Method and device for producing carbon black by utilizing big data

A technology of big data and carbon black, applied in fibrous fillers and other directions, can solve the problems of increased labor burden, insignificant granulation effect, low degree of automation, etc., to improve safety, improve manufacturing process, and improve production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

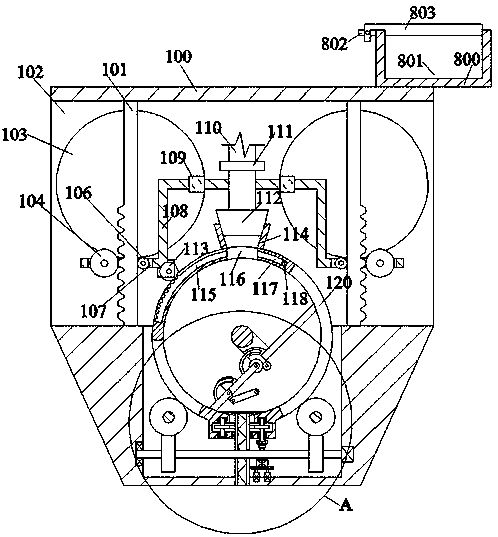

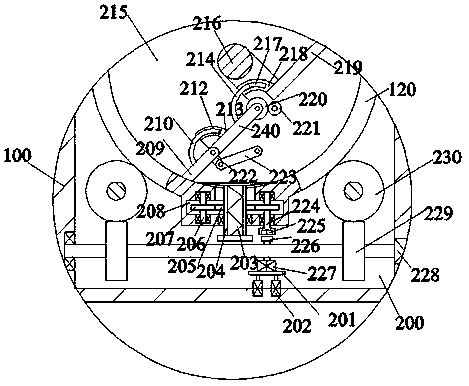

[0016] Combine below Figure 1-2 The present invention will be described in detail.

[0017] According to a kind of carbon black granulation equipment of embodiment, described carbon black granulation equipment comprises box body 100, and in described box body 100, there is a penetrating chamber 102 that penetrates left and right through at high speed, and in the lower end wall of described penetrating chamber 102 A drive chamber 200 is connected to it, and a left-right symmetrical connection rack 101 is fixed between the upper and lower end walls of the penetration chamber 102, and a motor-driven rotating disk 103 is fixed on the rear end wall of the penetration chamber 102. Turning plate 103 is provided with turning block 109 for rotating at the front end, and lifting rod 108 is arranged slidingly in said turning block 109, and said lifting rod 108 is fixedly provided with connecting cavity 107 penetrating up and down and symmetrical left and right, said connecting cavity 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com