Multilayer PE water purification pipe mold

A pipe and mold technology, applied in the field of multi-layer PE water purification pipe molds, can solve the problems of water purification pipe scrapping and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

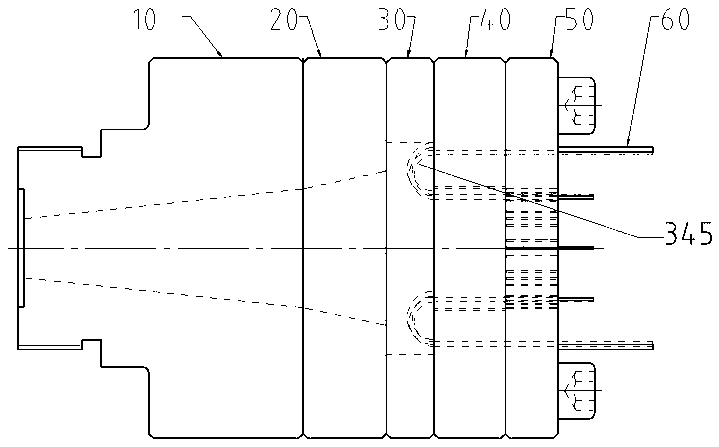

[0015] A multi-layer PE water purification pipe mold (hereinafter referred to as the mold), including a rear mold body 10, a transition plate 20, a sinker plate 30, a bracket plate 40 and a mouth template 50 connected in sequence. The specific assembly relationship is as follows: the rear mold body 10 Connected to the extrusion equipment; the transition plate 20 is positioned on the rear mold body 10 with positioning pins, the sinking plate 30 is positioned on the transition plate 20 with positioning pins, and the bracket plate 40 is positioned on the sinking plate 30 with positioning pins. The formwork 50 is fixed on the rear mold body 10 with the support plate 40, the sinker plate 30, and the transition plate 20 with 12.9 grade high-strength hexagon socket bolts. The mold was heated on all sides with cast aluminum heaters.

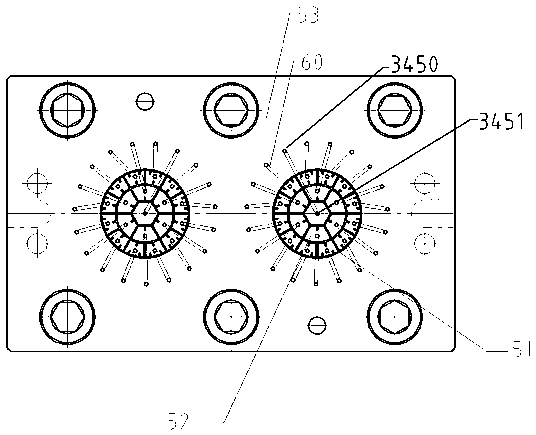

[0016] The mouth template 50 has a structure such as figure 1 As shown, for accommodating and shaping PE, the mouth template 50 includes a PE groove 51...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com