Equipment and method for removing VOC

A technology of equipment and exhaust gas, applied in the field of VOC removal equipment, can solve problems such as unsatisfactory results, and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

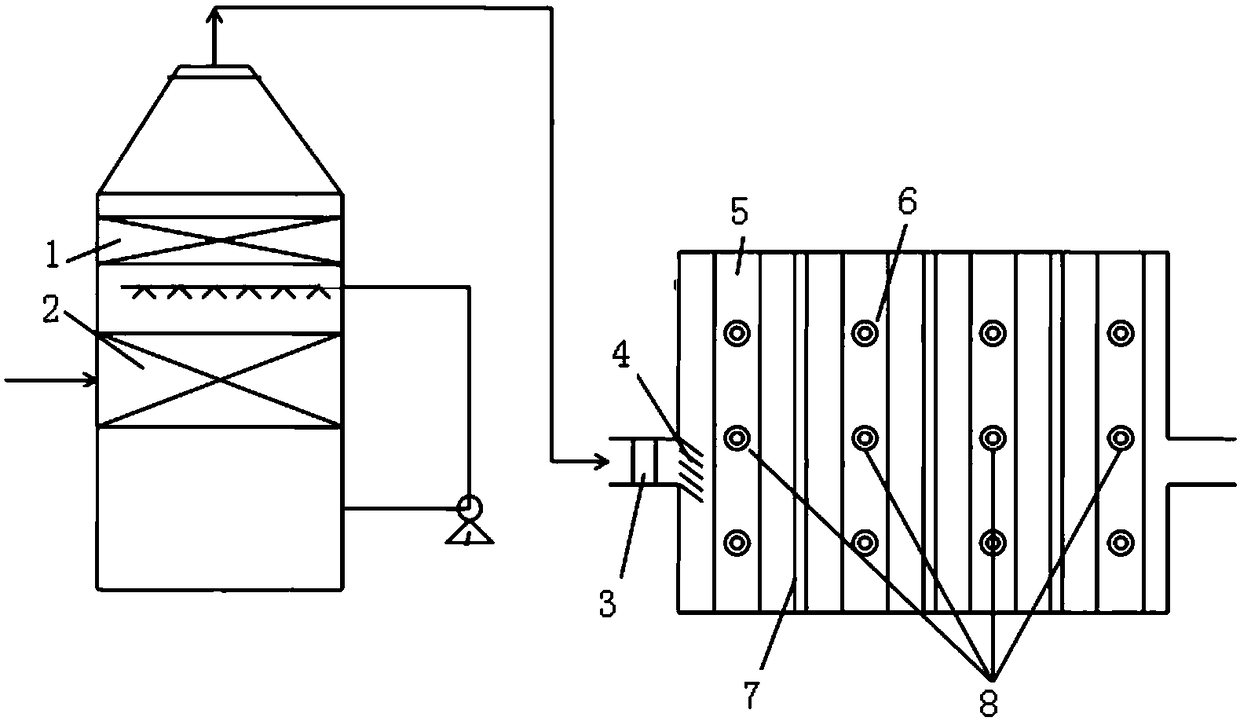

[0024] Such as figure 1 As shown, a device for removing VOC includes a connected spray system and a photocatalytic unit, the spray system is used to spray exhaust gas to remove dust in the exhaust gas; the photocatalytic unit includes a photocatalytic plate 7 and a light source, and the light source is arranged on It can be irradiated to the position of the photocatalytic plate 7, which is used to decompose VOC through photocatalysis; there is a humidity control device 3 connected between the spray system and the photocatalysis part, and the humidity control device 3 is used to control the exhaust gas filtered and dedusted from the spray system. The relative humidity is 30-50%.

[0025] The present invention finds that not only particles have a great influence on the photocatalytic process, but also humidity has a great influence on the photocatalytic process. On the one hand, moisture will increase the generation of hydroxyl radicals and superoxide radicals in the photocataly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com