Nuclear power pipeline branch pipe opening welding mould

A technology for welding molds and pipes, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of heavy preparation work, high difficulty, and low welding efficiency, and achieve small preparation work and low difficulty , The effect of improving welding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

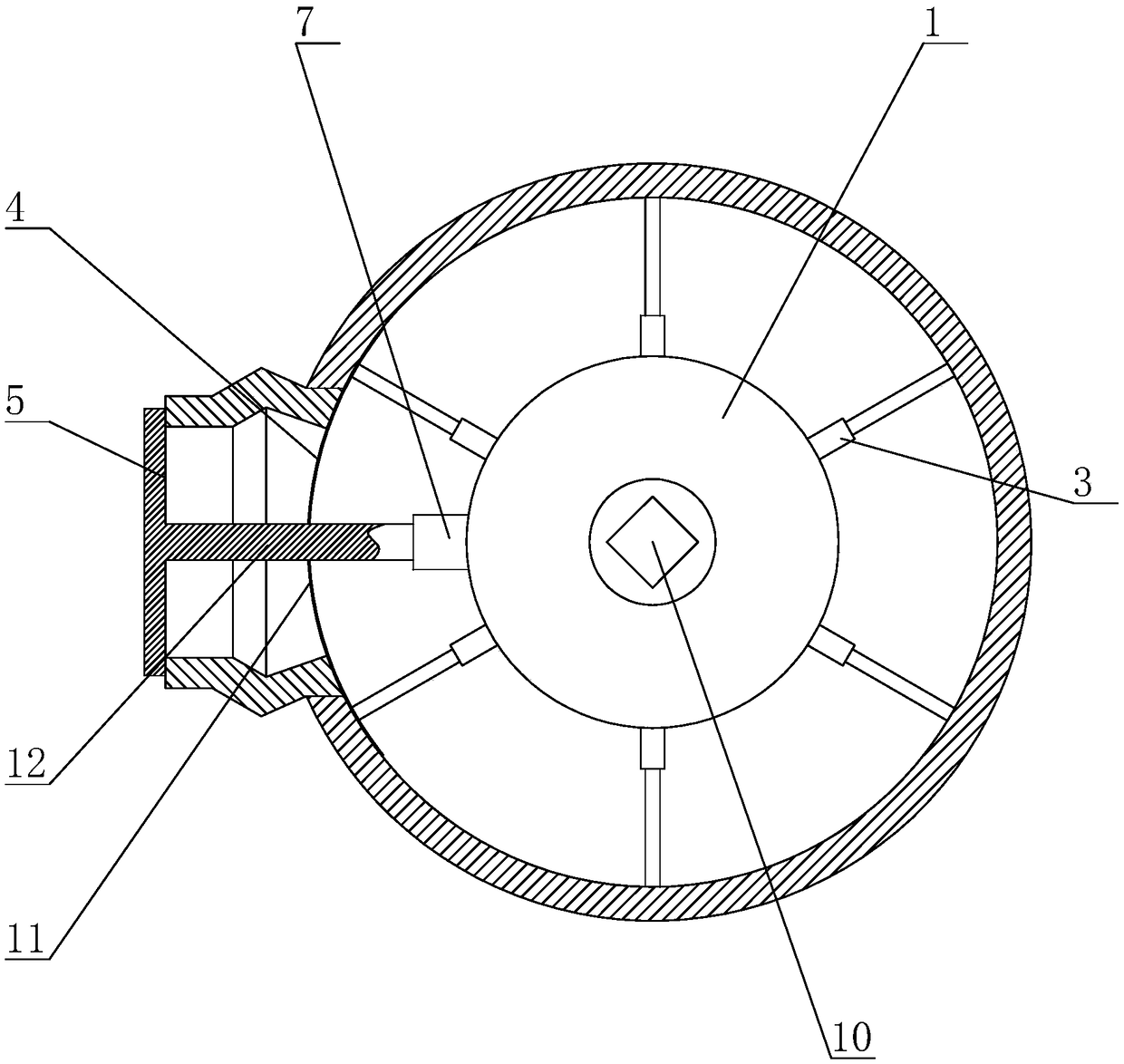

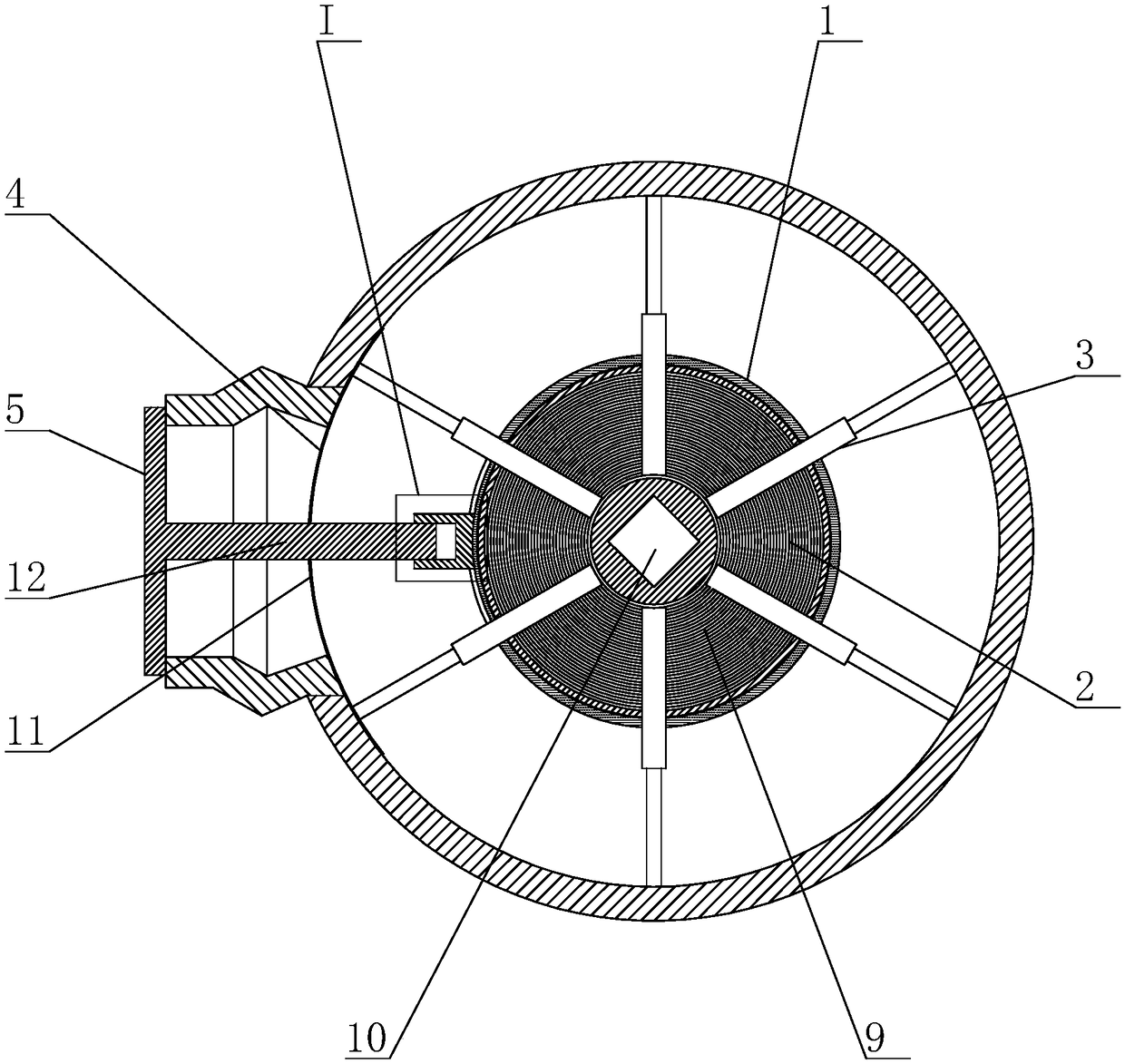

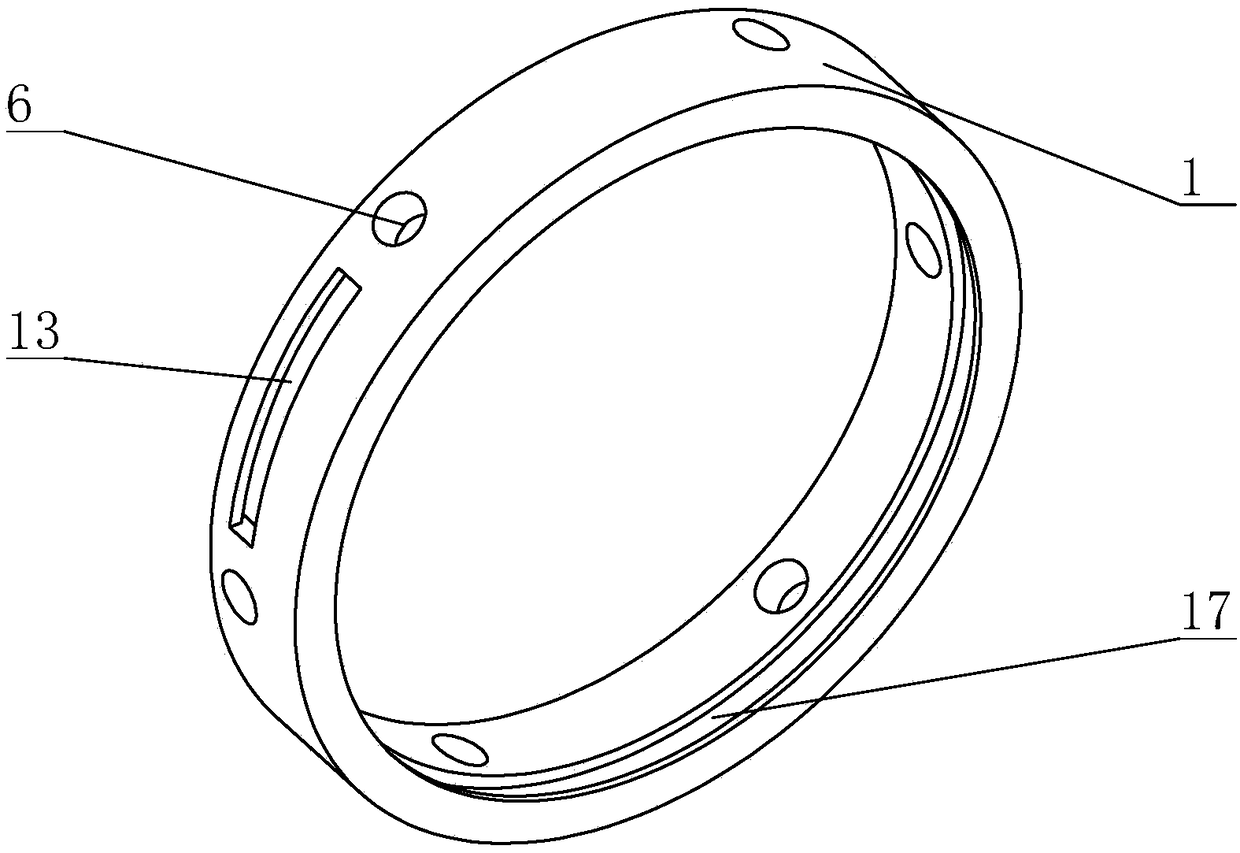

[0029] The present invention is a nuclear power pipeline branch nozzle welding mold. The main structure includes an outer ring 1, an inner disk 2, a brace 3, an arc-shaped backing plate 4, and a pressure plate 5. The outer ring 1 is provided with a plurality of through holes 6, so The outer surface of the outer ring 1 is provided with a sliding groove 13 with a T-shaped cross section, a fixed post 7 is slidably connected to the sliding groove 13 and a threaded hole is provided on the fixed post 7, and the inner disk 2 is arranged on the outer ring 1, the inner surface of the outer ring 1 is provided with a groove 14, the inner disk 2 is arranged in the groove 14 and rotates along the groove 14, a plane thread structure 9 is provided on one side of the inner disk 2, and the inner disk 2. A rocker socket 10 is provided at the center position; the strut 3 is a telescopic rod with an adjustable length, and a plurality of the struts 3 are distributed along the circular array of the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com