Control method of deviation of looper of galvanization production line entrance

A zinc production line and looper technology, which is applied in the control field of looper deviation at the entrance of the galvanizing production line, can solve problems such as deviation of the looper at the entrance of the galvanizing production line and deviation of the looper, and achieve a solution to the deviation of the looper Offset, prevent looper deviation, reduce the effect of scraping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

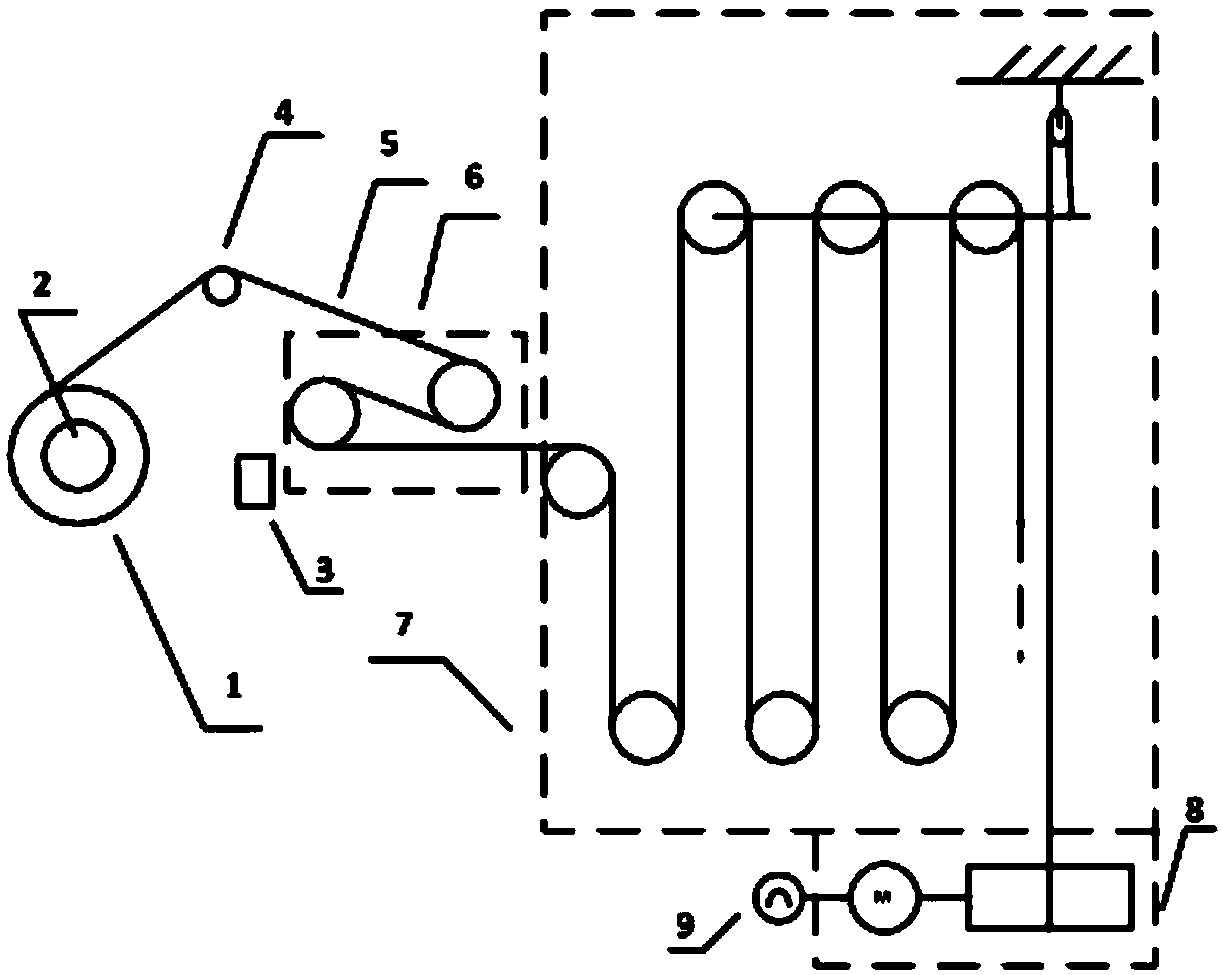

[0029] An embodiment of the present invention provides a control method for looper deviation at the entrance of a galvanizing production line to solve the technical problem in the prior art that the deviation of the looper is likely to occur at the entrance of the galvanizing production line.

[0030] In order to solve the technical problems in the above-mentioned prior art, the general idea of the technical solution provided by the embodiment of the present application is as follows:

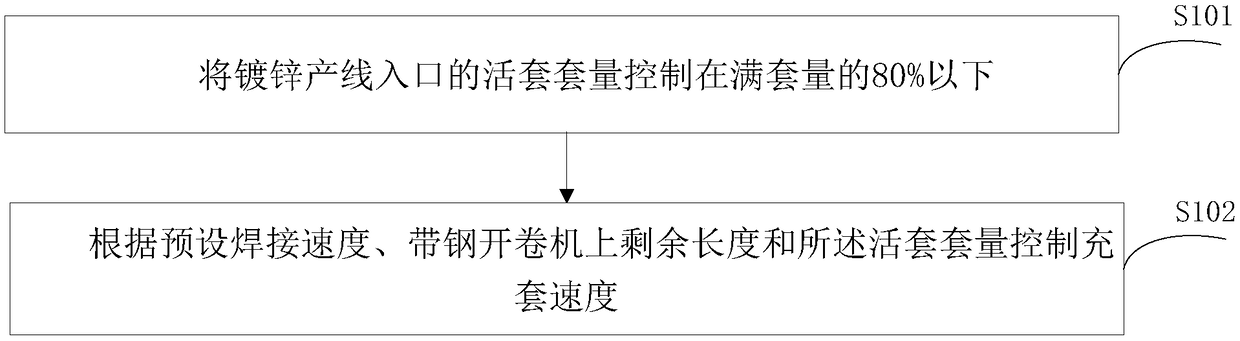

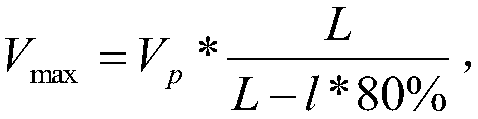

[0031] The amount of loopers at the entrance of the galvanizing production line is controlled below 80% of the full amount, and the filling speed is controlled according to the preset welding speed, the remaining length on the strip uncoiler and the amount of loopers.

[0032] In the above method, by controlling the amount of loops at the entrance of the galvanizing production line to less than 80% of the full set; the scraping of the strip steel in the loops can be reduced, thereby preventing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com