Welding mold for nuclear power pipeline branch

A technology for welding molds and pipes, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of high difficulty, heavy preparation work, and low welding efficiency, and achieve small difficulty and small preparation work , The effect of improving welding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

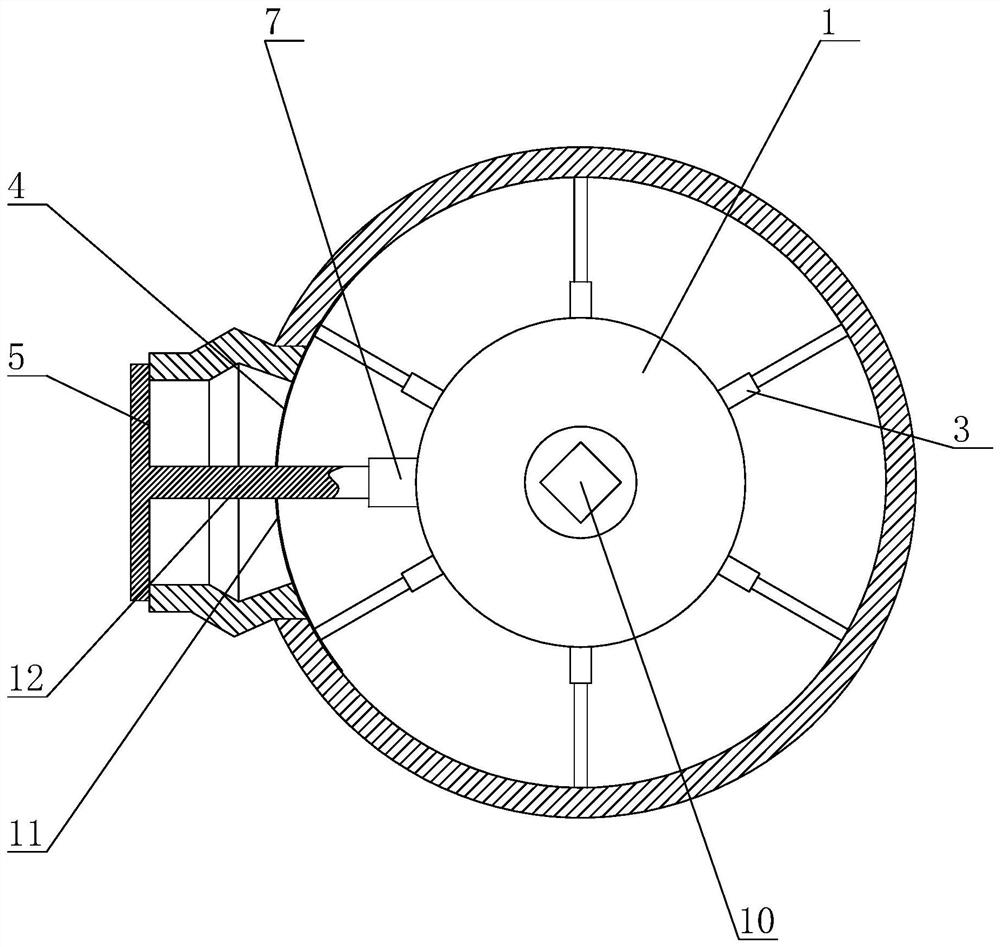

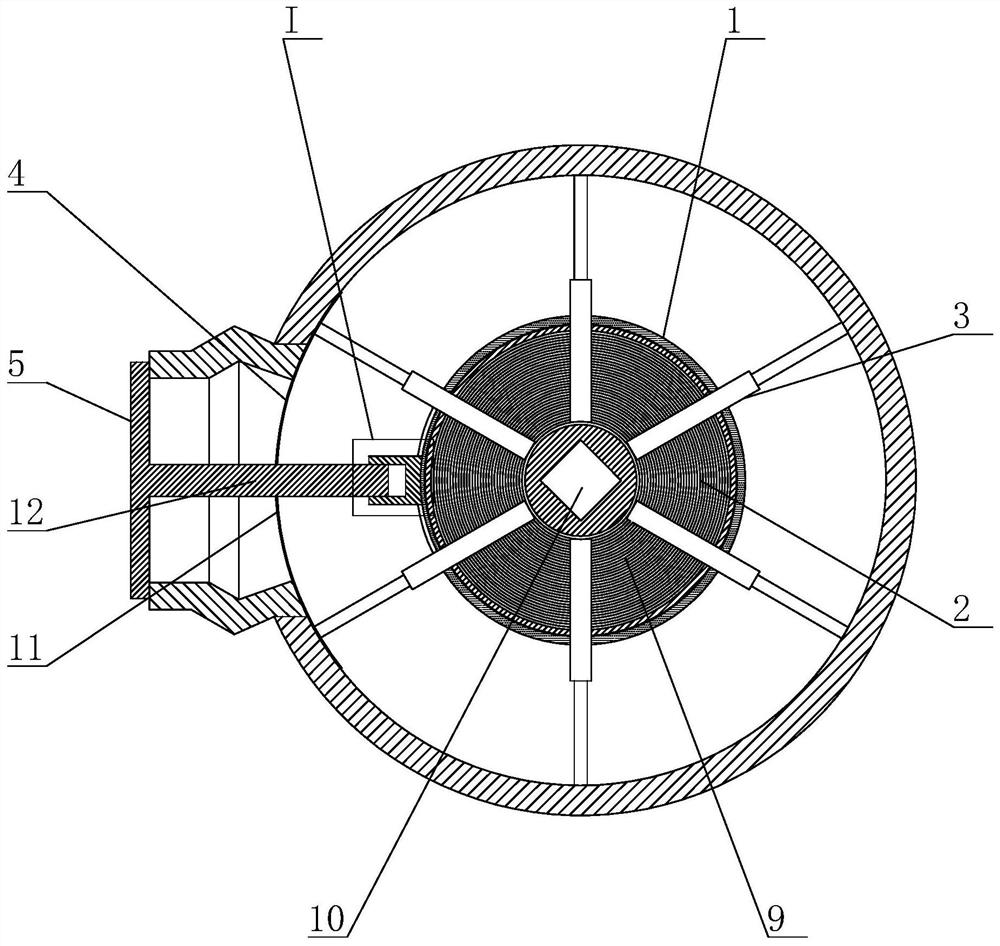

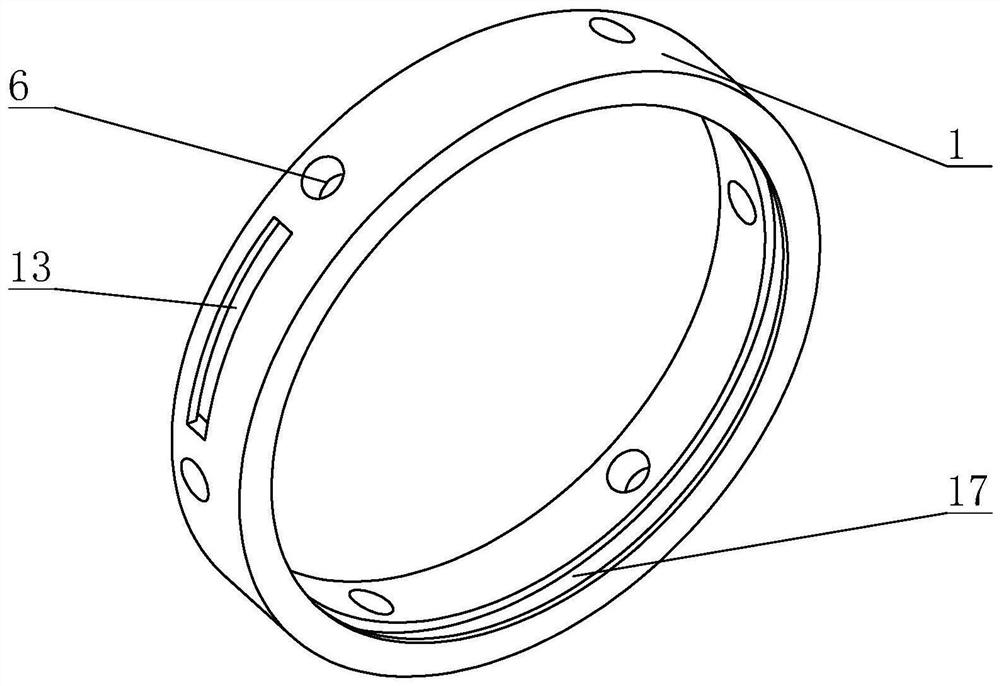

[0029] The present invention is a nuclear power pipeline branch port welding mold, the main structure includes an outer ring 1, an inner plate 2, a strut 3, an arc backing plate 4 and a pressure plate 5; the outer ring 1 is provided with a plurality of through holes 6, so The outer surface of the outer ring 1 is provided with a chute 13 with a T-shaped cross-section, and a fixed column 7 is slidably connected to the chute 13. The fixed column 7 is provided with a threaded hole, and the inner disc 2 is arranged on the outer ring. 1, the inner surface of the outer ring 1 is provided with a groove 14, the inner disk 2 is set in the groove 14, and rotates along the groove 14, and one side of the inner disk 2 is provided with a plane thread structure 9, and the inner disk 2 2. There is a handle socket 10 at the center; the struts 3 are telescopic rods with adjustable length, and a plurality of the struts 3 are distributed along the center of the inner disk 2 in a circular array, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com