Novel modified starch oven

A modified starch, oven technology, applied in progressive dryers, drying solid materials, dryers, etc., can solve the problems of low water droplets, easy condensation of water vapor, and stagnation of upper gas to avoid dripping.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

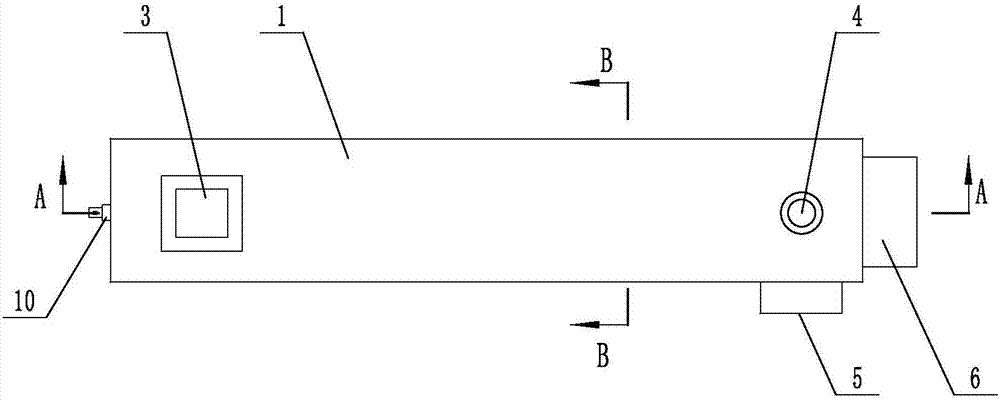

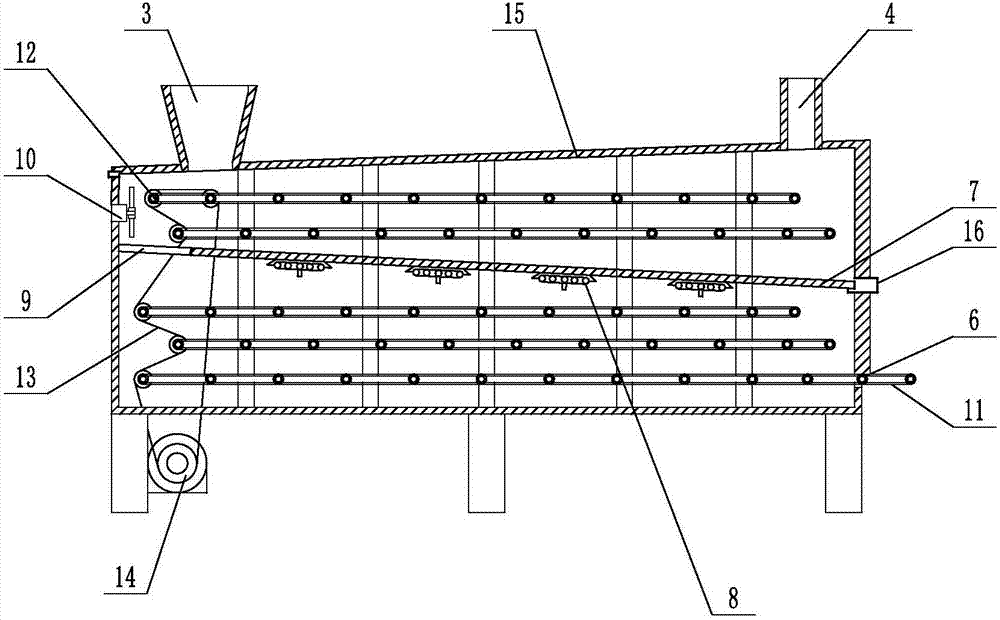

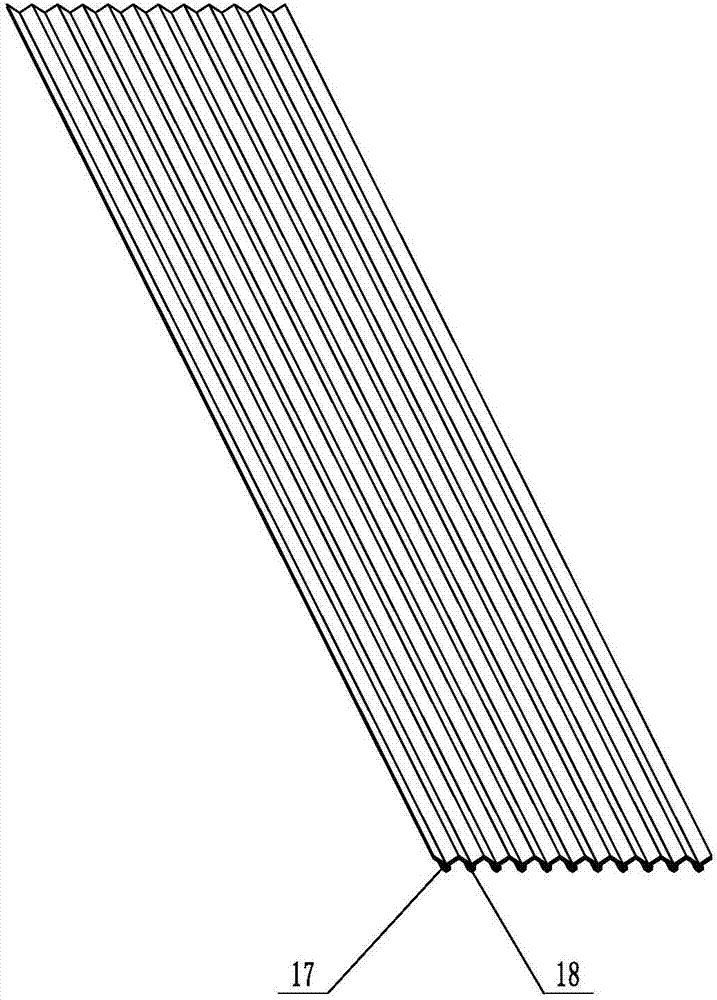

[0014] Such as Figure 1-3 Shown, the present invention comprises box body 1, support leg 2, the feed hopper 3 that is located at the upper end of box body 1 and exhaust port 4, the control panel 5 that is located at the side wall of box body 1 and discharge port 6, so A partition 7 is arranged in the middle of the inside of the box body 1, a plurality of heating lamp tubes 8 are arranged on the lower wall of the partition 7, a blanking opening 9 is provided at the left end of the partition 7, and a blanking opening 9 is provided on the upper side of the blanking opening 9. There is a horizontal fan 10 fixed on the inner wall of the box body 1; the upper and lower ends of the partition 7 are provided with a multi-layer staggered conveyor belt 11, and the transmission roller 12 at the left end of the conveyor belt 11 is connected with a drive motor 14 through a chain 13; Both the partition plate 7 and the top plate 15 of the box body 1 are inclined flaps, and the lower ends of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com