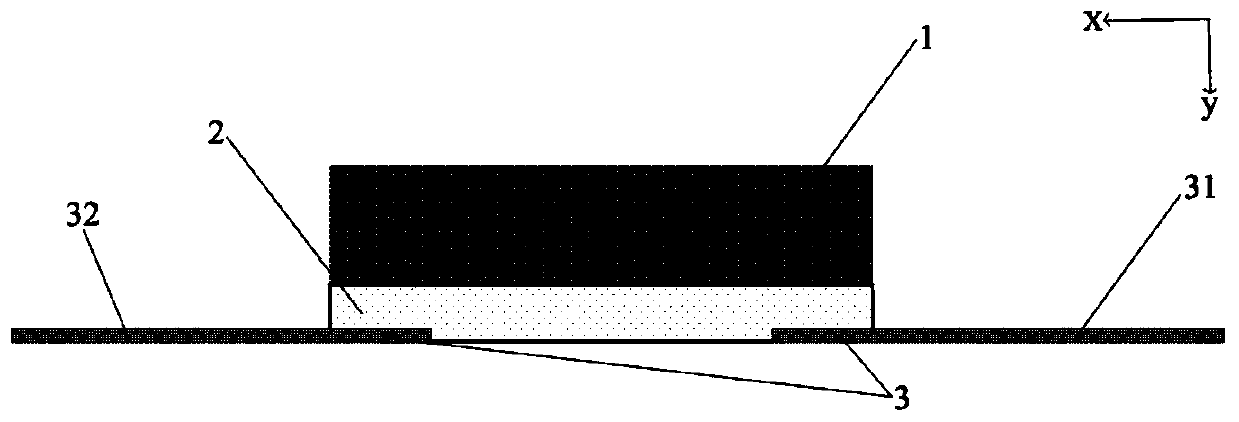

[0047] In the first embodiment of the present invention, a flexible bionic electronic skin is provided. Such as figure 1 As shown, the flexible bionic electronic skin includes:

[0048] piezoresistive layer 1;

[0049] Thin film electrode 3;

[0050] The piezoresistive layer 1 at least partially has a porous structure,

[0051] The piezoresistive layer 1 is in contact with the thin film electrode 3, and,

[0052] In the piezoresistive layer 1 in the contact interface area between the piezoresistive layer 1 and the thin film electrode 3, there is at least partially a filling area 2, and the filling area 2 contains an elastomer; wherein,

