An ultra-low resistance three-dimensional composite membrane filter element and a protective mask made of it

A three-dimensional composite and composite membrane technology, which is applied in protective clothing, applications, and dispersed particle filtration, can solve the problems of repeated regeneration, limited ability to block bacteria, viruses, and ultrafine particles, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

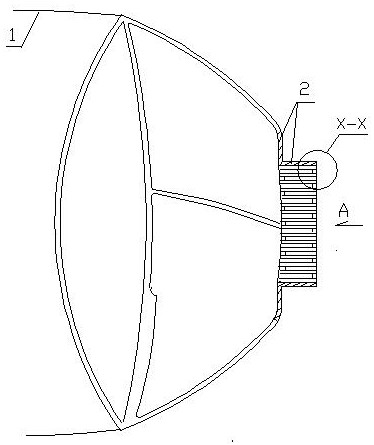

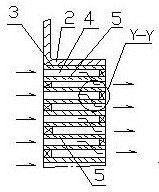

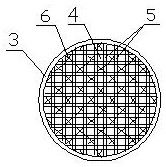

[0027] In the figure, an ultra-low resistance three-dimensional composite membrane filter element and a protective mask made of a composite membrane filter element, the protective mask includes a cover body 2, a lace 1 connected to the cover body and a cover body (filter box) Composite membrane filter element on the composite membrane filter element composed of plastic support), the composite membrane filter element is a three-dimensional honeycomb support body 3, the honeycomb support body has honeycomb holes 4, and a three-dimensional composite film layer is formed on the surface of the inner wall of the honeycomb hole 5 8. The honeycomb holes are arranged staggeredly or parallelly along the axial direction of the honeycomb support body, the two ports of the honeycomb holes are respectively staggered with plugs 6, and the three-dimensional composite film layer 8 dip-coated on the surface of the inner wall of the honeycomb holes 5 The pore diameter of the membrane is 0.05-0.5u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com