A paint injection device used in the later stage of ceramic processing

A ceramic processing and spraying device technology, applied in the direction of ceramic molding machines, manufacturing tools, etc., can solve the problems that dyes cannot be cleaned quickly, dyes are contaminated with equipment, and automatic spraying is not provided.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

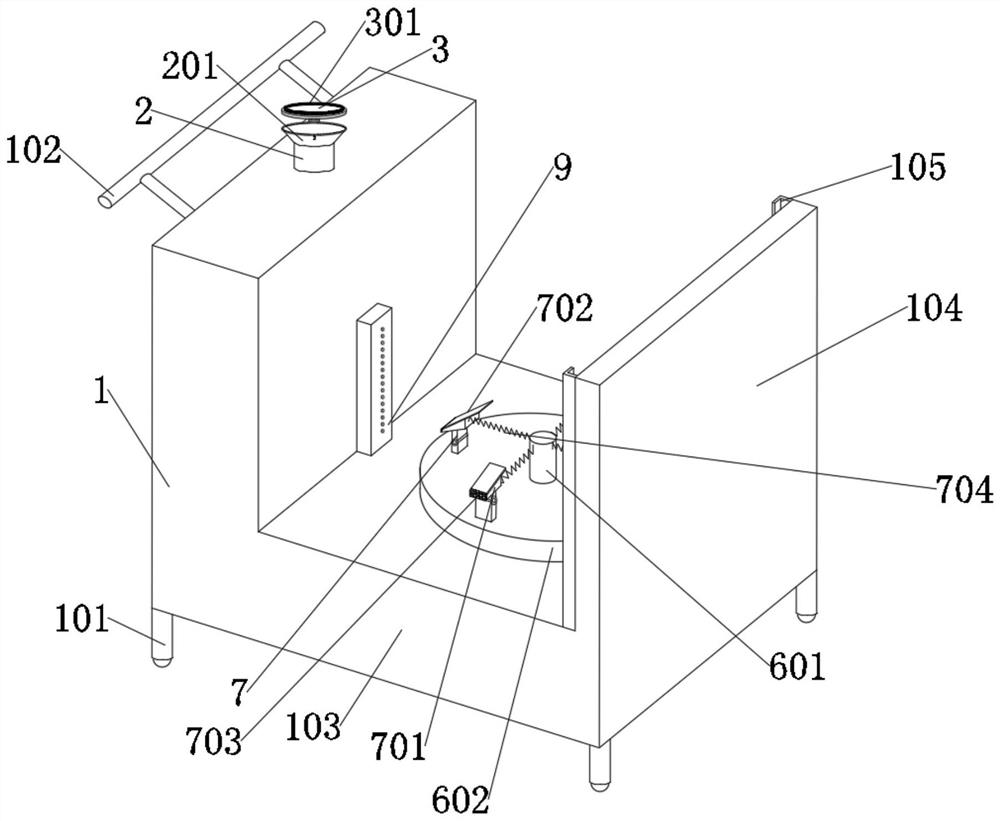

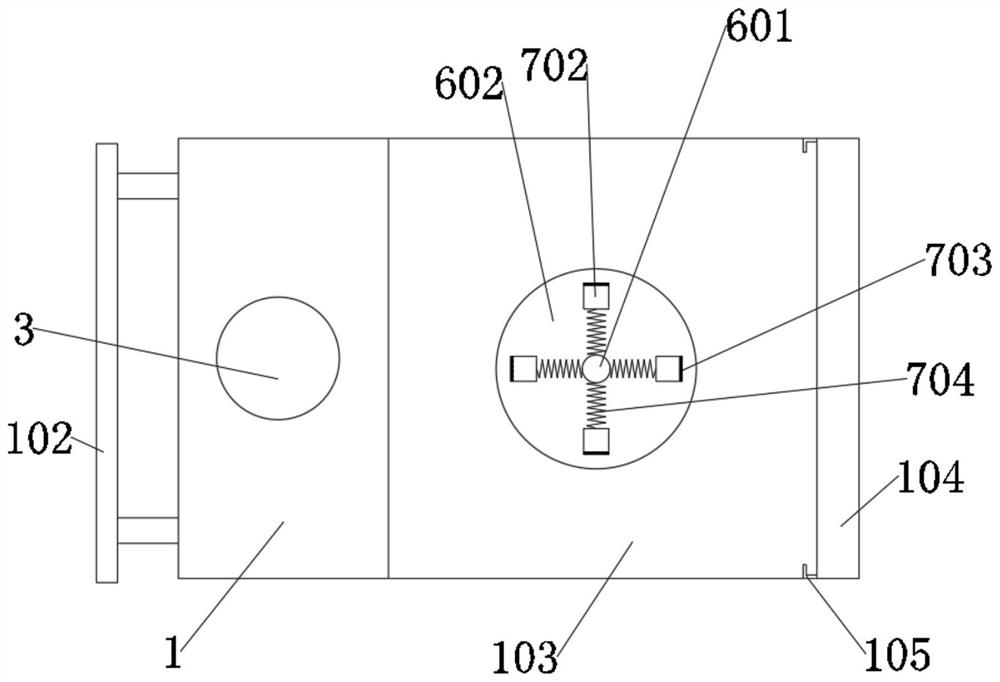

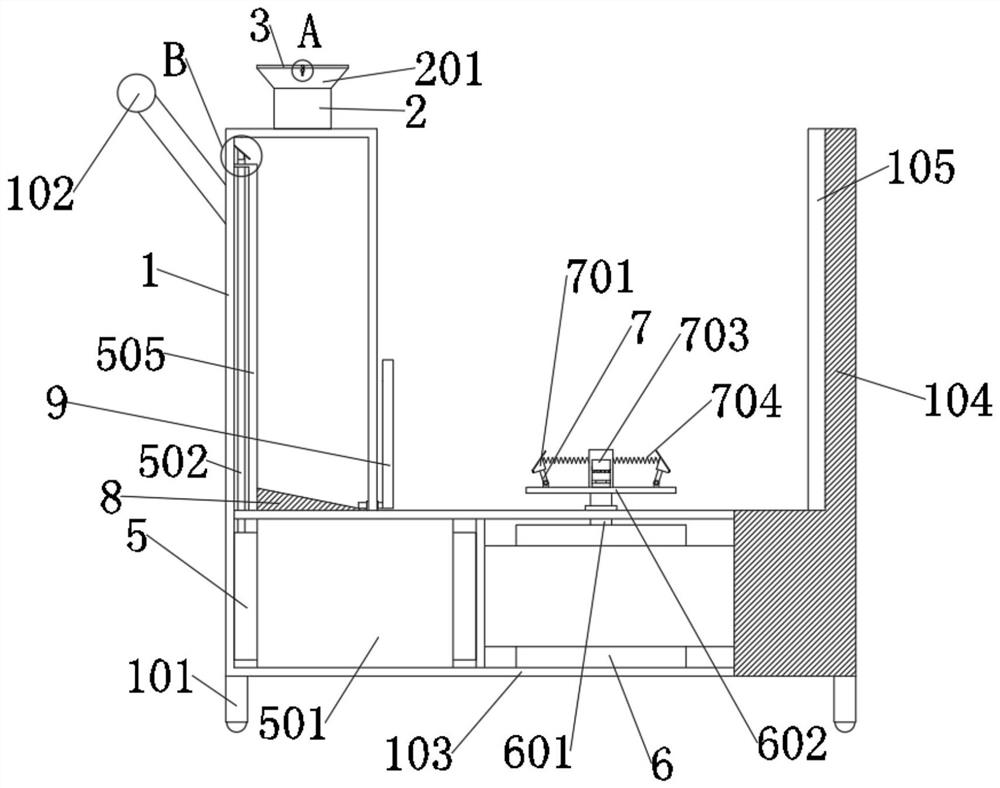

[0024] as attached figure 1 to attach Figure 9 Shown:

[0025]The present invention provides a paint spraying device used in the late stage of ceramic processing, including: a main chamber 1, a universal wheel 101, a push rod 102, a bottom chamber 103, a vertical plate 104, an insert 105, a feeding pipe 2, and a feeding port 201 , embedded groove 202, connecting shaft 203, fixing part 204, cover plate 3, sealing strip 301, fixing bolt 302, supercharger 5, fixing part 501, pipe 502, air outlet 503, stopper 504, protective cover 505, motor 6. Transmission rod 601, rotating part 602, flipping part 7, connecting block 701, sliding plate 702, anti-slipping block 703, outer support spring 704, diversion block 8 and spray head 9; the main chamber 1 is a rectangular internal hollow structure, and the main The bin 1 is installed on the upper left side of the bottom bin 103 by welding, and the upper left side of the main bin 1 is installed with a push rod 102 by means of welding thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com