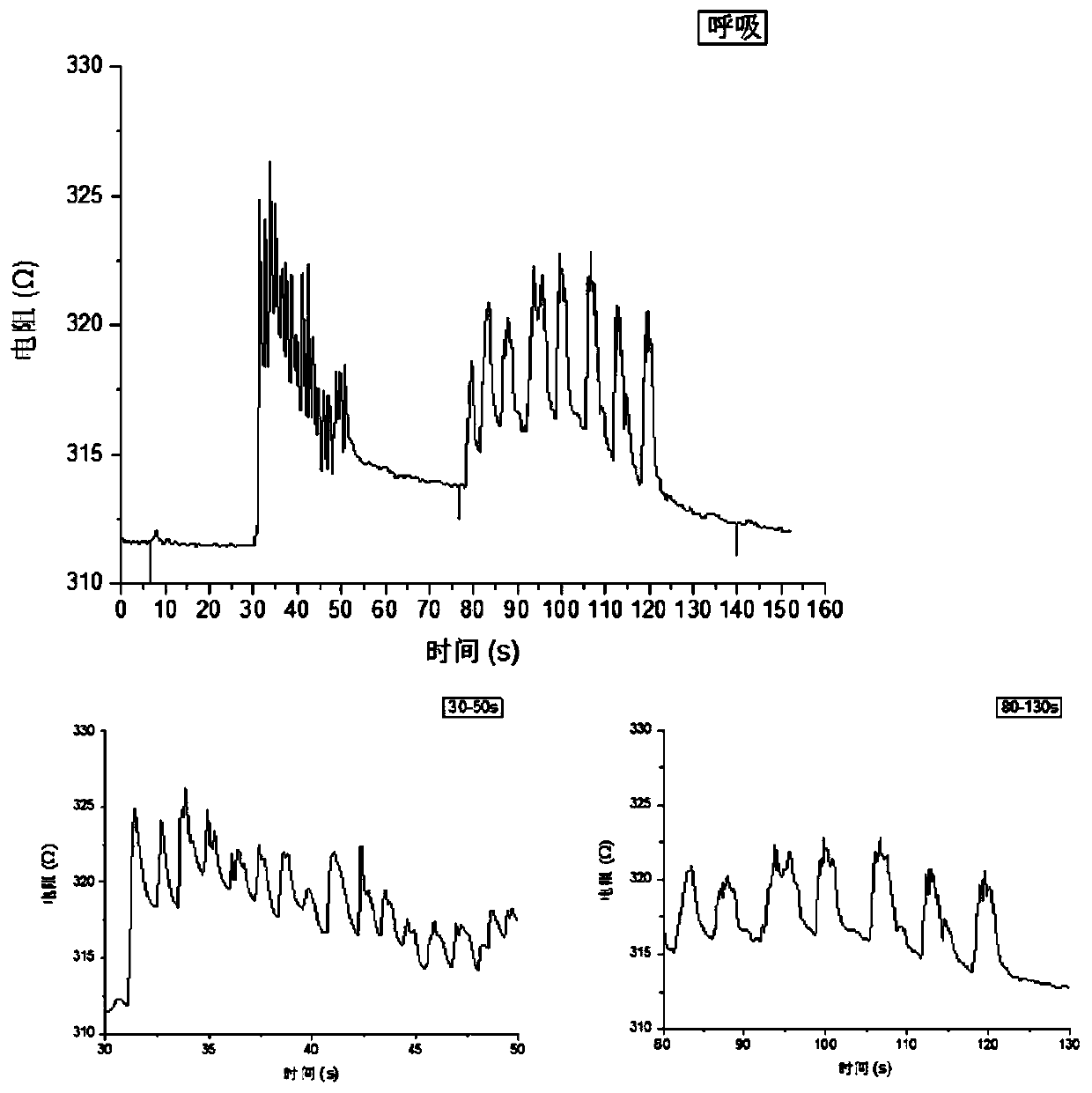

[0053] The resistance value of the piezoresistive layer 1 is detected by the thin-film electrode 3, and the force on the flexible bionic electronic skin is determined according to the detection result. Wherein, the received force may be the force generated by the gas flow above the flexible bionic electronic skin, or the force exerted by...

no. 2 approach

[0088]The second embodiment of the present invention provides a method for preparing a flexible bionic electronic skin. The method comprises the steps of:

[0089] The step of connecting the piezoresistive layer 1 with the thin film electrode 3;

[0090] A step of forming a filling region 2 on one side of the piezoresistive layer 1;

[0091] Wherein, the filled region 2 on one side of the piezoresistive layer 1 is adjacent to the thin film electrode 3,

[0092] The piezoresistive layer 1 at least partially has a porous structure, and the filled region 2 contains elastomer.

[0093] Typically, the preparation method of the present invention can be carried out according to the following steps:

[0094] Connecting the piezoresistive layer 1 to the film electrode 3, pouring an elastomer solution on at least a part of the junction between the piezoresistive layer 1 and the film electrode 3, so that a part of the piezoresistive layer 1 is infiltrated by the elastomer solution, f...

