Vibration test system and method for reliability test of helicopter blade heating components

A technology for heating components and vibration testing, which is applied in the testing of aircraft components, etc. It can solve the problems of high test cost, long cycle, high quality and rigidity of test pieces, etc., and achieve high test frequency, low cost, and convenient replacement and maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the objectives, technical solutions and advantages of the present invention clearer, the technical solutions in the embodiments of the present invention will be described in more detail below in conjunction with the drawings in the embodiments of the present invention.

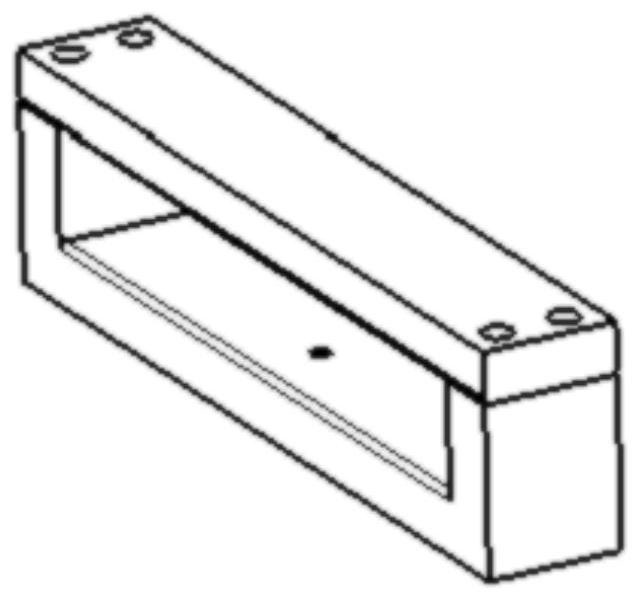

[0027] In order to verify the reliability of the helicopter blade heating assembly, the present invention designs a vibration test system that can be used for the reliability test of the helicopter blade heating assembly. The vibration test system mainly includes three parts: simulated blade 1, heating assembly 2 And excitation system 3.

[0028] The simulated blade 1 is not a real helicopter blade, but a rectangular plate-shaped structure made of composite materials, and its material strain parameters are the same as the real blade.

[0029] The heating component 2 conforms to the characteristics of the heating component on the real blade (continuous heating, the heating temperature is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com