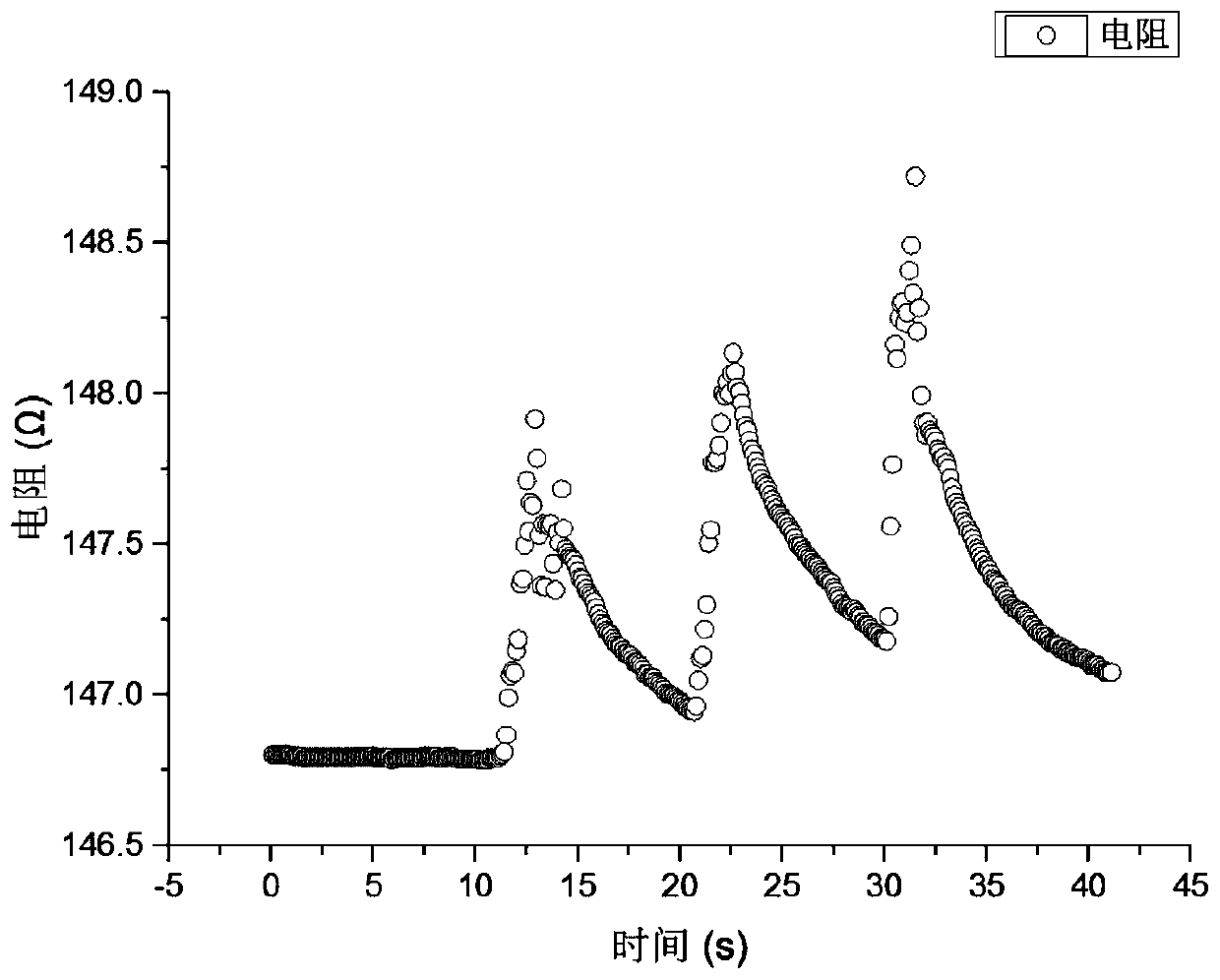

Embodiment 1

[0113] In this embodiment, a three-dimensional carbon nanofiber material is firstly prepared as a piezoresistive layer, and then ecoflex30 is used as a raw material of an elastomer, and a carbon nanotube film electrode is selected as a film electrode. Concrete preparation steps are as follows:

[0114] (1) Dissolve polyacrylonitrile in N,N dimethylformamide solvent, and stir at 60°C for 5 hours; wherein the mass percentage of polyacrylonitrile is 16wt.%. Quality anhydrous aluminum chloride, make the mass percentage of anhydrous aluminum chloride in the electrospinning base solution be 2wt.%, stir at 60°C for 5 hours, then stand at 25°C for 1 hour to obtain the electrospinning Solution; the voltage is 13kV, the inner diameter of the needle is 0.8mm, the volume of the spinning liquid is 7mL, the advancing speed of the spinning liquid is 0.3ml / h, the distance between the receiving drum and the spinneret is 25cm, the speed of the receiving drum is 200rpm, the air The relative hum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com